Flue gas deacidification and dust removal system

A dust removal system and flue gas technology, applied in gas treatment, dispersed particle filtration, membrane technology, etc., can solve the problems of dew condensation on the surface of the cloth bag, low flue gas temperature, sticking of the bag, etc., to increase the processing capacity, improve the processing efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

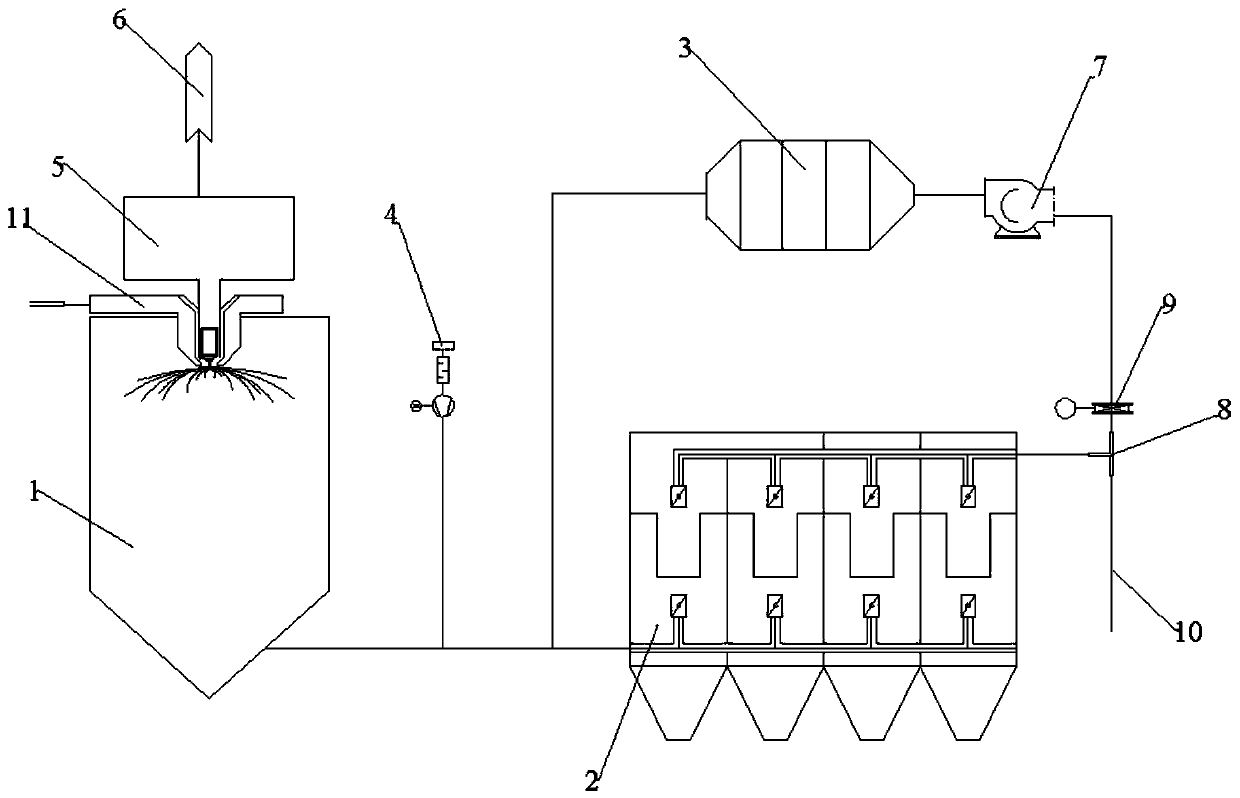

[0025] As a kind of flue gas deacidification and dust removal system of the embodiment of the present invention, such as figure 1 As shown, the flue gas deacidification and dust removal system includes a deacidification tower 1, a slurry tank 6, a dry powder injection device 4, a bag filter 2, an electric duct heater 3, a rotary atomizer 5 and a fan 7;

[0026] The deacidification tower 1 is provided with a flue gas inlet, a slurry inlet and a flue gas outlet. The flue gas inlet of the deacidification tower 1 is a spiral flue gas inlet 11, and the spiral flue gas inlet 11 is provided with deflectors. The diversion direction is opposite to the spray tangential direction of the rotary atomizer 5. The rotary atomizer 5 has a slurry inlet and a slurry outlet. The slurry inlet of the rotary atomizer 5 is connected to the slurry tank 6. The slurry of the rotary atomizer 5 The outlet is connected to the slurry inlet pipeline of the deacidification tower 1;

[0027] The bag filter 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com