Patents

Literature

34results about How to "Avoid Acid Corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor silicon material water base cutting liquid

The alkaline water-base cutting liquid for silicon wafer and other semiconductor material consists of polyglycol of molecular weight 200-1000 in 30-90 weight portions, pH regulator 9-30 weight portions, chelating agent 1-10 weight portions and deionized water for the rest. The present invention has the beneficial effects of homogeneous stable chemical splitting effect coexisting with the mechanical effect, less stress, lowered damage of the semiconductor material, raised chip cutting efficiency and quality, simple post-treatment, and avoiding the chemical bonding and adsorption on the surface of silicon wafer.

Owner:HEBEI UNIV OF TECH

Wire cutting liquid of semiconductor material

InactiveCN1618936AReduce wire breakage rateAddress stressSemiconductor/solid-state device manufacturingBase-materialsSemiconductor materialsCooling effect

A linear cutting liquid for semiconductor material is prepared from polyethanediol 10-10000, amine soda, penetrant, ether-alcohol as activating agent, chelating agent and deionized water. Its advantages are less corrosion to cutting wire, no filings deposit on the surface of Si chip, high penetrating, lubricating and cooling effect and low cost.

Owner:刘玉岭

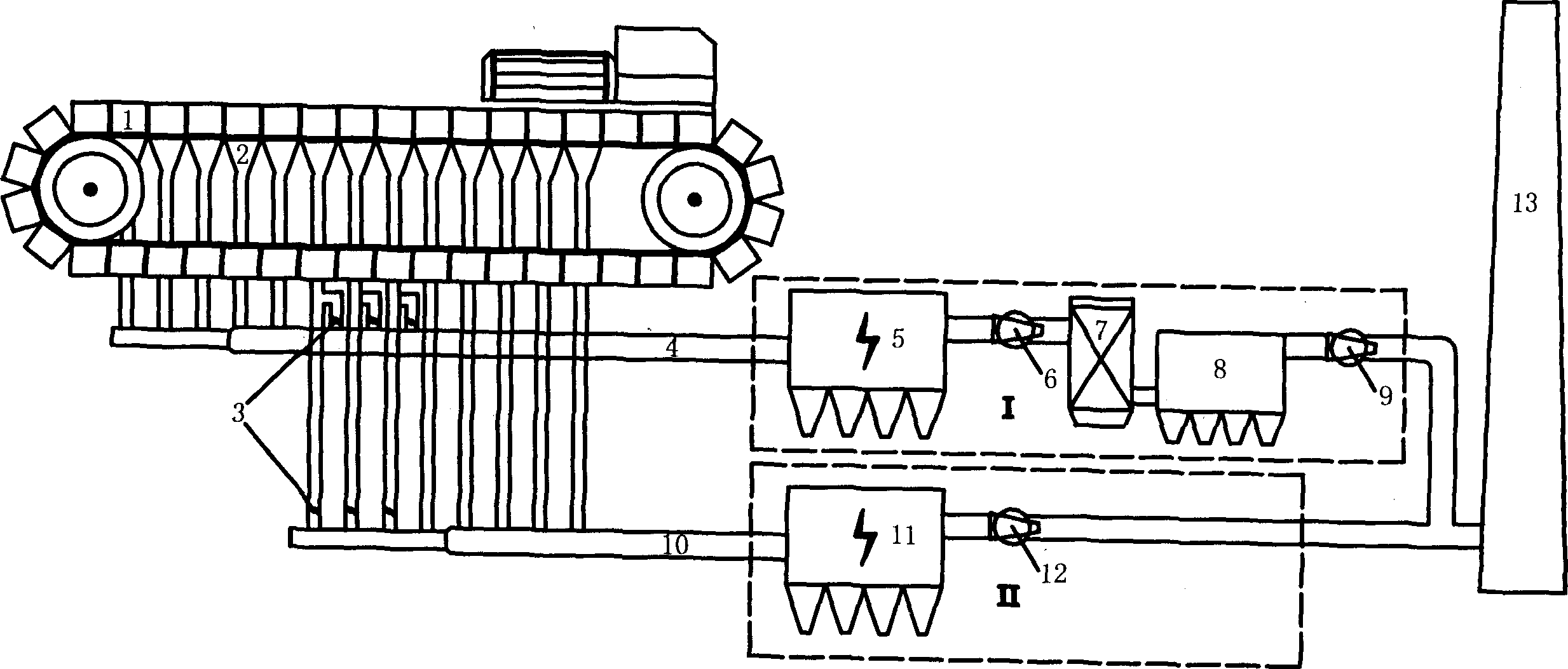

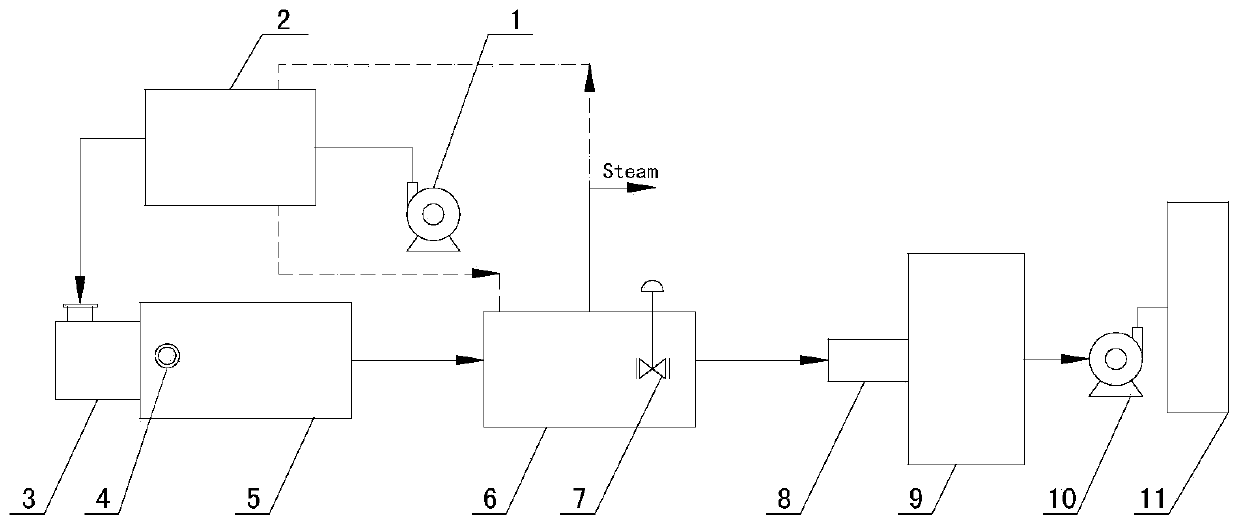

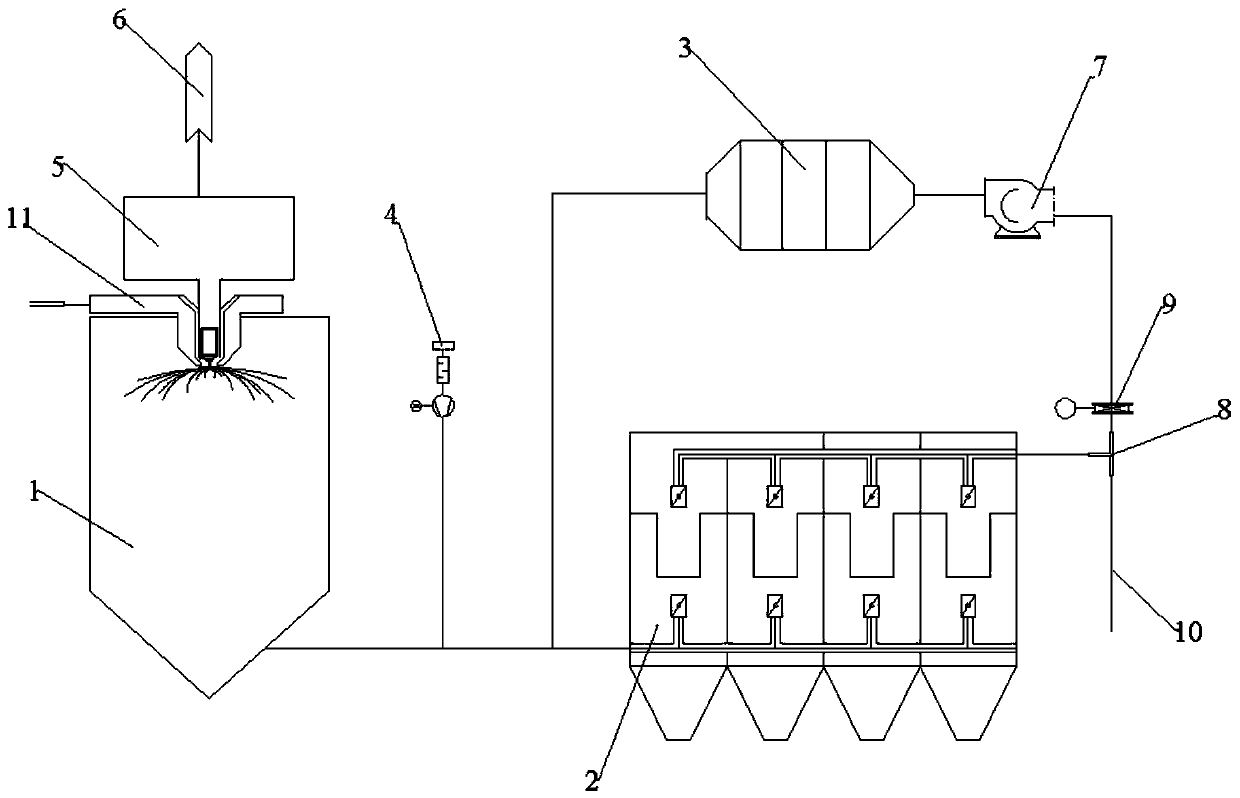

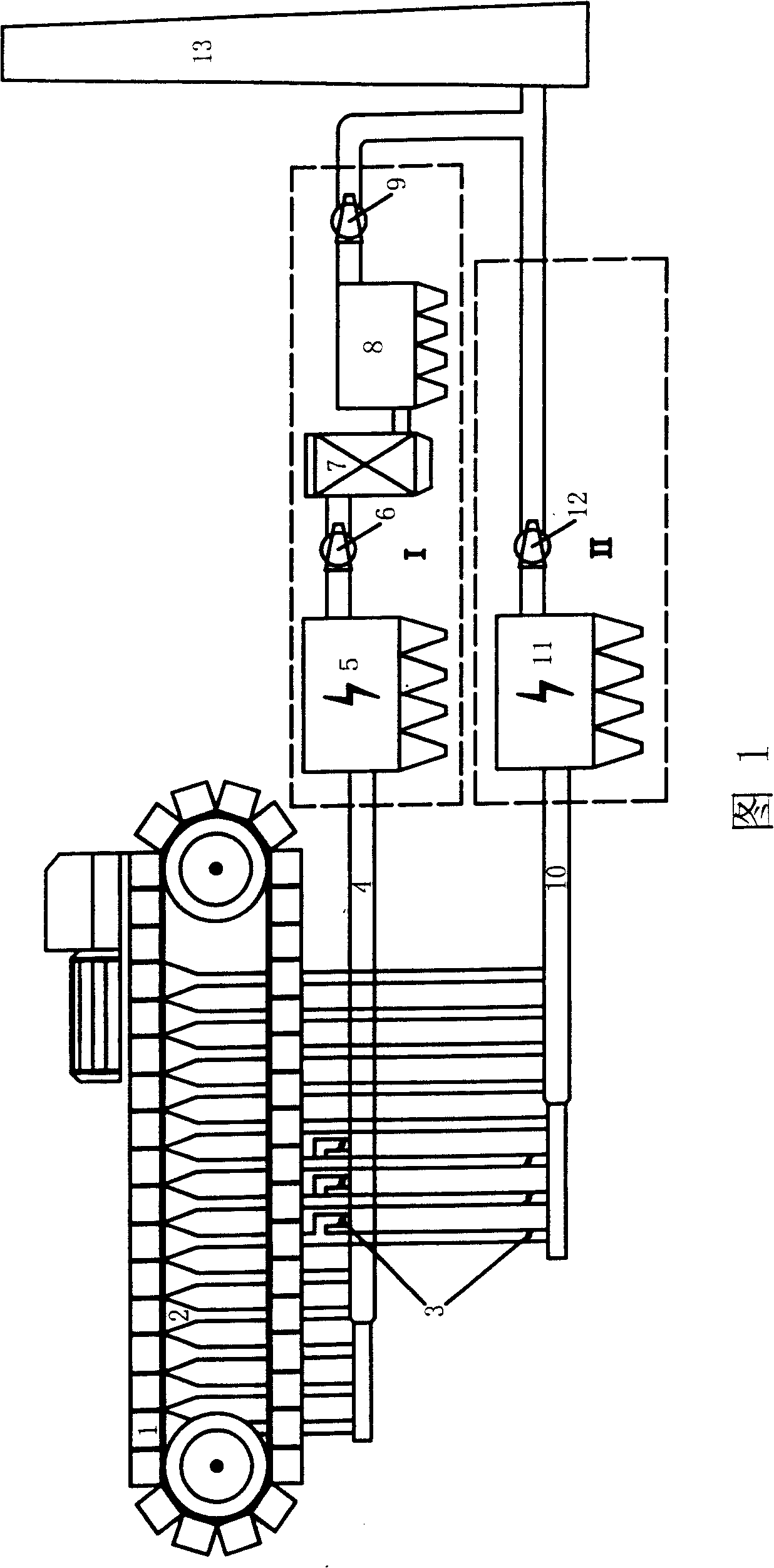

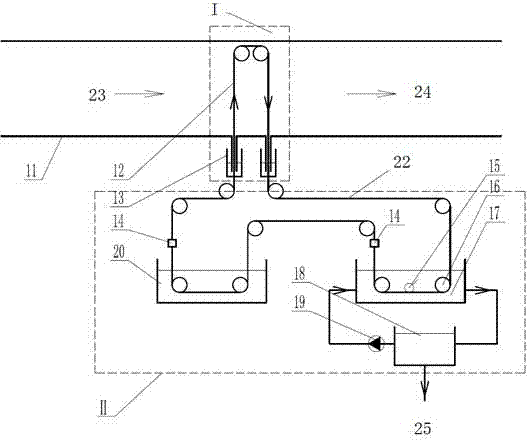

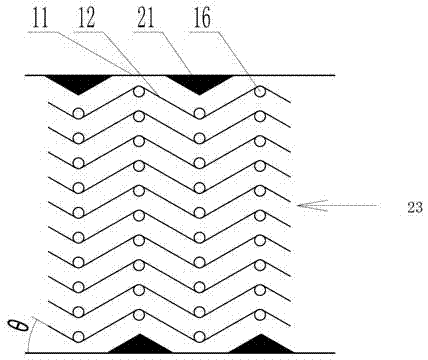

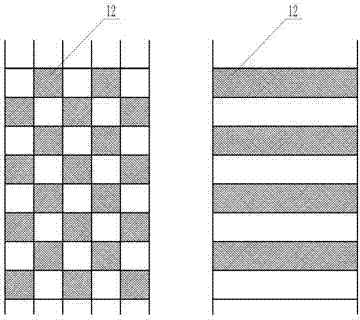

Selectivelly-desulfurized dense-phase tower drier

A closely coherent tower system for selective desulfurizing is composed of a desulfurizing system A and a non-desulfurizing system B, which serve a single sintering motion at same time. Said desulfurizing system A consists of wind gathering hopper, flue valve, flue, electric duster, exhaust blower, closely coherent tower, cloth-bag duster and boosting blower. Said non-desulfurizing system B comprises flue, electric duster and exhaust blower.

Owner:UNIV OF SCI & TECH BEIJING +1

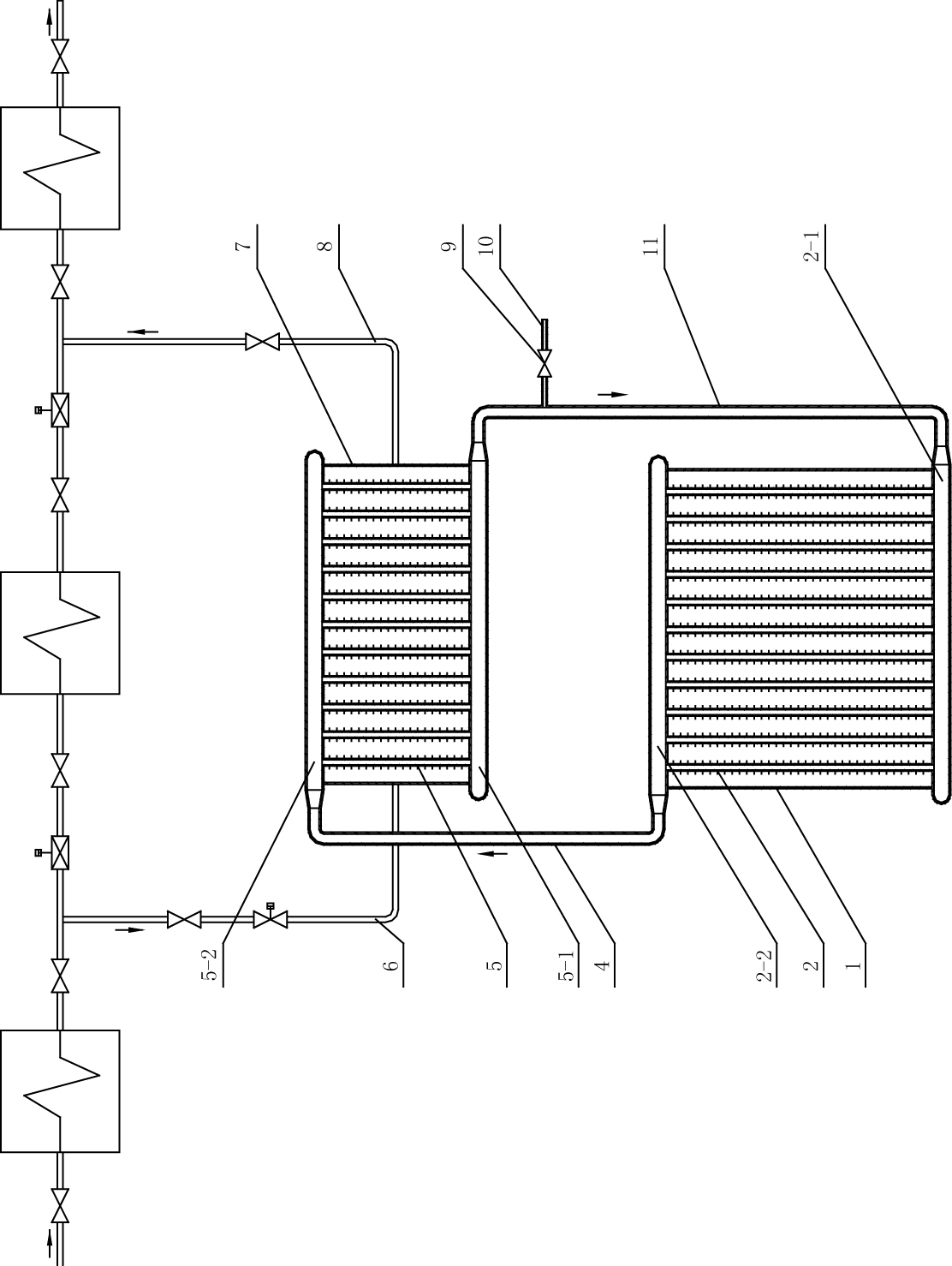

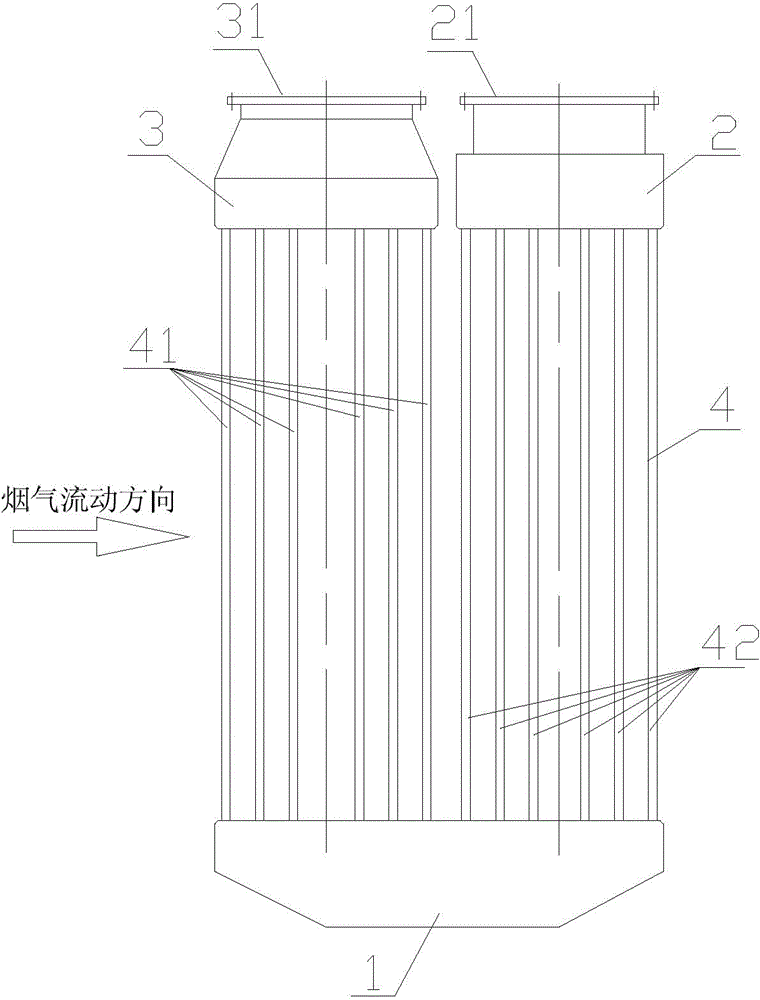

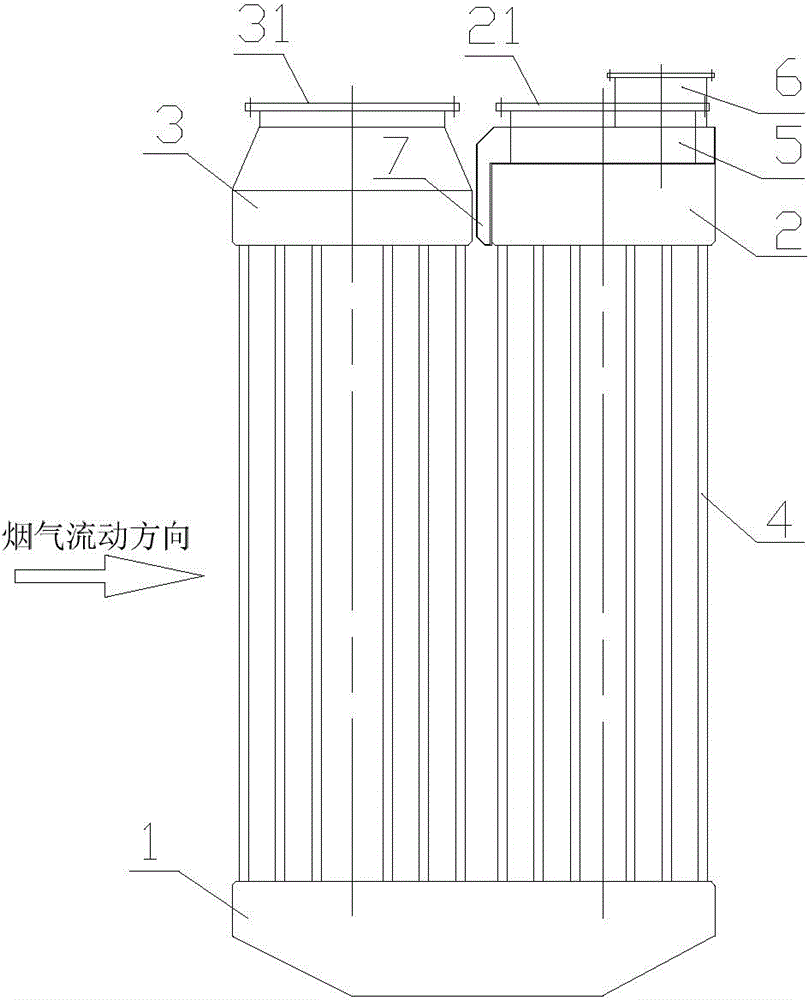

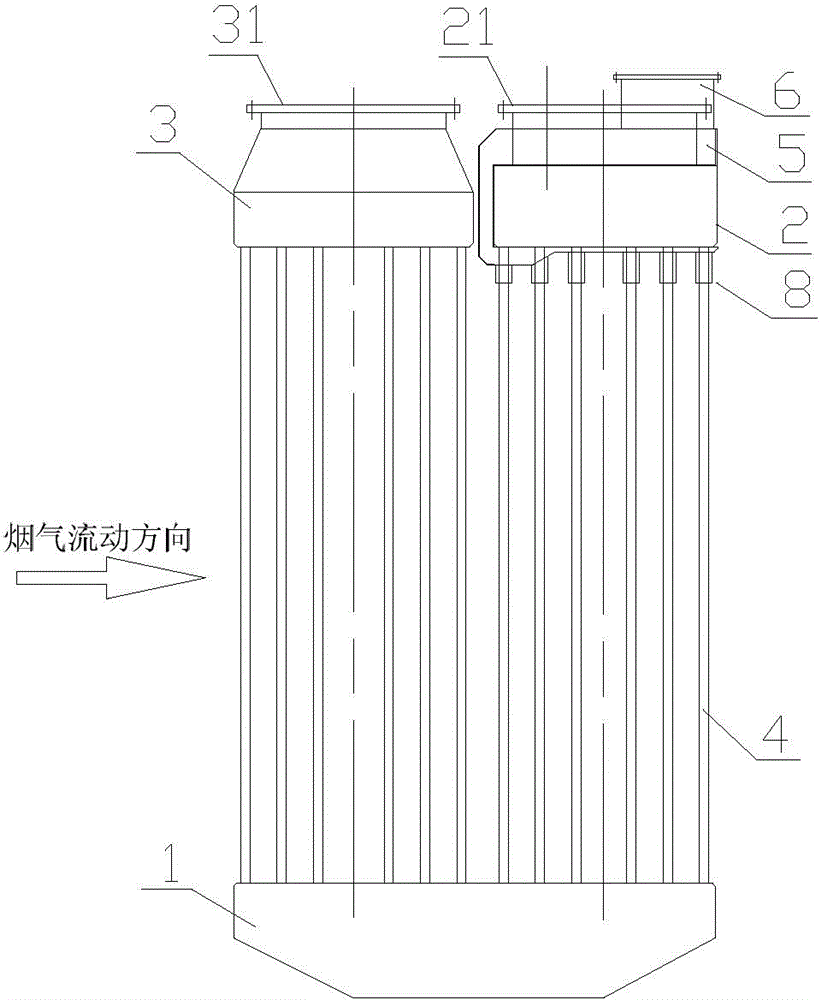

Separate low pressure coal economizer of elliptical fin heat pipe

InactiveCN101881436AReduce volumeReduce power consumptionIndirect heat exchangersTubular elementsPipingCoal

The invention relates to a separate low pressure coal economizer of an elliptical fin heat pipe, relating to boiler waste heat recovery energy-saving equipment, in particular to a separate low pressure coal economizer of an elliptical fin heat pipe. The invention solves the problems of high investment and severe abrasion of banks of pipes caused by large volume and high resistance of a heat exchanger of the traditional boiler low pressure coal economizer. In the invention, both ends of a plurality of elliptical fin heat pipes arranged in parallel in a pipe panel of an evaporation section of the elliptical fin heat pipes are respectively communicated with a corresponding condensation water inlet header and a steam outlet header; both ends of a plurality of elliptical fin heat pipes arranged in parallel in a pipe panel of a condensation section of the elliptical fin heat pipes are respectively communicated with a corresponding condensation water outlet header and a corresponding steam inlet header; the steam outlet header of the pipe panel of the evaporation section is communicated with the steam inlet header of the pipe panel of the condensation section through a steam gas guide tube; and the condensation water outlet header of the pipe panel of the condensation section is communicated with the condensation water inlet header of the pipe panel of the evaporation section through a water return pipe. The invention is particularly suitable for the utilization of the waste heat of the discharge smoke of an electric plant boiler.

Owner:HEILONGJIANG ELECTRIC POWER RES INST

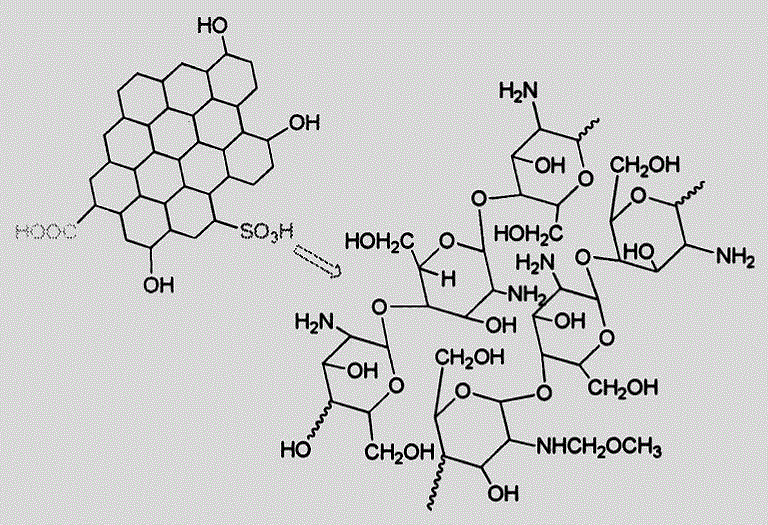

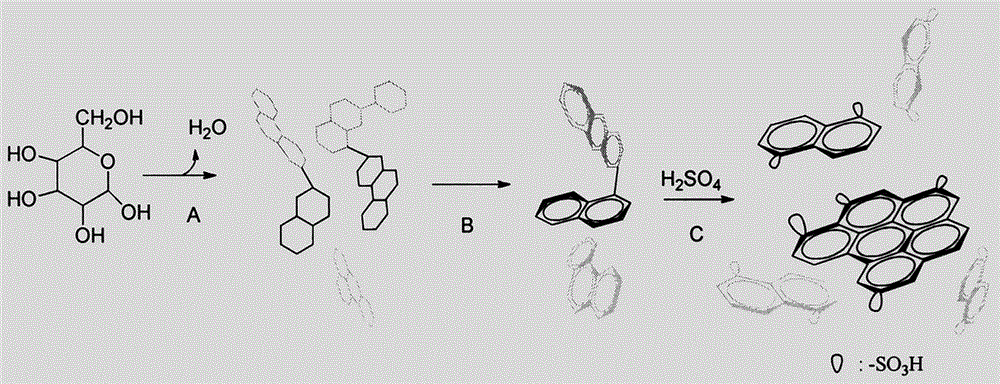

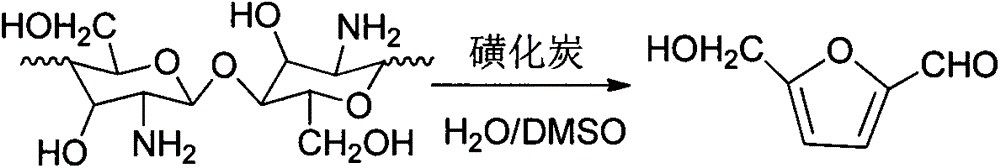

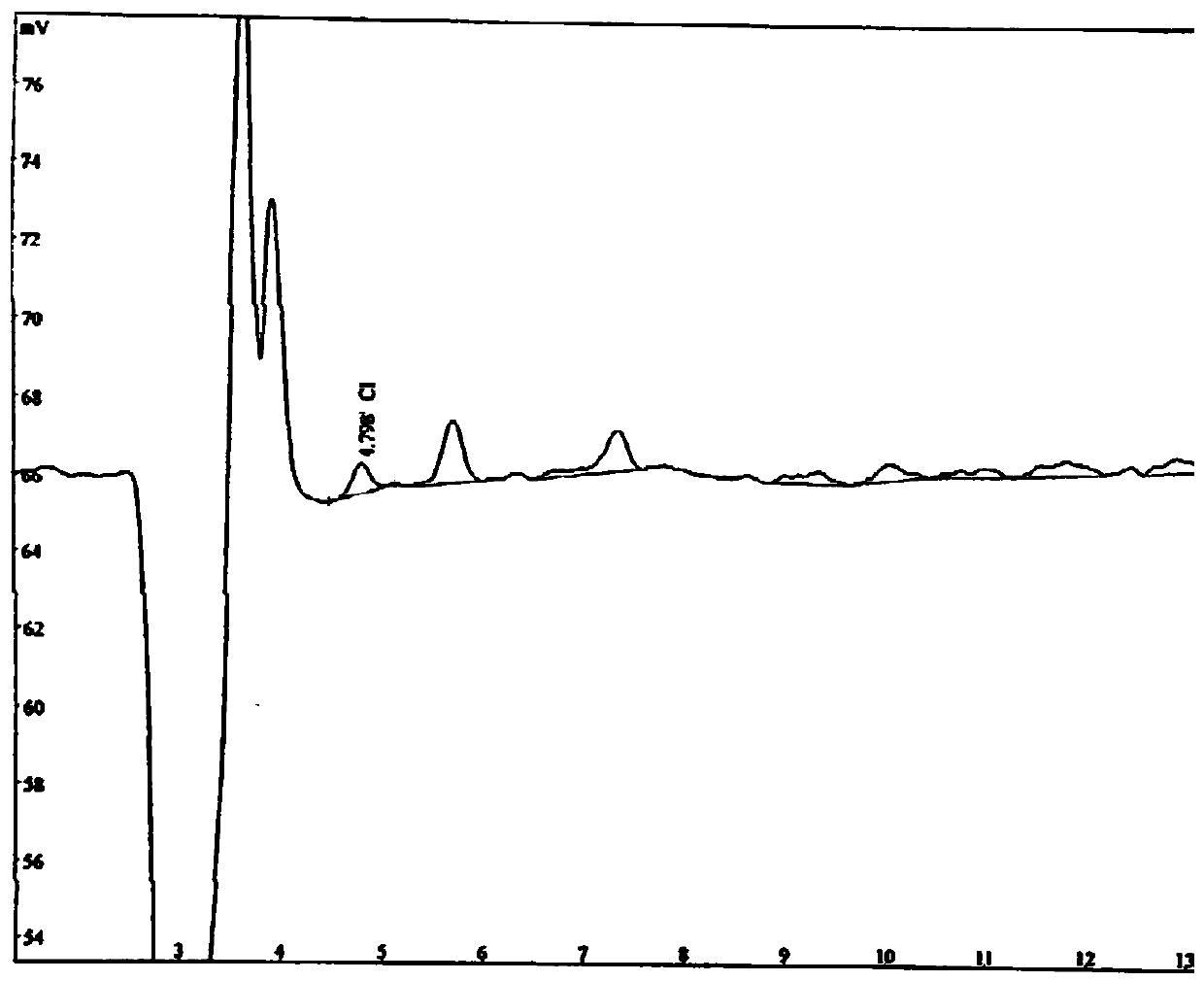

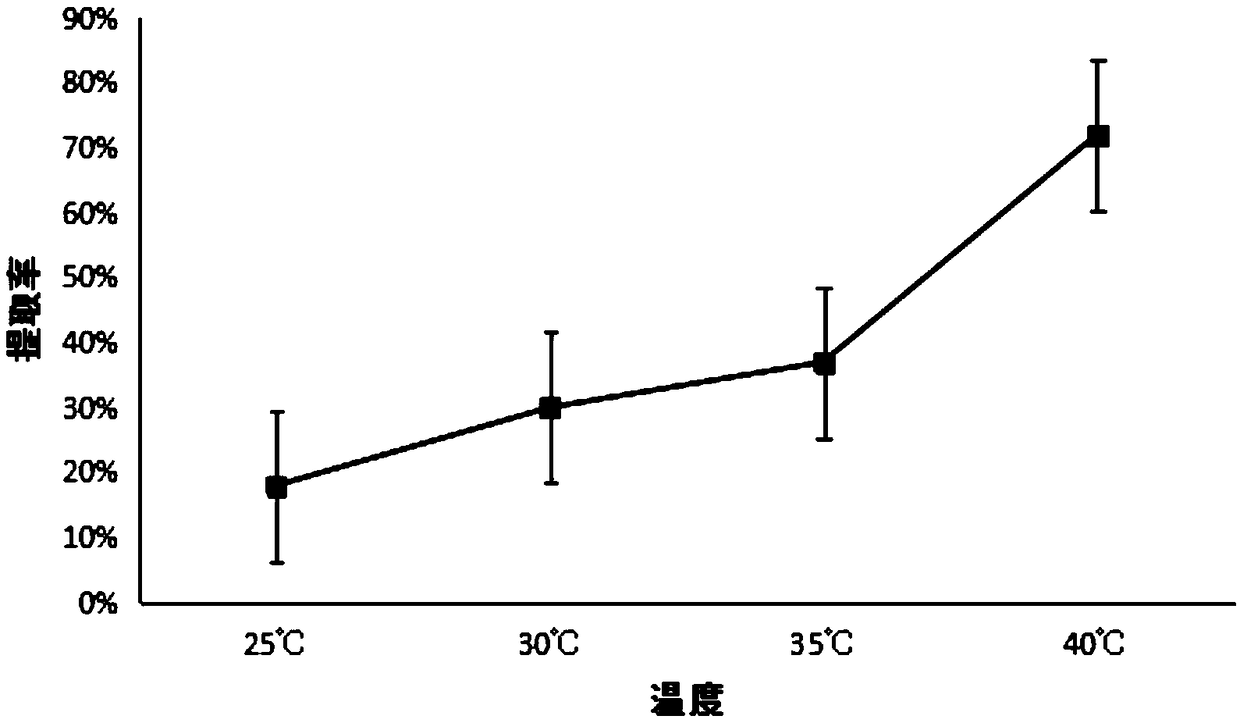

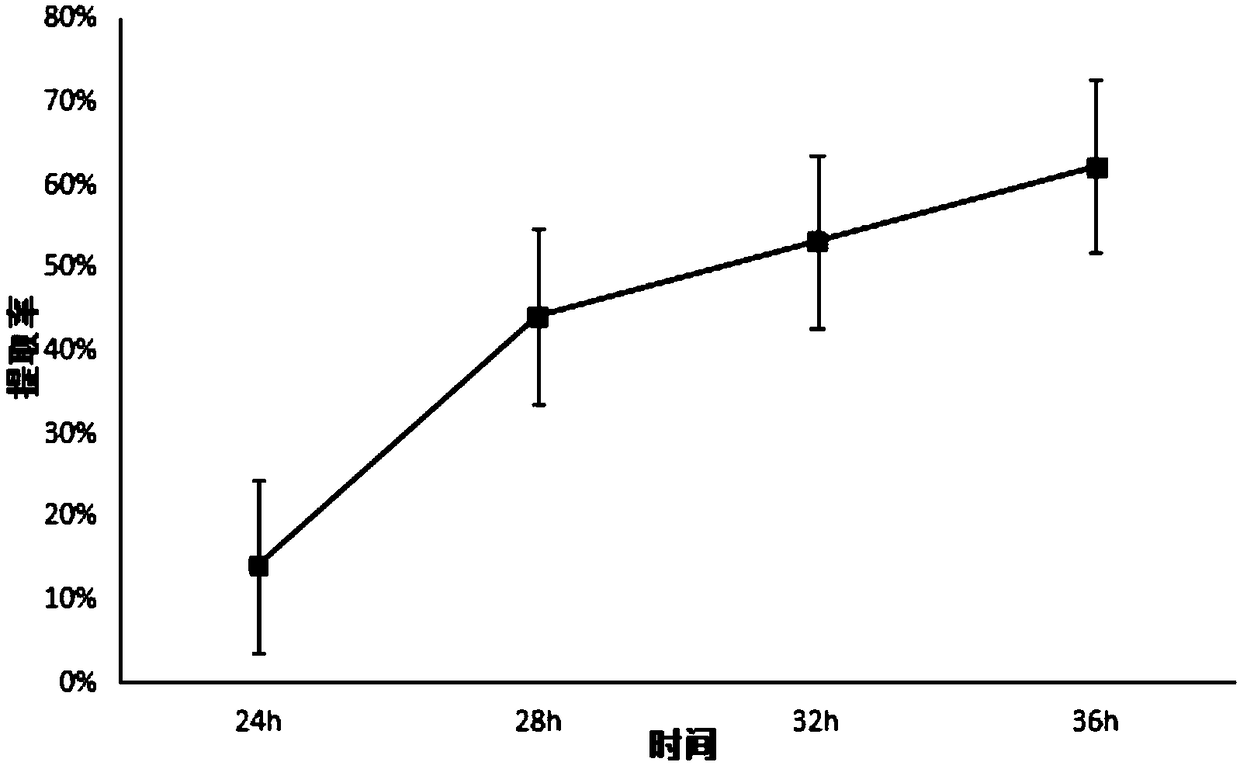

Degradation of chitosan/chitin with sulfonated carbon solid acid into high value 5-hydroxymethyl furfural

InactiveCN105254600ALow costReduce pollutionOrganic chemistryPhysical/chemical process catalystsSolid acidHydroxymethylfurfural

The invention discloses a method for preparation of 5-hydroxymethyl furfural from chitin / chitosan. The method is achieved by: taking chitin / chitosan as the raw material, adopting sulfonated carbon solid acid as the catalyst, degrading chitosan in a polytetrafluoroethylene hydrothermal reaction kettle to obtain 5-hydroxymethyl furfural, performing extraction separation, and then conducting detection with high performance liquid chromatography and carrying out quantification. The chitin / chitosan raw material involved in the invention is cheap, easily available and renewable, and also the application field of chitin / chitosan is also broadened. By adopting water and dimethyl sulfoxide as the reaction medium and catalyst, the activity of solid acid in heterogeneous reaction is enhanced. The catalyst is easy to prepare and cheap, and exists in the form of solid during reaction, and can be filtered and recovered for cyclic utilization. Also the aftertreatment is simple, and pollution to the environment is reduced.

Owner:TIANJIN POLYTECHNIC UNIV

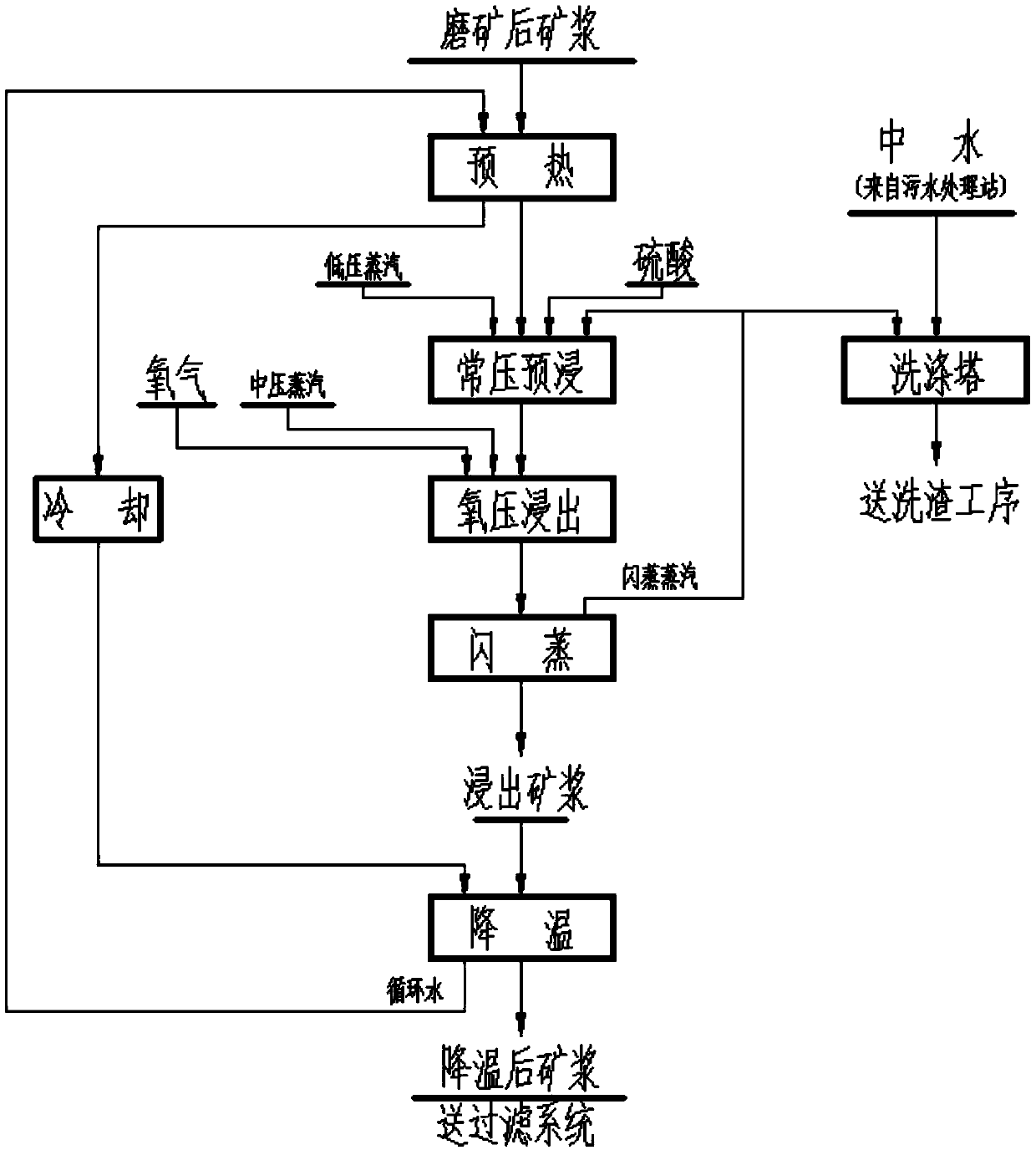

Industrial method for leaching of primary uranium-molybdenum ores

The invention belongs to the technical field of oxygen pressure acid leaching of primary uranium-molybdenum ores, and particularly relates to an industrial method for leaching of primary uranium-molybdenum ores. The industrial method aims to solve the problems that an existing uranium-molybdenum leaching process is poor in adaptability to mineral property change, low in molybdenum leaching rate, low in resource utilization rate, large in potential environmental risk and high in cost. The industrial method comprises the following steps that 1, uranium-molybdenum symbiotic raw ores are subjectedto ore grinding, grading and pulp mixing; 2, sulfuric acid with the concentration of 92.5%-98% is added into ore pulp for pre-soaking, and the ore pulp is preheated to 80-90 DEG C by utilizing recovered steam; 3, the preheated ore pulp is continuously fed into a horizontal type pressurization reaction kettle through an ore pulp pump, and continuously stirred at the first stage of the horizontal type pressurization reaction kettle, so that leached ore pulp is continuously obtained; 4, the obtained leached ore pulp is subjected to steam recovery through flash evaporation equipment for preheating the raw ore pulp, and the temperature of the ore pulp is reduced to 110 DEG C or below; and 5, the ore pulp further exchanges heat with washing cold water, through solid-liquid separation, slag is removed to a tailing warehouse, and filtrate enters the next process.

Owner:中核沽源铀业有限责任公司

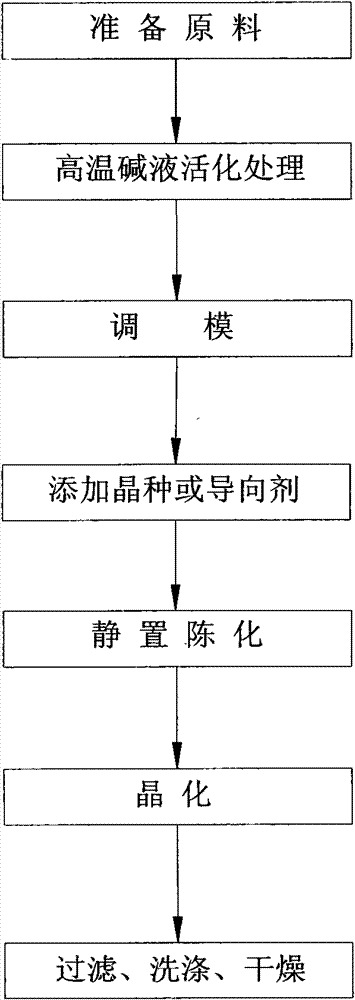

Method for preparing NaY zeolite

InactiveCN102107883BEasy to makeReduce stepsMolecular sieve catalystsFaujasite aluminosilicate zeoliteSodium BentoniteFiltration

The invention discloses a method for preparing NaY zeolite, and solves the technical problems in the prior art that the energy consumption is high, equipment is severely corroded, the zeolite output is low, the environment is polluted, and the like, which are caused during NaY zeolite preparation. Therefore, the invention provides a novel method for preparing the NaY zeolite. The technical scheme of the novel method comprises the following steps: raw materials are prepared; bentonite is ground and processed to 200 meshes below; activating treatment is conducted by using high temperature lye; a die is adjusted; seed crystals or directing agents are added; standing and ageing are conducted; crystallization is conducted; and then filtration, washing and drying are conducted. Through the adoption of the technical scheme provided by the invention, the problems in the prior art are solved, and the technical effects that the energy consumption is low during preparation, the cost is low, the raw materials are easy to manufacture, no pollution is caused, instruments and the equipment cannot be damaged, and the like are achieved.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

Pipeline joint watertightness anticorrosion hot melt adhesive

InactiveCN103602289AAvoid acid corrosionImprove anti-corrosion performanceNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesSeawaterBonding strength

The invention provides a pipeline joint watertightness anticorrosion hot melt adhesive. The formula of the hot melt adhesive comprises the following components: by weight, 25-45% of EVA resin, 15-30% of a tackifier, 1-20% of a flexibilizer, 25-35% of paraffin, 1-7% of a composite auxiliary agent and 0.5-2% of an anti-oxidant, wherein the VA content of EVA resin is 28%; melt index (MI) of EVA resin is 150g / 10min; and the tackifier is thermoplastic phenolic resin. The invention provides a pipeline joint watertightness anticorrosion hot melt adhesive which is an efficient water-stop hot melt adhesive prepared by using EVA resin as the matrix resin and using thermoplastic phenolic resin as the tackifier. The hot melt adhesive has good waterproof airtightness, high bonding strength and excellent resistance to chemical corrosion, and can meet anticorrosion requirement of a pipeline joint which is immersed in seawater for a long time.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

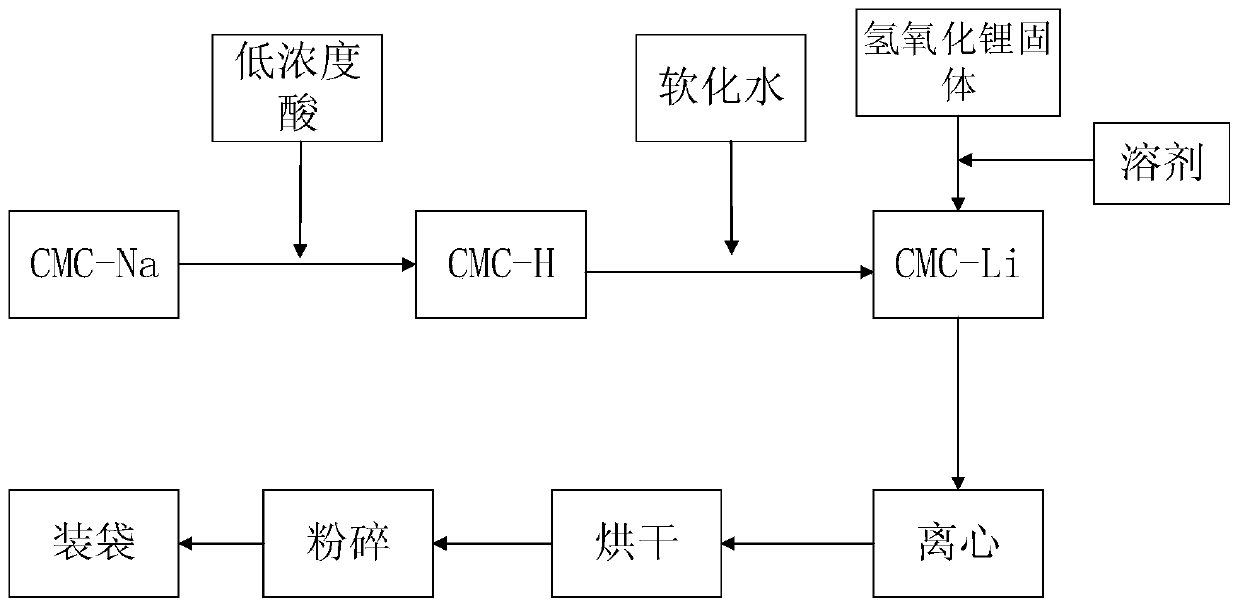

Method for synthesizing ultrahigh-viscosity lithium carboxymethyl cellulose of ultralow solvent system

PendingCN111363049AAvoid acid corrosionIncrease productionCell electrodesSodium carboxymethylcelluloseMother liquor

The invention discloses a method for synthesizing ultrahigh-viscosity lithium carboxymethyl cellulose of an ultralow solvent system. The method is a two-step synthesis method and specifically comprises the following steps: mixing CMC-Na and sulfuric acid or nitric acid with the concentration of 10-50%, adding the obtained mixture into a glass lining reactor, stirring, centrifuging, and removing acid mother liquor to obtain CMC-H without adding any organic solvent; washing with softened water; and mixing the washed CMC-H, a lithium hydroxide solid and an organic solvent, reacting at 20-50 DEG C, centrifuging, removing mother liquor, and washing the obtained product. The viscosity of the lithium carboxymethyl cellulose prepared by the method is far higher than that of lithium carboxymethylcellulose prepared by other methods, the cost is lower, the conversion is more direct, the efficiency is higher, the solvent amount is smaller, and industrial production is easier to realize.

Owner:瑞红锂电池材料(苏州)有限公司

Incineration device and method for treating sulfur recovery tail gas

InactiveCN110793044ATo save energyIncrease operating pressureChemical industryDispersed particle separationAir preheaterCombustor

The invention discloses an incineration device and method for treating sulfur recovery tail gas, and belongs to the technical field of chemical engineering. The device adopts a low-NOx burner, and theNOx content can be controlled to be smaller than 100mg / m <3> by controlling oxygen deficiency. According to the device and method, an air preheater is adopted to heat combustion-supporting air, and 20%-30% of fuel can be saved; a waste heat boiler is further adopted to recover waste heat in flue gas, and the energy-saving purpose is achieved through the arrangement of the air preheater and the waste heat boiler; a waste heat boiler center pipe adjusting valve is adopted to adjust the heat exchange flue gas amount, meanwhile, the operation pressure of steam is improved, so that the flue gas temperature is larger than the acid dew point temperature, and acid corrosion of equipment can be effectively prevented; and an induced draft fan is adopted to guarantee the negative pressure of the whole system, leakage of harmful gas is prevented, and the device and method are safer.

Owner:BEIJING HANGHUA ENERGY SAVING ENVIRONMENTAL PROTECTION TECH CO LTD

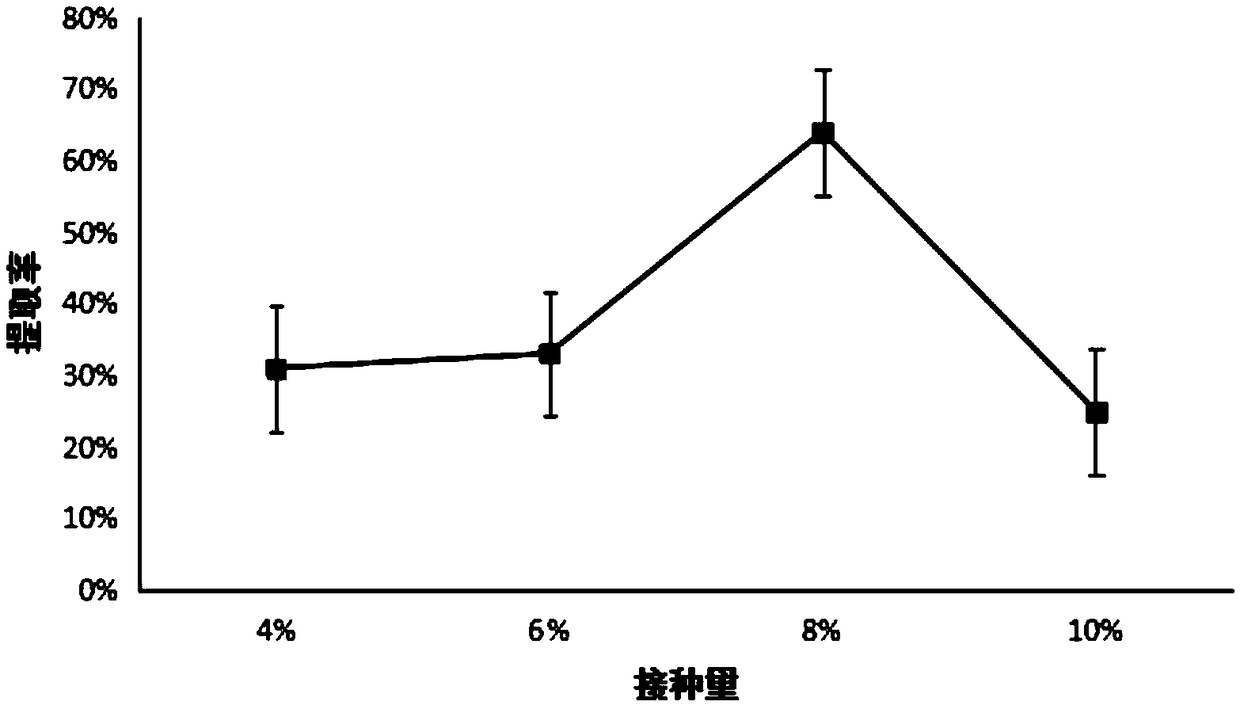

Bacillus H3, use of bacillus H3 in preparation of collagen polypeptide through fermenting fish skin and collagen polypeptide

InactiveCN109486730AImprove hydrolysis efficiencyImprove hydrolysis effectConnective tissue peptidesBacteriaSolubilityFreeze-drying

The invention provides bacillus H3, use of bacillus H3 in the preparation of collagen polypeptide from fermenting fish skin and collagen polypeptide. The preservation number of bacillus H3 is CGMCC NO:15830, and bacillus H3 can be separated from soil; a seed solution is prepared by virtue of bacillus H3, a fermentation culture medium is prepared through crushing the fish skin, and the collagen polypeptide is prepared through sequential bacteria grafting fermentation, fermentation liquid centrifugation, rotary evaporation fermentation and vacuum freeze drying; and the prepared collagen polypeptide preserves a complete three-screw structure and has good solubility, emulsifying property and stability. Compared with an existing preparation method of collagen polypeptide, the preparation methodhas the advantages that the process is simple, the operation is convenient, use of a large quantity of chemical regents is avoided, the environmental protection is promoted, and the extracted collagen polypeptide is relatively small in molecular weight and easy to absorb and can be applied to the fields of foods, cosmetics and health products.

Owner:SHANGHAI OCEAN UNIV

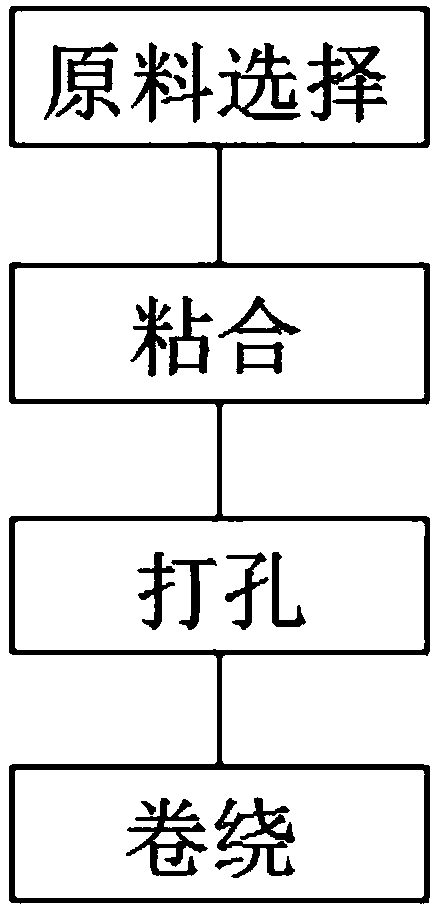

Shielding paper processing method

InactiveCN107599581AEffective immersionEffective shieldingLaminationLamination apparatusTransformerAdhesive

The invention discloses a shielding paper processing method, which comprises: raw material selection: selecting aluminum foil paper and high-voltage electric cable paper; adhering: integrally the aluminum foil paper and the high-voltage electric cable paper through an adhesive; drilling: drilling holes on the adhered aluminum foil paper and the adhered high-voltage electric cable paper by using afine pinhole drilling machine; and winding: winding the shielding paper with the holes on a transformer. According to the present invention, the aluminum foil paper and the high-voltage electric cablepaper are adhered, and the hole is drilled on the aluminum foil paper and the high-voltage electric cable paper, such that oil can be effectively immersed, the shielding can be effectively formed, and the electric signal can be effectively shielded; and by using the non-acid non-fat adhesive, the acid corrosion can be avoided, and the service life can be prolonged.

Owner:南通亚振电力科技有限公司

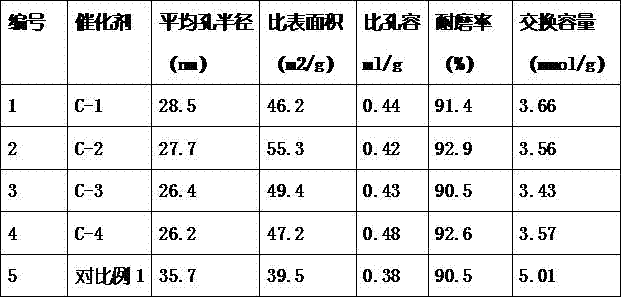

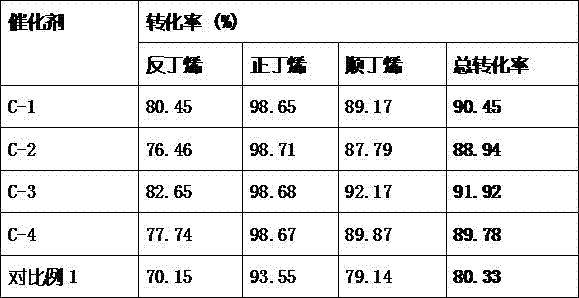

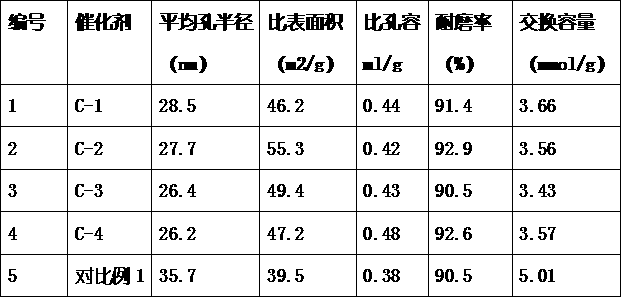

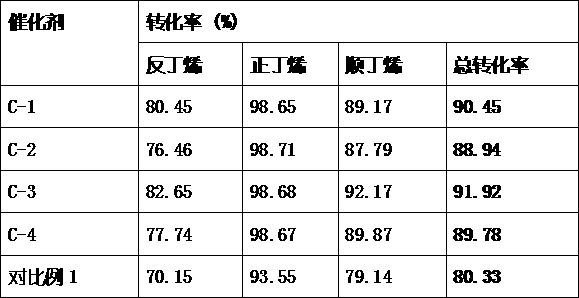

Strong-acid high-temperature resistant cationic resin catalyst and preparation method thereof

ActiveCN107537570AImprove product qualityImprove high temperature resistanceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPhosphoric Acid EstersBenzoyl peroxide

The invention provides a strong-acid high-temperature resistant cationic resin catalyst and a preparation method thereof. The strong-acid high-temperature resistant cationic resin catalyst is preparedfrom styrene and divinyl benzene through suspension polymerization, and is prepared by using a preparation method of structure stabilization, halogenation, sulfonation and active group stabilizationafter suspension polymerization, wherein the water phase of the catalyst is a mixture of lauryl sulfonated succinic acid monoester disodium, lauryl alcohol phosphoric acid ester potassium and water; and the oil phase of the catalyst is a mixture of styrene, divinyl benzene and benzoyl peroxide. The catalyst prepared by using the preparation method is high in both catalysis activity and high temperature resistance, is particularly applied to a sec-butyl acetate synthesis reaction and is excellent in thermal stability, and the total conversion rate of the catalyst is up to 90% or higher.

Owner:丹东明珠特种树脂有限公司

Semiconductor silicon material water base cutting liquid

The alkaline water-base cutting liquid for silicon wafer and other semiconductor material consists of polyglycol of molecular weight 200-1000 in 30-90 weight portions, pH regulator 9-30 weight portions, chelating agent 1-10 weight portions and deionized water for the rest. The present invention has the beneficial effects of homogeneous stable chemical splitting effect coexisting with the mechanical effect, less stress, lowered damage of the semiconductor material, raised chip cutting efficiency and quality, simple post-treatment, and avoiding the chemical bonding and adsorption on the surface of silicon wafer.

Owner:HEBEI UNIV OF TECH

Steel wire surface treatment process

PendingCN112430818AClean thoroughlyImprove toughnessEdge grinding machinesHot-dipping/immersion processesWire rodElectric machinery

The invention discloses a steel wire surface treatment process, and particularly relates to the technical field of steel wires. The steel wire surface treatment process comprises the following steps that step 1, primary hot water cleaning is carried out, specifically, a steel wire is put into a container, adding-into hot water of 80 DEG C-90 DEG C is carried out, a hydrocarbon cleaning agent is added, soaking is carried out for 3-5 hours, and one end of the steel wire is enabled to penetrate through a sleeve after soaking; and cleaning cloth is arranged in the sleeve, the steel wire is wrappedby the cleaning cloth, the sleeve is firmly installed through a clamp and a positioning device, the steel wire penetrates through one end of the sleeve and then is fixed to a roller, a motor is usedfor driving the roller to rotate, oil stains on the outer surface of the steel wire are cleaned away, and then clean water is used for flushing again. After the steel wire is subjected to surface treatment, the steel wire is cleaner and brighter, the cleaning effect is thorough, a very good foundation is laid for later plating or spraying, the steel wire surface treatment efficiency is improved, and the quality of the steel wire is guaranteed.

Owner:德清县豪鹰金属制品有限公司

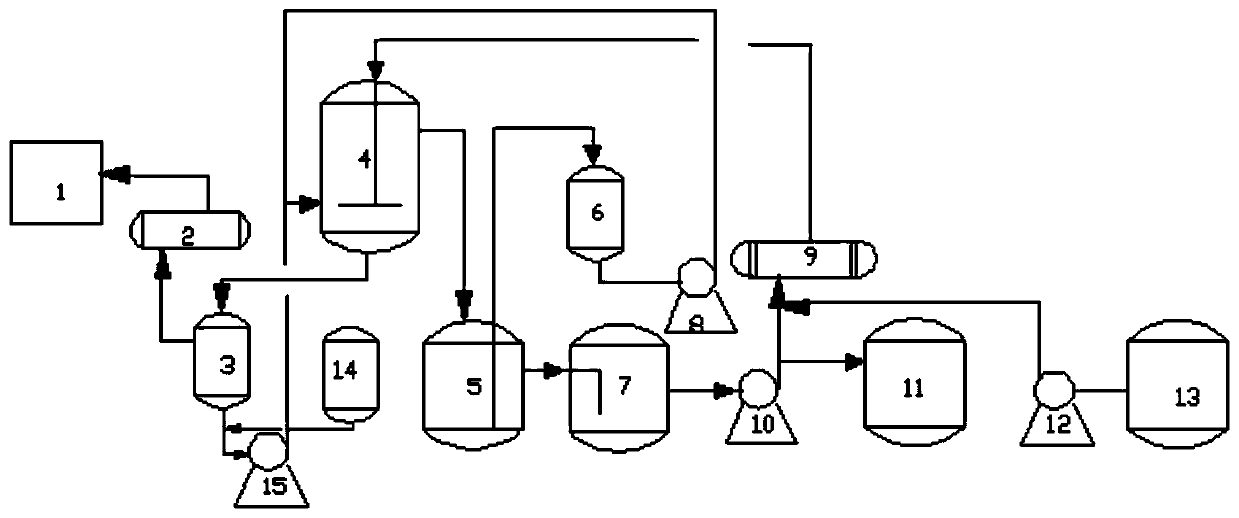

Device for continuously producing acidified oil and co-producing sodium sulfate crystal from nigre

PendingCN109749853AIncrease profitSolve the emission problemFatty oils/acids recovery from wasteFatty substance recoveryBuffer tankFiltration

The invention provides a device for continuously producing an acidified oil and co-producing a sodium sulfate crystal from nigre. The device comprises a suction filtration tank, a reactor, a settlingtank, a buffer tank, a circulating oil tank, an acid liquid circulating pump, a heater, a circulating oil pump, an acidified oil tank, a raw material pump, a raw material tank, an acid preparation tank and an acid discharge pump, wherein the reactor is provided with an acid liquid feed port, a nigre feed port, an upper discharge port and a lower discharge port; the raw material tank is connected to the heater through the raw material pump; the heater is connected with the nigre feed port of the reactor; the upper discharge port of the reactor is connected to the settling tank; the lower discharge port is connected to the suction filtration tank; the self-priming buffer tank is connected with the bottom of the settling tank through a self-priming pipe and is connected to the acid liquid feed port of the reactor through the acid liquid circulating pump; the settling tank is provided with an overflow port connected to the circulating oil tank; the circulating oil tank is connected to thecirculating oil pump; the circulating oil pump is respectively connected to the heater and the acidified oil tank; the acid preparation tank and the suction filtration tank are connected to the acid discharge pump; and the acid discharge pump is connected to the acid liquid feed port of the reactor.

Owner:山东格瑞材料科技有限公司

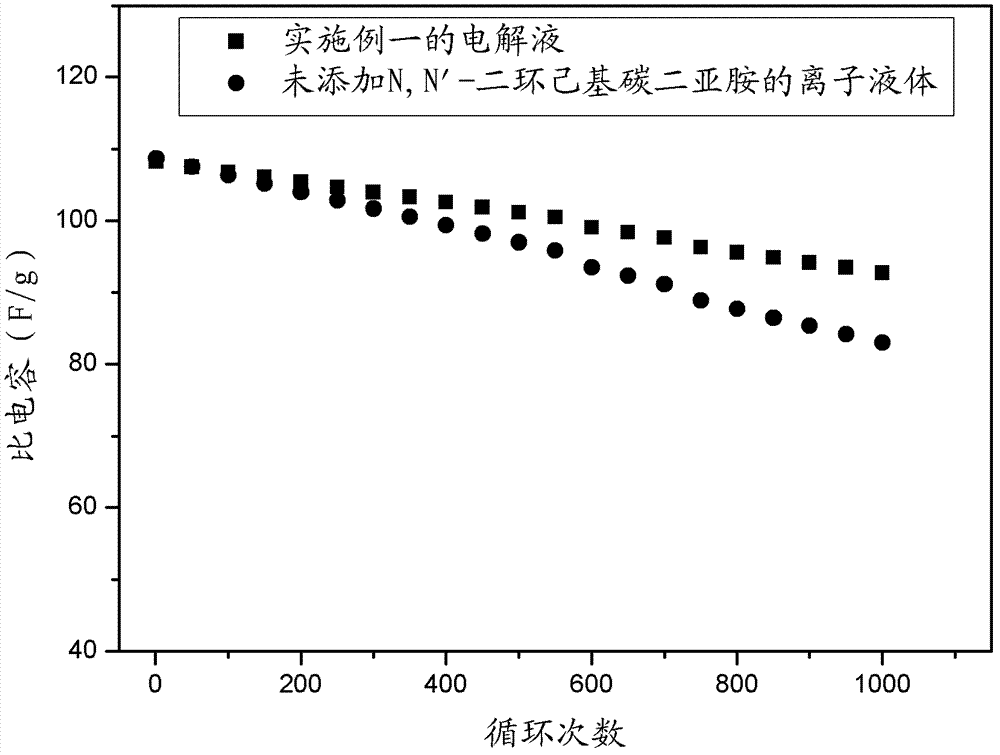

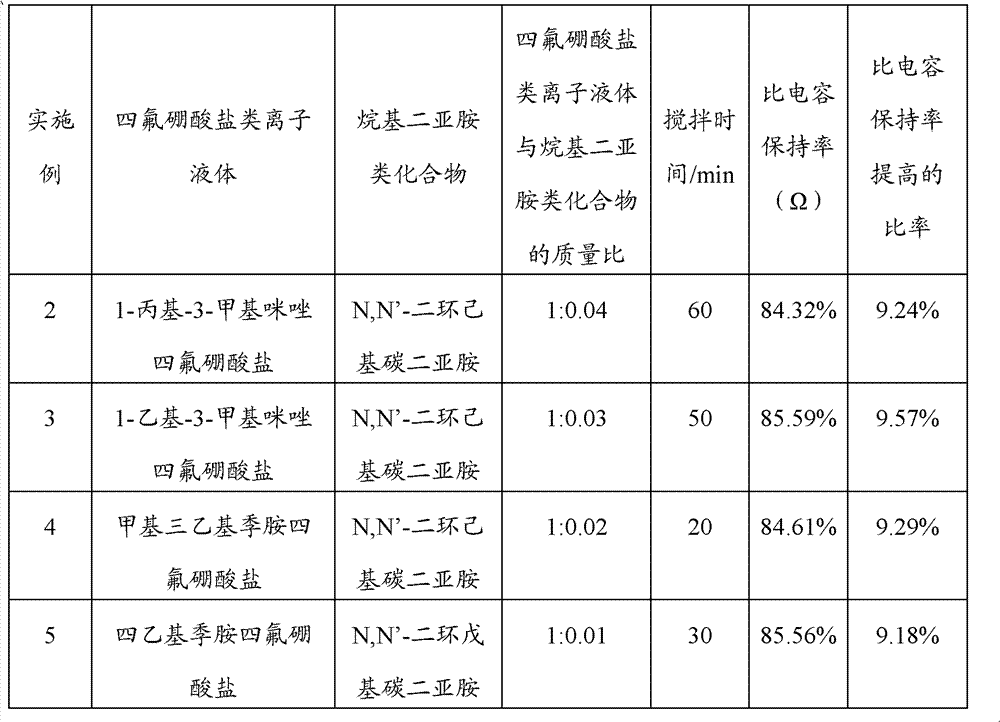

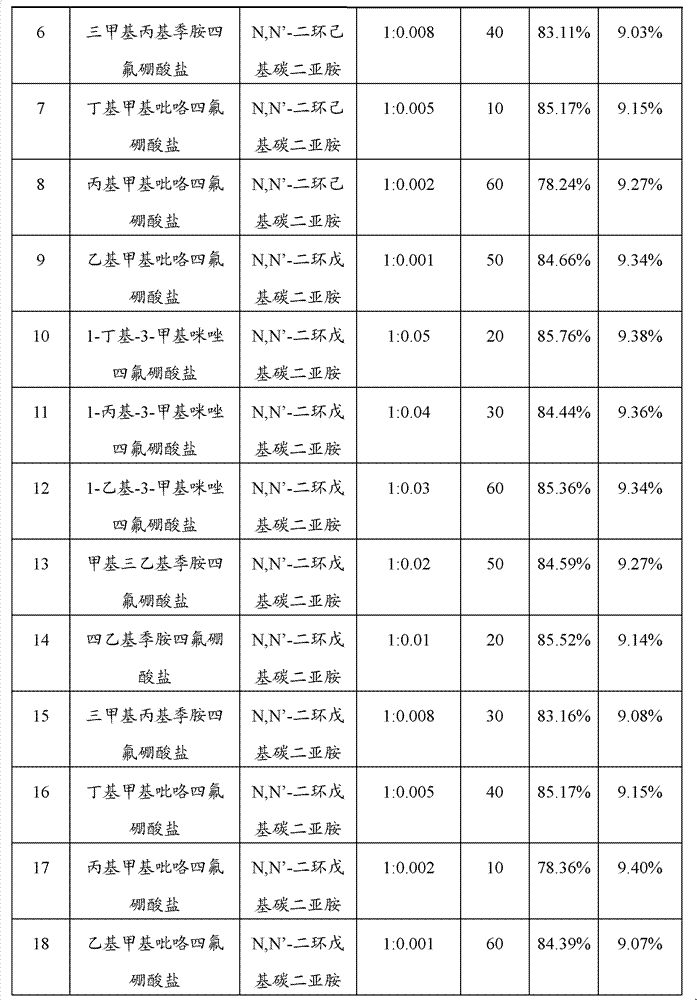

Electrolyte and preparation method thereof

InactiveCN102956367AAvoid generatingAvoid acid corrosionHybrid capacitor electrolytesHybrid/EDL manufactureTetrafluoroborateDiimine

An electrolyte comprises tetrafluoroborate ionic liquid and an alkyl diimine compound dissolved in the tetrafluoroborate ionic liquid. The mass ratio of the tetrafluoroborate ionic liquid and the alkyl diimine compound is 1 :( 0.001-1):0.05. In the electrolyte, the added alkyl diimine compound can be combined with an H bondof water molecules, and accordingly water is prevented from participating in an electrode reaction so as not to produce acid to corrode aluminum foil of a double-layer capacitor, stability of the double-layer capacitor using the tetrafluoroborate ionic liquid as the electrolyte can be greatly improved, the stability of the double-layer capacitor using the electrolyte can be greatly improved by adding the alkyl diimine compound, and cost is lowered.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

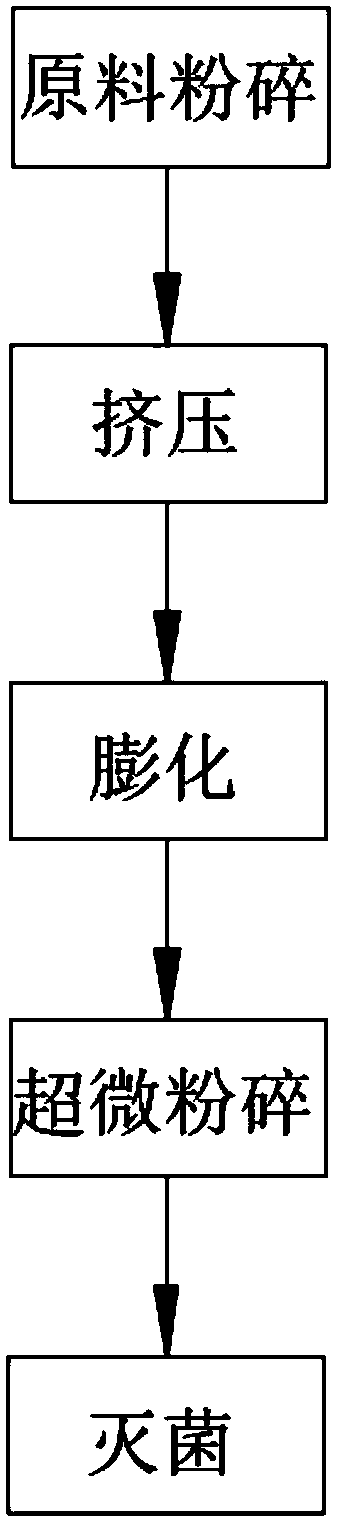

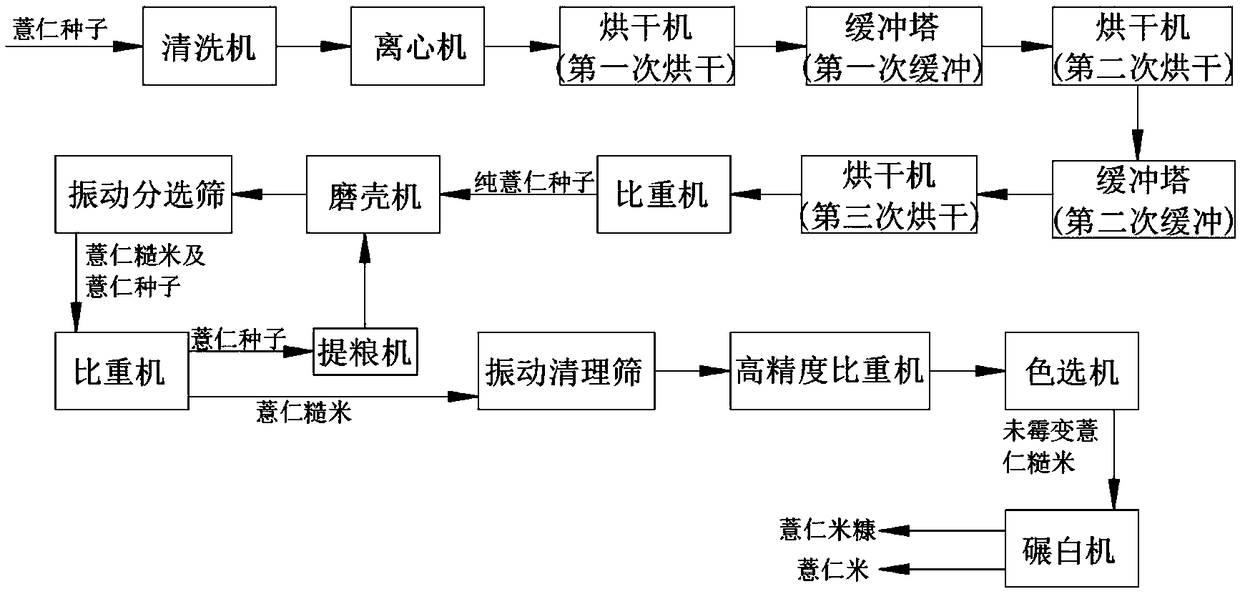

Health-care product using coix seeds as substrate and capable of resisting cancer and reducing weight and processing method of health-care product

InactiveCN109480176AGive full play to the anti-cancer effectPromote absorptionFood ingredient functionsBiotechnologyBran

The invention discloses a health-care product using coix seeds as a substrate and capable of resisting cancer. The health-care product comprises raw materials in parts by weight of 30-40 parts of coixseed bran, 30-40 parts of coix seeds, 17-26 parts of polished round-grained rice and 3-8 parts of ginger. A processing method of the health-care product comprises the following steps of (1) respectively and thoroughly cleaning all raw materials except the coix seed bran, performing drying, and performing crushing for standby application; (2) mixing the crushed raw materials with the coix seed bran to obtain a mixture, putting the mixture in an extruding machine, performing extruding, setting the extrusion time to be 40-80 seconds, and controlling extrusion temperature to be 120-150 DEG C; (3)taking out the extruded mixture, and performing puffing; (4) putting the puffed mixture into an ultrafine crushing machine, and performing crushing; and (5) performing sterilization treatment on themixture powder obtained through ultrafine crushing so as to obtain the health-care product using coix seeds as a substrate and capable of resisting cancer. According to the health-care product disclosed by the invention, the coix seeds and coix seed ferment and coix seed ester in the coix seed bran are sufficiently utilized, so that the absorptive capacity by human bodies can be improved, and favorable health-care effects can be achieved.

Owner:贵州一颗米食品科技有限公司

Wall face tile cleaning agent and preparing method thereof

InactiveCN104004610AQuick clearWon't hurtSurface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsHydrogen fluorideBenzotriazole

The invention relates to a wall face tile cleaning agent and a preparing method thereof, and belongs to the technical field of cleaning agents for buildings. The wall face tile cleaning agent is low in price and good in cleaning effect. The wall face tile cleaning agent comprises, by mass, 17%-22% of hydrochloric acid, 2%-3% of hydrogen fluoride, 1%-2% of nonyl phenol polyoxyethylene ether, 0.1%-0.5% of benzotriazole and the balance water. The preparing method of the wall face tile cleaning agent comprises the steps that the hydrochloric acid, the hydrogen fluoride, the nonyl phenol polyoxyethylene ether and the benzotriazole are added in the water in sequence, stirring is carried out until all the raw materials are completely dissolved, and thus the wall face tile cleaning agent is obtained. Through experiments, dirt of wall face tiles can be fast cleaned out, the surfaces of the tiles cannot be damaged, the side effect is small, cost is low, and the cleaned tiles are still pure white as new after being placed for 15 days.

Owner:XIAMEN UNIV

Flue gas deacidification and dust removal system

PendingCN110898641AEasy to handleImprove processing efficiencyGas treatmentDispersed particle filtrationBaghouseDust control

The invention provides a flue gas deacidification and dust removal system. The flue gas deacidification and dust removal system comprises a deacidification tower, a slurry tank, a dry powder injectiondevice, a bag type dust collector and a circulating heater, wherein the slurry tank, the deacidification tower and the bag type dust collector are sequentially communicated, a dry powder injection port is connected to a pipeline between a flue gas outlet of the desulfurization tower and a gas inlet of the bag type dust collector, a gas outlet of the bag type dust collector is communicated with agas inlet pipeline of the circulating heater, and a gas outlet of the circulating heater is communicated with a gas inlet pipeline of the bag type dust collector. According to the flue gas deacidification and dust removal system, flue gas exhausted by an incinerator is treated when the incinerator works abnormally, the situations that dew is formed on the surface of a cloth bag of the bag type dust collector, the cloth bag is pasted and corroded by acids are avoided, exhausted gas does not contain dust, and the removal efficiency of acid pollutants in the flue gas subjected to cyclic heating treatment is higher.

Owner:XIAN XIKUANG ENVIRONMENTAL PROTECTION

Selectivelly-desulfurized dense-phase tower drier

A closely coherent tower system for selective desulfurizing is composed of a desulfurizing system A and a non-desulfurizing system B, which serve a single sintering motion at same time. Said desulfurizing system A consists of wind gathering hopper, flue valve, flue, electric duster, exhaust blower, closely coherent tower, cloth-bag duster and boosting blower. Said non-desulfurizing system B comprises flue, electric duster and exhaust blower.

Owner:UNIV OF SCI & TECH BEIJING +1

Low temperature protection device for metal heat exchange tube of preheater

InactiveCN102230636BImprove heat recovery efficiencyExtended service lifeCombustion processCorrosion preventionAir interfaceAcid corrosion

Owner:BAOSTEEL IND FURNACE ENG TECH

Wet-type cloth bag deep dedusting system

InactiveCN103566670BDust removal effect plusAdapt to the general trend of environmental protectionCombination devicesDispersed particle filtrationEnvironmental engineeringDust abatement

Owner:SHANDONG UNIV

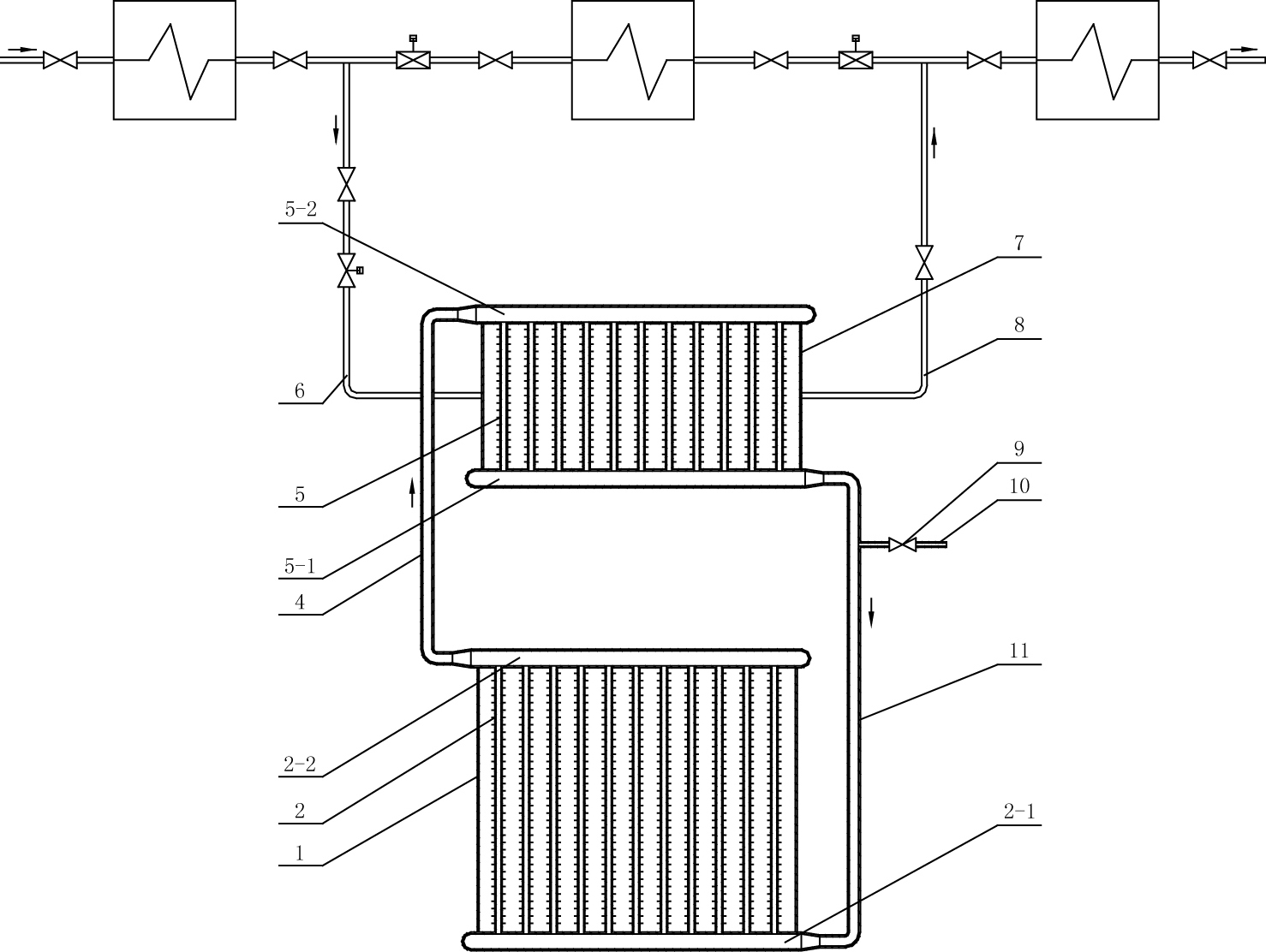

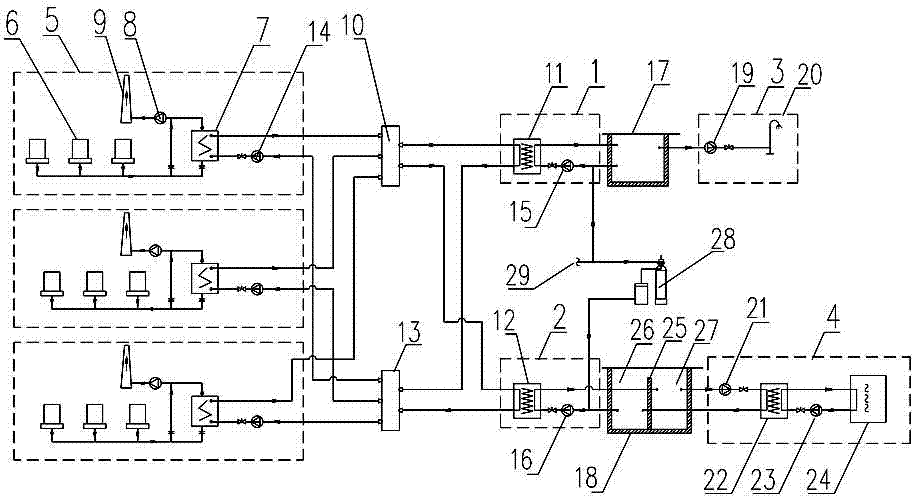

Waste heat recovery and comprehensive utilization system of industrial furnace group

ActiveCN103673649BRealize the use effectTimely and flexible heatingIncreasing energy efficiencyWaste heat treatmentWaste heat recovery unitProcess engineering

The invention discloses a waste heat recovery and comprehensive utilization system of an industrial furnace group. The waste heat recovery and comprehensive utilization system of the industrial furnace group comprises a heat collecting unit, a first heat exchange unit, a second heat exchange unit, a first heat supply unit and a second heat supply unit. The heat collecting units are formed by connecting multiple heat collecting subunits in parallel. Heat pipe heat exchangers in the heat collecting units are communicated with the same water collector inlet. A water collector outlet is communicated with a plate heat exchanger of the first heat exchange unit and a plate heat exchanger of the second heat exchange unit through pipelines. The plate heat exchanger of the first heat exchange unit and the plate heat exchanger of the second heat exchange unit are communicated with the same water distributor inlet, and the plate heat exchanger of the first heat exchange unit and the plate heat exchanger of the second heat exchange unit are communicated with a first heat storage tank and a second heat storage tank through circulating water pumps. The first heat storage tank is communicated with the first heat supply unit through a water pump, the second heat storage tank is communicated with a plate heat exchanger of the second heat supply unit through a circulating water pump, and the plate heat exchanger of the second heat supply unit is communicated with the second heat supply unit through a circulating water pump. According to the waste heat recovery and comprehensive utilization system of the industrial furnace group, comprehensive utilization of waste heat in the aspects of heat collecting and technology production is achieved, and recovery and utilization of the waste heat are balanced through heat storage and heat release.

Owner:SIPPR ENG GROUP

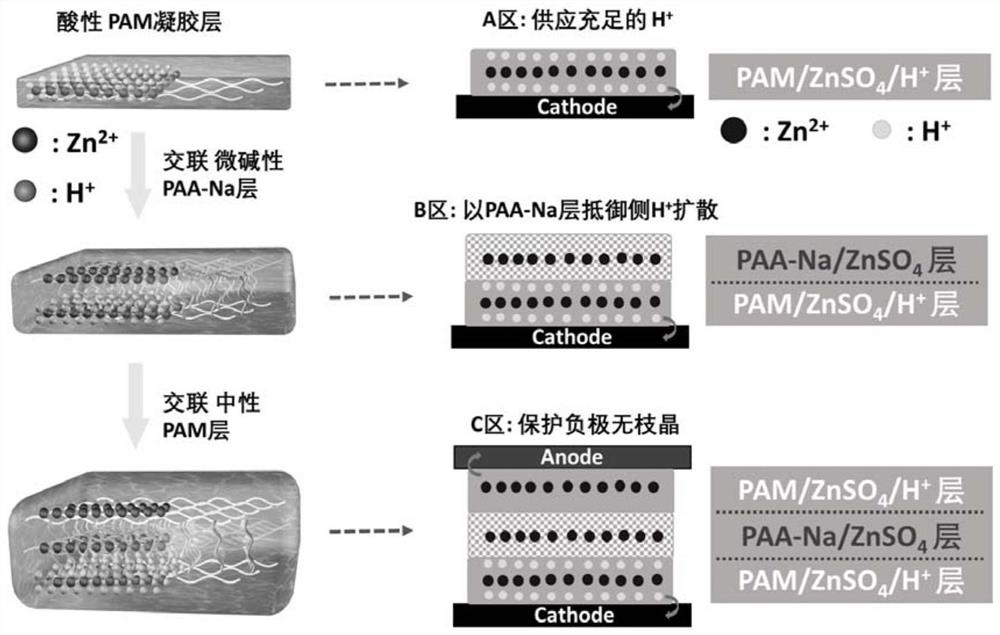

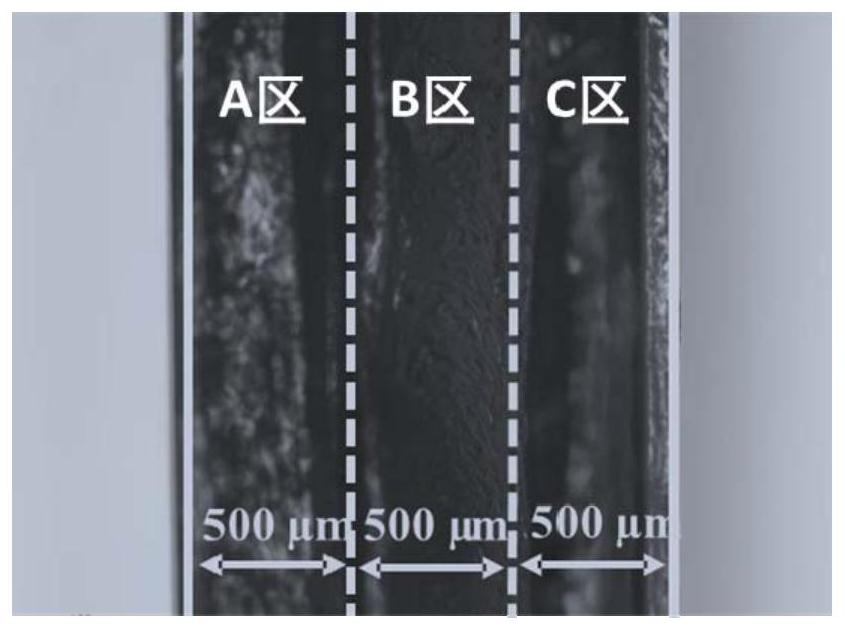

Gel electrolyte for aqueous zinc-manganese battery and preparation method of gel electrolyte

PendingCN113904002AInhibition of dissolutionInhibit migrationFinal product manufactureSecondary cellsElectrical batteryNew energy

The invention provides a gel electrolyte for an aqueous zinc-manganese battery and a preparation method of the gel electrolyte. The gel electrolyte at least sequentially comprises an acidic gel layer, an alkalescence gel layer and a neutral gel layer from bottom to top. When the gel electrolyte is applied to the assembly of the water-based zinc-manganese battery, the acidic gel layer is positioned at one side of a manganese dioxide positive electrode, and sufficient hydrogen ions can be provided to prevent the manganese dioxide from being dissolved; the neutral gel layer is located at one side of the zinc negative electrode, does not cause acid corrosion to the zinc negative electrode, and can effectively prevent zinc dendrite growth caused by alkalinity; and the alkalescence gel layer is positioned between the acidic gel layer and the neutral gel layer, so that hydrogen ions can be prevented from being migrated to the negative electrode from the positive electrode, and the corrosion of the zinc negative electrode is prevented. The structure and performance of the battery are stabilized, the service life of the battery is prolonged, meanwhile, the water-based zinc-manganese battery has better capacity, reversibility, flexibility and bendability, and the gel electrolyte has very good industrial application prospects in the field of new energy batteries.

Owner:UNIVERSITY OF MACAU

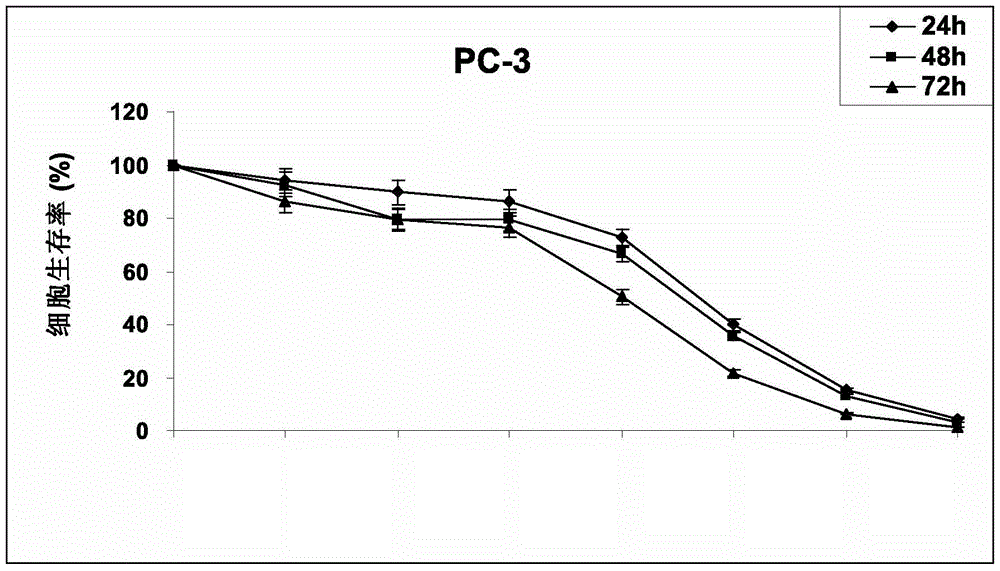

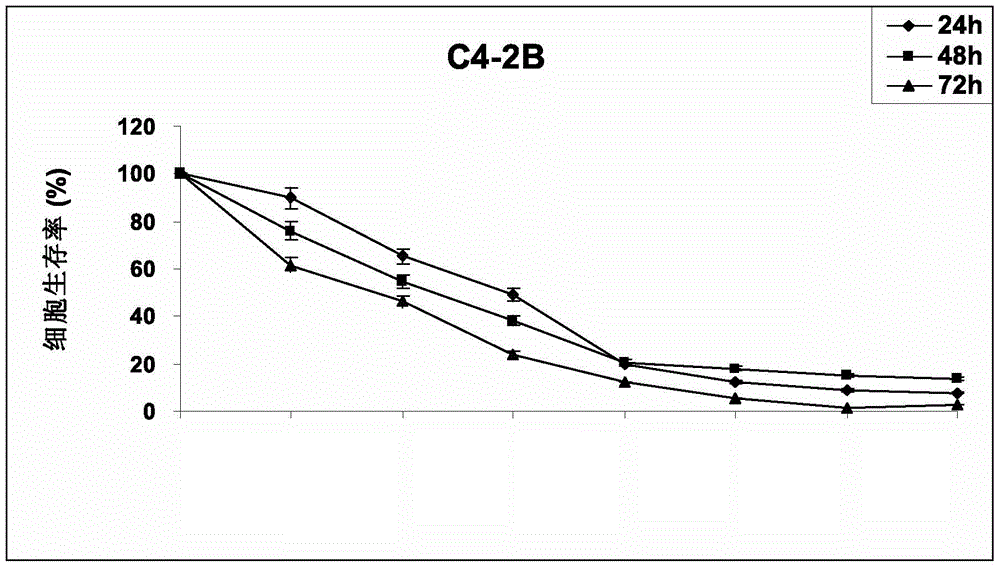

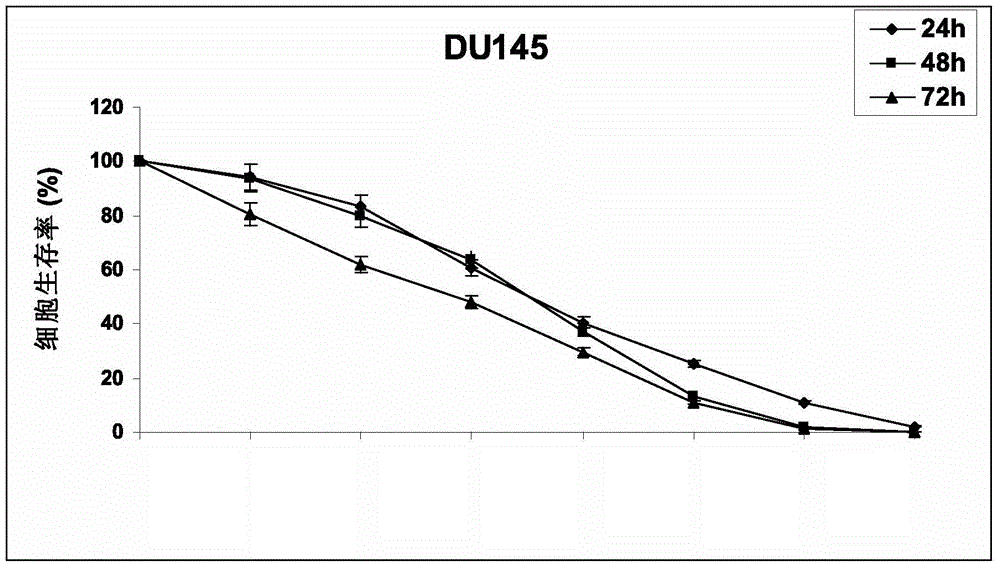

A preparation method and application of litchi core extract for preventing and treating prostate cancer

ActiveCN104225037BPromote leachingEasy extractionAntineoplastic agentsFood scienceReflux extractionMedicine

The invention relates to a preparation method and application of litchi seed extract for preventing and treating prostate cancer, and belongs to the technical field of traditional Chinese medicine extracts. The present invention adopts dipping, ultrasonic, microwave, reflux extraction, extraction and other processes to fully destroy the cell wall, accelerate and increase the dissolution of active ingredients, and obtain the litchi core extract of the present invention. The extraction method has high efficiency and good quality of the extract, and can be directly Made into tablets, granules, powders, dripping pills, teas, decoctions, capsules, mixtures or syrups, etc., and added to related foods, beverages or medicines as functional additives for adjuvant therapy or treatment of prostate cancer, Thereby expanding the medicinal scope and value of litchi core.

Owner:广西爱呗利生物科技有限公司

Wire cutting liquid of semiconductor material

InactiveCN100560702CReduce wire breakage rateAddress stressSemiconductor/solid-state device manufacturingBase-materialsSemiconductor materialsActive agent

The invention relates to a wire cutting fluid for semiconductor materials. Its composition and weight % ratio are as follows: polyethylene glycol 10-10000: 35-90, amine base: 8-30, penetrating agent: 1-5, ether alcohols Active agent: 0.5-5, chelating agent: 0.5-5, deionized water: 0-55. The advantages of the present invention are: 1. The existing neutral or acidic wire cutting fluid is improved into an alkaline wire cutting fluid having a chemical interaction with silicon, which can avoid acid corrosion of equipment and reduce wire saw wire breakage rate. 2. It effectively solves the problem of re-deposition of chips and diced powder, avoids the phenomenon of chemical bonding and adsorption on the surface of silicon wafers, and facilitates the cleaning and subsequent processing of silicon wafers. 3. The effects of penetration, lubrication and cooling are remarkable, and the surface damage, mechanical stress, thermal stress and pollution of metal ions to silicon wafers of the obtained slices are significantly reduced. 4. The cost price is low, which is beneficial to replace the imported wire cutting fluid.

Owner:刘玉岭

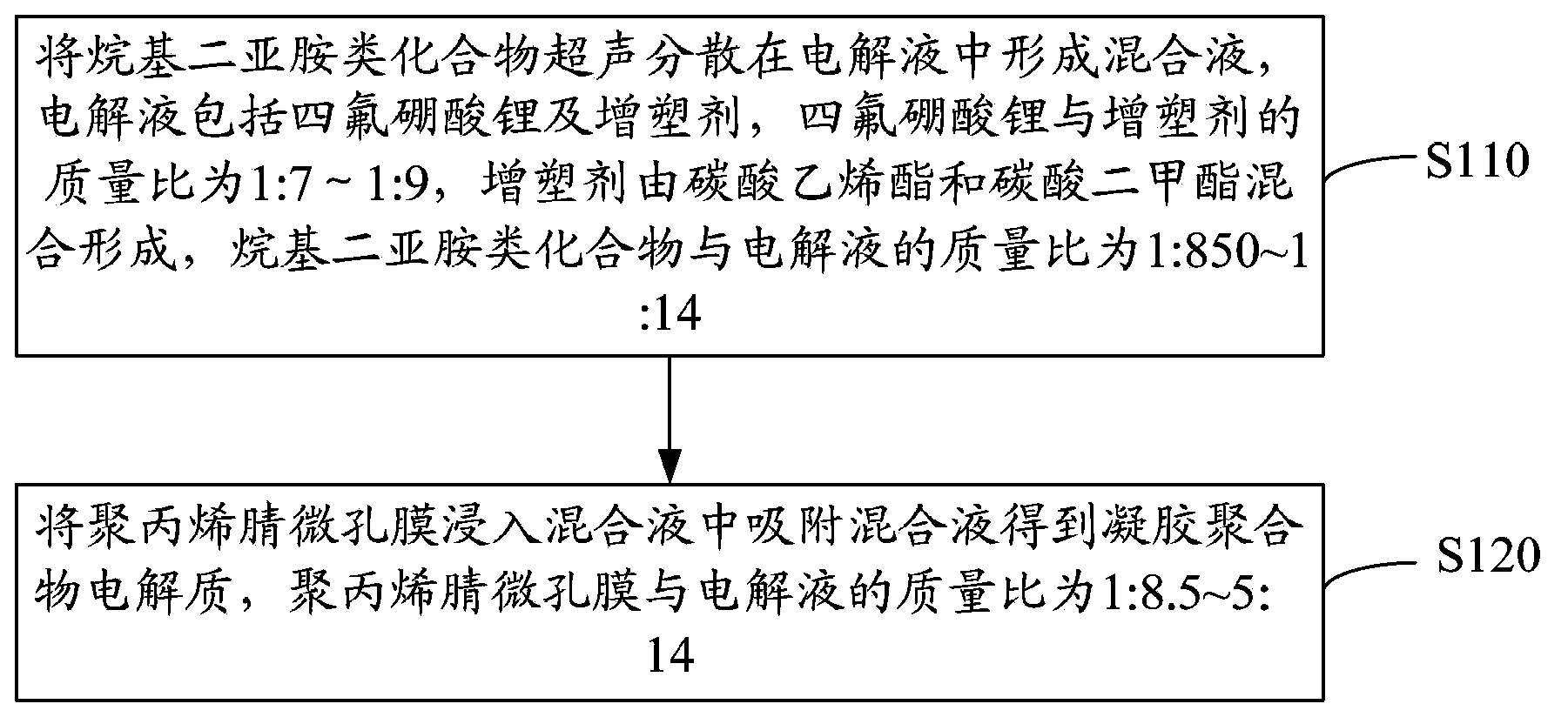

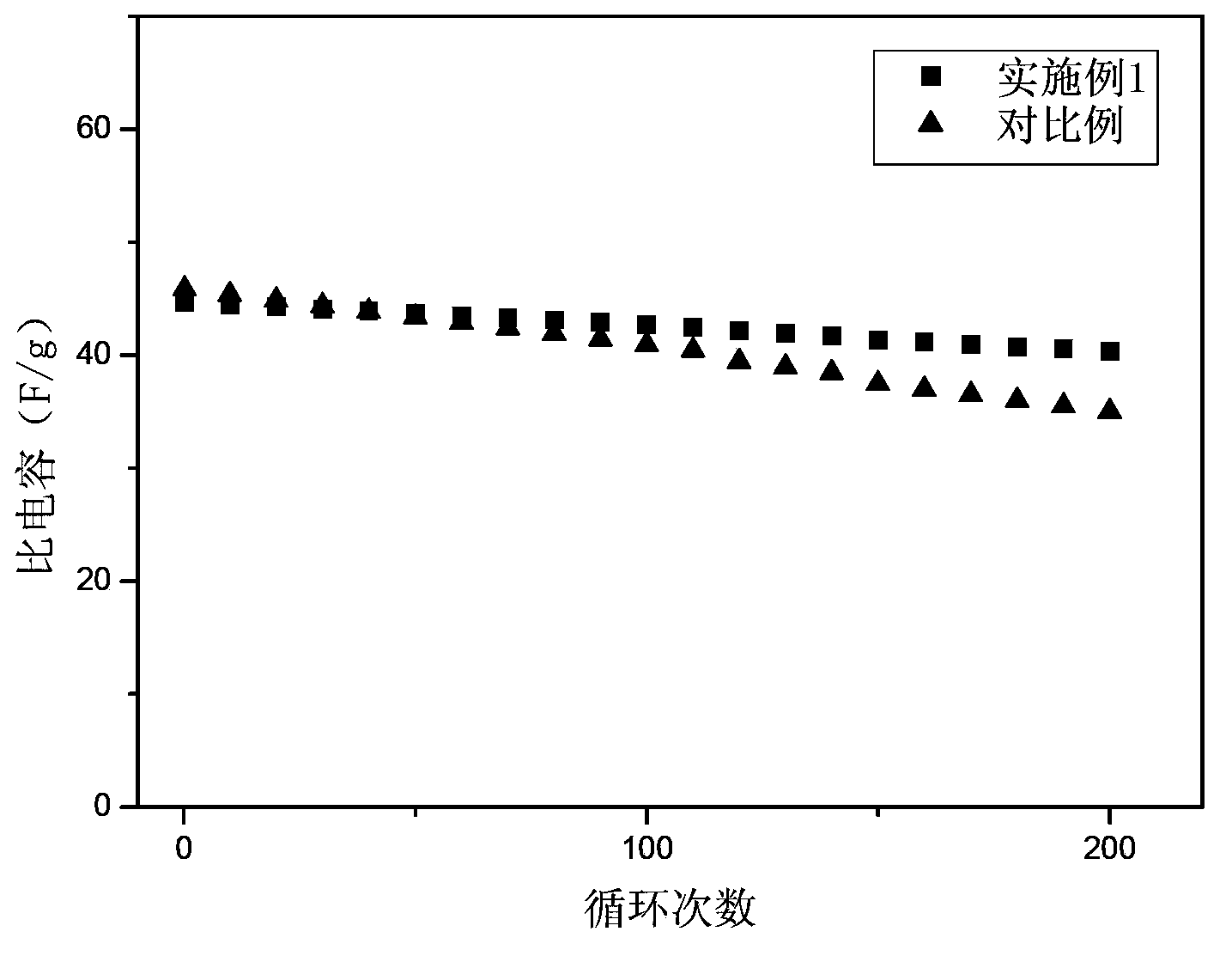

Gel polymer electrolyte and preparation method thereof

InactiveCN103811194AAvoid generatingAvoid acid corrosionHybrid capacitor electrolytesHybrid/EDL manufacturePolymer electrolytesPolymer science

The invention discloses a gel polymer electrolyte comprising polyacrylonitrile and an electrolytic solution and an alkyl-diimine compound which are absorbed into the polyacrylonitrile. In the gel polymer electrolyte, the mass percent of the polyacrylonitrile is in the range from 10% to 25%, the mass percent of the electrolytic solution in the range from 70% to 85%, and the mass percent of the alkyl-diimine compound in the range from 0.1% to 5%. The electrolytic solution comprises lithium tetrafluoroborate and a plasticizer, wherein the mass ratio of the lithium tetrafluoroborate to the plasticizer is in the range from 1:7 to 1:9, and the plasticizer is formed by mixing ethylene carbonate and dimethyl carbonate. The gel polymer electrolyte can be used to avoid the corrosion of an aluminum foil. The invention further provides a preparation method of the gel polymer electrolyte.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

A kind of strong acid type high temperature resistant cationic resin catalyst and preparation method thereof

ActiveCN107537570BImprove product qualityImprove high temperature resistanceOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPhosphoric Acid EstersPolymer science

Owner:丹东明珠特种树脂有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com