Incineration device and method for treating sulfur recovery tail gas

A technology of sulfur recovery tail gas and incineration device, applied in the chemical industry, can solve the problems of mixing, no recovery of flue gas waste heat, high cost, and achieve the effects of increasing operating pressure, preventing leakage and preventing acid corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further explained and described below in conjunction with preferred embodiments of the present invention and accompanying drawings.

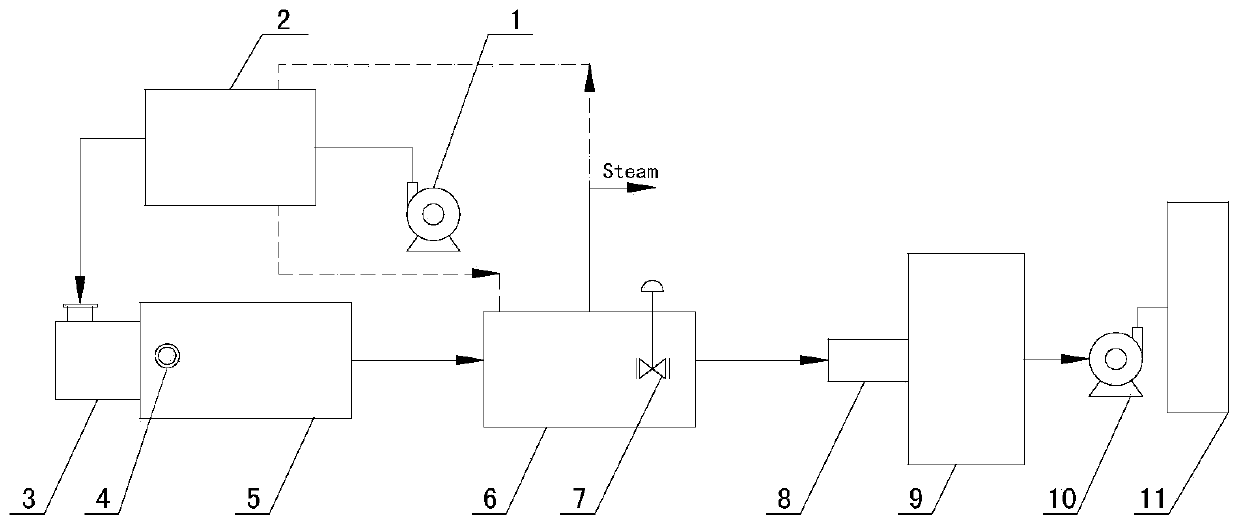

[0054] Such as figure 1 As shown, an incineration device for treating sulfur recovery tail gas includes a blower 1, an air preheater 2, a burner 3, an incinerator 5, a waste heat boiler 6, a quencher 8, an alkali washing tower 9, and an induced draft fan 10 connected in sequence. and the chimney 11, and the mixing inlet 4 located at the front end of the incinerator 5 furnace, the inlet end of the mixing inlet 4 includes a first inlet and a second inlet, and the first inlet is used to transport tail gas to be treated, and the second inlet and The outlet end of the air preheater 2 is connected.

[0055] 1. Blower 1 is used to inhale air and generate combustion-supporting air to enter air preheater 2;

[0056] 2. The air preheater 2 is used to heat the combustion-supporting air to generate heated combustion-supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com