Patents

Literature

519 results about "Oxygen deficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxygen deficiency is a condition of shortage of oxygen in the blood of any human being. The condition is also known as asphyxia or hypoxia. Such a condition may severely affect the activities of cells, tissues and organs unless he or she breathes sufficient oxygen immediately.

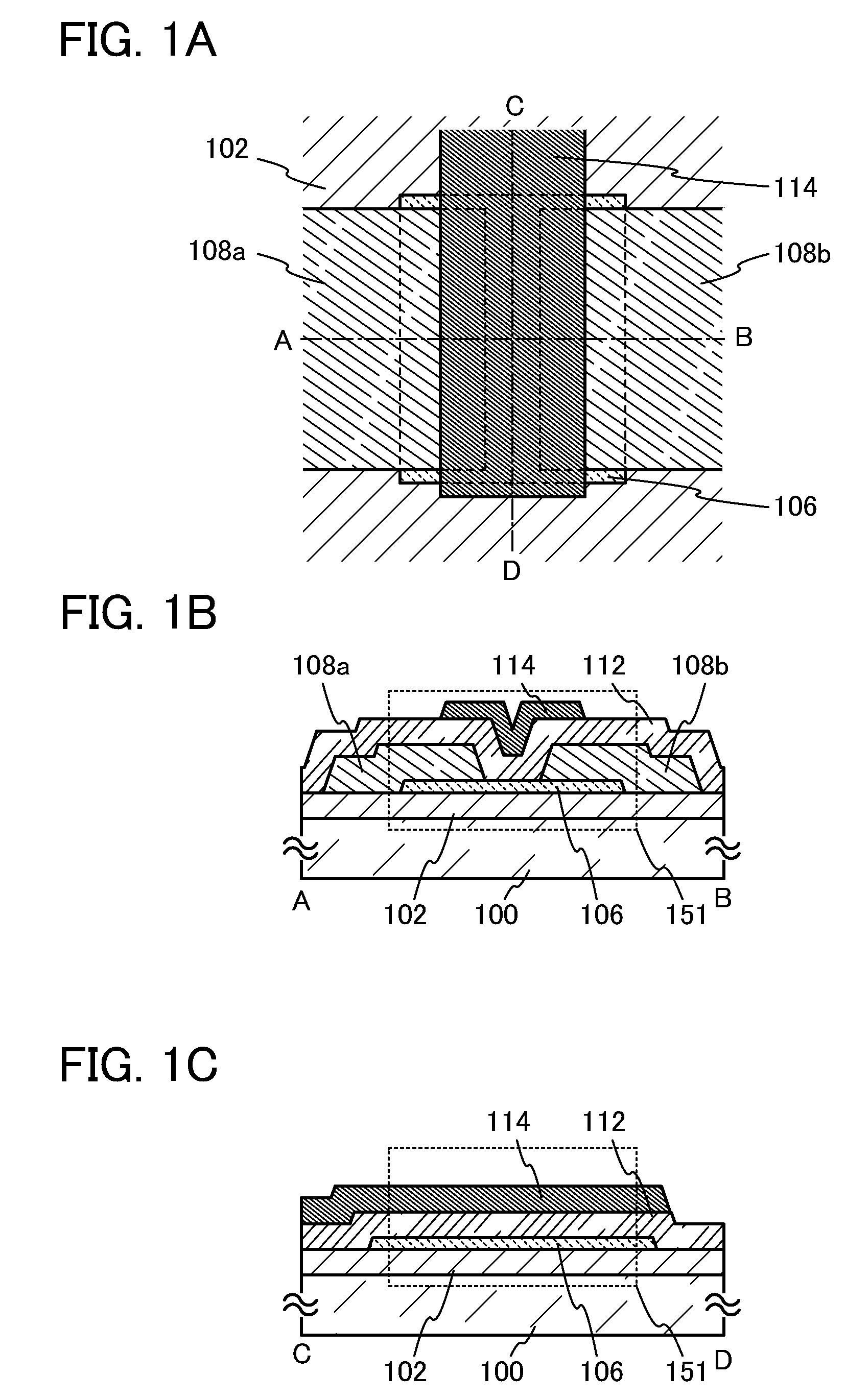

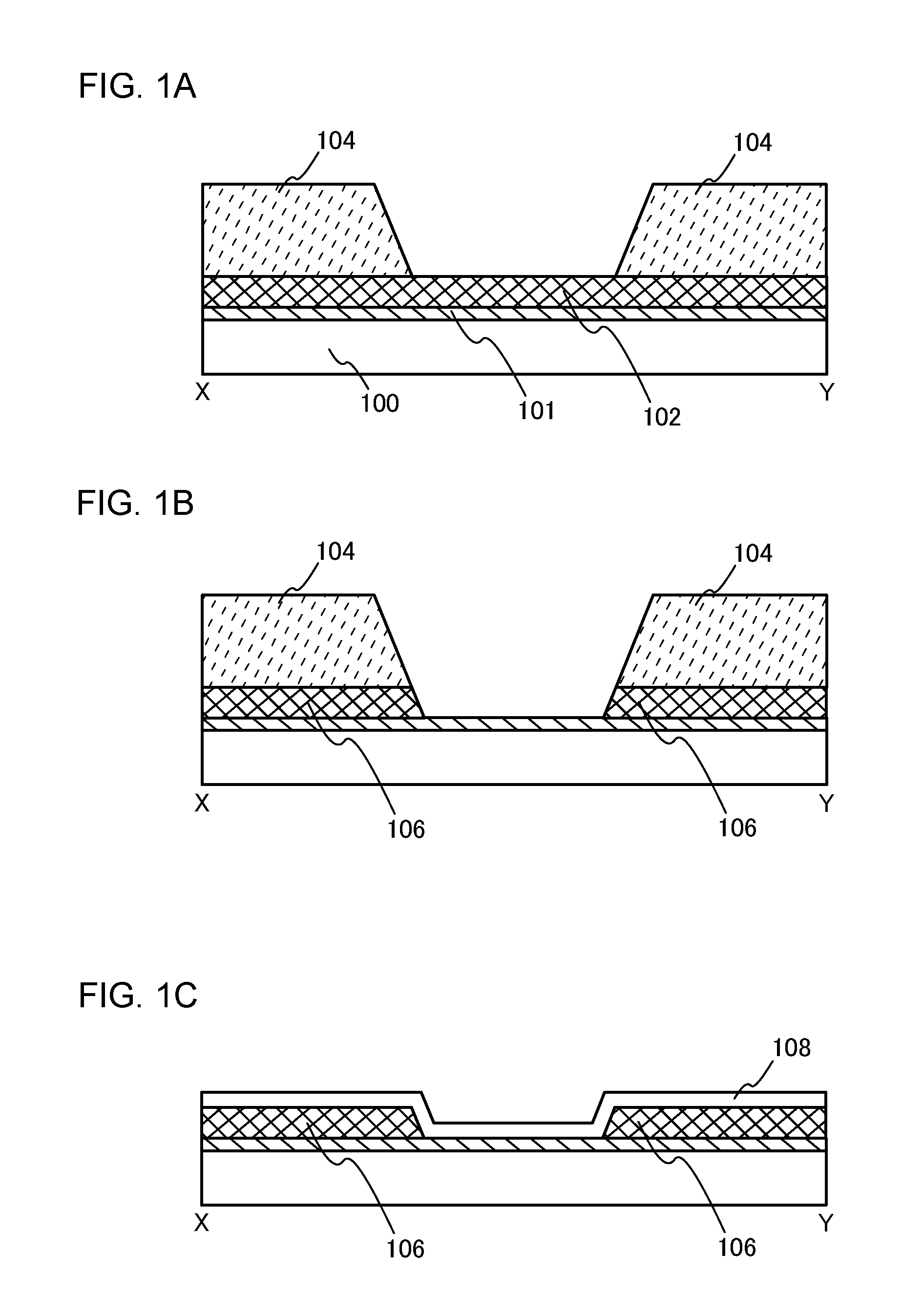

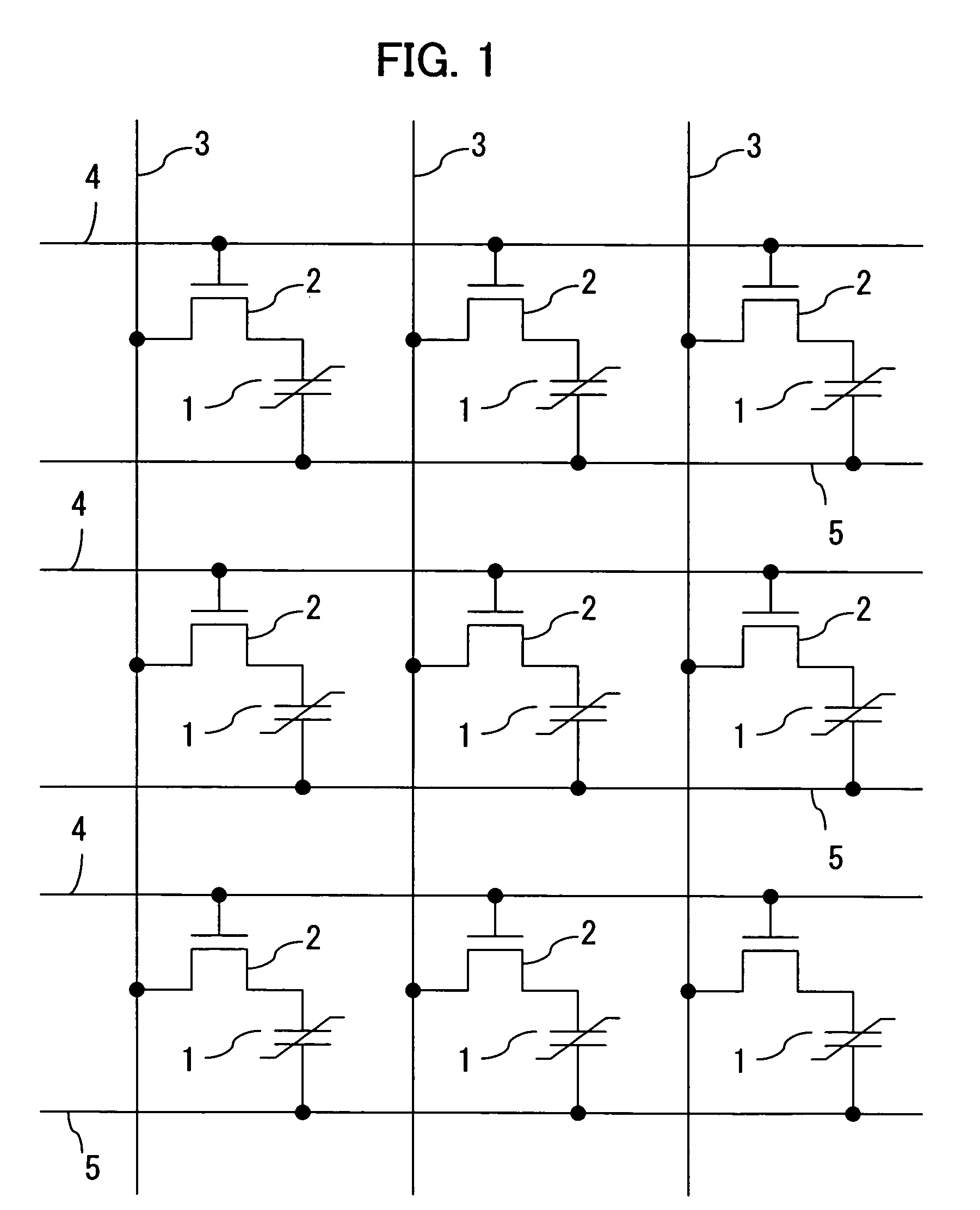

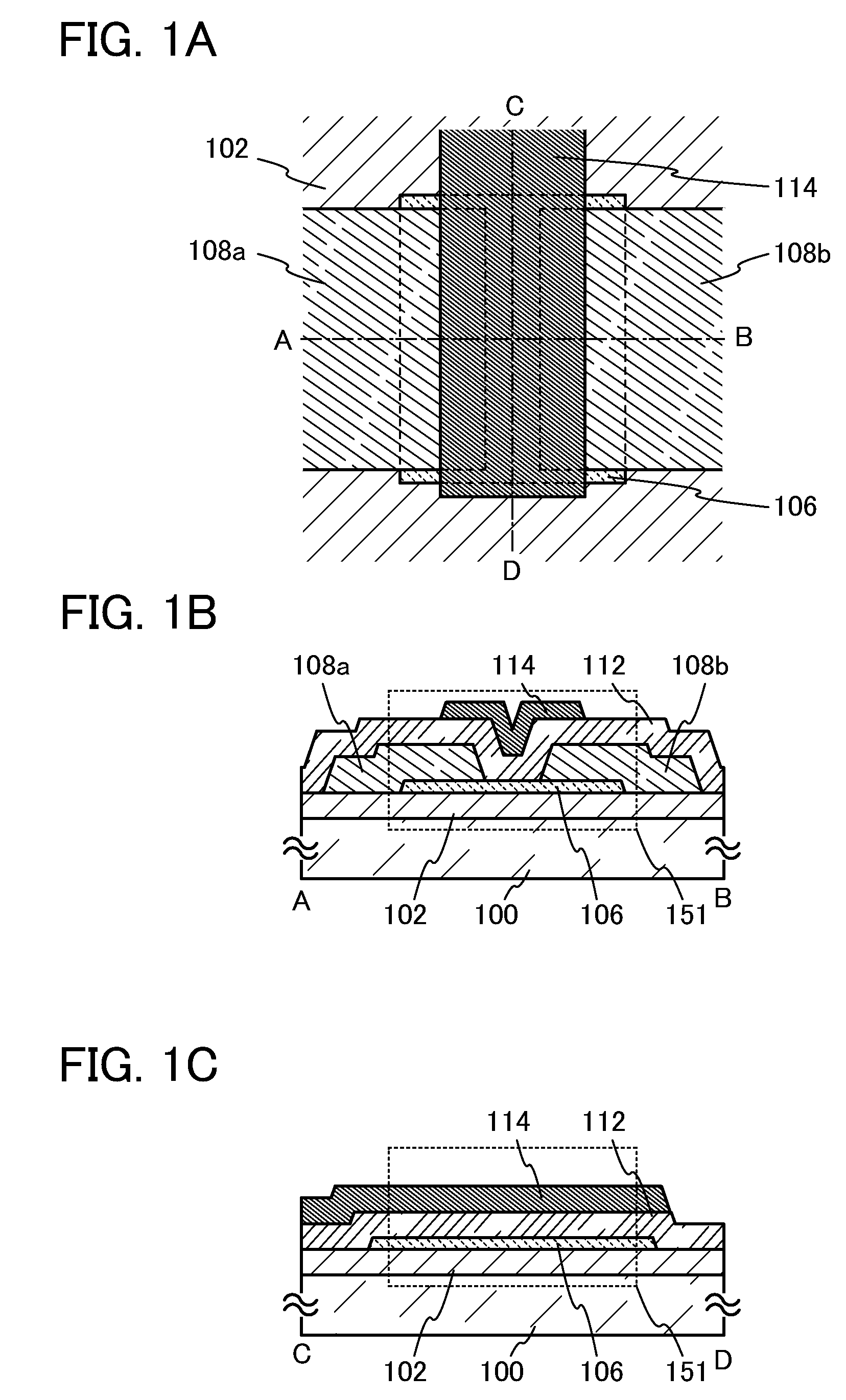

Semiconductor device

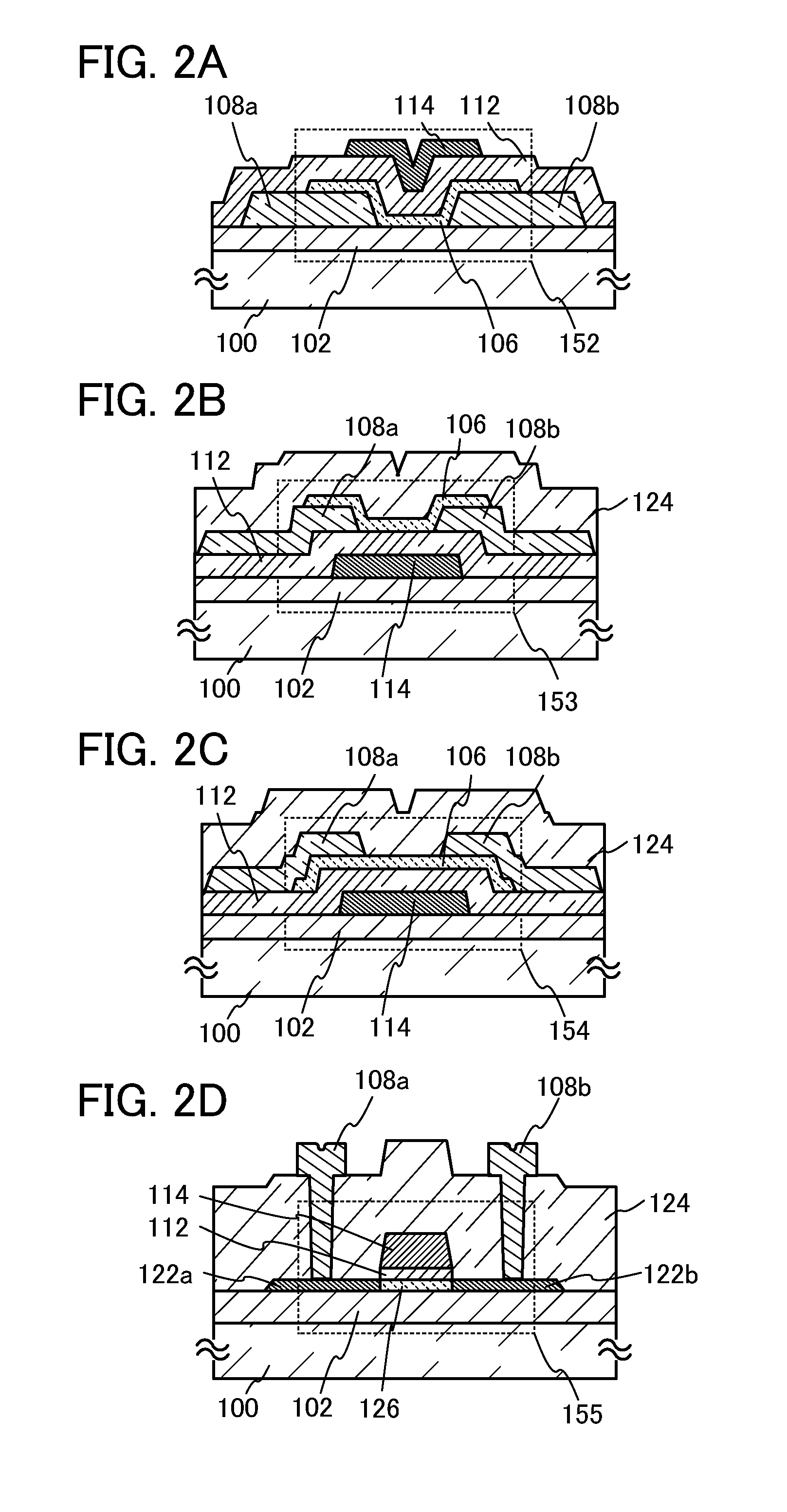

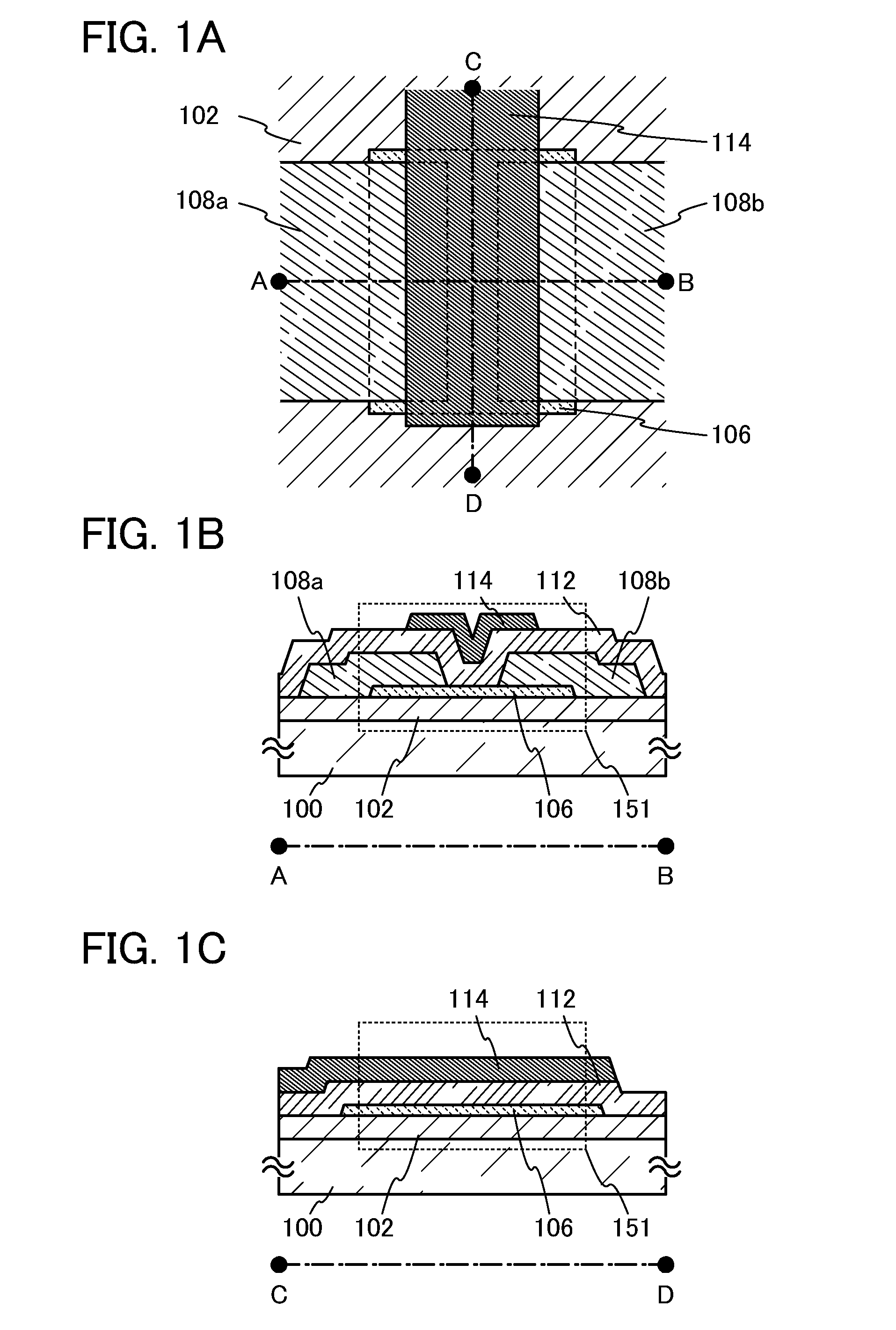

ActiveUS20110284844A1Small currentLittle changeTransistorSemiconductor/solid-state device manufacturingElectricitySemiconductor

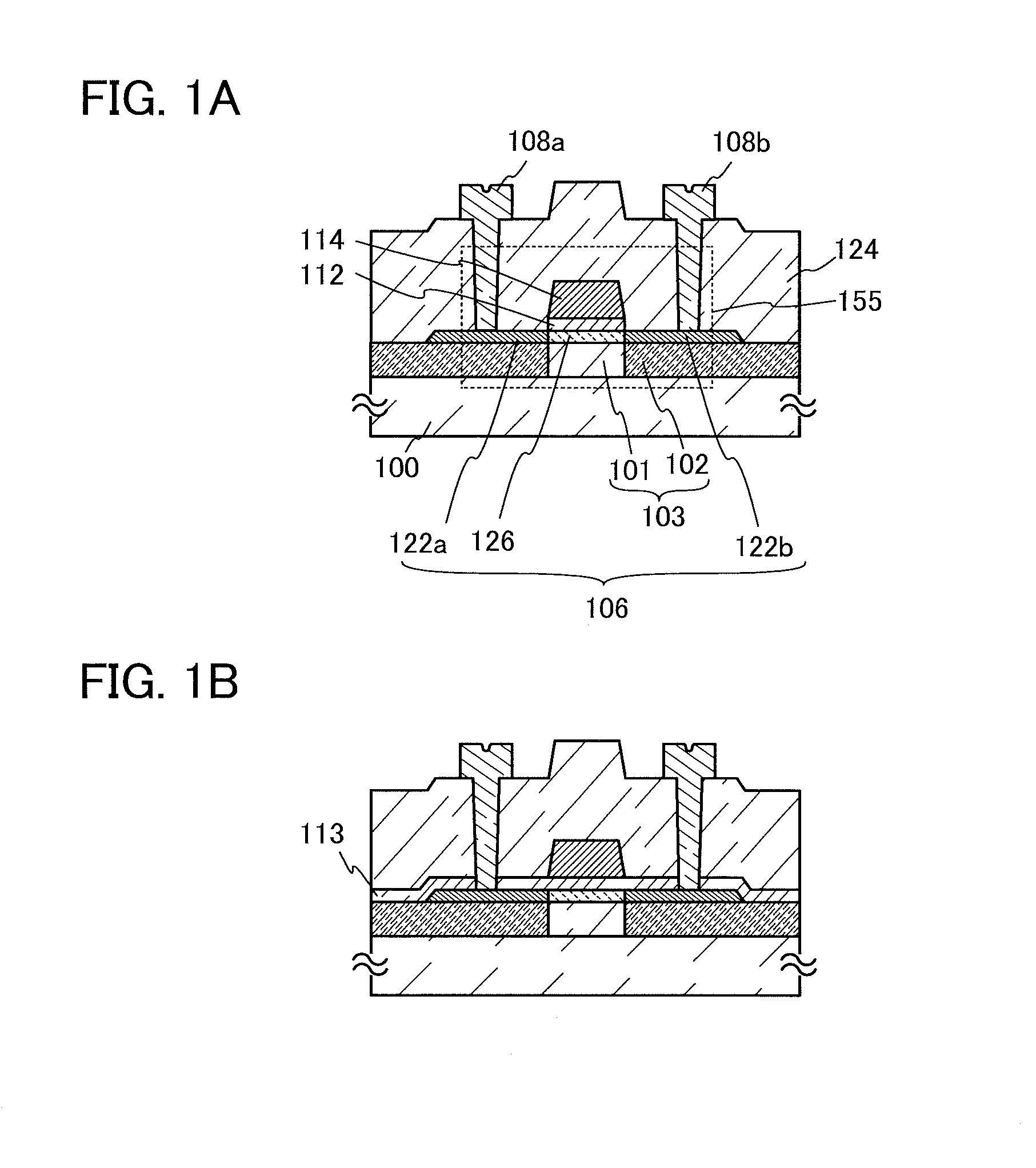

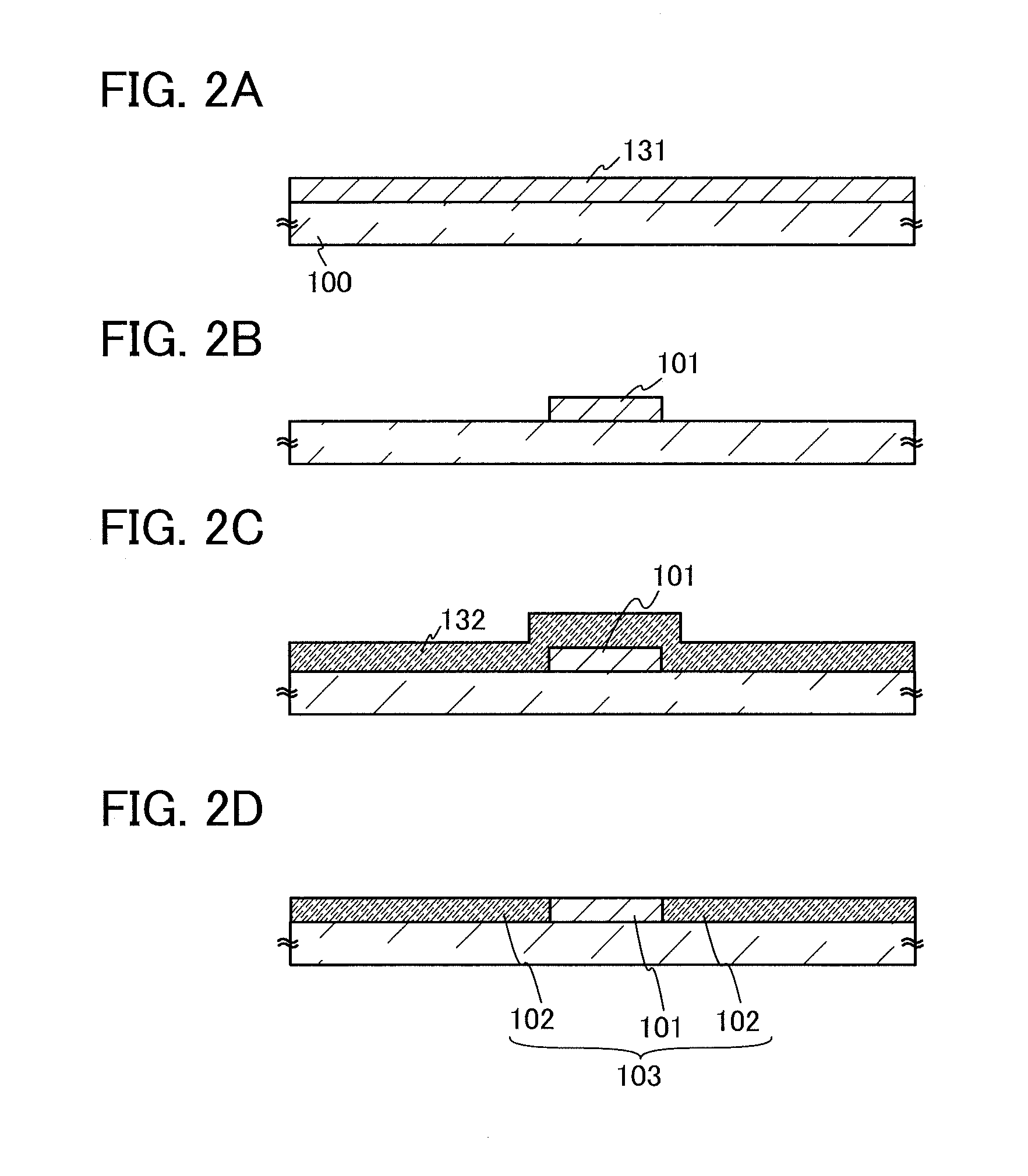

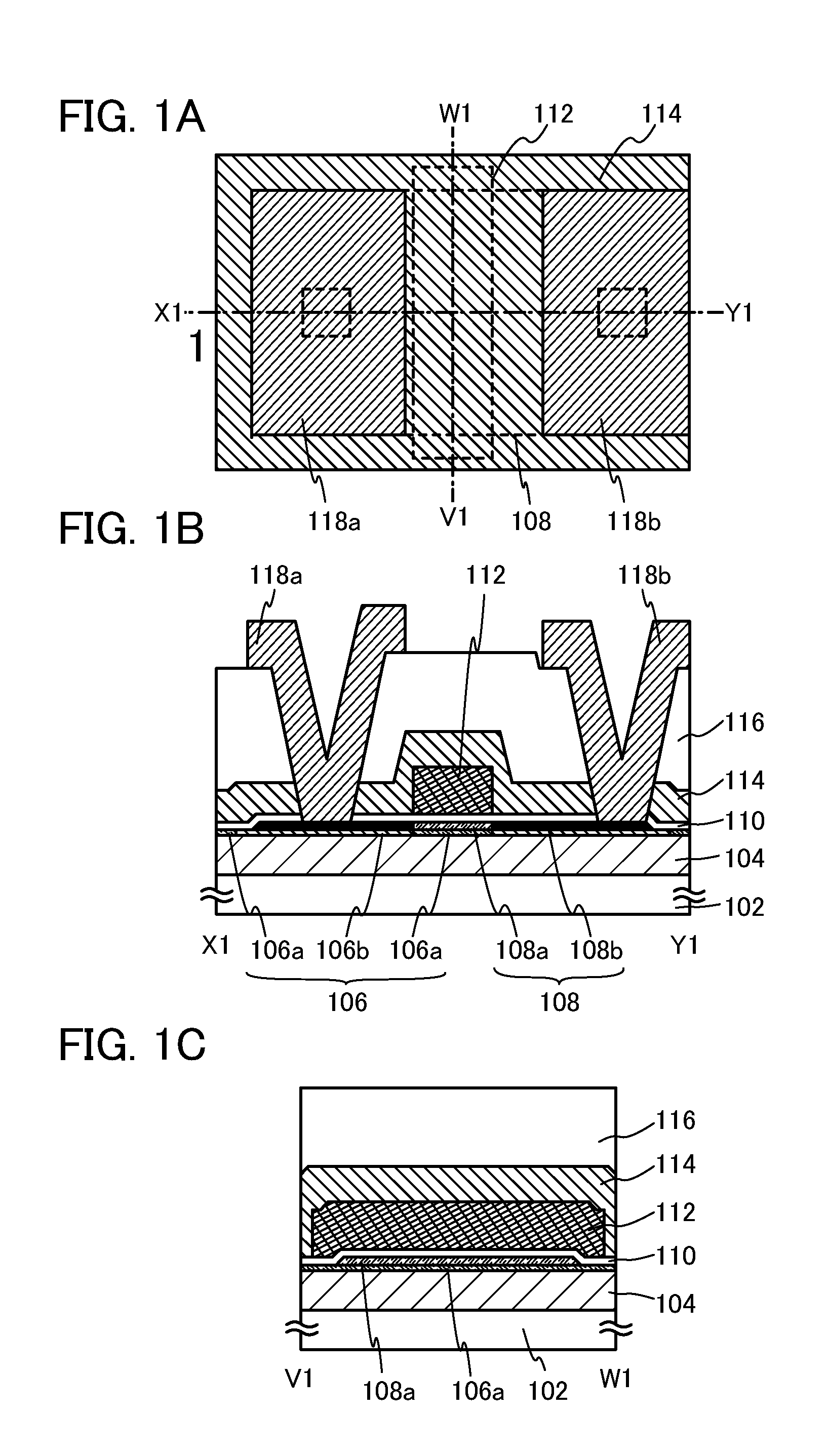

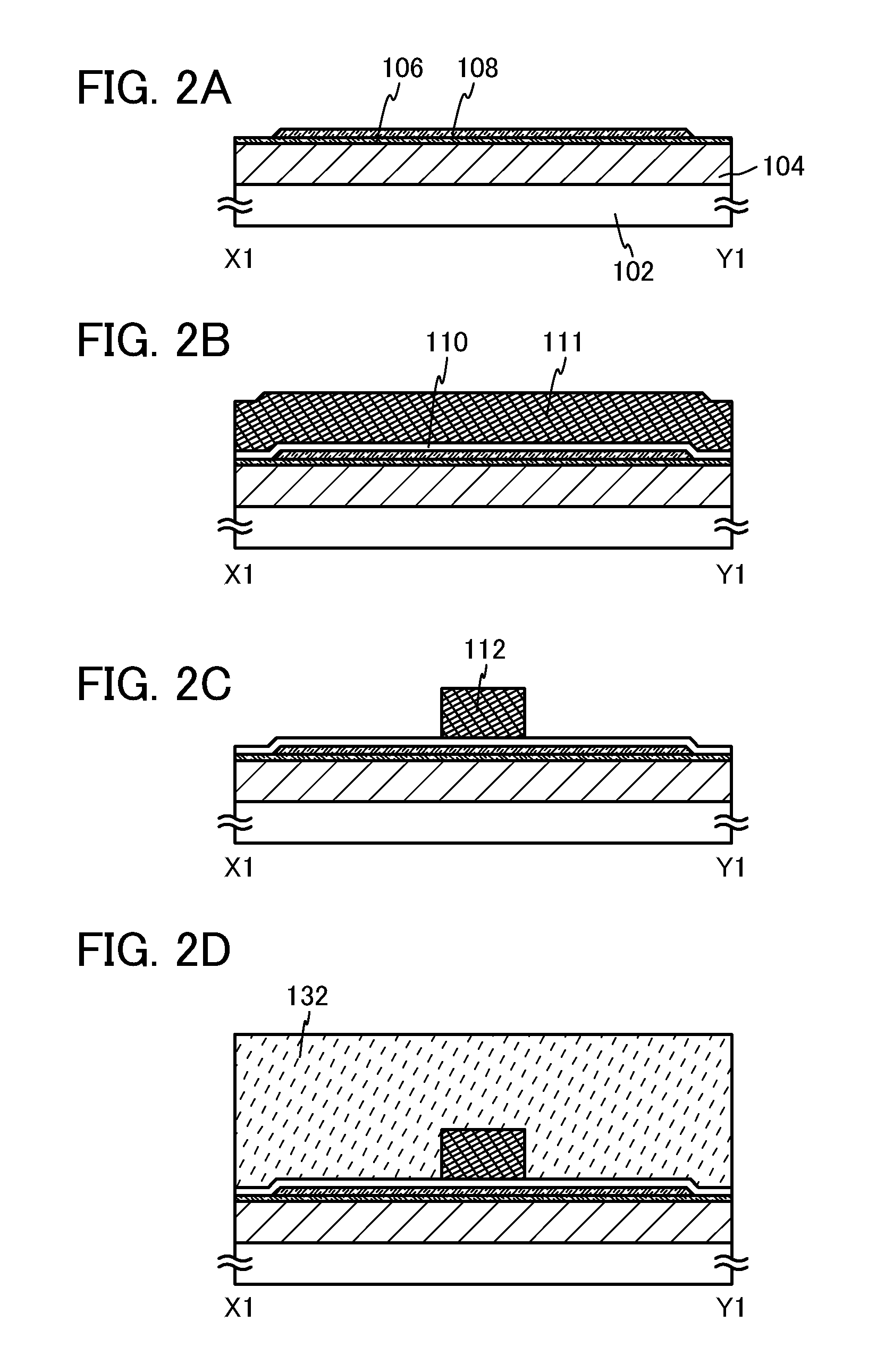

An object of the present invention is to manufacture a semiconductor device where fluctuation in electrical characteristics is small and reliability is high in a transistor in which an oxide semiconductor is used. An insulating layer from which oxygen is released by heating is used as a base insulating layer of an oxide semiconductor layer which forms a channel. Oxygen is released from the base insulating layer, whereby oxygen deficiency in the oxide semiconductor layer and an interface state between the base insulating layer and the oxide semiconductor layer can be reduced. Thus, a semiconductor device where fluctuation in electrical characteristics is small and reliability is high can be manufactured.

Owner:SEMICON ENERGY LAB CO LTD

Complex foam extinguishing agent for coal mine

InactiveCN102614615AHigh bonding strengthReduce the drainage rateFire extinguisherSodium bicarbonateMass ratio

The invention discloses a complex foam extinguishing agent for a coal mine and belongs to the technical field of fire prevention and extinguishing. The extinguishing agent is prepared from the following raw materials: main materials are 40 to 60 percent aqueous solution of ammonium bicarbonate or sodium bicarbonate and concentrated sulfuric acid in a solute mass ratio of 2:1-3:1, and auxiliary materials are a stabilizer and a foamer, wherein the auxiliary materials are 0.1 to 2 percent of the total weight of the main materials. Through a test, the extinguishing agent has the foaming coefficient of 20-200 and the foam stabilizing time of more than or equal to 2.5 hours. According to the foam extinguishing agent, the foam of inert gas carbon dioxide is applied to fire prevention and extinguishing of the coal mine, and the foam is diffused in a fire area and fills a fire space, so that the oxygen concentration in the fire area is rapidly reduced, fire is extinguished due to oxygen deficiency in the fire area, temperature is reduced and a fire extinguishing effect is good. The technology also can be applied to coal bed transformation, CO2 foam is easily absorbed by coal to displace partial methane, the recovery ratio of coal seam gas is improved, and CO2 is acid to reduce the generation of secondary precipitates, so that a gas drainage effect is improved. The complex foam extinguishing agent is simple and feasible, and low in cost.

Owner:抚顺正工矿业科技发展有限公司

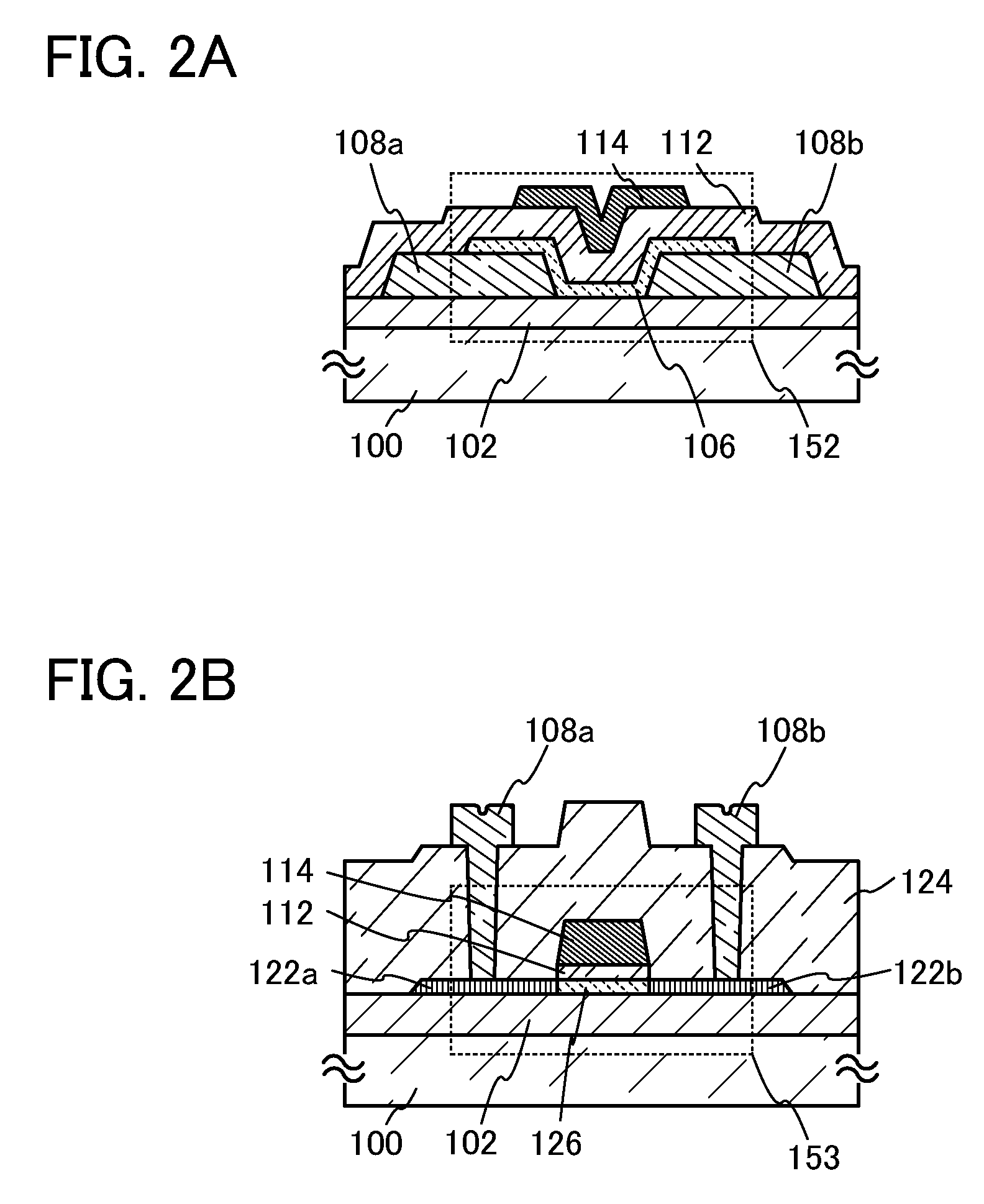

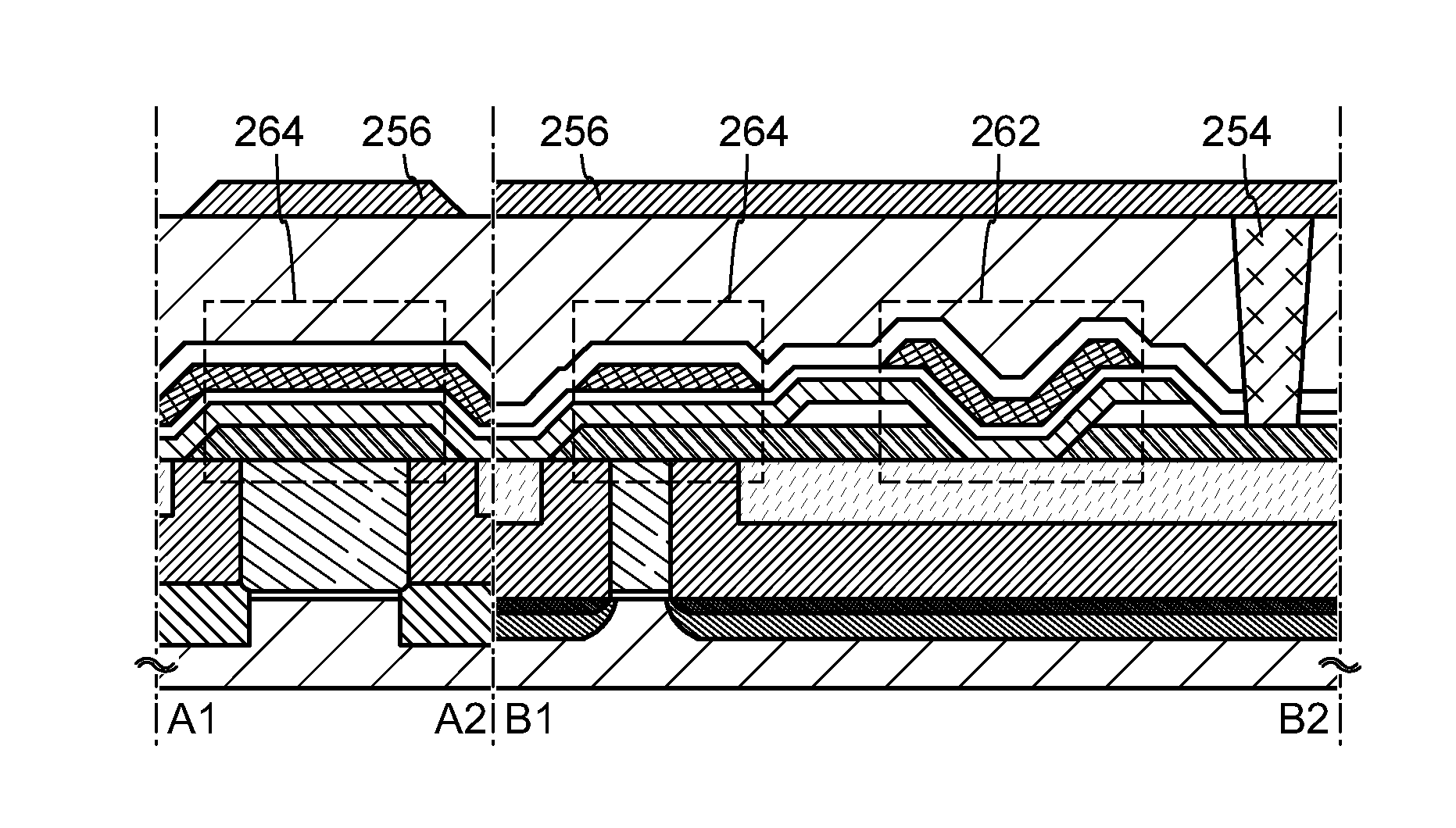

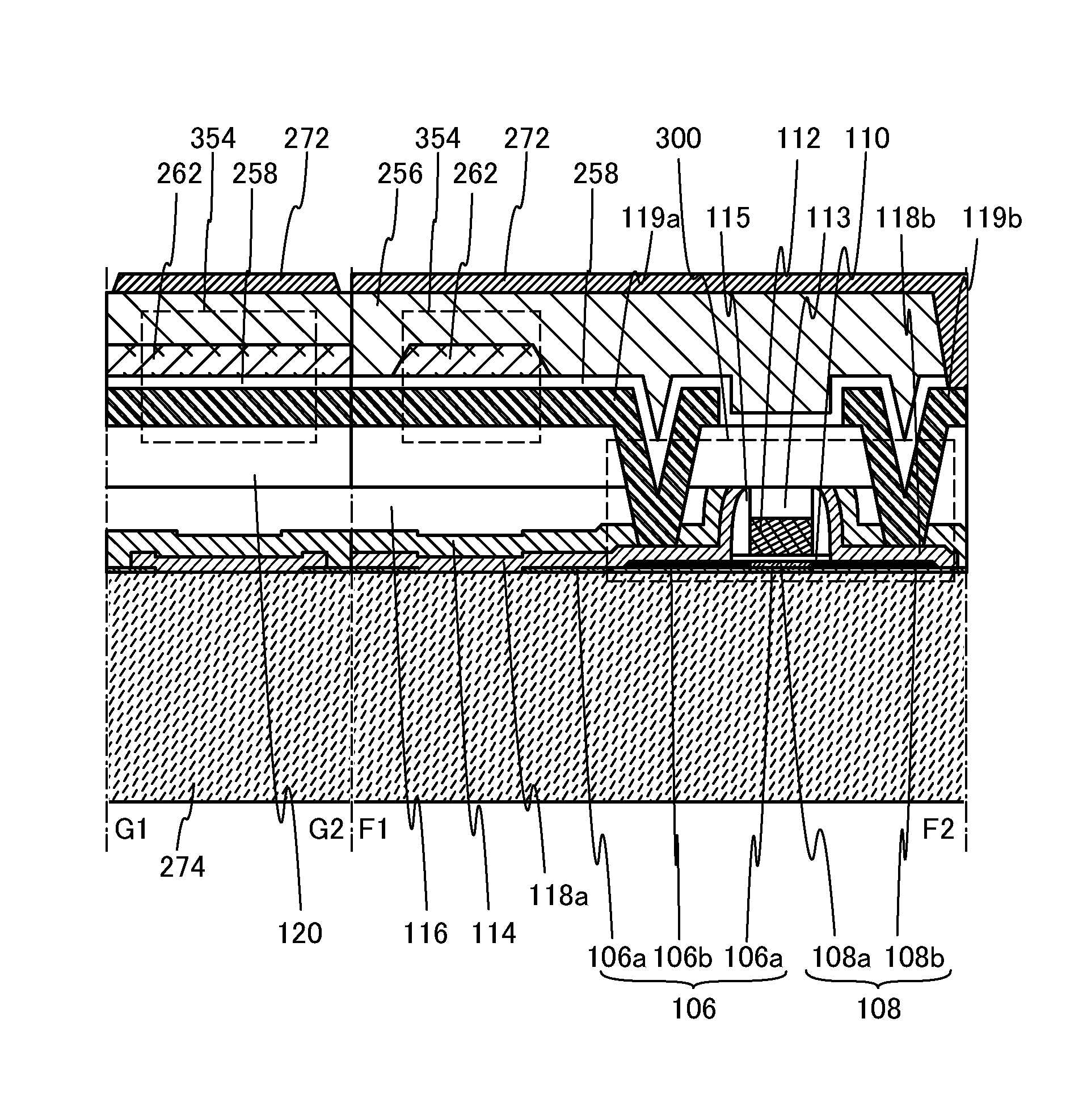

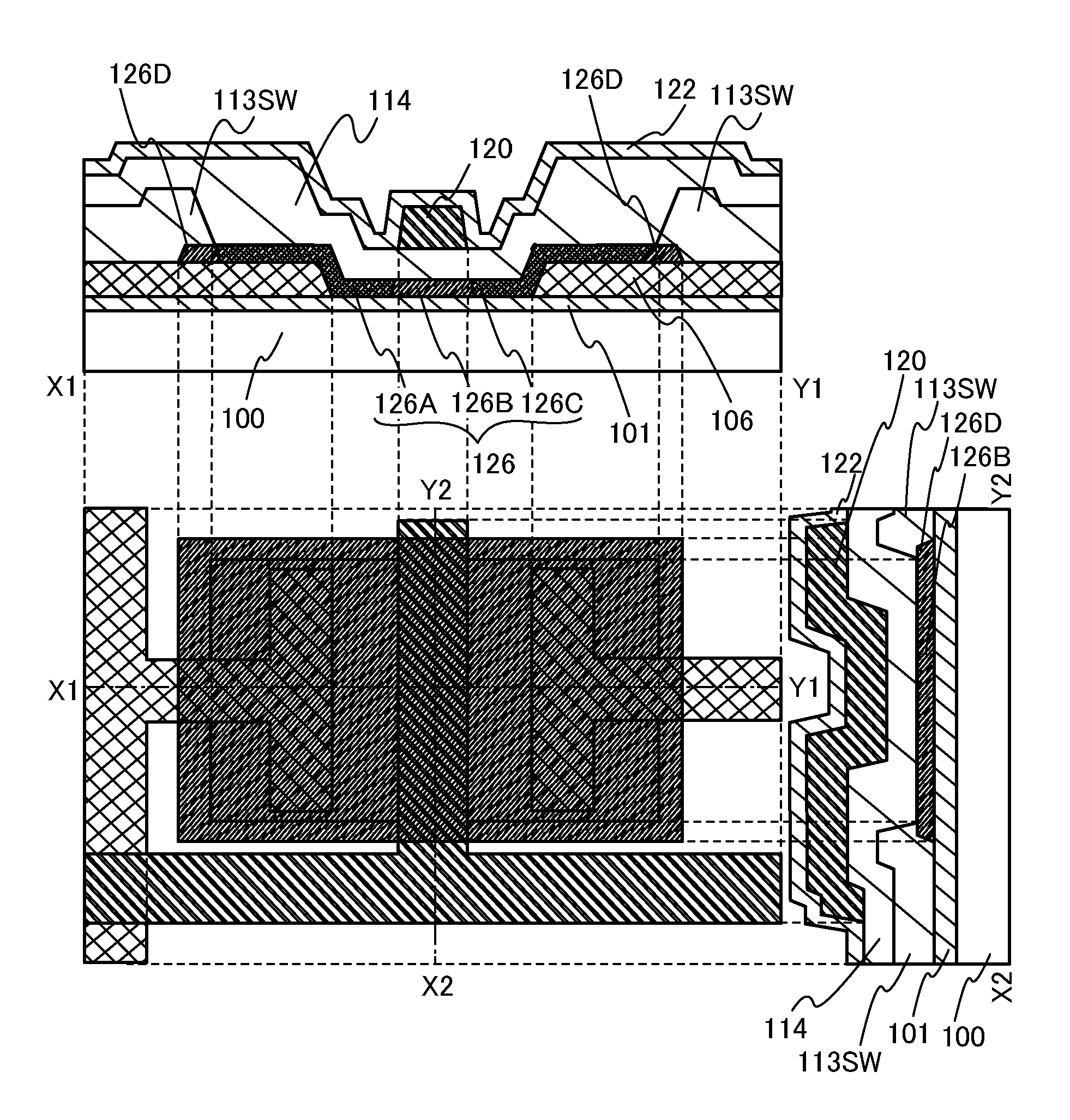

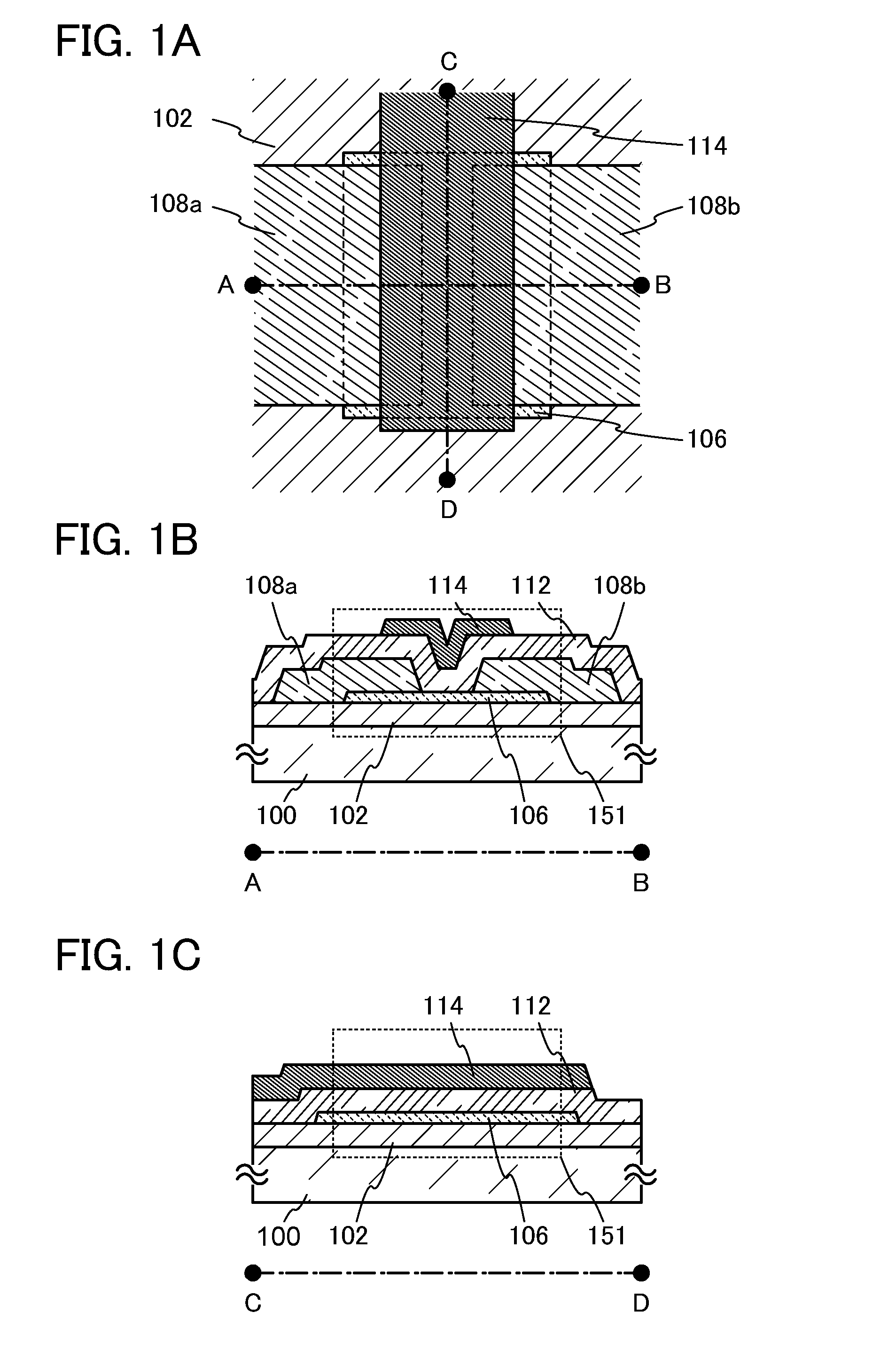

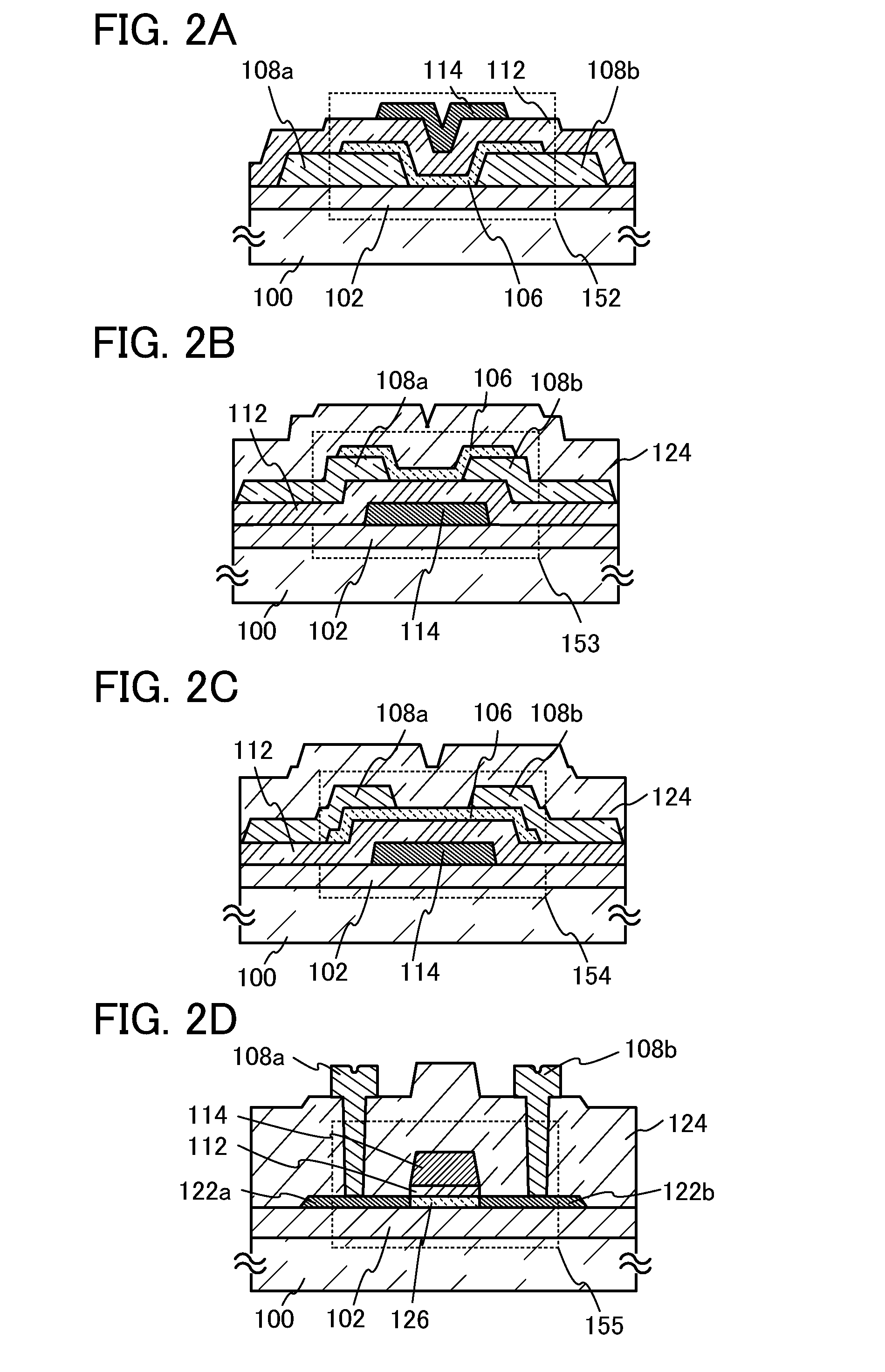

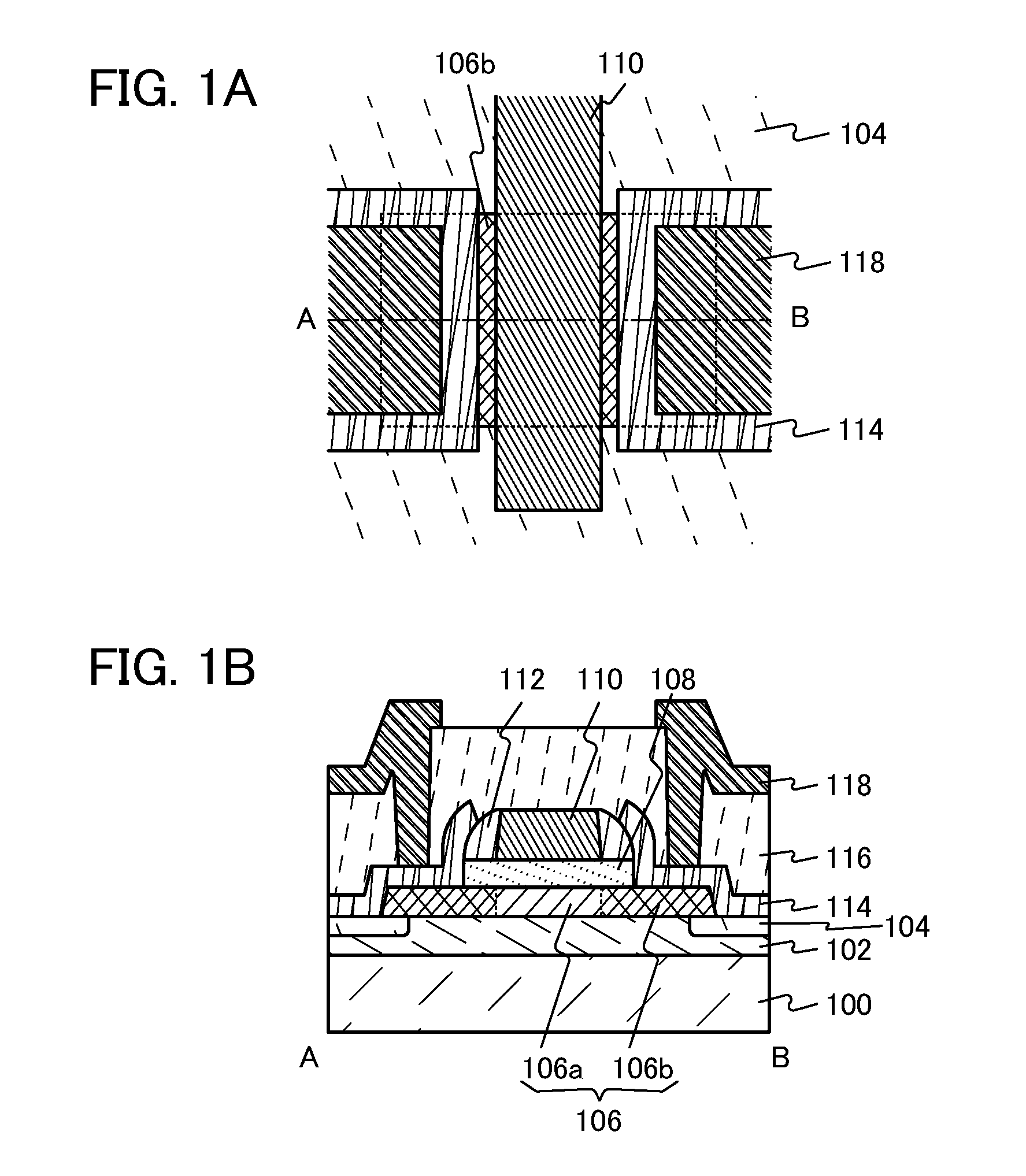

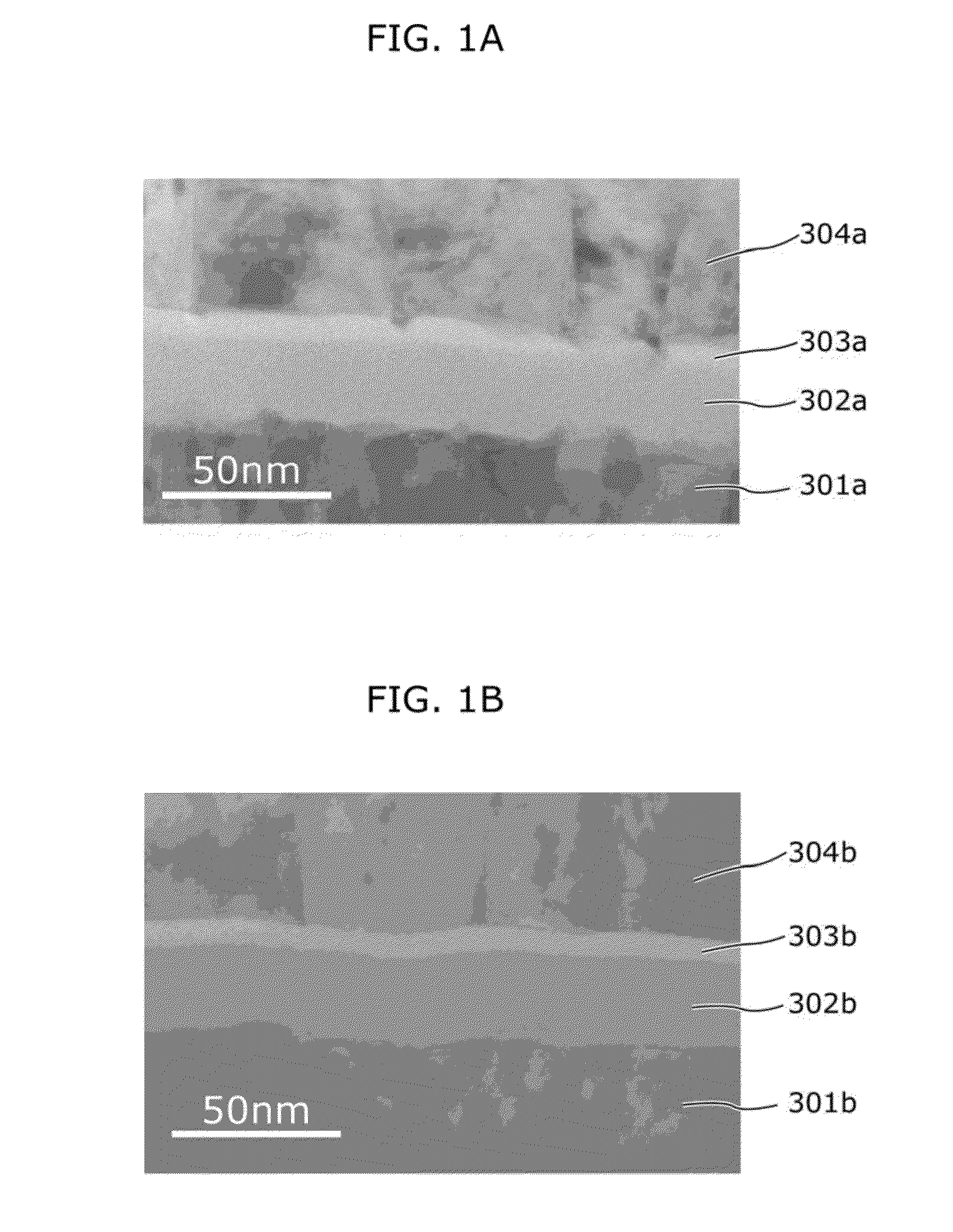

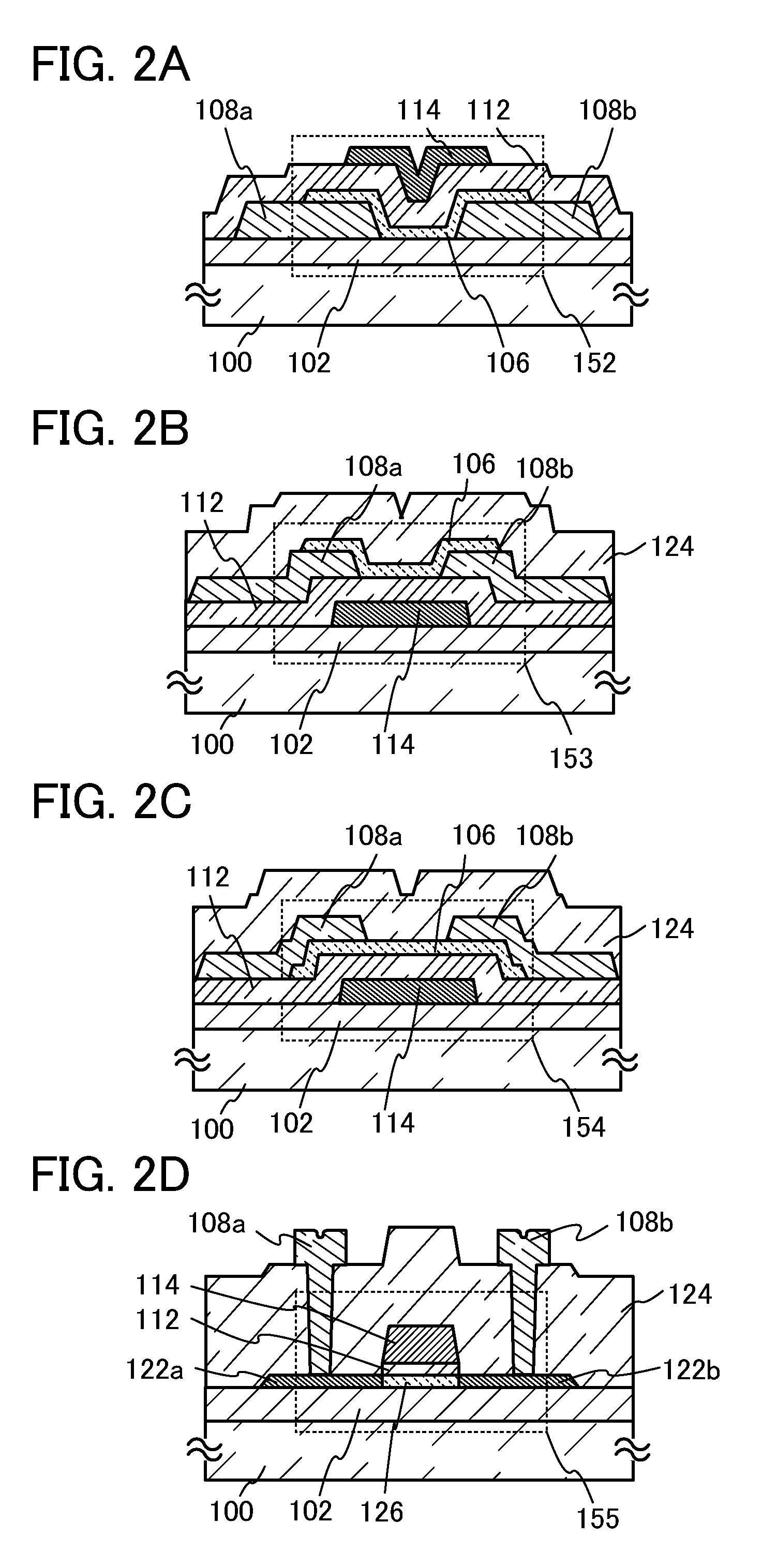

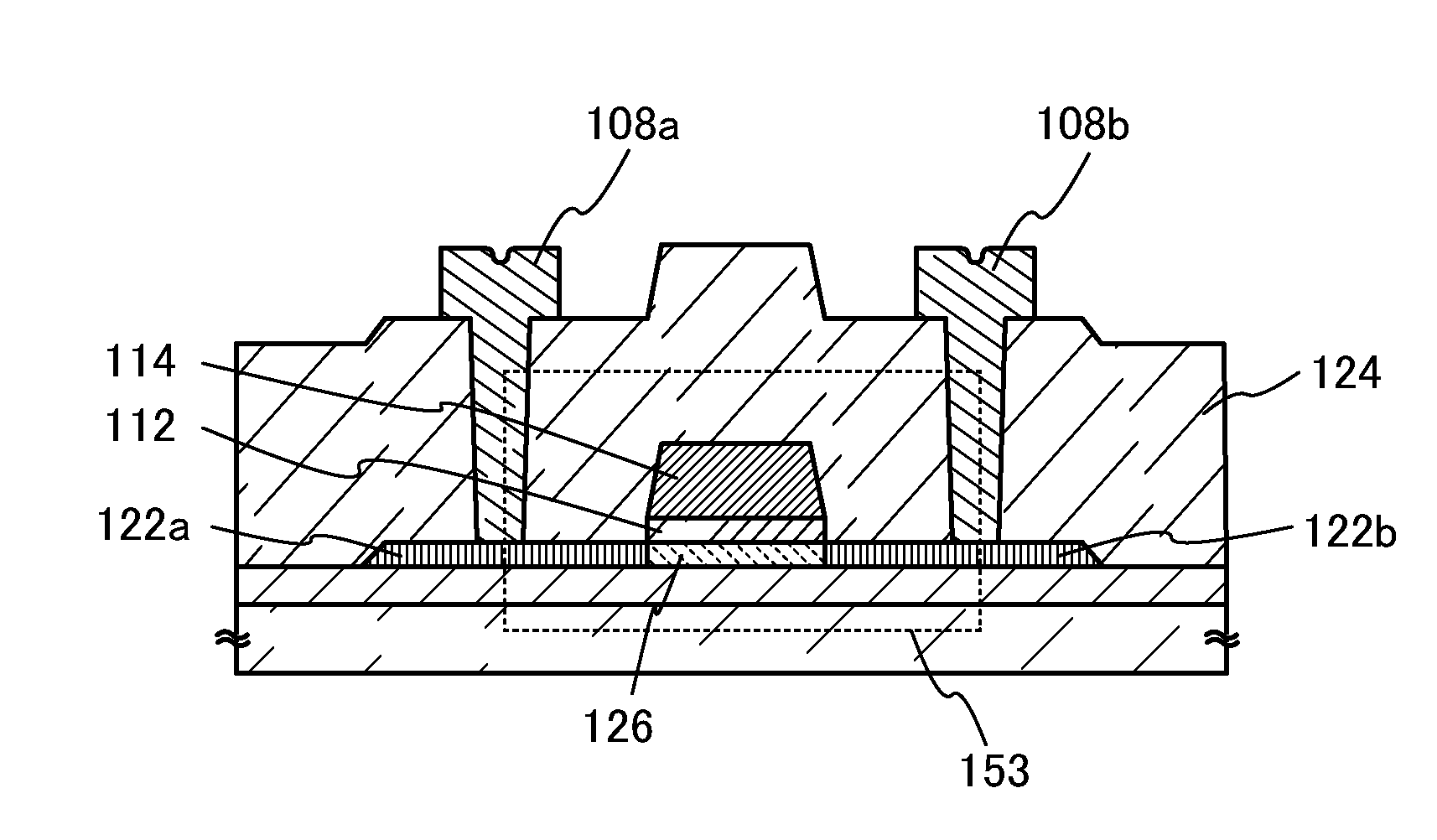

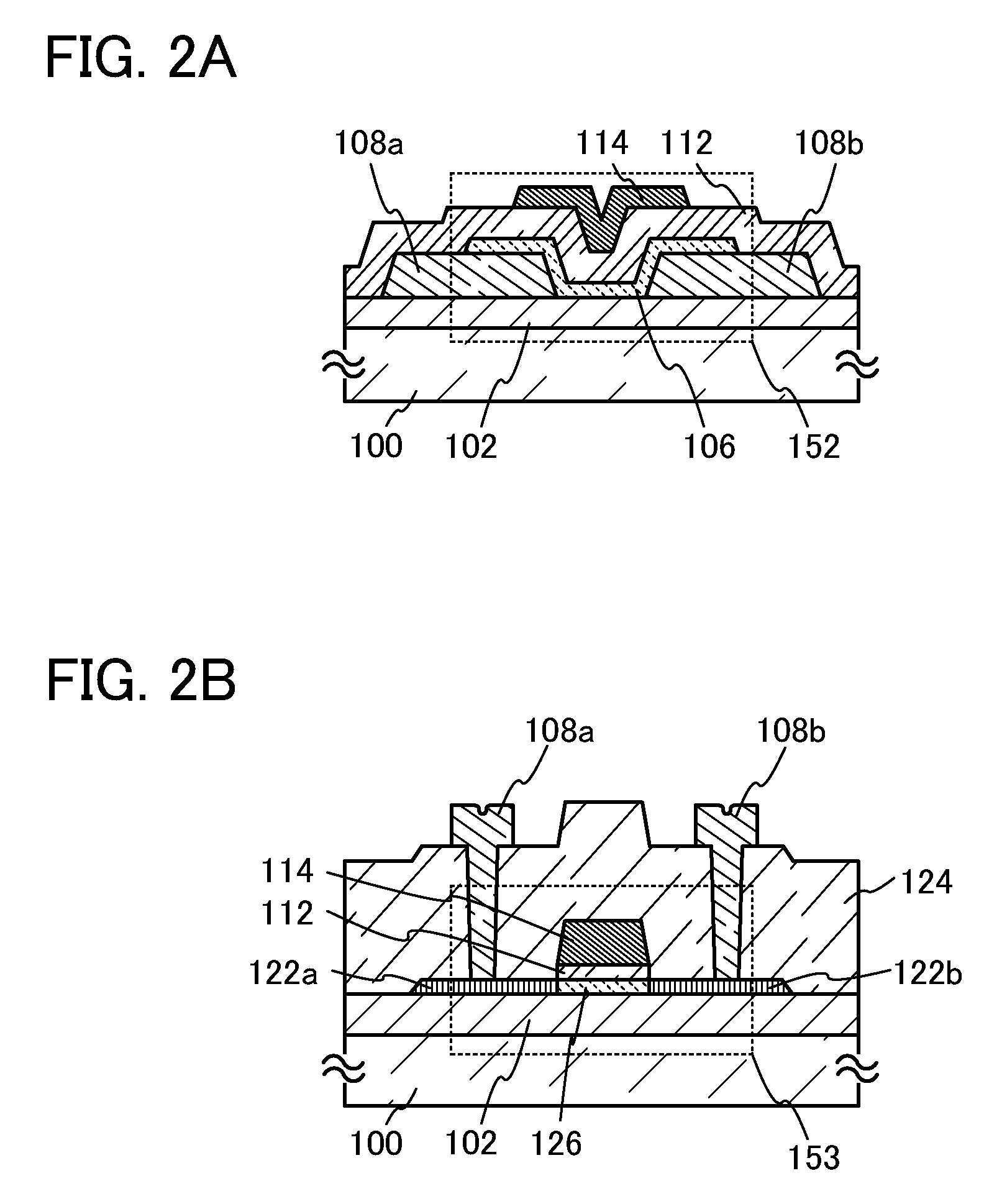

Semiconductor device and method for manufacturing the same

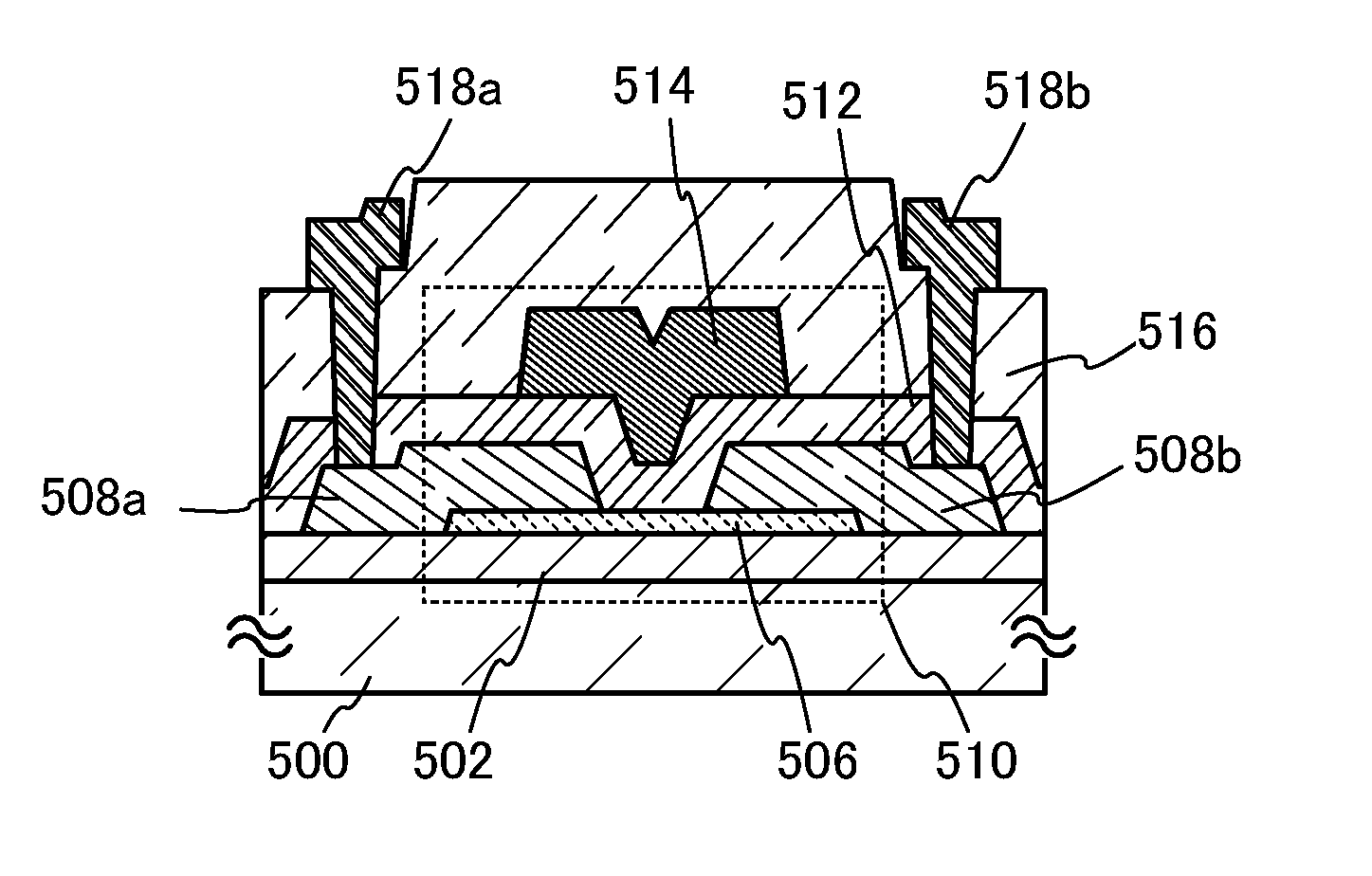

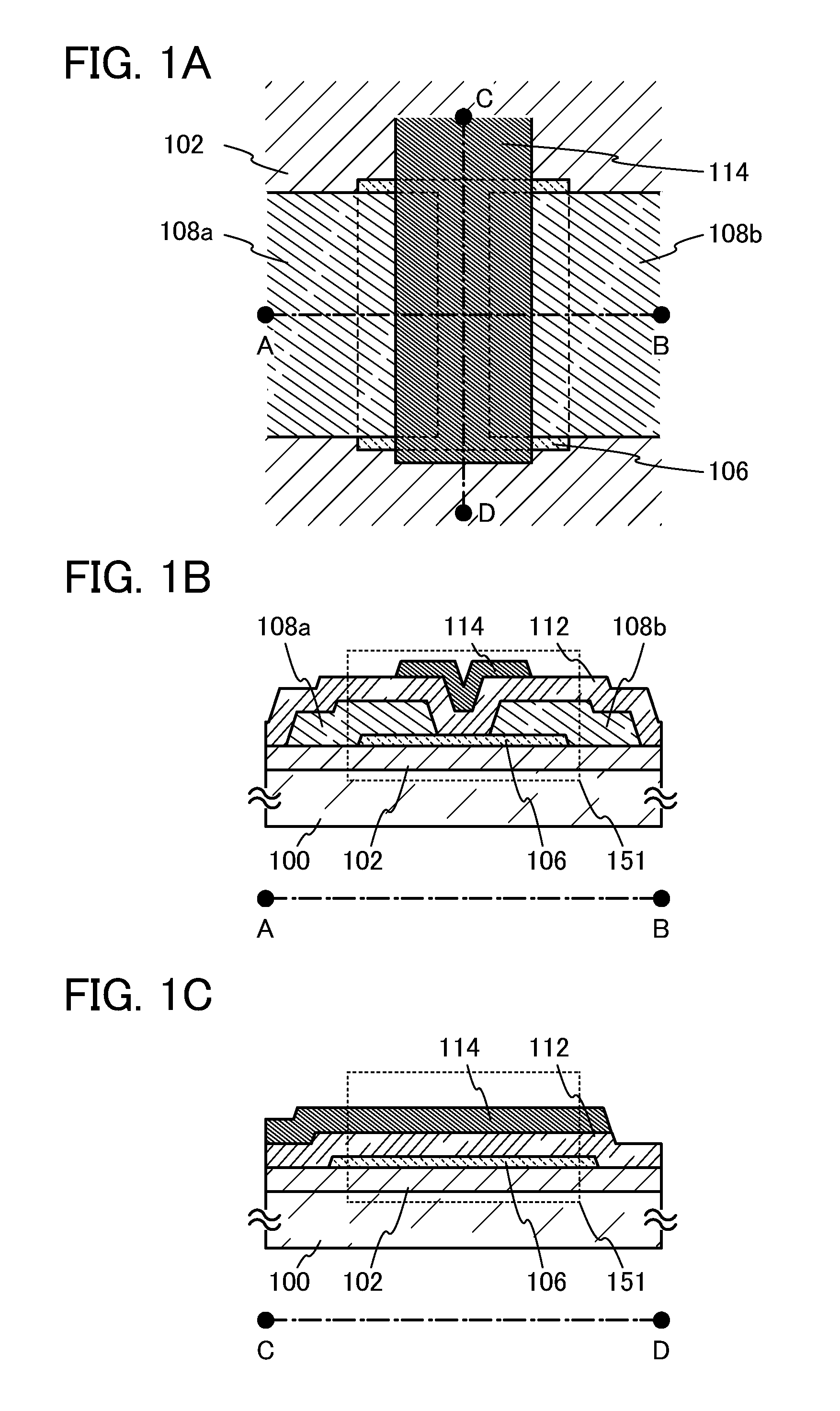

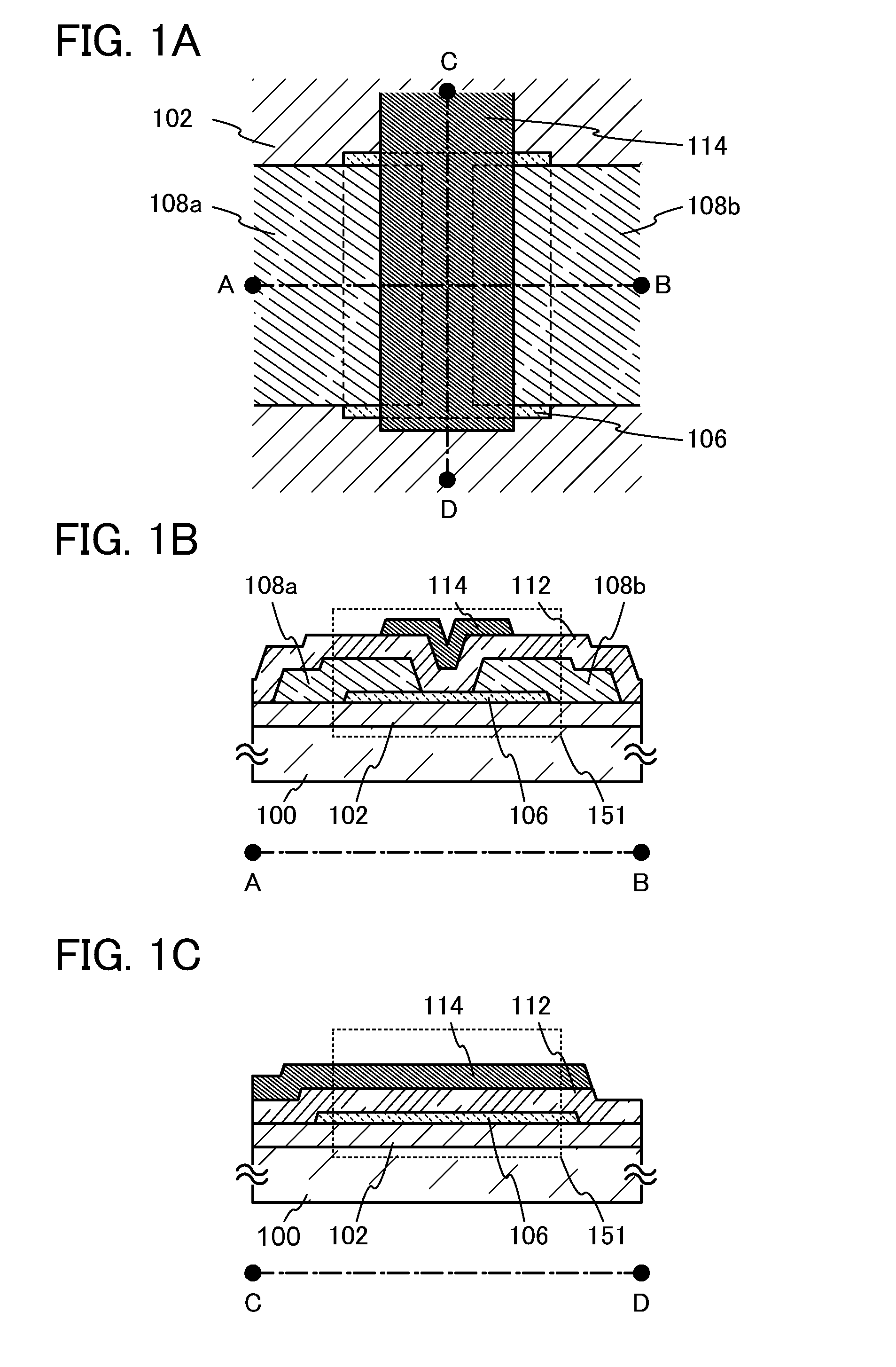

ActiveUS20120018727A1Stable electrical characteristicsLittle changeTransistorSemiconductor/solid-state device manufacturingElectrical resistance and conductanceState density

An insulating layer which releases a large amount of oxygen is used as an insulating layer in contact with a channel region of an oxide semiconductor layer, and an insulating layer which releases a small amount of oxygen is used as an insulating layer in contact with a source region and a drain region of the oxide semiconductor layer. By releasing oxygen from the insulating layer which releases a large amount of oxygen, oxygen deficiency in the channel region and an interface state density between the insulating layer and the channel region can be reduced, so that a highly reliable semiconductor device having small variation in electrical characteristics can be manufactured. The source region and the drain region are provided in contact with the insulating layer which releases a small amount of oxygen, thereby suppressing the increase of the resistance of the source region and the drain region.

Owner:SEMICON ENERGY LAB CO LTD

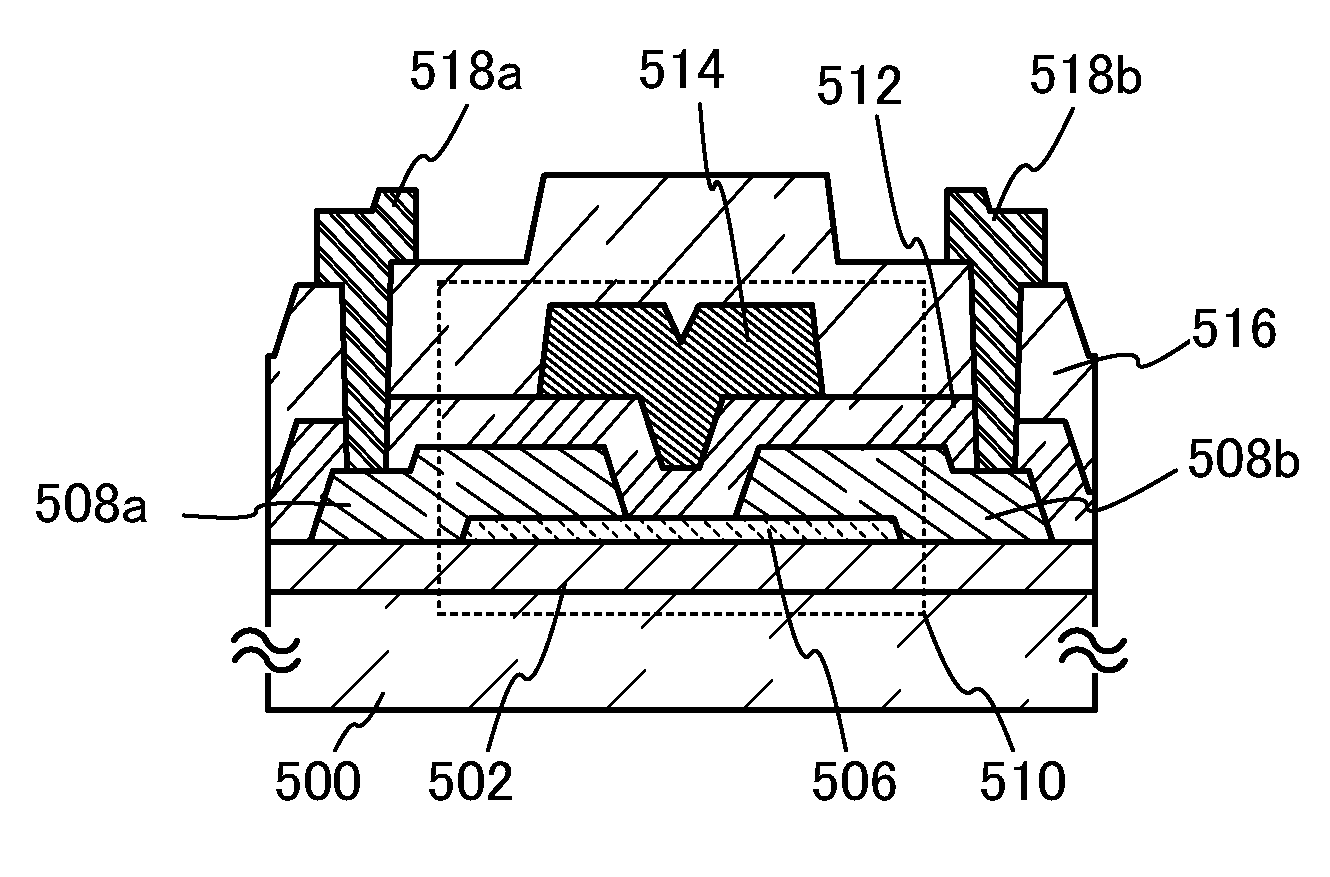

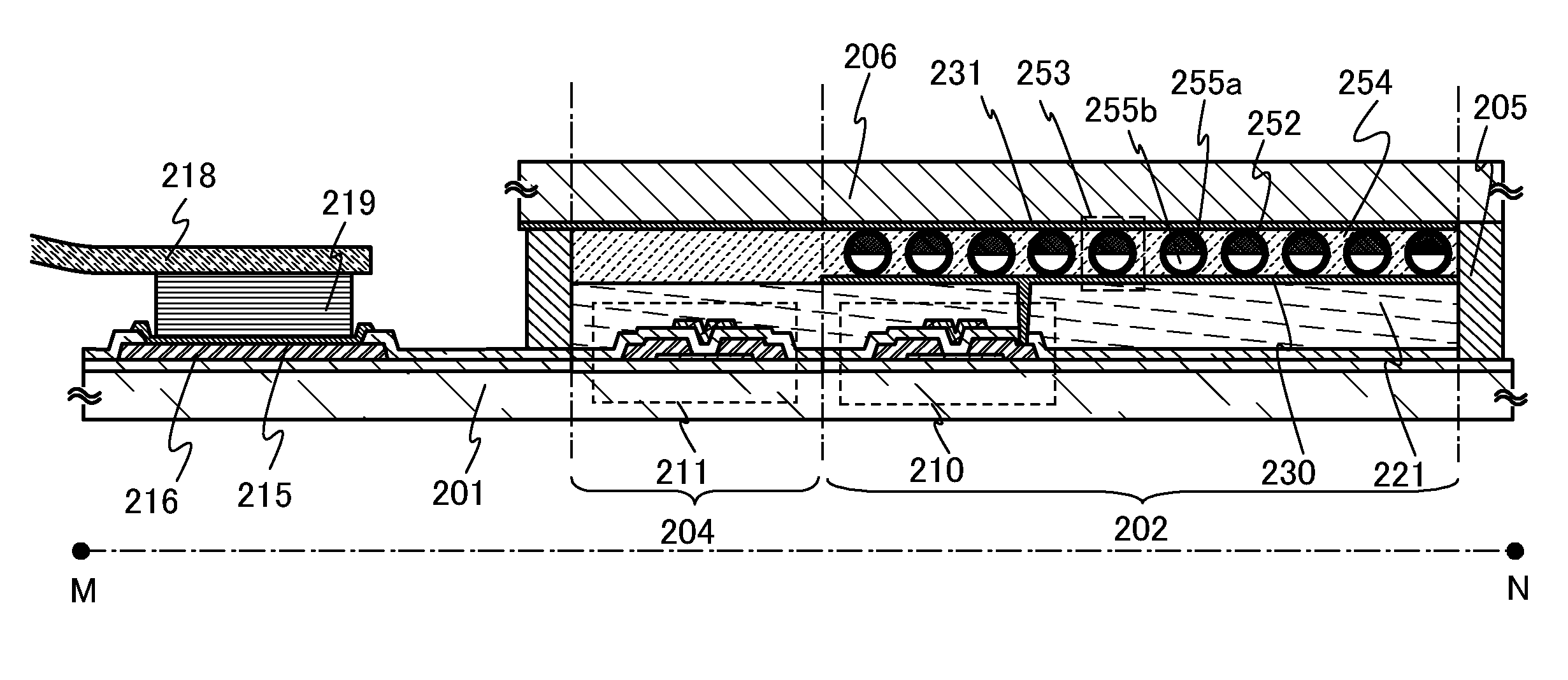

Semiconductor device and method for manufacturing the same

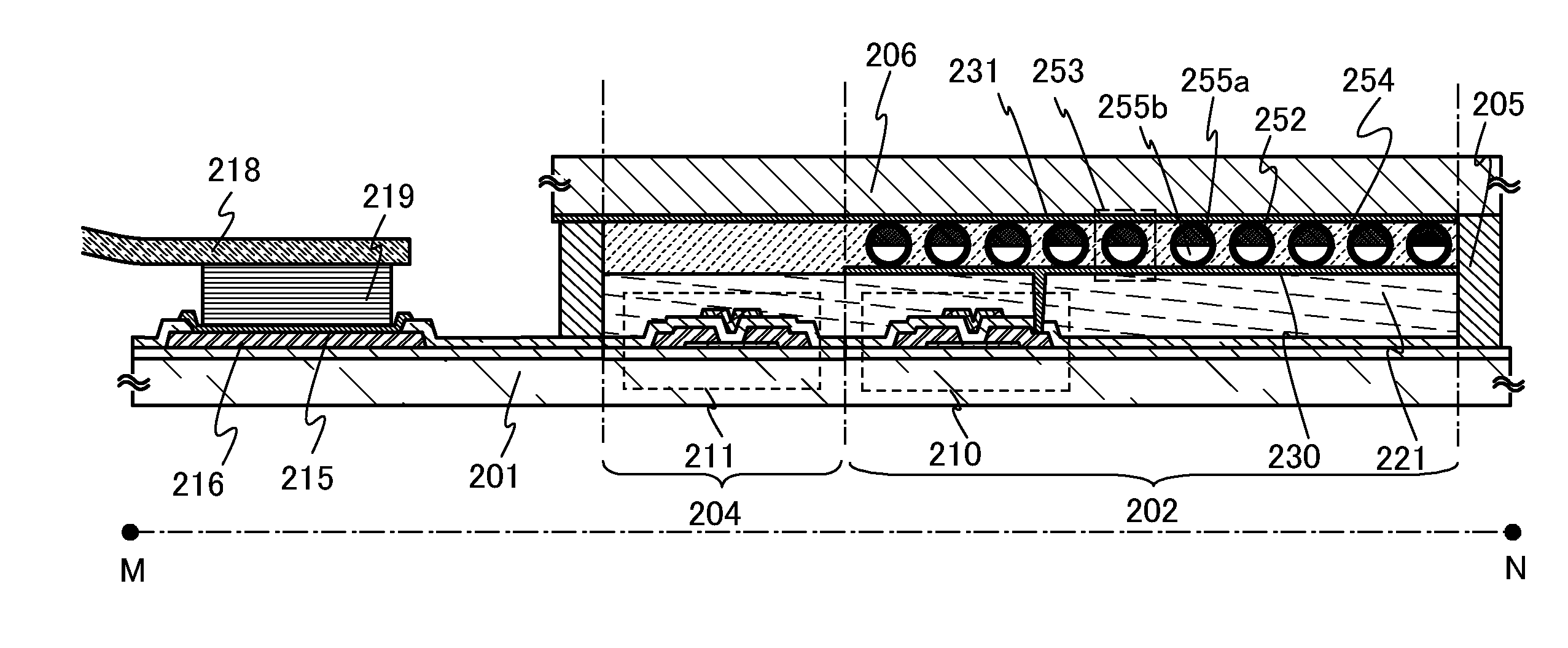

InactiveUS20110303913A1Stable electrical characteristicsElectrical instabilityTransistorSemiconductor/solid-state device testing/measurementElectricityBottom gate

An object of an embodiment of the present invention is to manufacture a highly-reliable semiconductor device comprising a transistor including an oxide semiconductor, in which change of electrical characteristics is small. In the transistor including an oxide semiconductor, oxygen-excess silicon oxide (SiOX (X>2)) is used for a base insulating layer of a top-gate structure or for a protective insulating layer of a bottom-gate structure. By using the oxygen-excess silicon oxide, oxygen is discharged from the insulating layer, and oxygen deficiency of an oxide semiconductor layer and the interface state density between the oxide semiconductor layer and the base insulating layer or the protective insulating layer can be reduced, so that the highly-reliable semiconductor device in which change of electrical characteristics is small can be manufactured.

Owner:SEMICON ENERGY LAB CO LTD

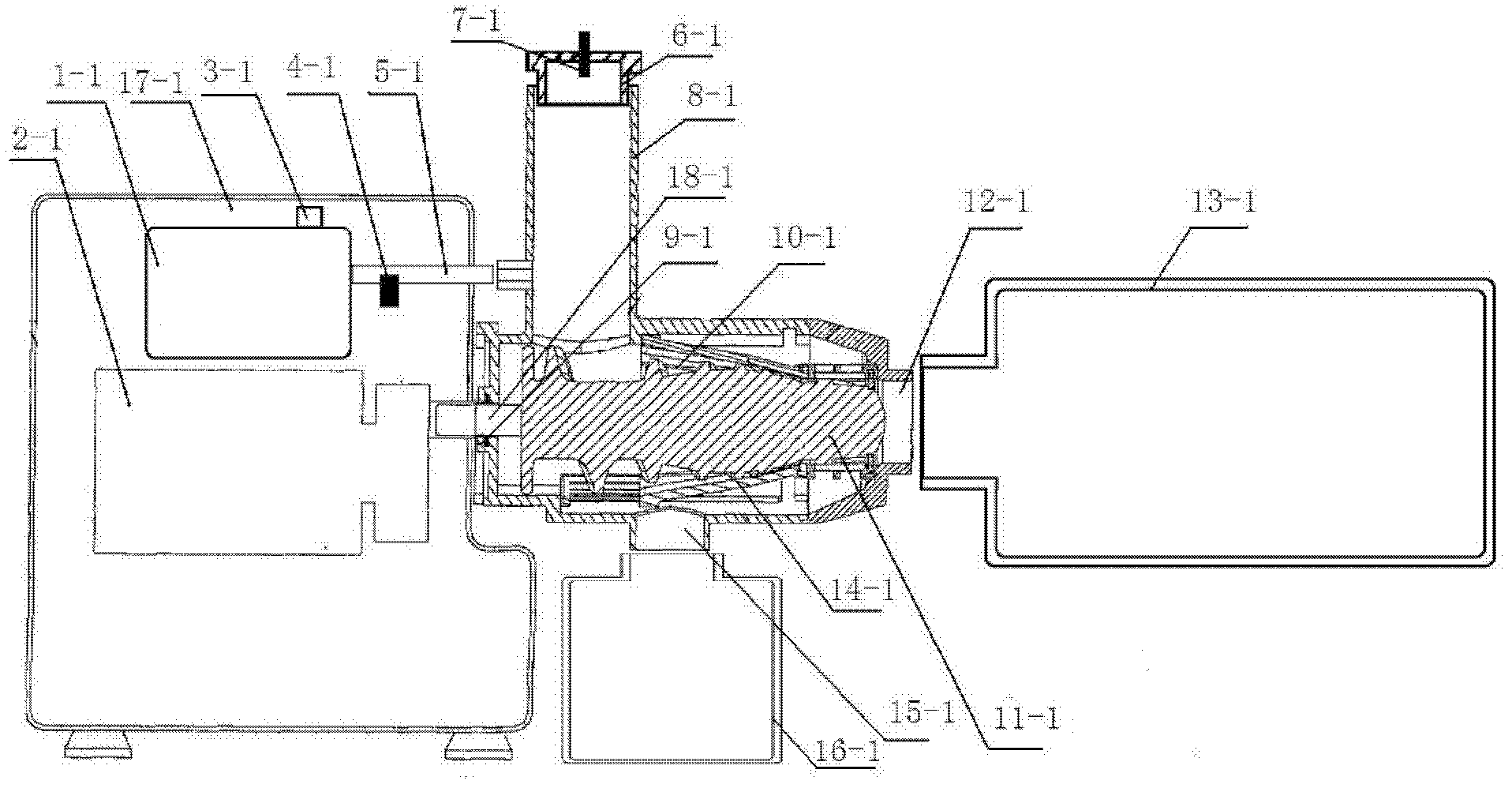

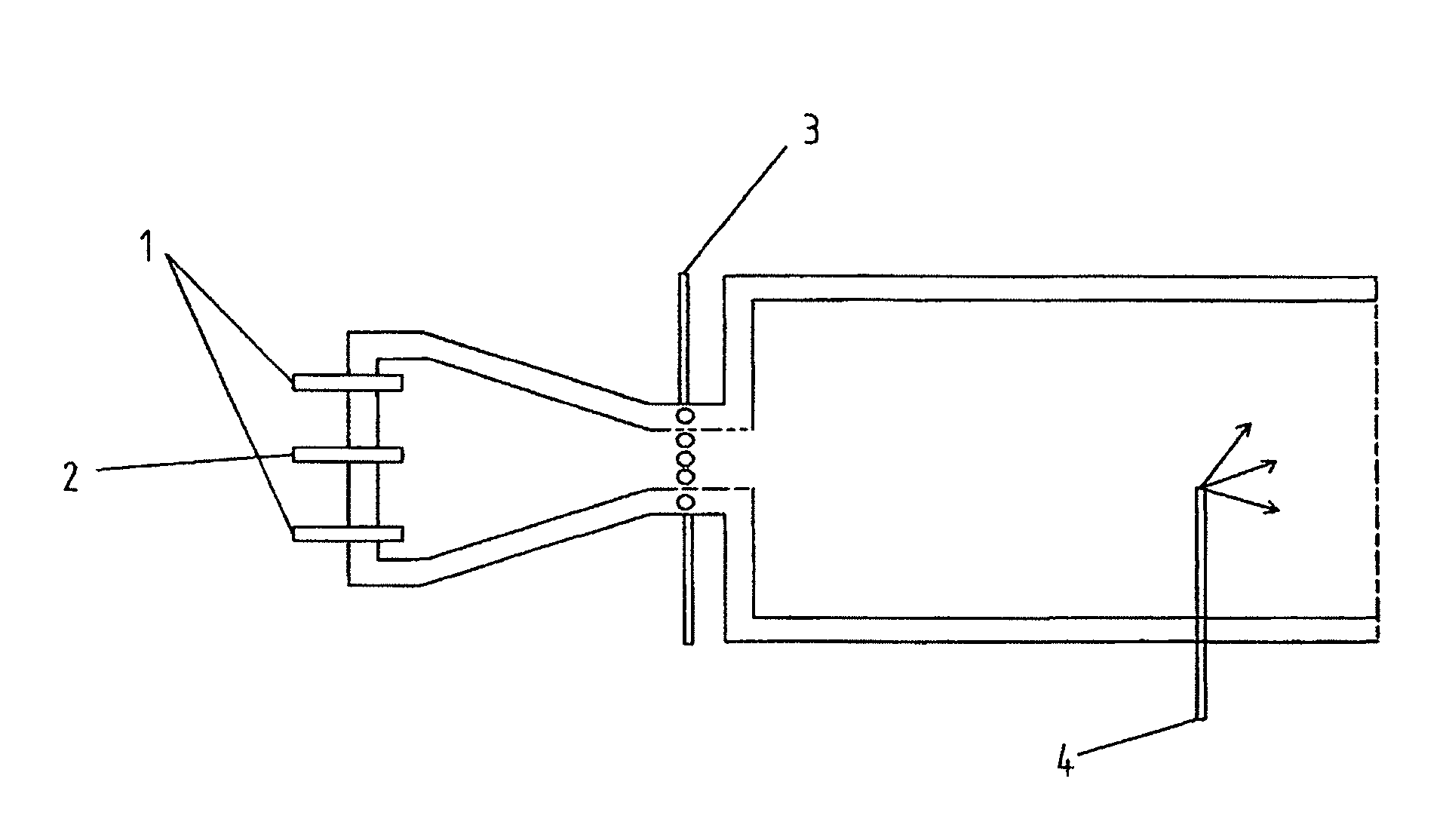

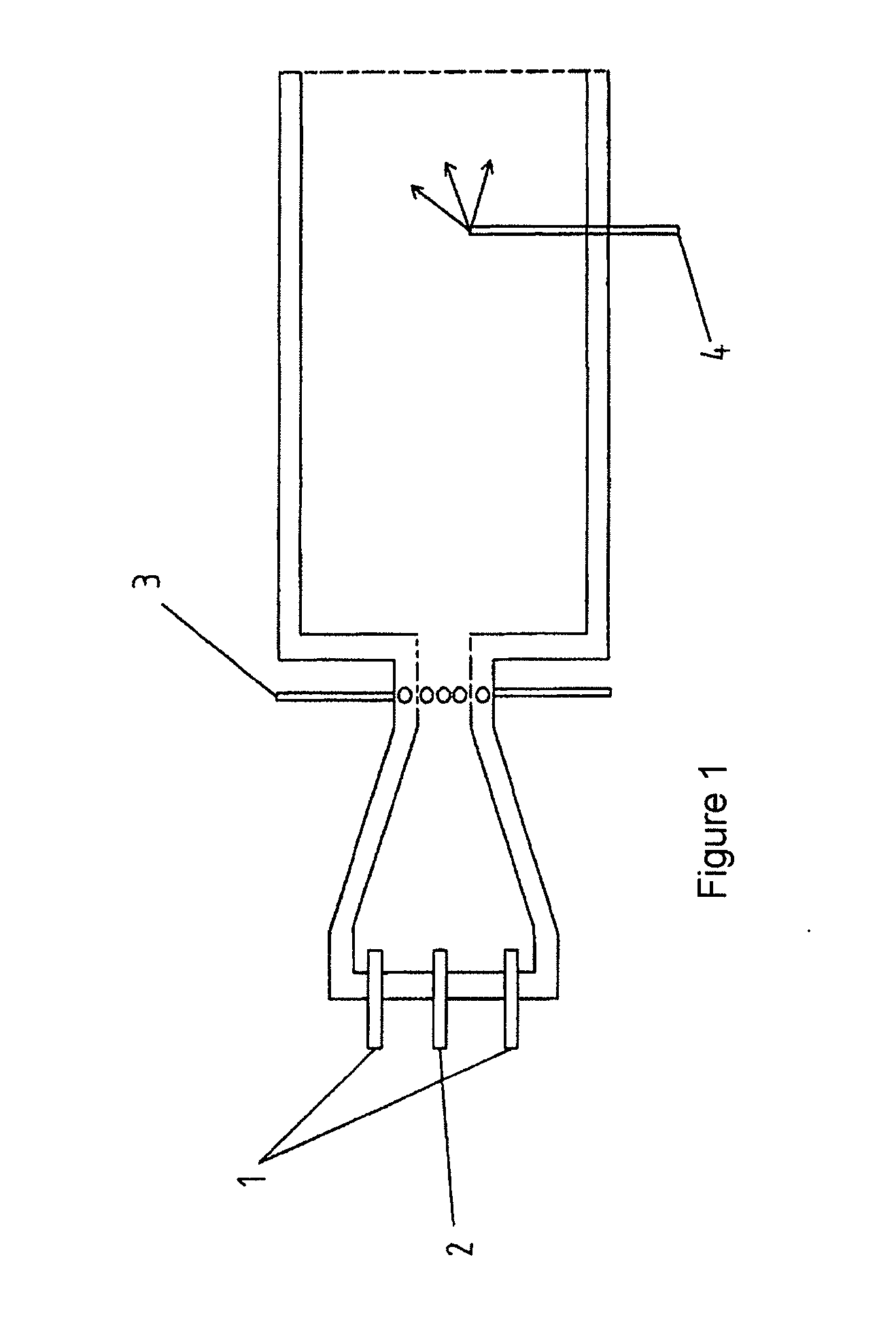

Juicer with air bleeding function

The invention discloses a juicer with the air bleeding function and aims at providing the juicer which can greatly reduce the oxygen content in a juicing cavity, prevents the browning from occurring in the juicing process and maintains the nutritional components and mouth feel of fruit juice or vegetable juice. The juicer is characterized in that a charging barrel is arranged on the juicing cavity; a juicing mechanism is arranged in the juicing cavity; an output shaft of a juicing motor is connected with a driving shaft of the juicing mechanism; the juicer also comprises an air bleeding device; a sealing device is arranged on the charging barrel; an interconnected cavity is formed by the charging cavity, the juicing cavity, a juice receiving part and a residue part; the mutual connecting parts of the cavity body are connected in a sealing manner; the connecting part between the cavity and any one part is sealed; the cavity is airtight in the juicing process; an air bleeding port of the air bleeding device is communicated with the cavity; and an exhaust port of the air bleeding device is arranged outside the cavity. The juicer can juice foodstuff in the juicer under an oxygen deficiency condition, thereby the browning is effectively controlled, the browning of foodstuff liquid is greatly reduced in the juicing process, the nutritive loss is reduced, and the good mouth feel and appearance color are maintained.

Owner:王晓东

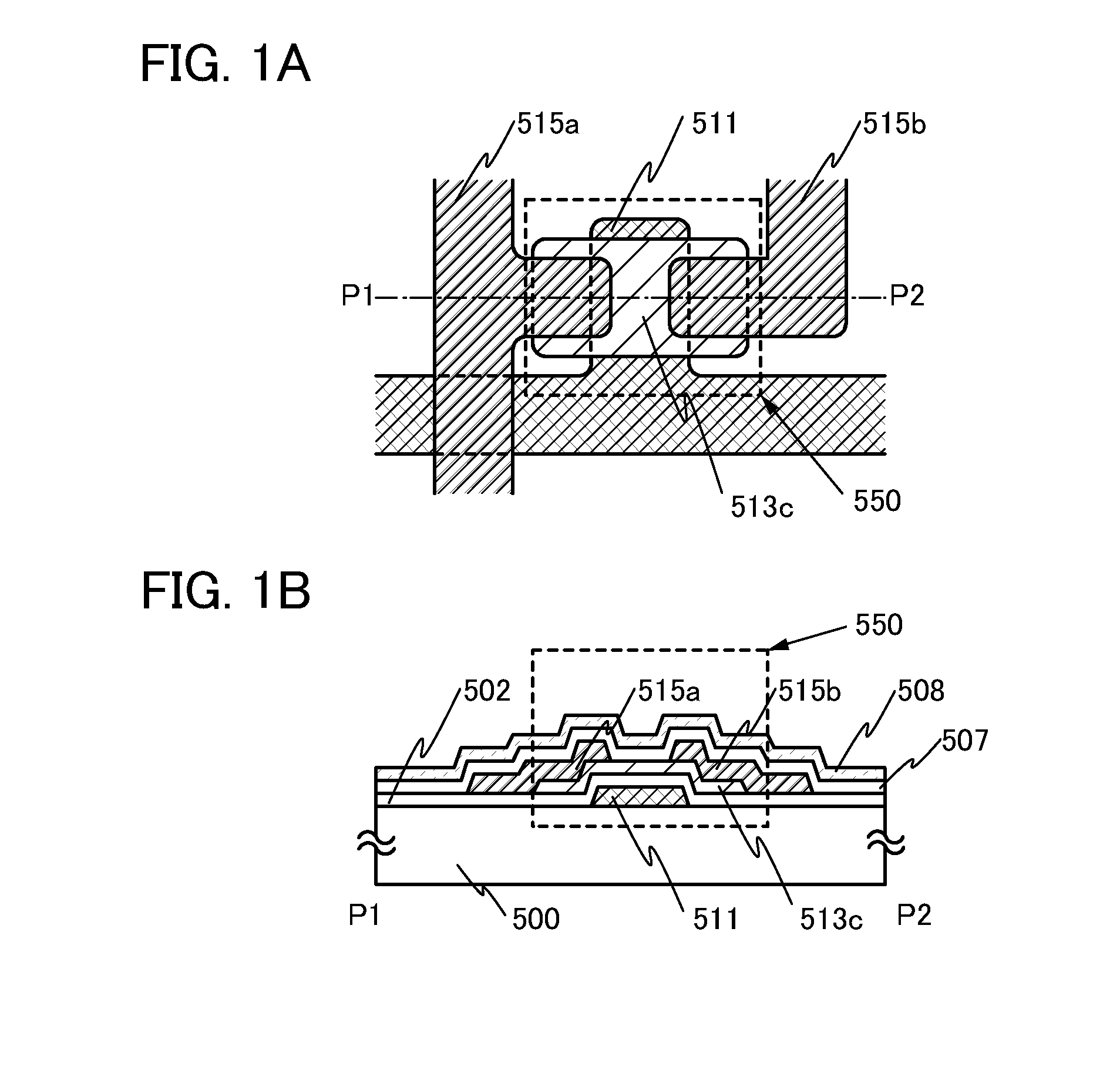

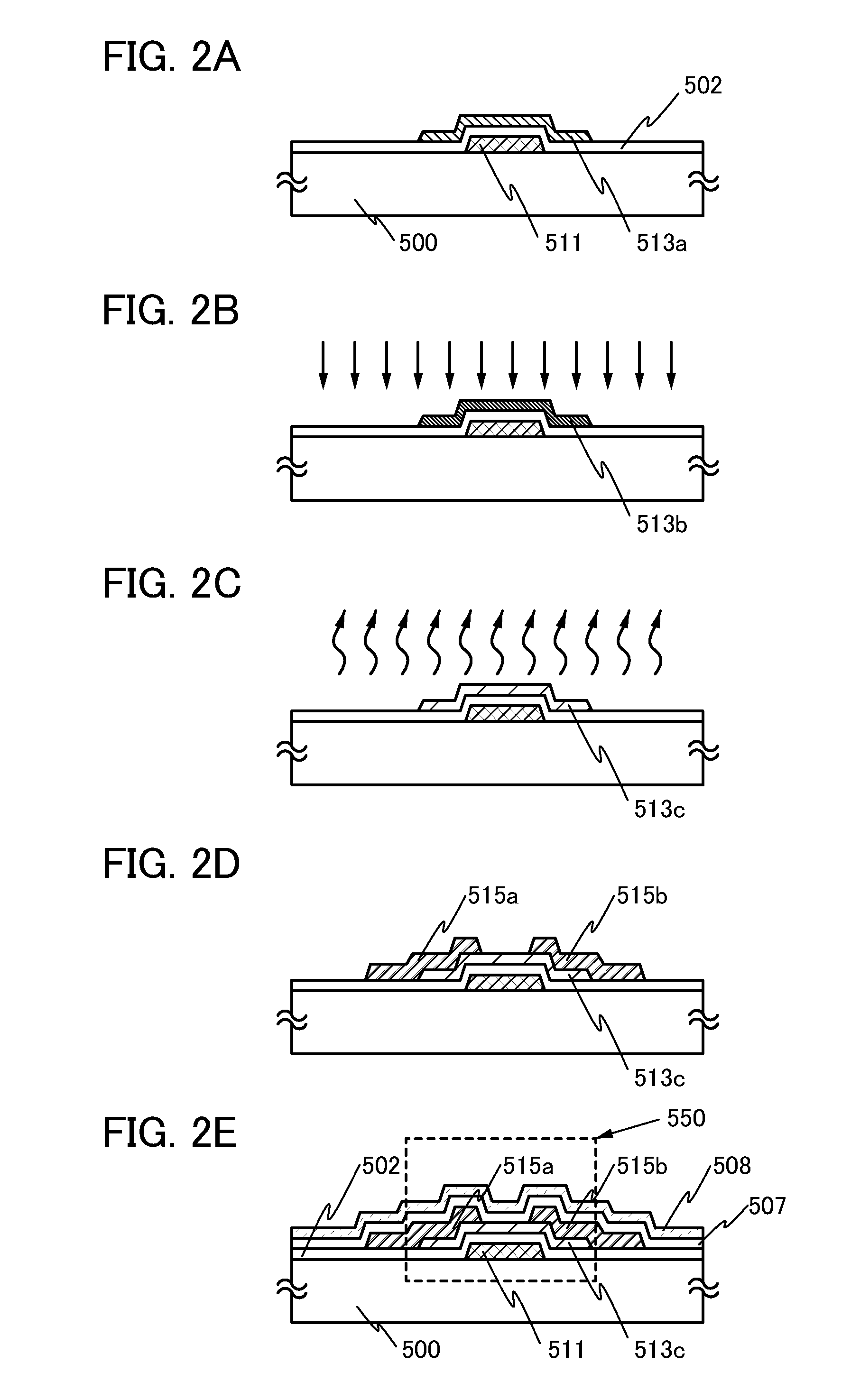

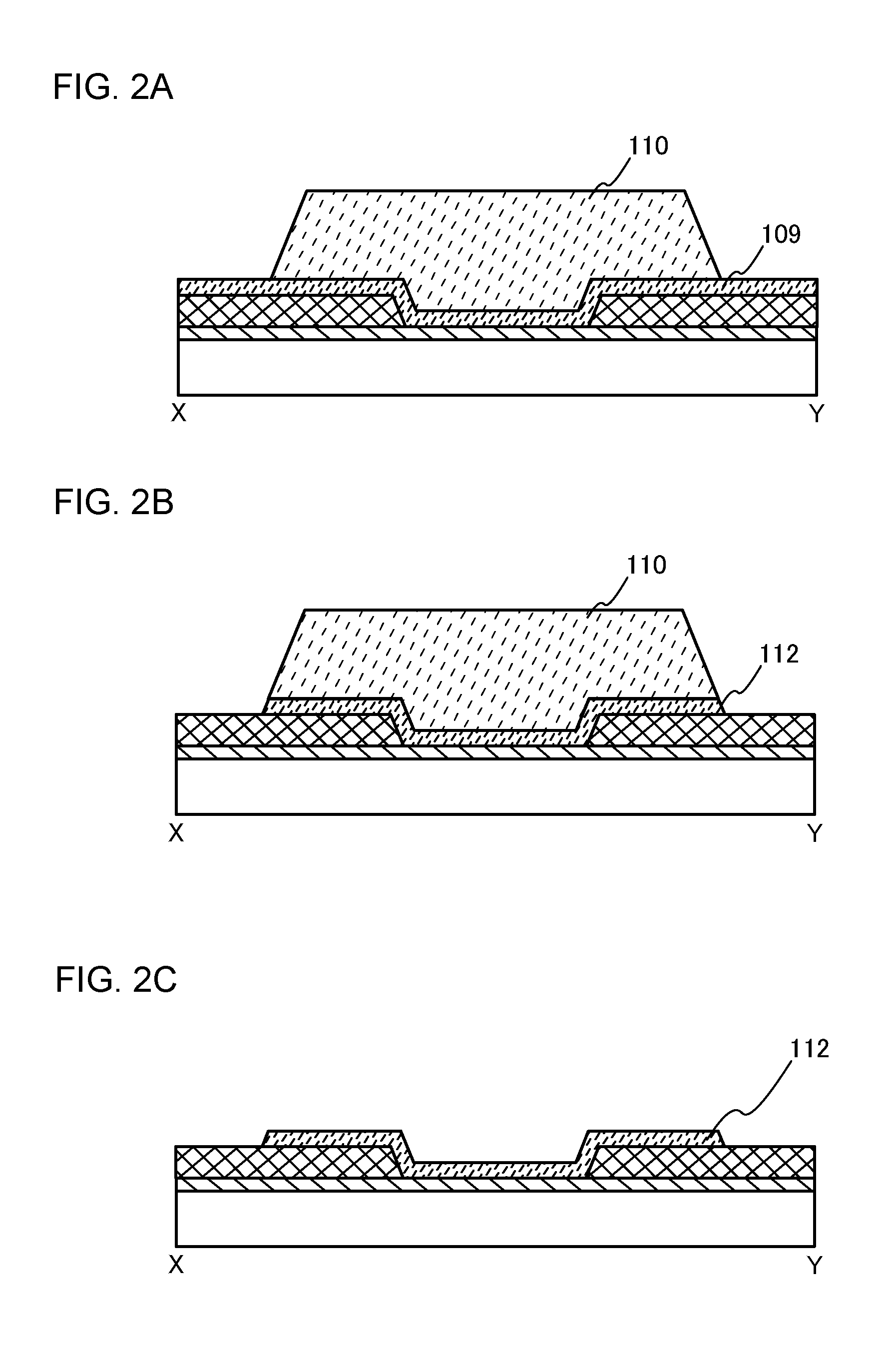

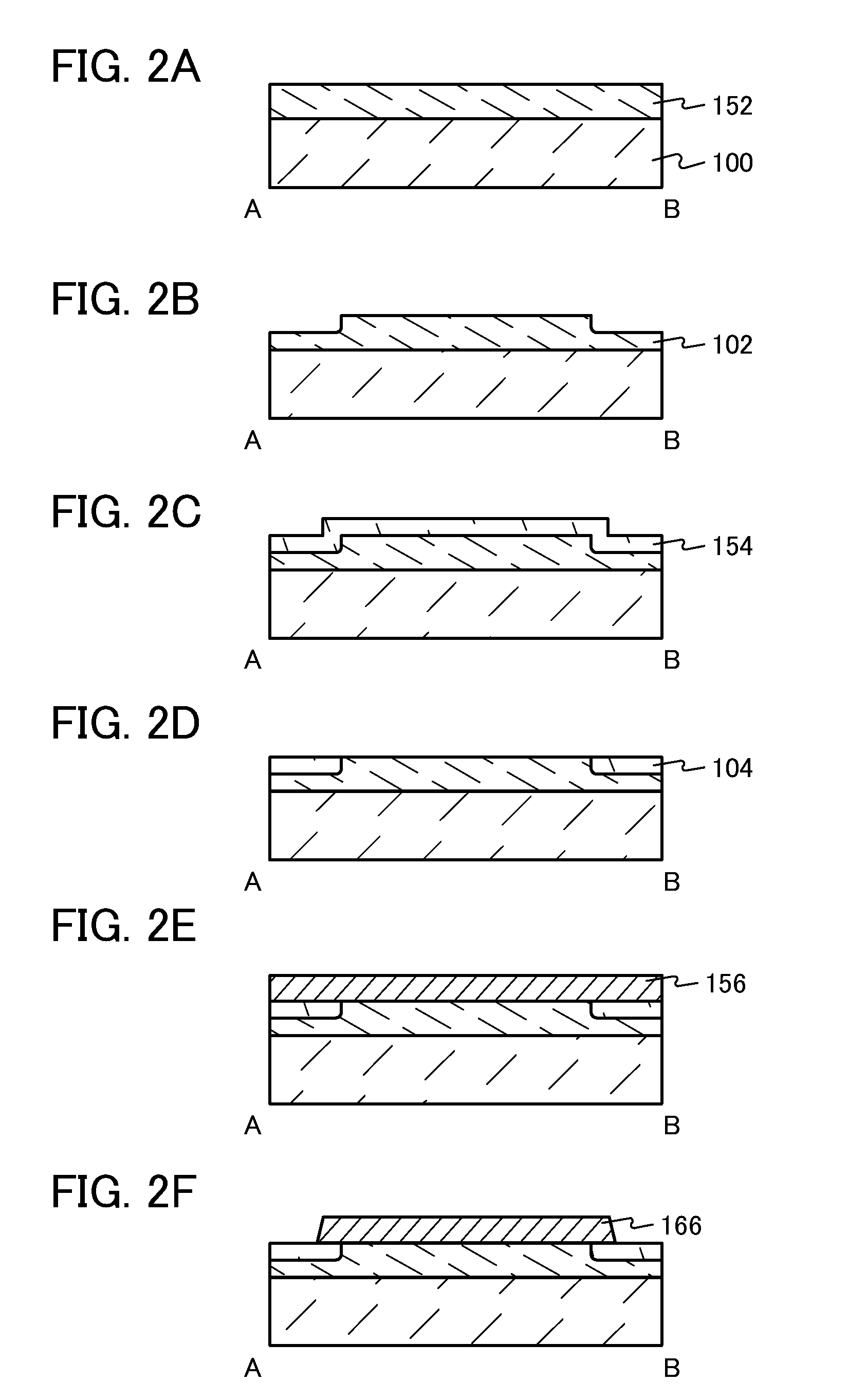

Method for manufacturing semiconductor device

ActiveUS20110212570A1Low reliabilityIncreased power consumptionSolid-state devicesSemiconductor/solid-state device manufacturingHigh energyOxygen deficiency

It is an object to provide a highly reliable semiconductor device, a semiconductor device with low power consumption, a semiconductor device with high productivity, and a method for manufacturing such a semiconductor device. Impurities left remaining in an oxide semiconductor layer are removed without generating oxygen deficiency, and the oxide semiconductor layer is purified to have an extremely high purity. Specifically, after oxygen is added to the oxide semiconductor layer, heat treatment is performed on the oxide semiconductor layer to remove the impurities. In order to add oxygen, it is preferable to use a method in which oxygen having high energy is added by an ion implantation method, an ion doping method, or the like.

Owner:SEMICON ENERGY LAB CO LTD

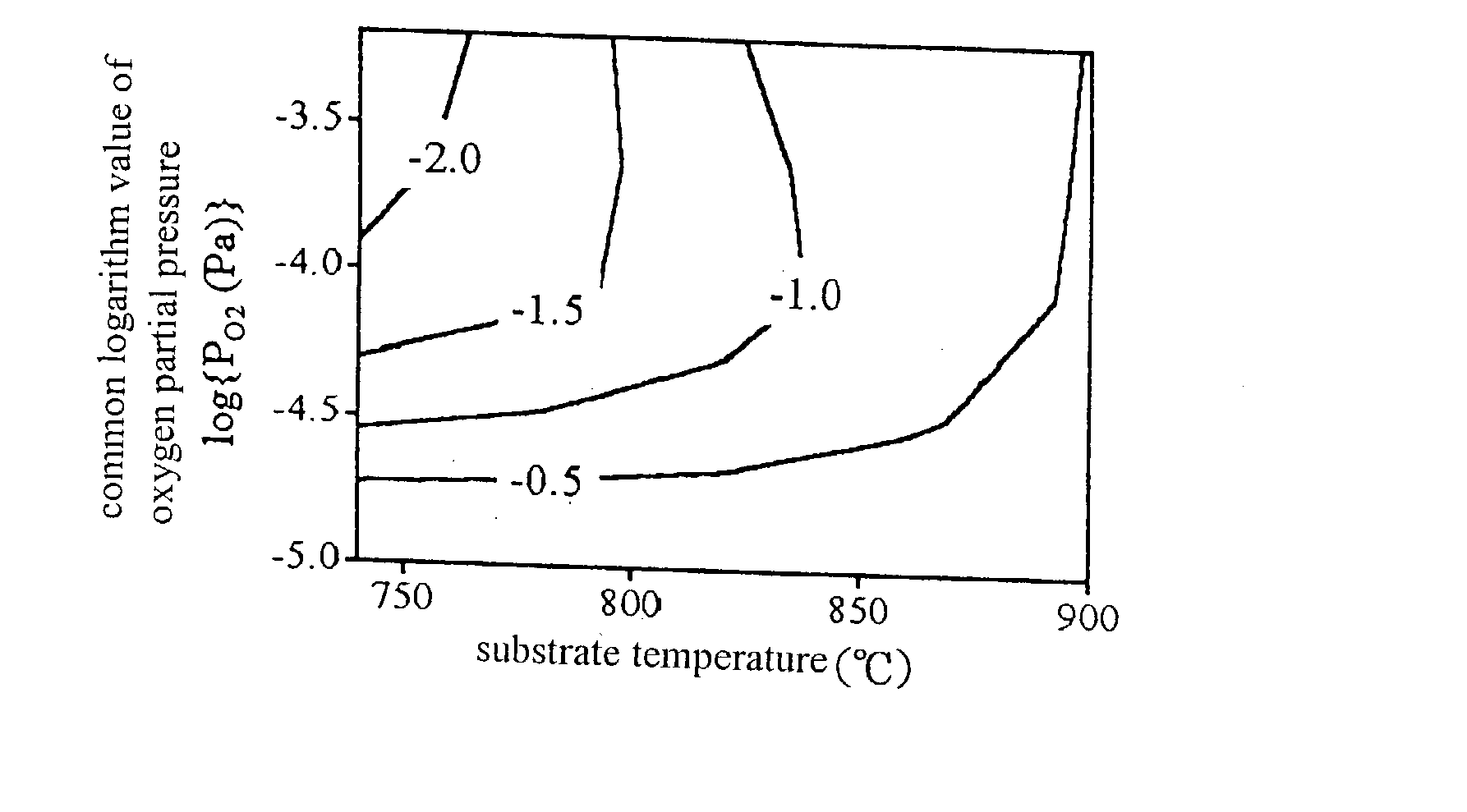

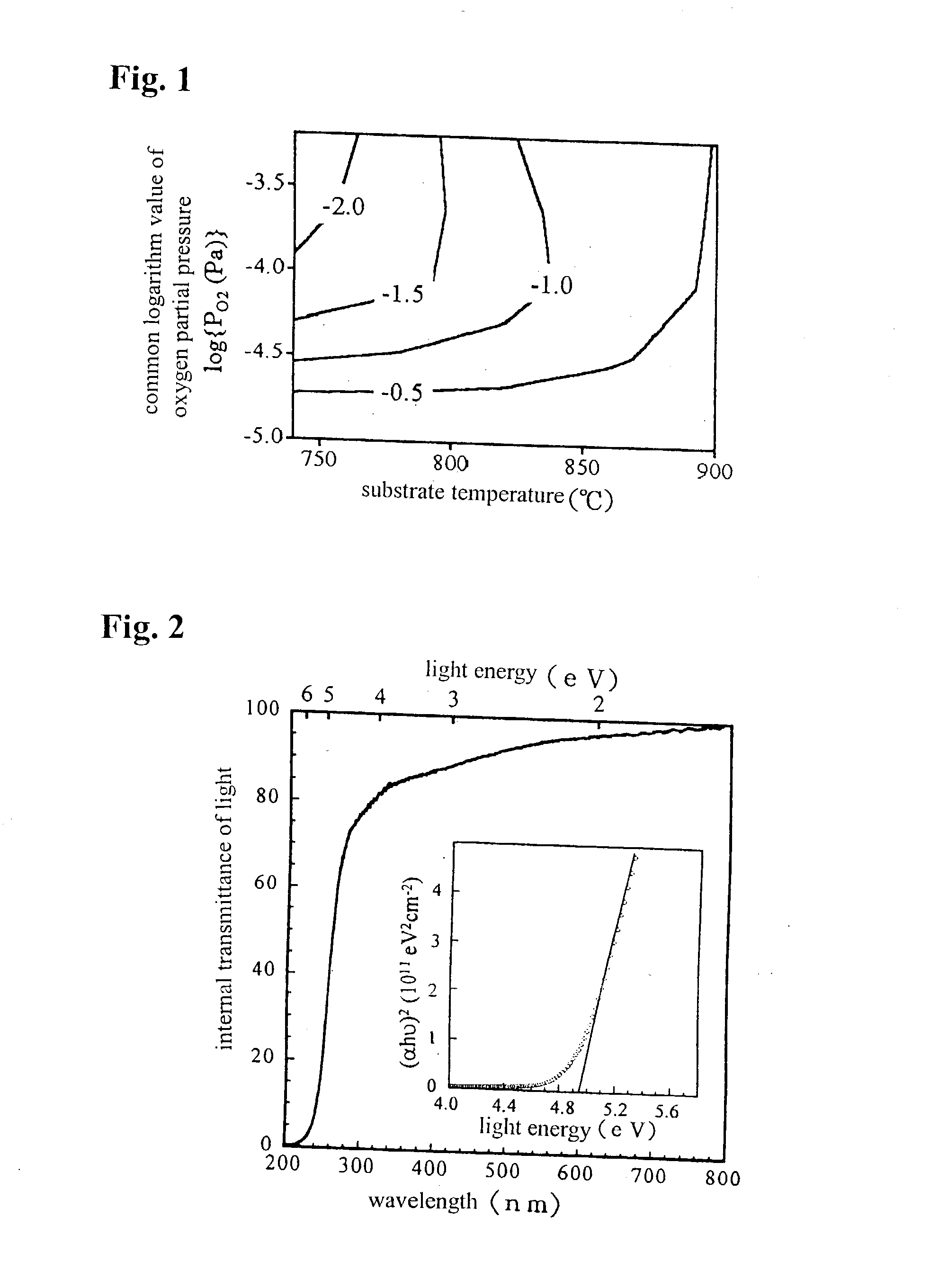

Ultraviolet-transparent conductive film and process for producing the same

The present invention provides an ultraviolet-transparent conductive film comprising a Ga2O3 crystal. The film has a transparency in the wavelength range of 240 to 800 nm, or 240 to 400 nm, and an electric conductivity induced by an oxygen deficiency or dopant in the Ga2O3 crystal. The dopant includes at least one element selected from the group consisting of the Sn, Ge, Si, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo and W. The ultraviolet-transparent conductive film is formed through either one of a pulsed-laser deposition method, sputtering method, CVD method and MBE method, under the conditions with a substrate temperature of 600 to 1500° C. and an oxygen partial pressure of 0 to 1 Pa.

Owner:HOYA CORP +1

Carbon black, method for the production thereof, and use thereof

ActiveUS20110236816A1Narrow aggregate size distributionHigh modulusPigmenting treatmentNatural cellulose pulp/paperOxygen deficiencyBuilding material

The invention relates to carbon black having a C-14 content greater than 0.05 Bq / g and a ratio ΔD50 / Dmode of the aggregate size distribution of less than 0.7. The carbon black is produced by thermal oxidative pyrolysis or thermal cleavage of the carbon black raw material in that the carbon black raw material contains renewable carbon black raw materials and an oxygen deficiency is present in the pyrolysis / cleavage reaction. The carbon blacks can be used in rubber and rubber mixtures, plastic, printing inks, inks, inkjet inks, toners, lacquers, paints, paper, adhesives, batteries, pastes, bitumens, concrete, and other building materials and as reducing agents in metallurgy.

Owner:EVONIK CARBON BLACK GMBH

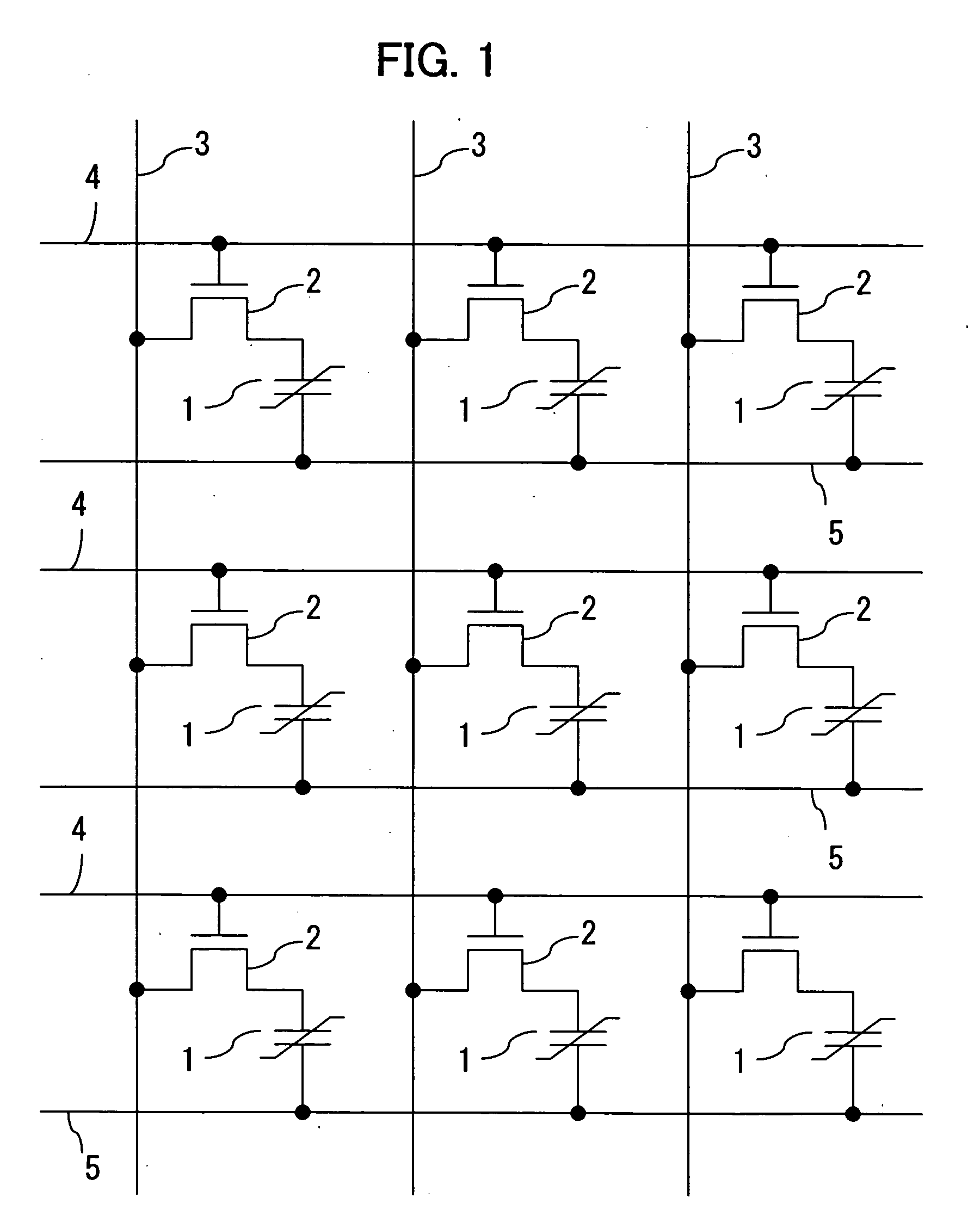

Semiconductor device

InactiveUS8796683B2Easy to operateEasy to manufactureSemiconductor devicesOxygen deficiencySemiconductor

Owner:SEMICON ENERGY LAB CO LTD

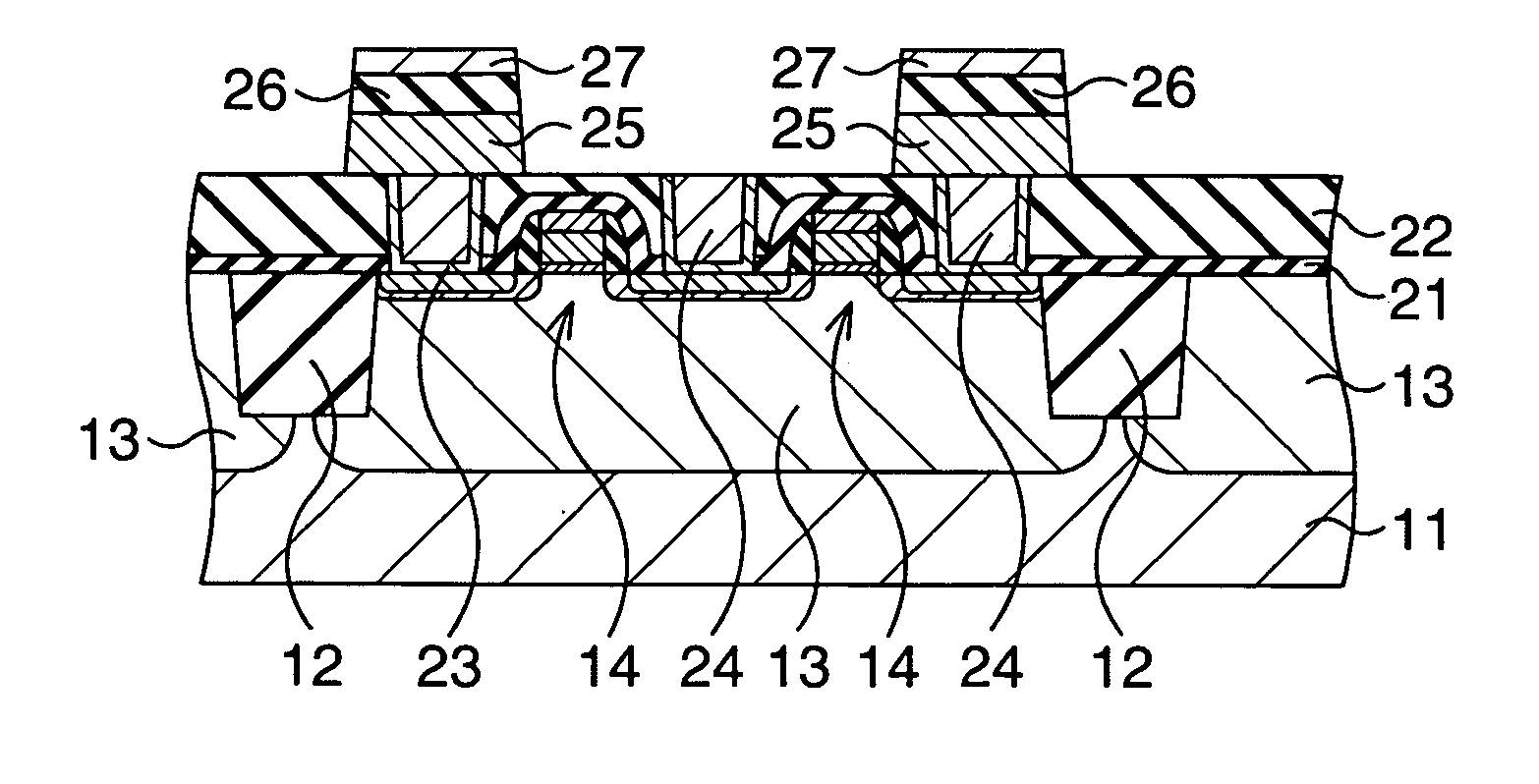

Semiconductor device and method of manufacturing the same

ActiveUS20110284846A1Less variationStable electrical characteristicsTransistorSolid-state devicesOxygen deficiencySemiconductor

Oxygen is released from the insulating layer, whereby oxygen deficiency in the oxide semiconductor layer and an interface state between the insulating layer and the oxide semiconductor layer can be reduced. Accordingly, a semiconductor device where reliability is high and variation in electric characteristics is small can be manufactured.

Owner:SEMICON ENERGY LAB CO LTD

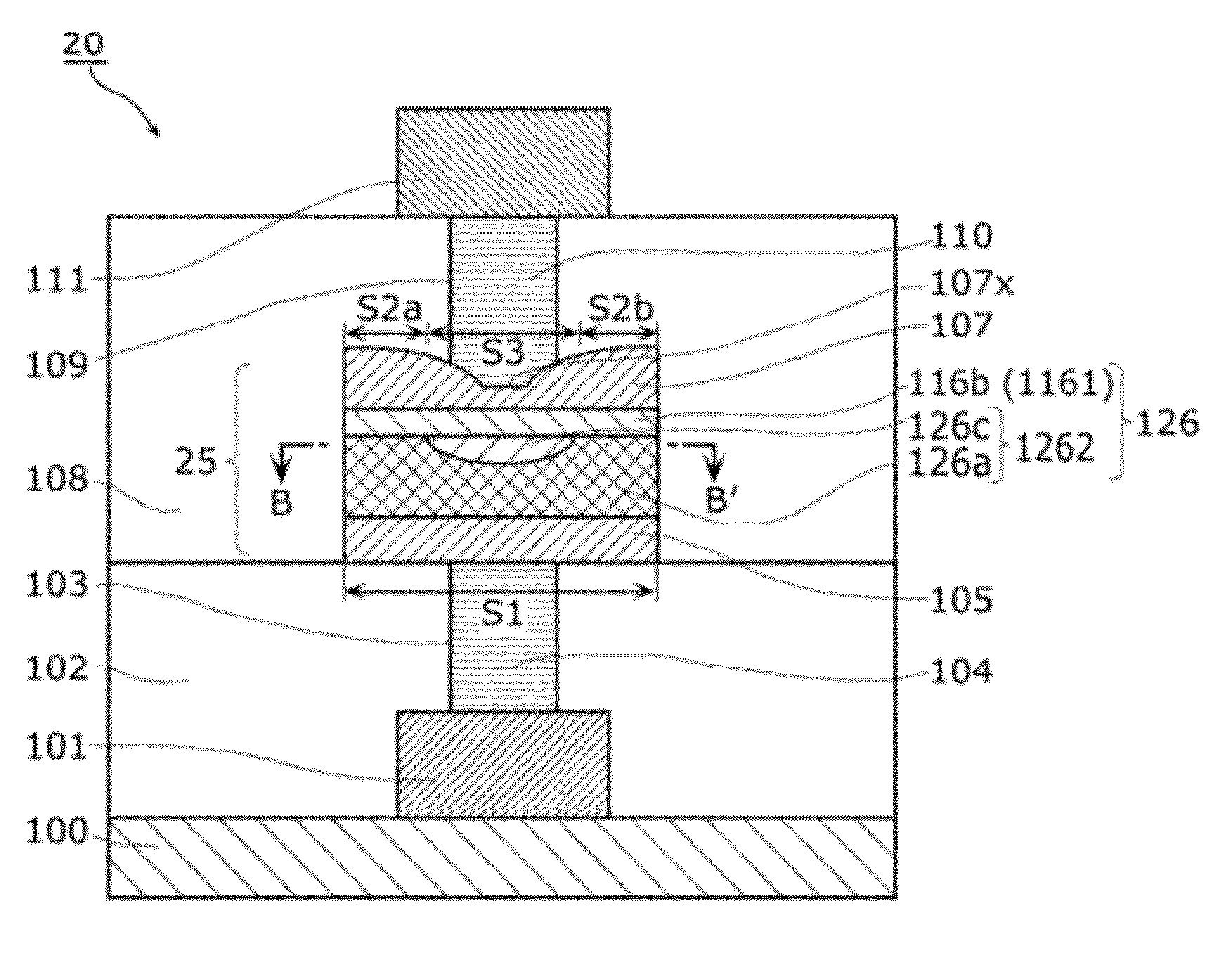

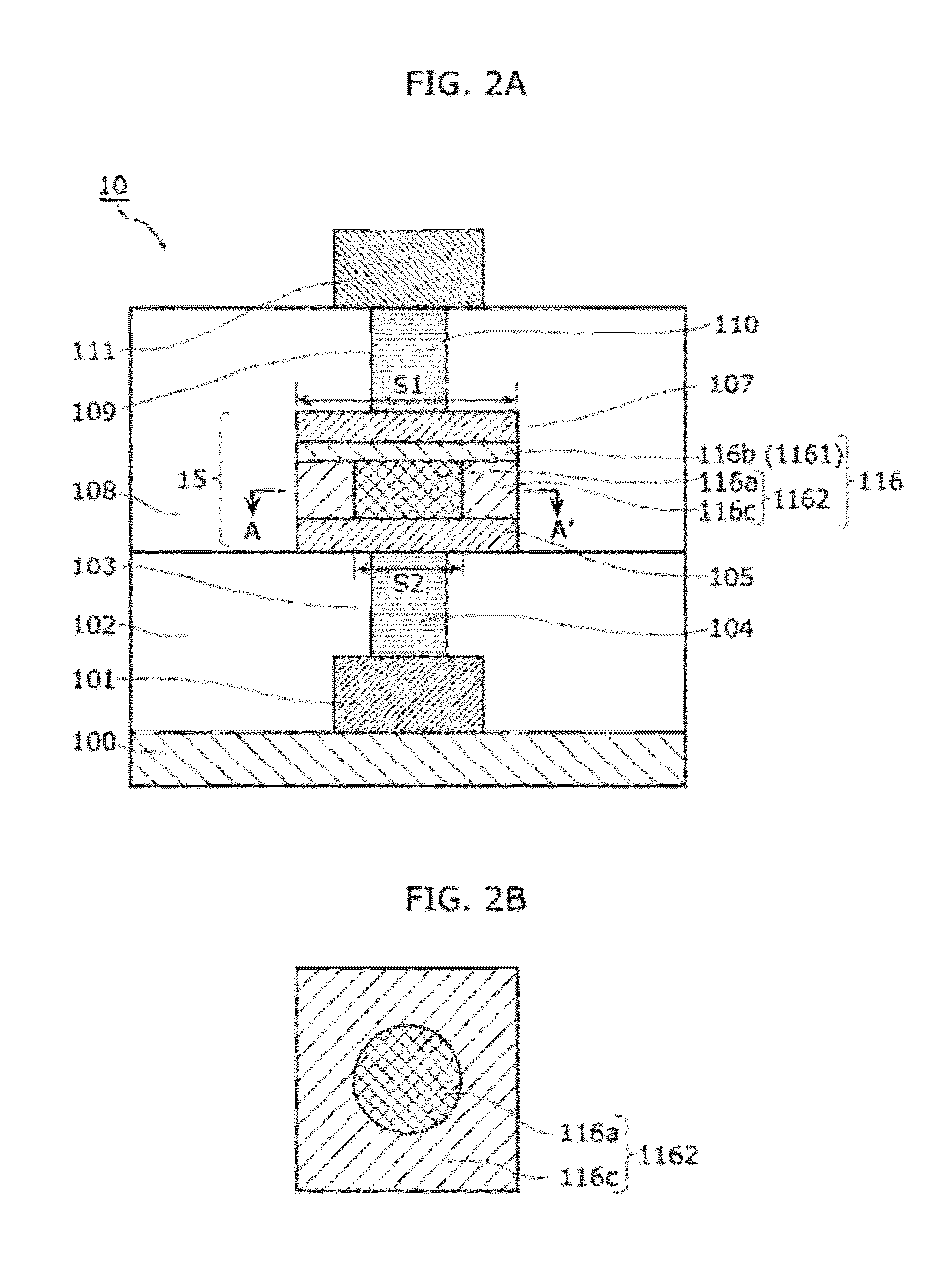

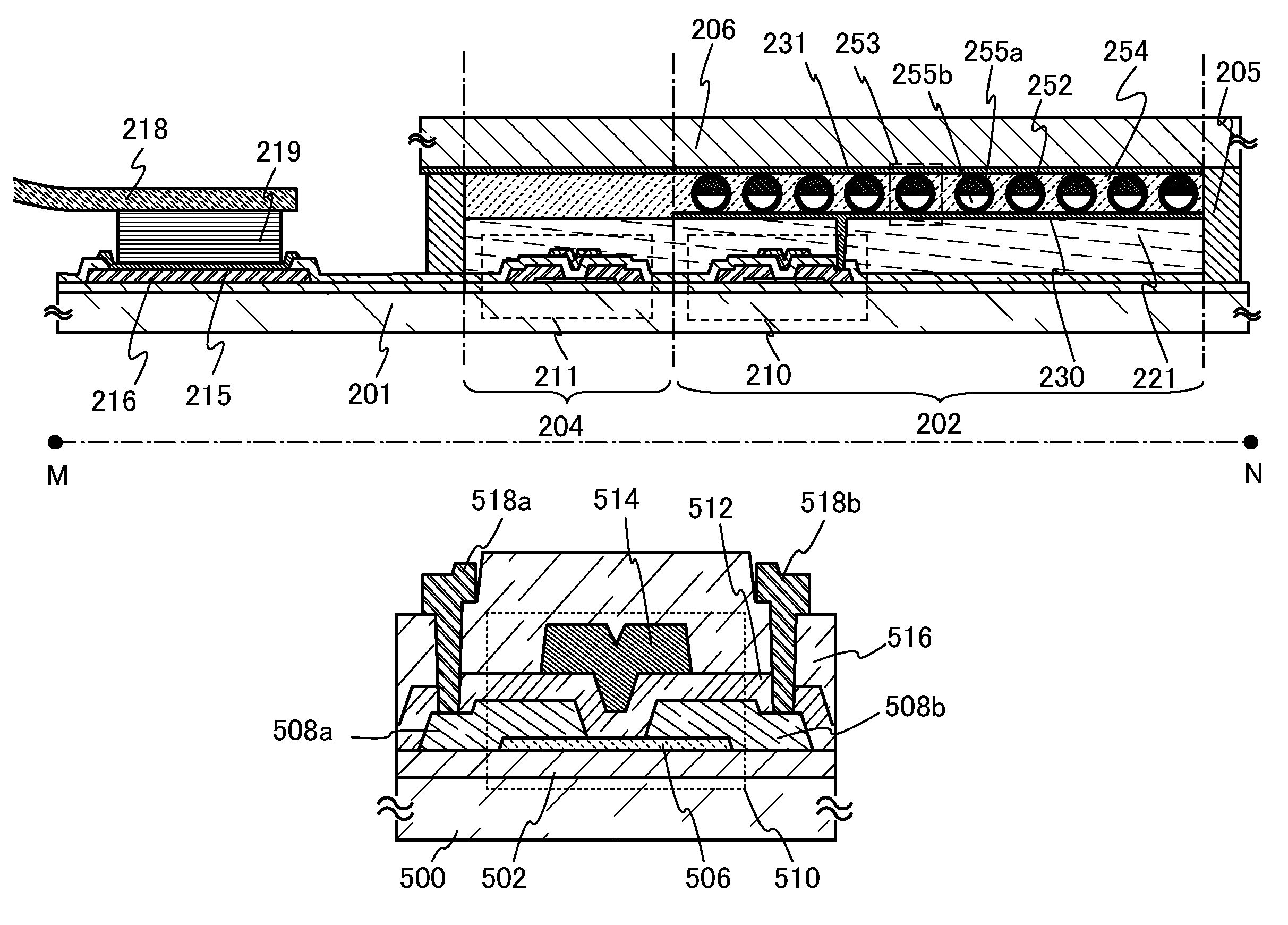

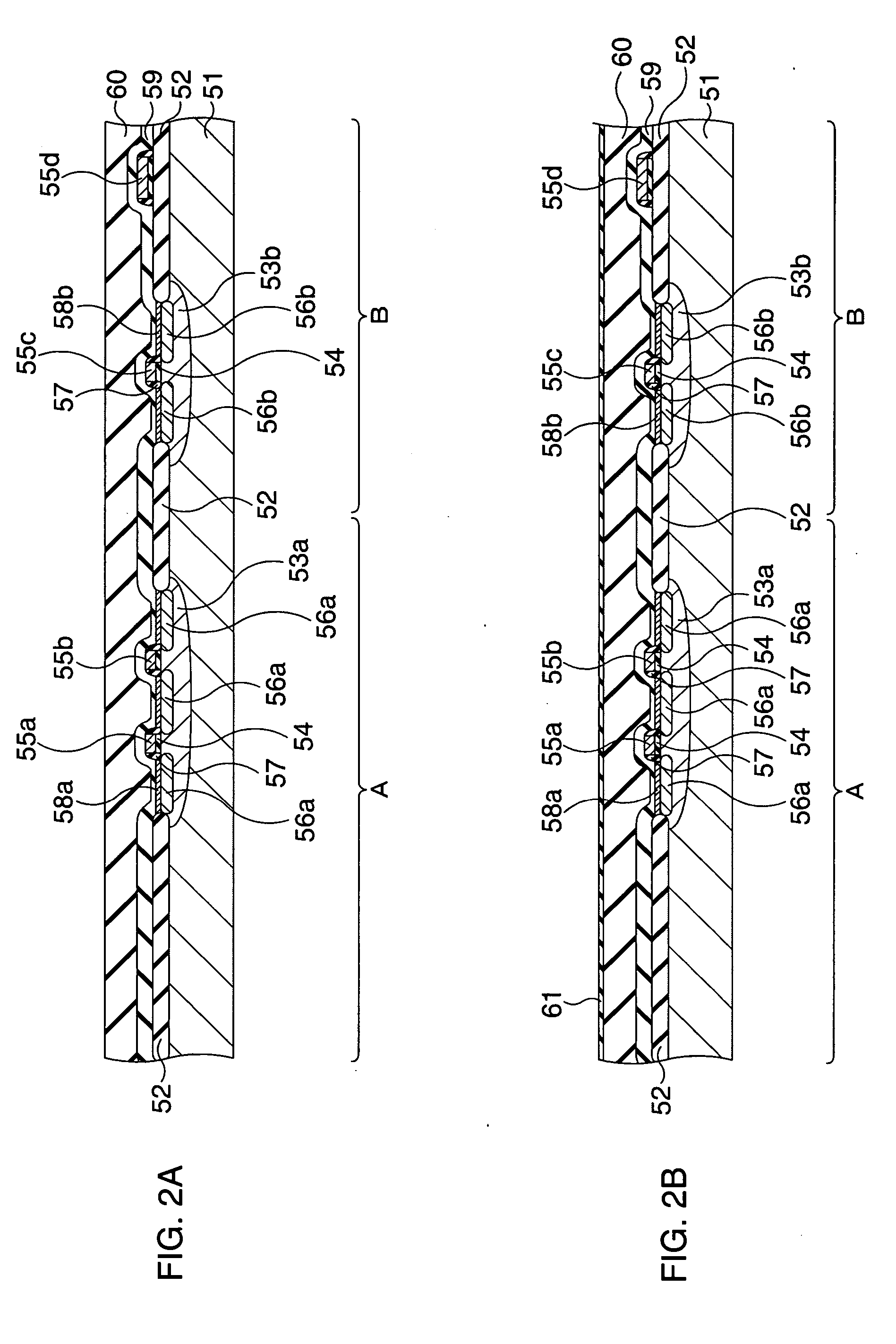

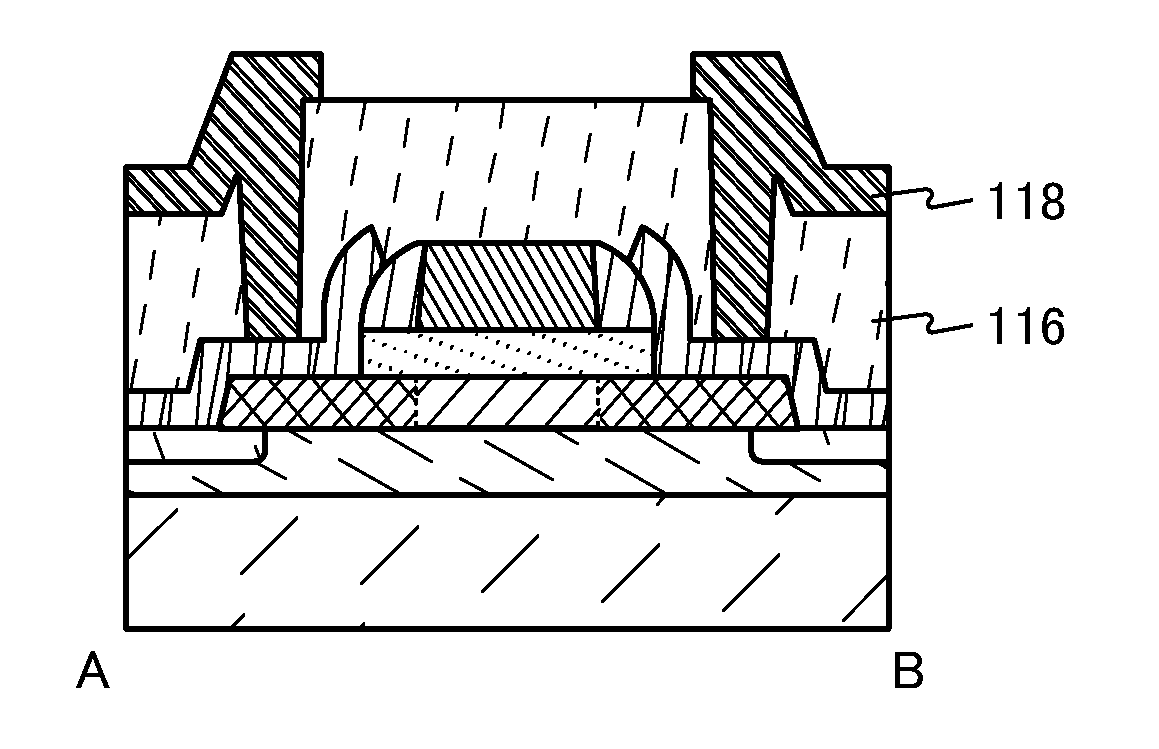

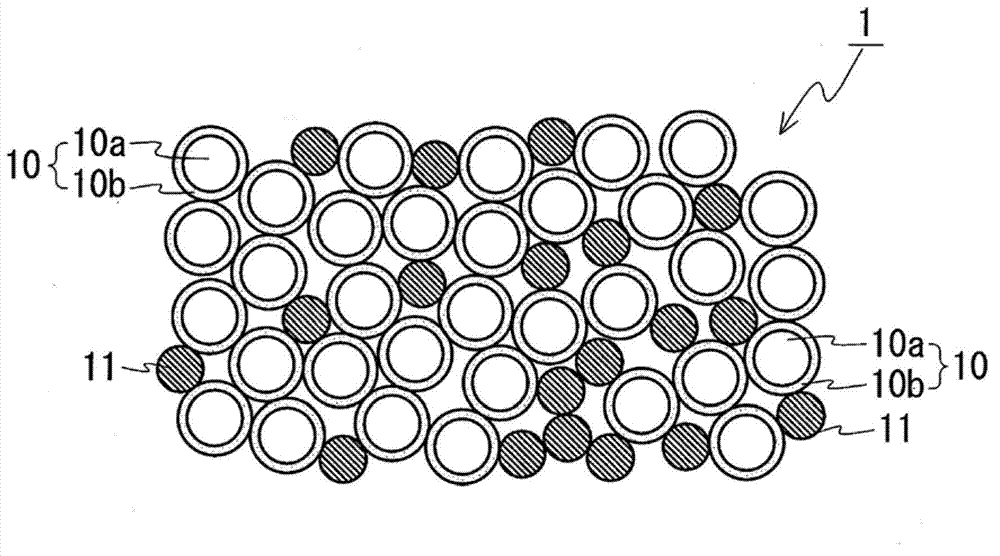

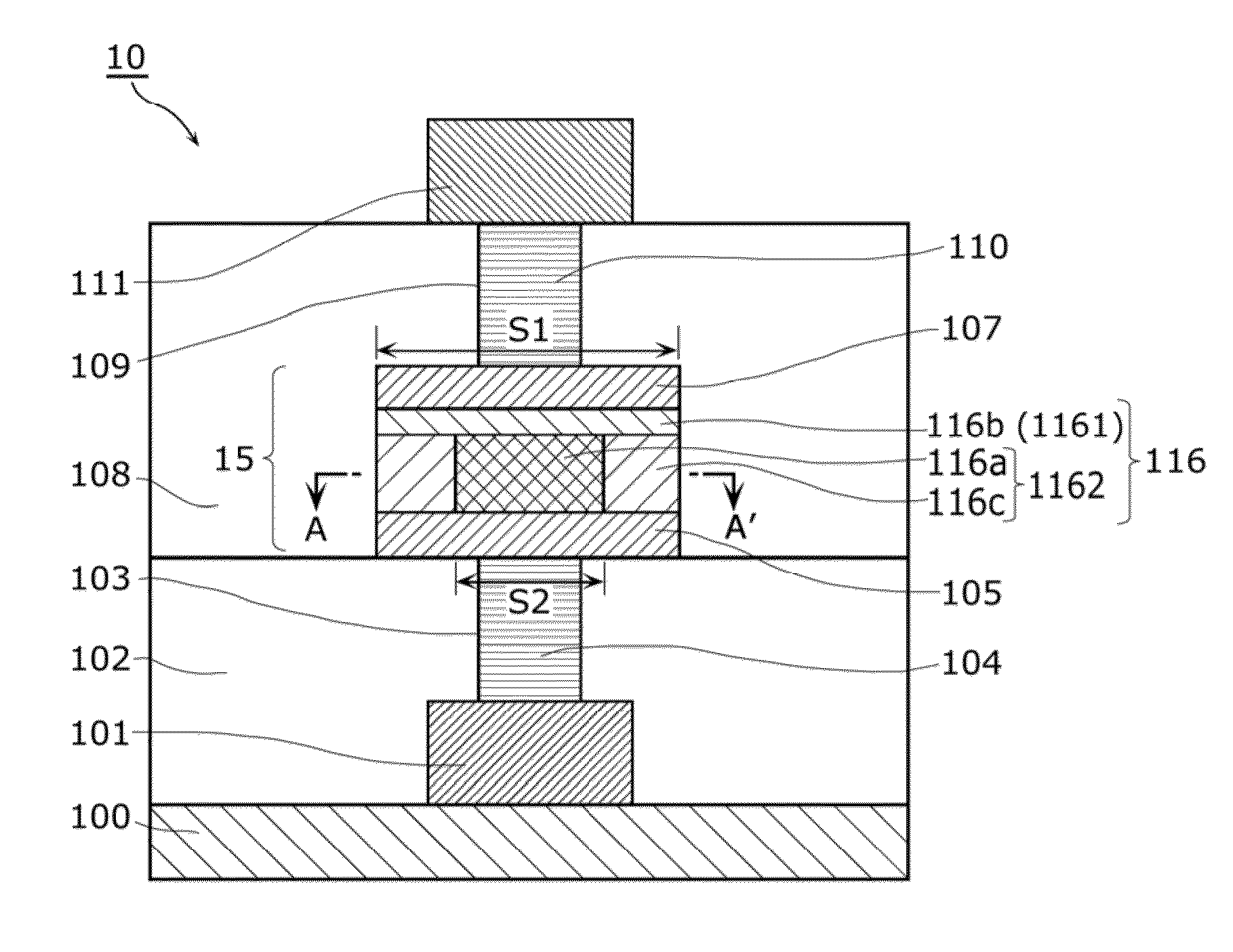

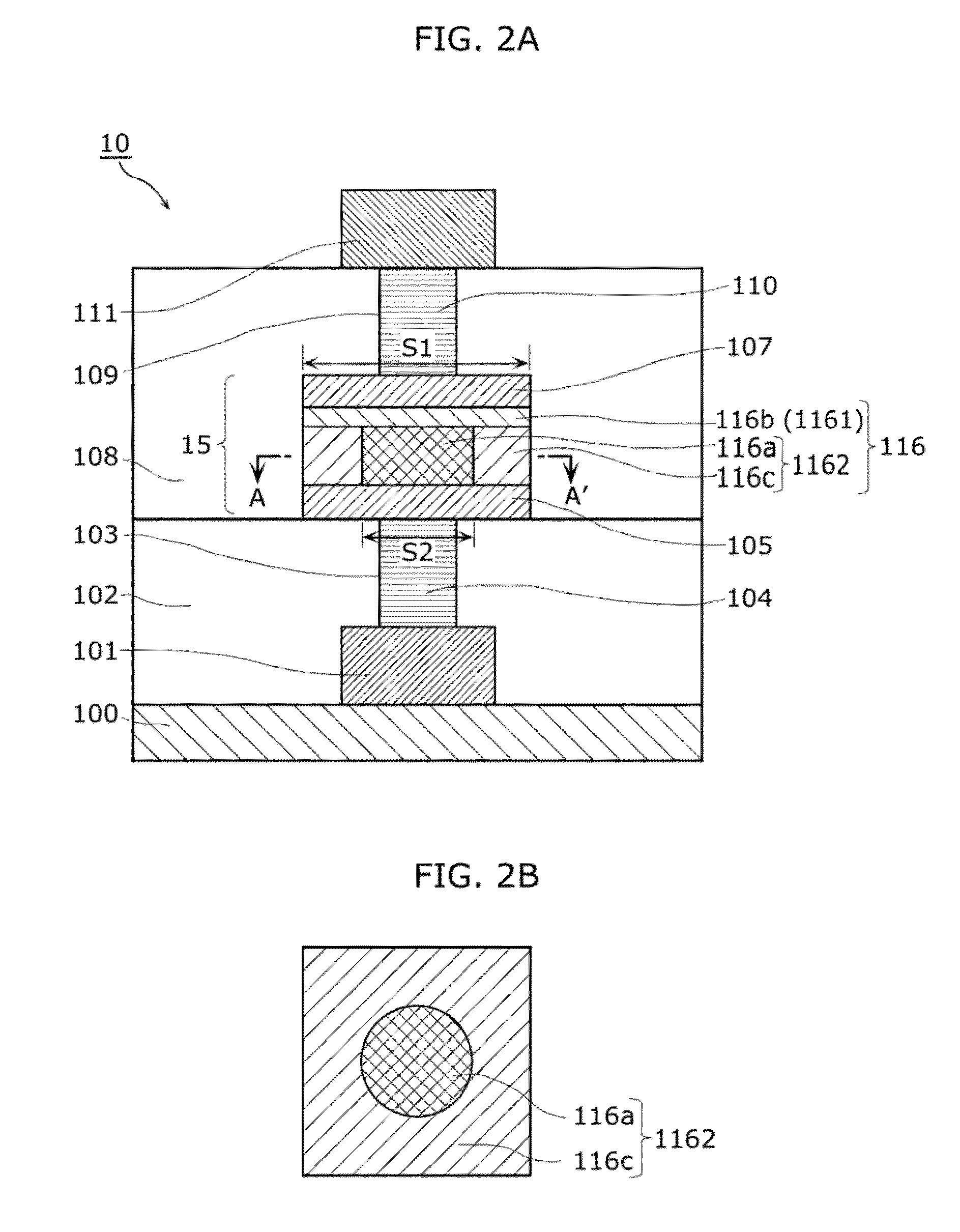

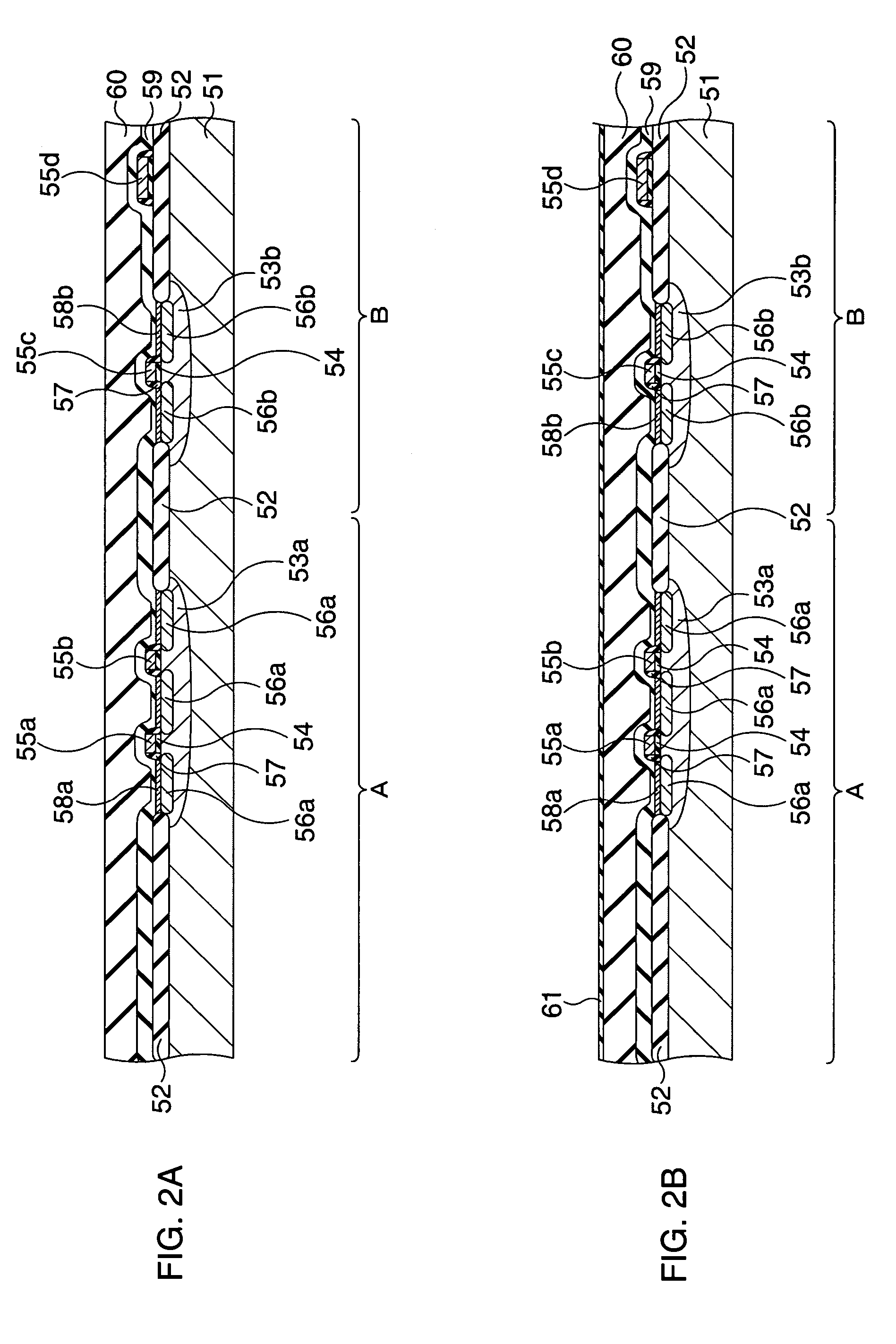

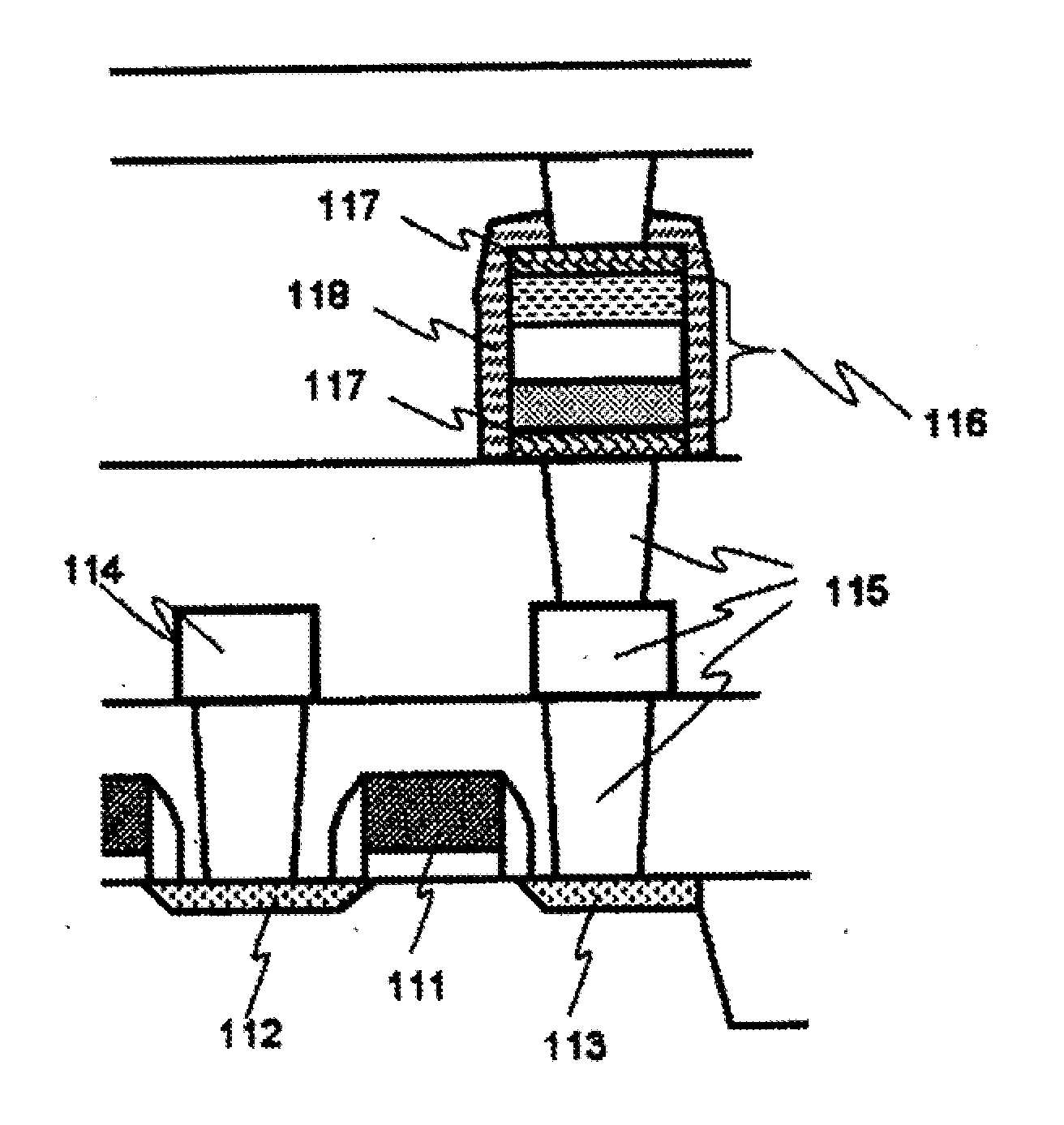

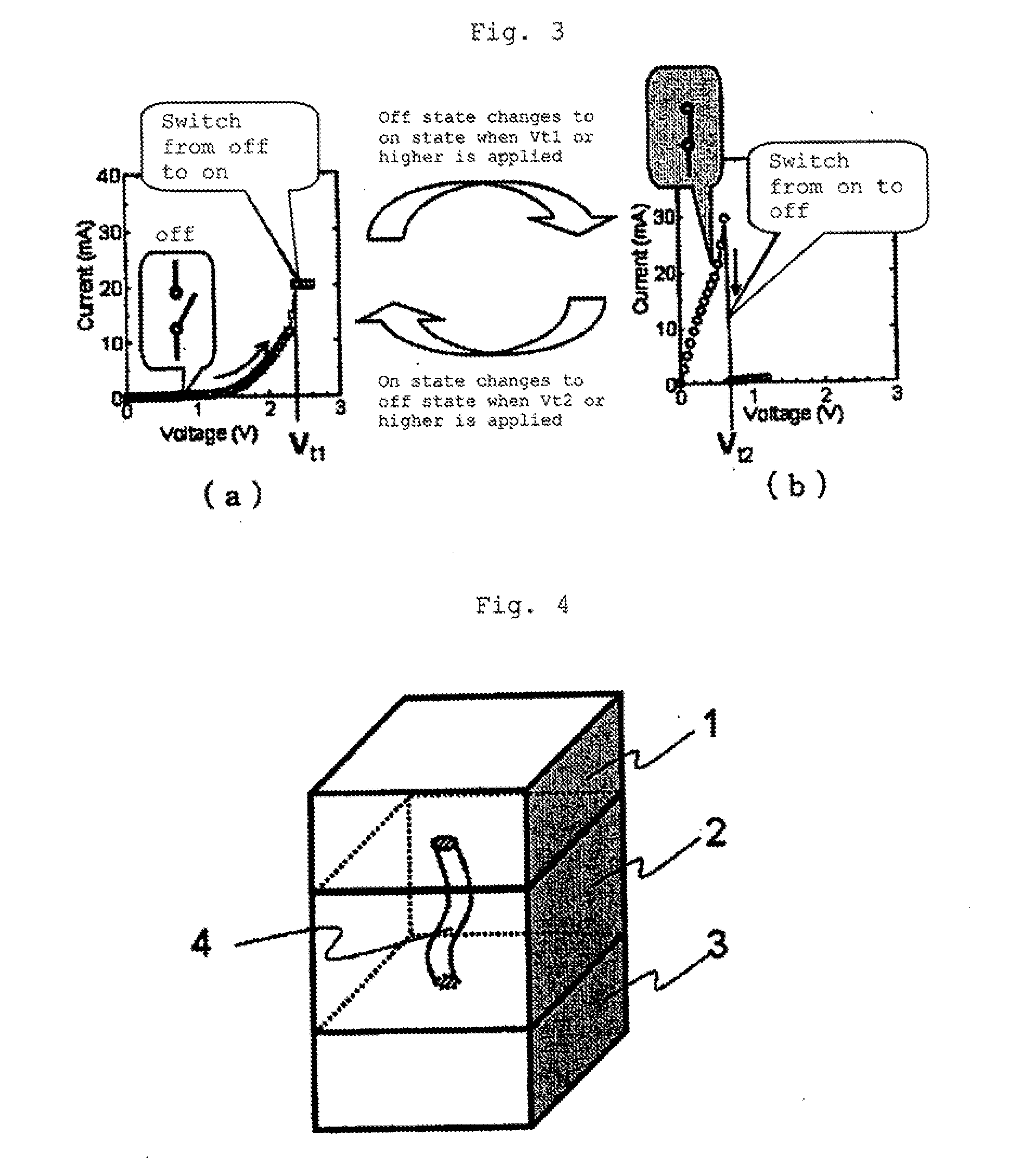

Nonvolatile memory element, production method therefor, design support method therefor, and nonvolatile memory device

ActiveUS20120063201A1Reduces initialization voltageFacilitates formation of conductive pathSolid-state devicesSemiconductor/solid-state device manufacturingLow voltageEngineering

A nonvolatile memory element which can be initialized at low voltage includes a variable resistance layer (116) located between a lower electrode (105) and an upper electrode (107) and having a resistance value that reversibly changes based on electrical signals applied between these electrodes. The variable resistance layer (116) includes at least two layers: a first variable resistance layer (1161) including a first transition metal oxide (116b); and a second variable resistance layer (1162) including a second transition metal oxide (116a) and a third transition metal oxide (116c). The second transition metal oxide (116a) has an oxygen deficiency higher than either oxygen deficiency of the first transition metal oxide (116b) or the third transition metal oxide (116c), and the second transition metal oxide (116a) and the third transition metal oxide (116c) are in contact with the first variable resistance layer (1161).

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

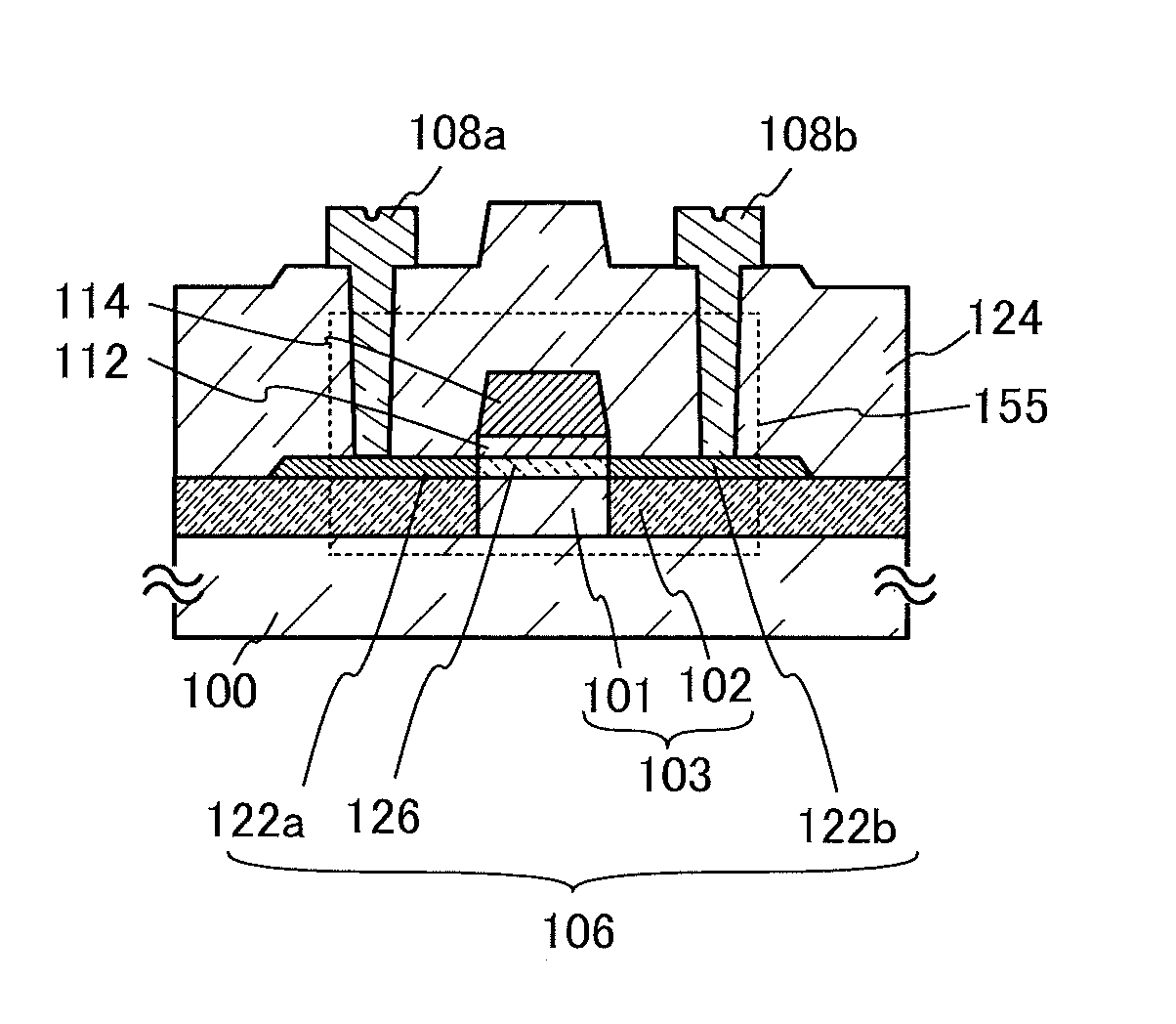

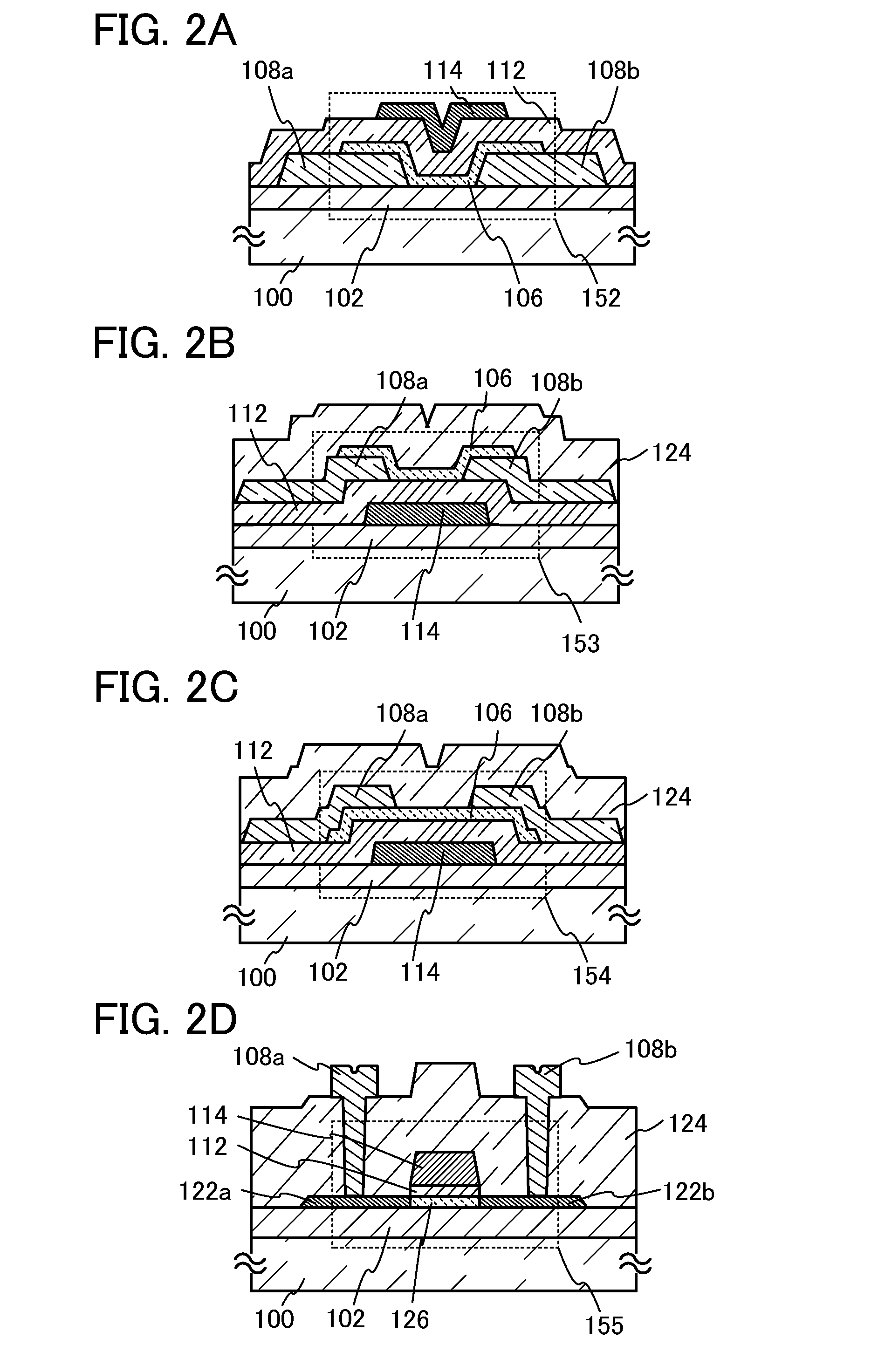

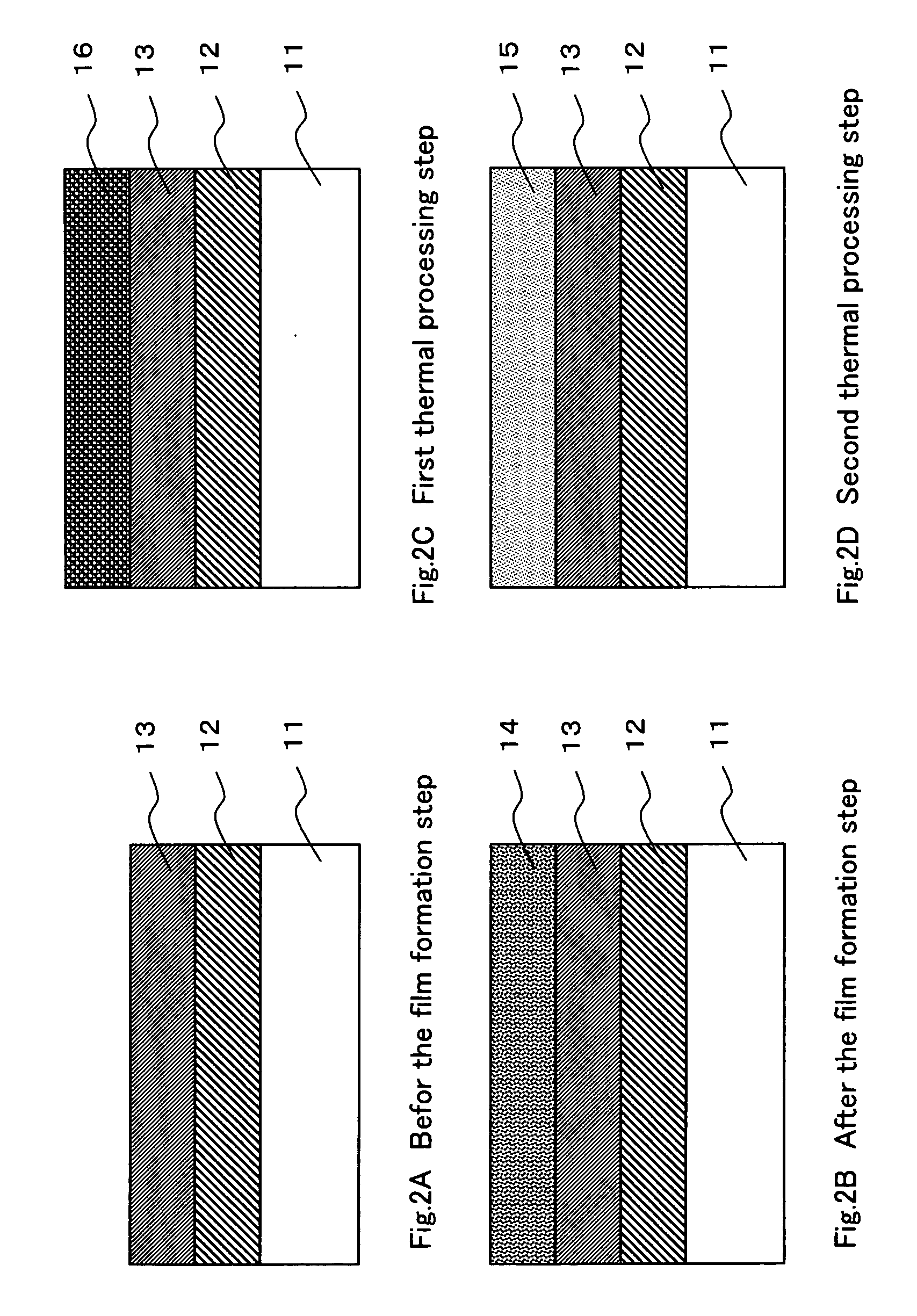

Method for manufacturing semiconductor device

InactiveUS20120178224A1Reduce resistanceSuppress leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesDesorptionOxygen deficiency

To provide a semiconductor device in which desorption of oxygen from side surfaces of an oxide semiconductor layer is prevented, defects (oxygen deficiency) in the oxide semiconductor layer are sufficiently reduced, and leakage current between a source and a drain is suppressed. The semiconductor device is manufactured through the following steps: after first heat treatment is performed on an oxide semiconductor film, the oxide semiconductor film is processed to form an oxide semiconductor layer; immediately after that, side walls of the oxide semiconductor layer are covered with an insulating oxide; and in second heat treatment, the side surfaces of the oxide semiconductor layer are prevented from being exposed to a vacuum and defects (oxygen deficiency) in the oxide semiconductor layer are reduced. Side walls of the oxide semiconductor layer are covered with sidewall insulating layers. The semiconductor device has a TGBC structure.

Owner:SEMICON ENERGY LAB CO LTD

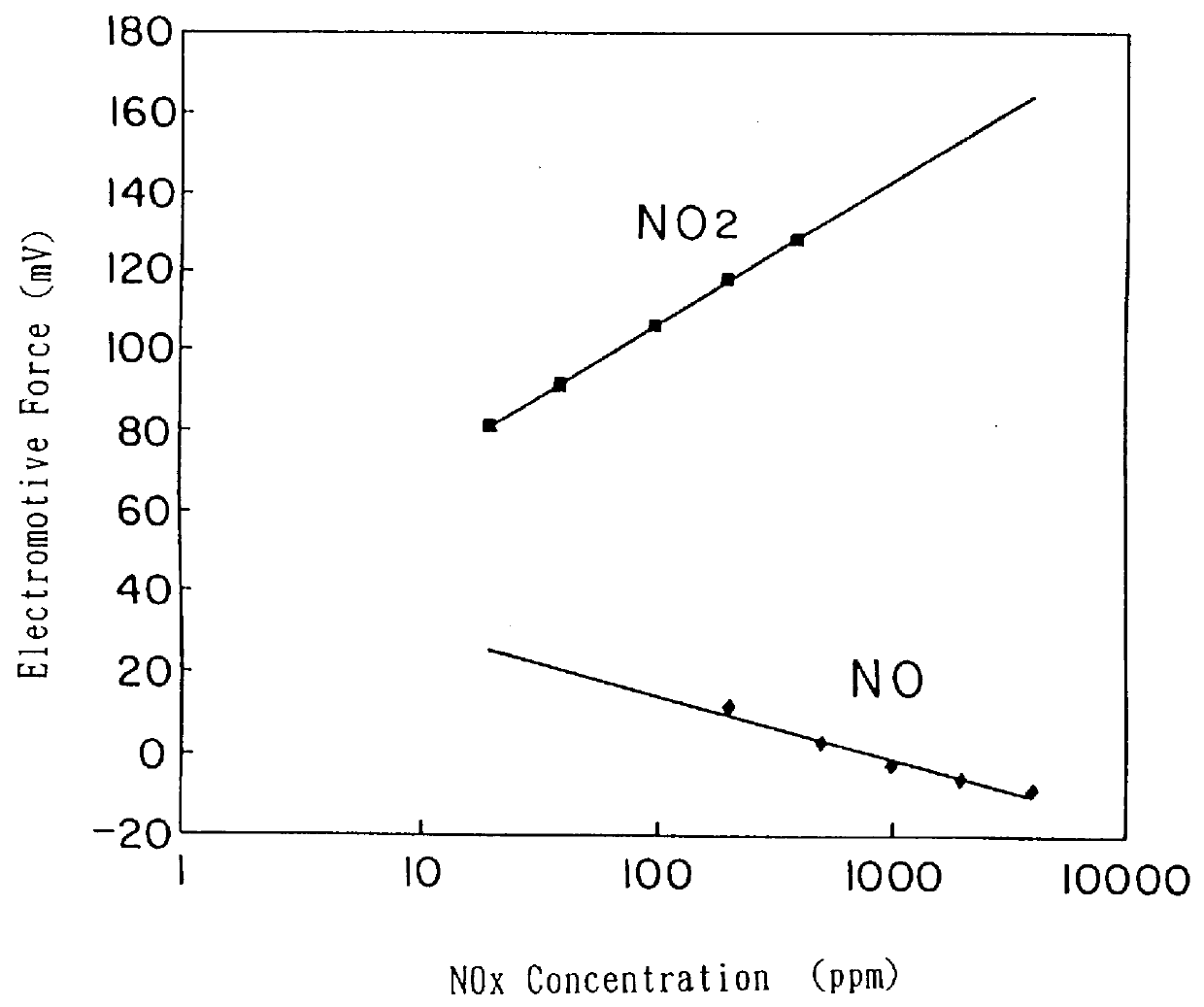

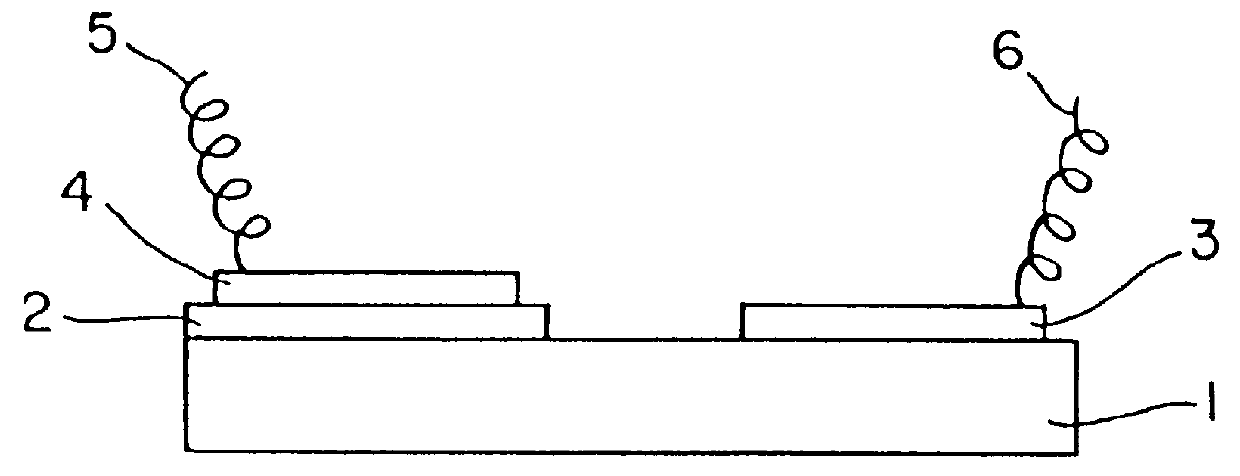

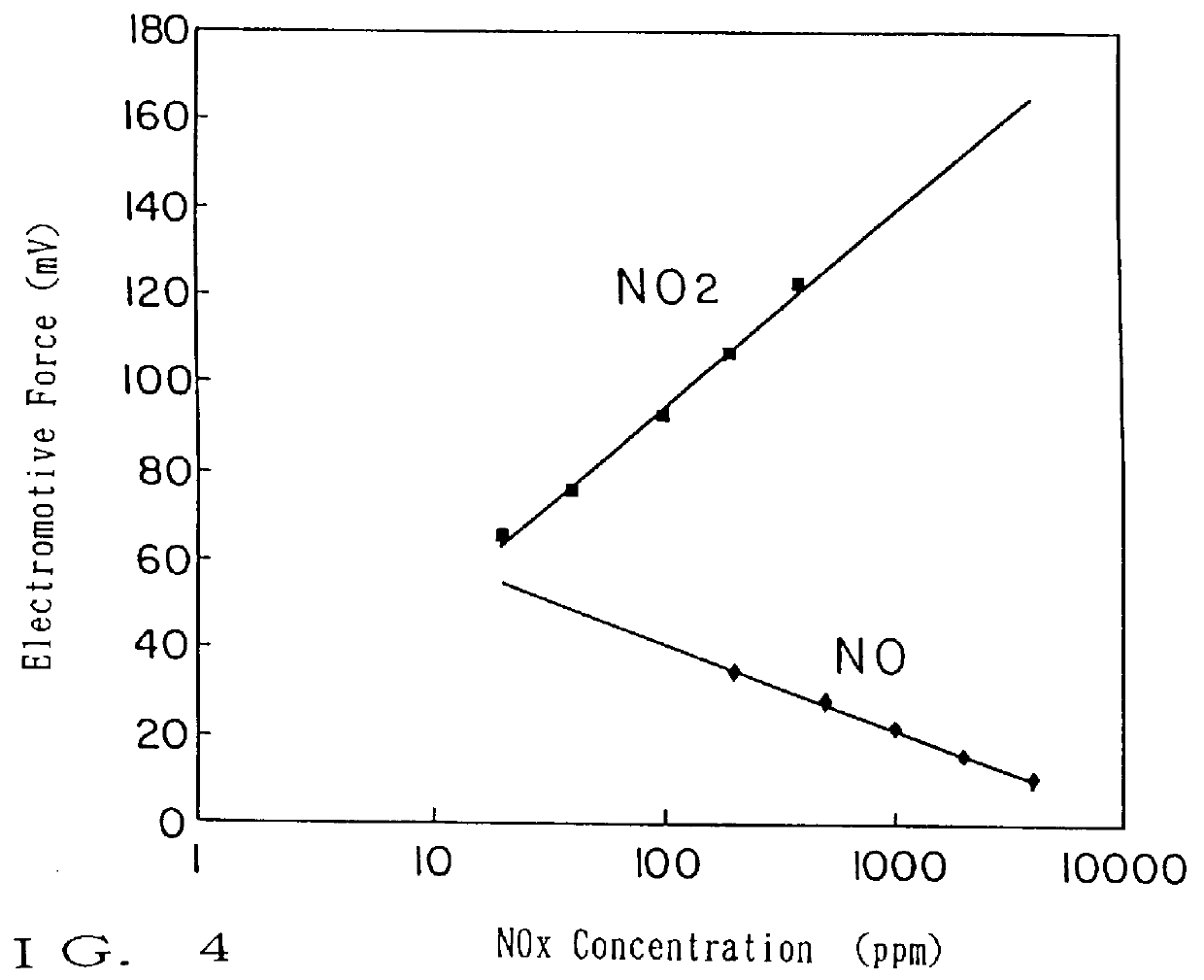

NOx sensor

InactiveUS6019881AHigh catalytic activityImprove performanceWeather/light/corrosion resistanceVolume/mass flow measurementOxygen deficiencyElectrolyte

The present invention discloses a NOx sensor consisting at least of a pair of the first and the second electrodes formed in touch with an oxygen conductive solid electrolyte; wherein at least the first elelctrode is composed of oxides of an element selected from 7a Group or 8 Group, especially from Mn, Fe, Co, and Ni or a substance containing said oxides or of hybrid oxides (including the one of oxygen deficiency expressed by ABO3, AB2 O4, A2 BO4 and ACBO4 including 7a Group and 8 Group. A NOx sensor acording to the present invention has a good sensitivity without being affected by the concentration of CO2 and detects NOx concentration in an exhaust gas at a temperature above 600 DEG C.

Owner:RIKEN CO LTD

Semiconductor device and method of manufacturing the same

ActiveUS8476719B2Low reliabilityImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingOxygen deficiencySemiconductor

Oxygen is released from the insulating layer, whereby oxygen deficiency in the oxide semiconductor layer and an interface state between the insulating layer and the oxide semiconductor layer can be reduced. Accordingly, a semiconductor device where reliability is high and variation in electric characteristics is small can be manufactured.

Owner:SEMICON ENERGY LAB CO LTD

Manufacturing method of semiconductor device

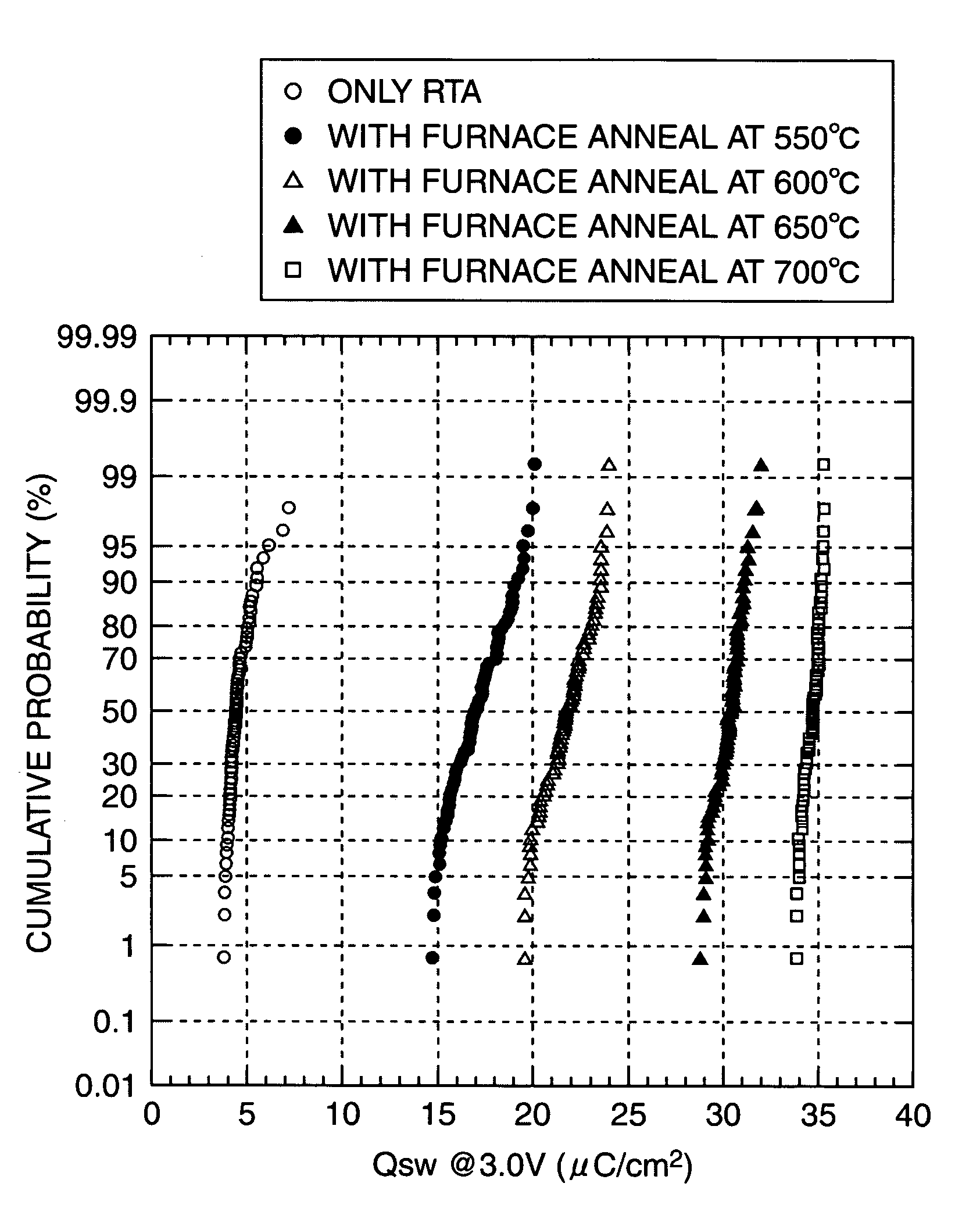

InactiveUS20050136556A1Avoid small quantitiesExcellent fatigue propertiesTransistorSolid-state devicesMetallurgyAtmospheric pressure

An IrOx film is formed as a first conductive oxide film on a PLZT film by a reactive sputtering method. Thereafter, thermal treatment by, for example, RTA is performed in an atmosphere containing oxygen having partial pressure of less than 5% of atmospheric pressure. As a result, crystallization of the PLZT film is promoted, and annealing treatment is performed for the IrOx film. Thereafter, furnace annealing at 600° C. or higher, for example, 650° C. is performed for 60 minutes in, for example, an O2 atmosphere as recovering annealing to recover oxygen deficiency in the PLZT film. Subsequently, an IrO2 film is formed as a second conductive oxide film on the IrOx film by a sputtering method.

Owner:FUJITSU SEMICON LTD

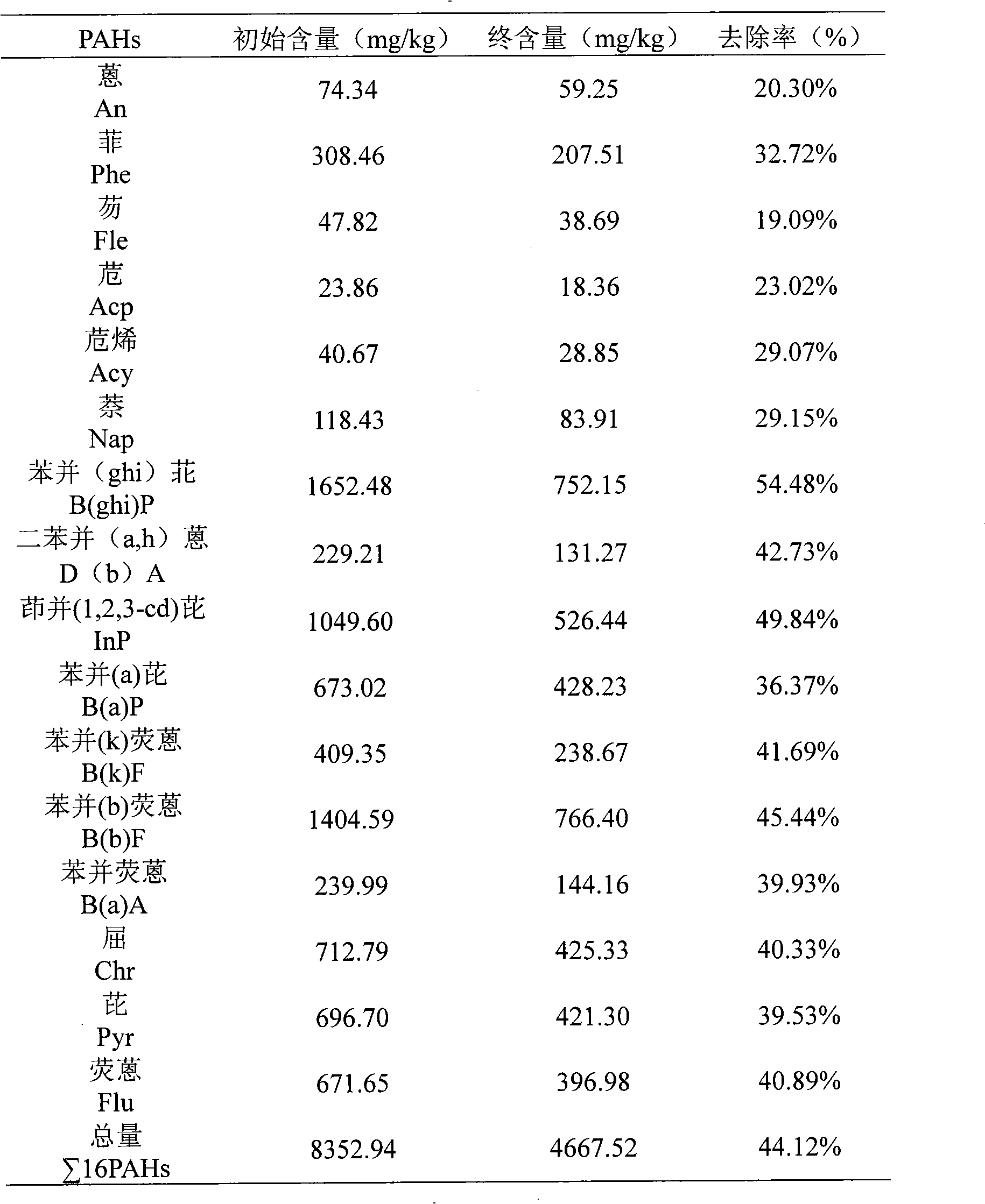

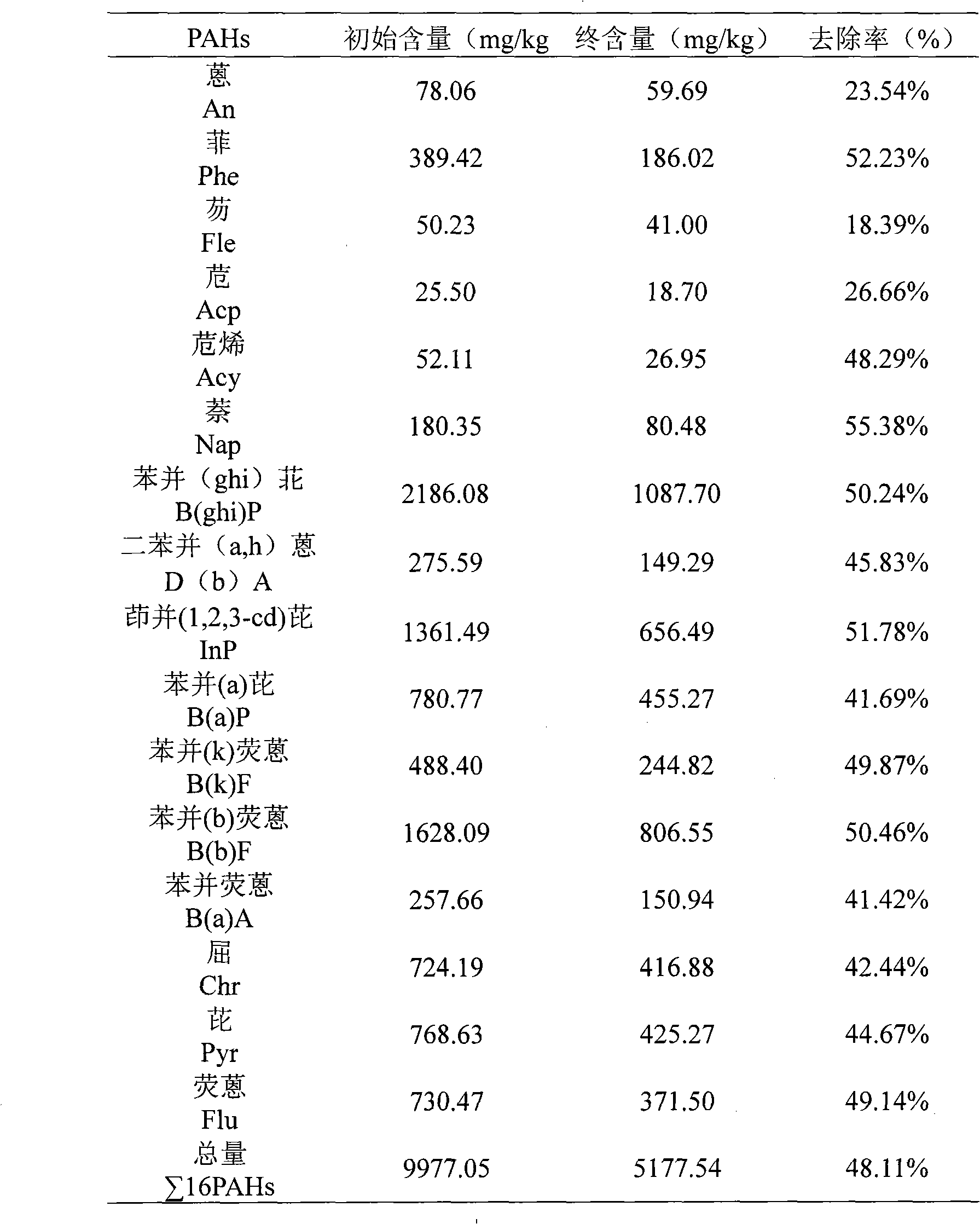

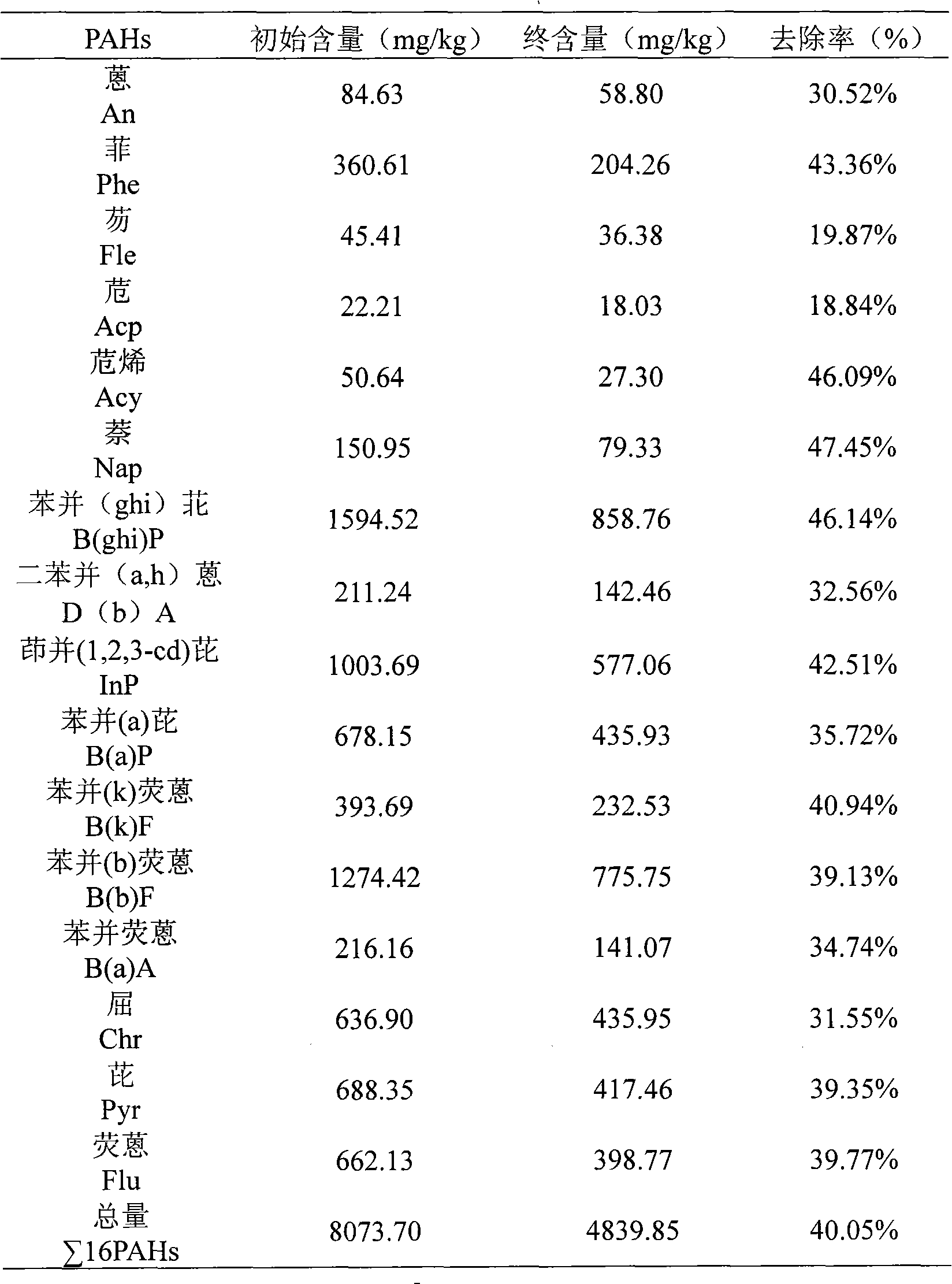

Method for restoring polycyclic aromatic hydrocarbon contaminated soil by charcoal

InactiveCN101618394ARealize resourcesWide variety of sourcesContaminated soil reclamationPolycyclic aromatic hydrocarbonPollution soil

The invention discloses a method for restoring polycyclic aromatic (PAHs) polluted soil by charcoal which is prepared by livestock and poultry manure and belongs to the field of polluted soil restoration. The method comprises the following steps: preparing charcoal by using livestock and poultry manure output by a livestock and poultry plant by a thermal cracking method under the conditions of oxygen deficiency and high temperature of 350-600 DEG C; crushing the prepared charcoal into grains of 2-8mm; mixing the charcoal and polluted soil sufficiently in proportion of 0.5-10 percent; maintaining the water content of soil from 10 to 17 percent; and processing the mixture for 30-300 days to remove various PAHs in the soil. The method for restoring polycyclic aromatic (PAHs) polluted soil by charcoal not only can be used for processing PAHs polluted soil in different places, but also can be used for restoring the land on site.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Method of manufacturing semiconductor device

A highly reliable transistor which includes an oxide semiconductor and has high field-effect mobility and in which a variation in threshold voltage is small is provided. By using the transistor, a high-performance semiconductor device, which has been difficult to realize, is provided. The transistor includes an oxide semiconductor film which contains two or more kinds, preferably three or more kinds of elements selected from indium, tin, zinc, and aluminum. The oxide semiconductor film is formed in a state where a substrate is heated. Further, oxygen is supplied to the oxide semiconductor film with an adjacent insulating film and / or by ion implantation in a manufacturing process of the transistor, so that oxygen deficiency which generates a carrier is reduced as much as possible. In addition, the oxide semiconductor film is highly purified in the manufacturing process of the transistor, so that the concentration of hydrogen is made extremely low.

Owner:SEMICON ENERGY LAB CO LTD

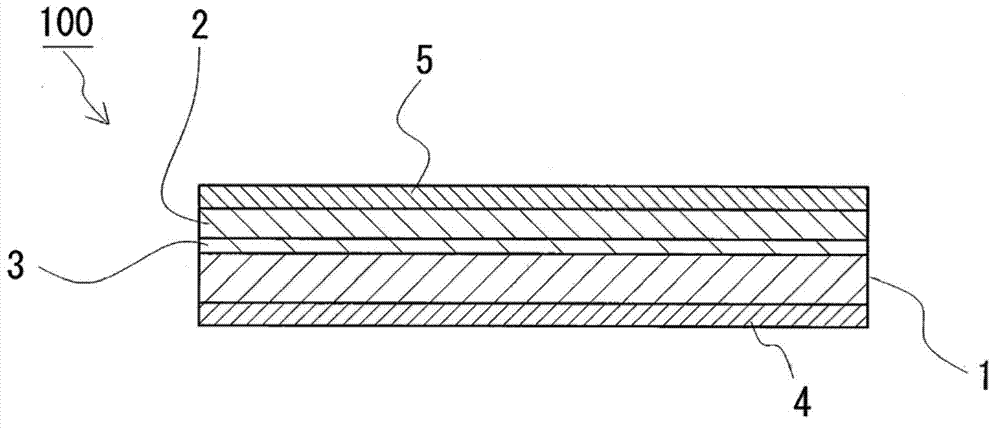

Positive electrode body for nonaqueous electrolyte battery, method for producing same, and nonaqueous electrolyte battery

InactiveCN102893431AImprove output characteristicsImprove interface resistanceLi-accumulatorsNon-aqueous electrolyte accumulator electrodesHigh resistanceBattery charge

Owner:SUMITOMO ELECTRIC IND LTD

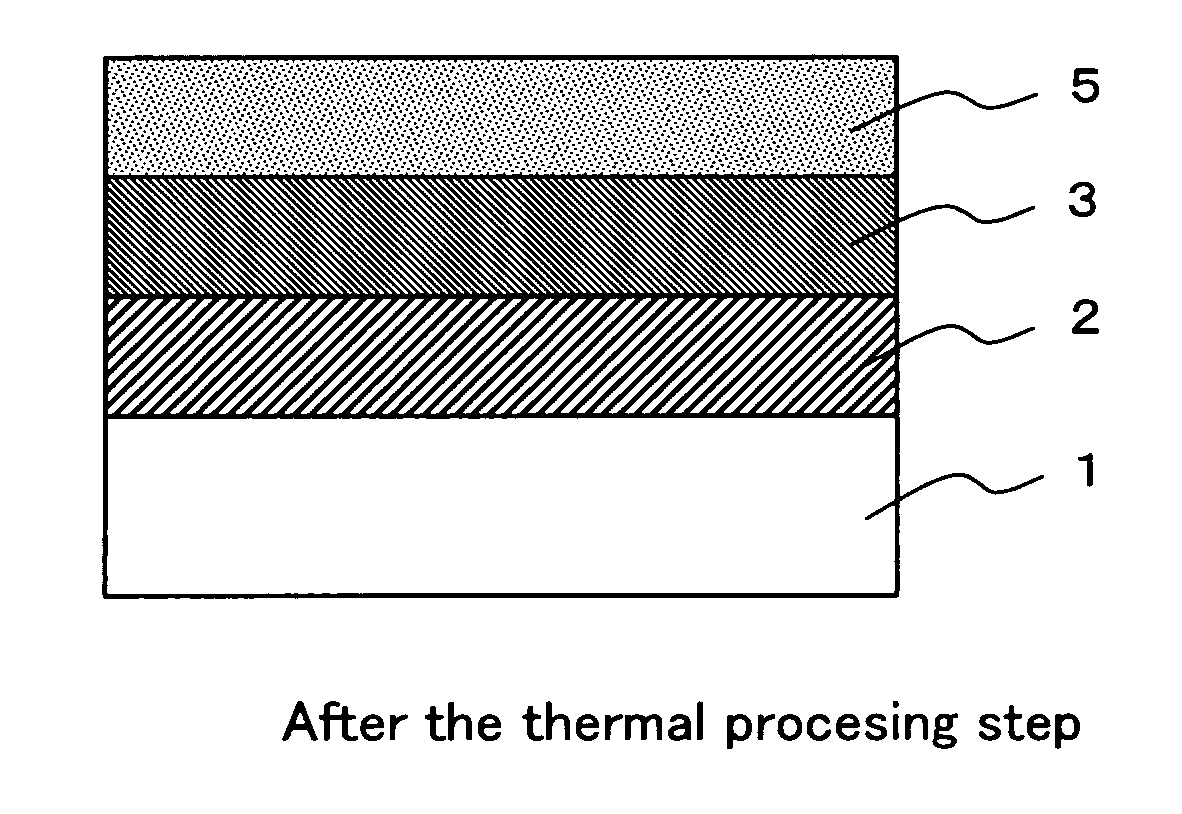

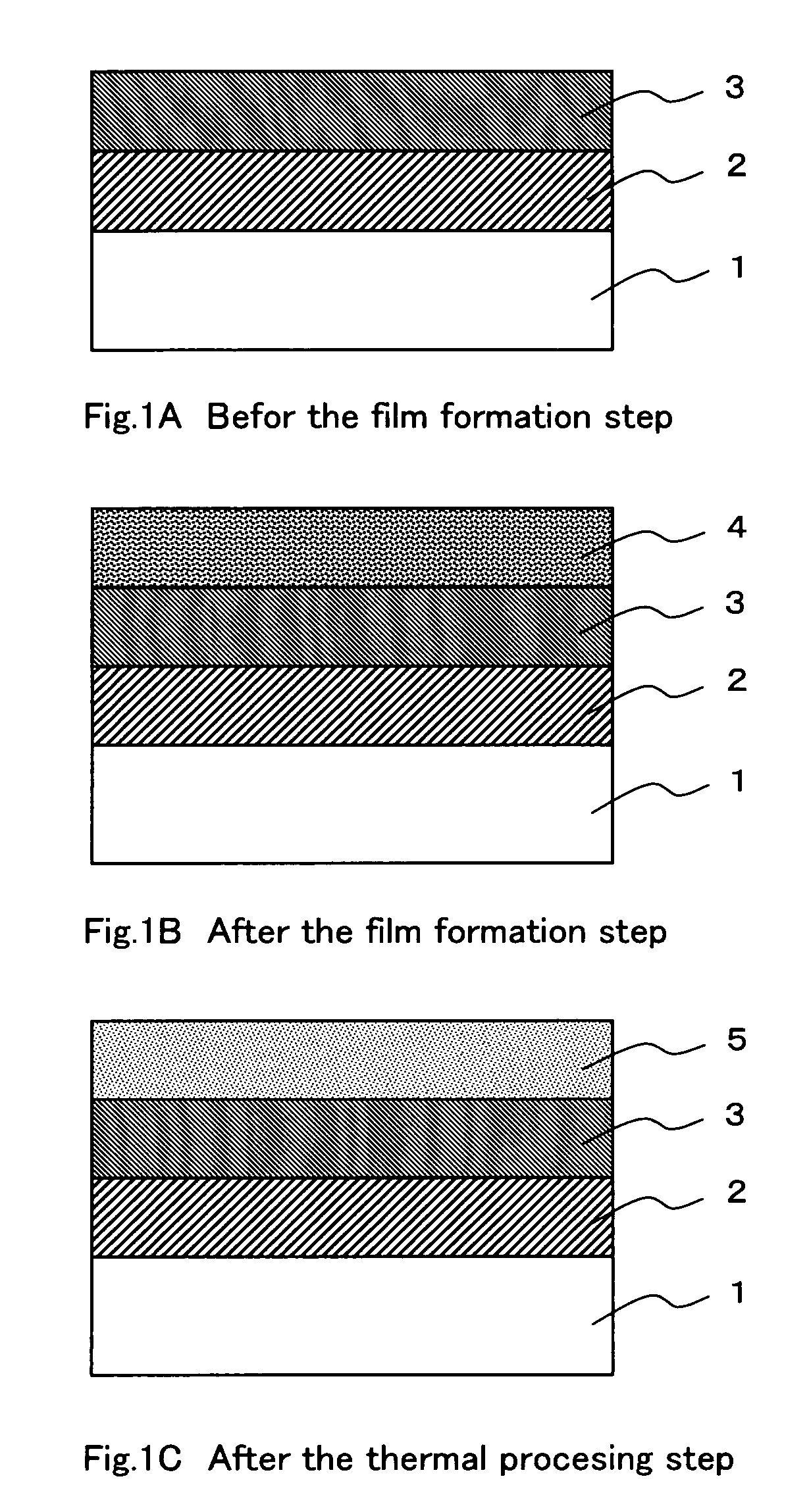

Semiconductor device and manufacturing method for same

InactiveUS20050270821A1Increase resistivity valueEasy to implementSolid-state devicesSemiconductor/solid-state device manufacturingDevice materialEngineering

The thermal processing step of thermally processing a variable resistor film in an oxidizing atmosphere is carried out after the film formation step of forming a variable resistor film (PCMO film), and ON radicals are introduced into positions of oxygen deficiency defects in the PCMO film, and thereby, the three-dimensionally coupled network structure having the PCMO perovskite structure is locally broken down so as to increase the resistivity value.

Owner:SHARP KK

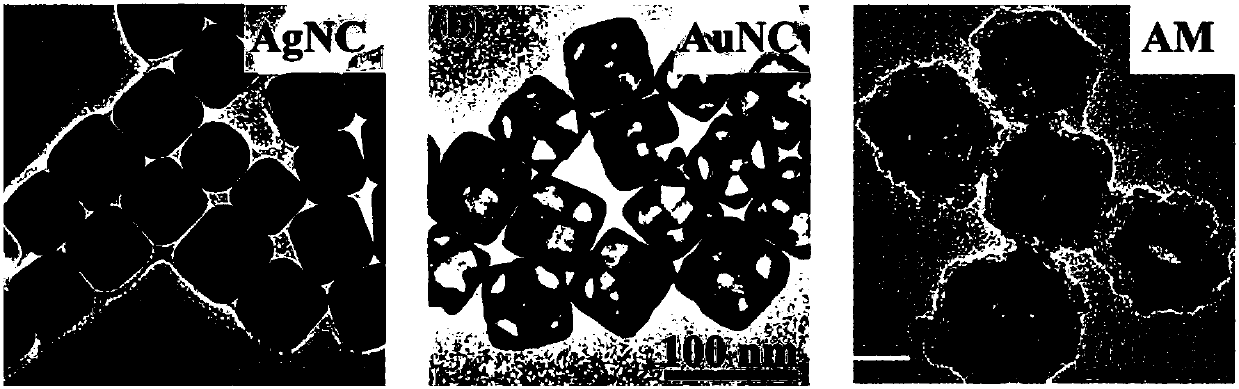

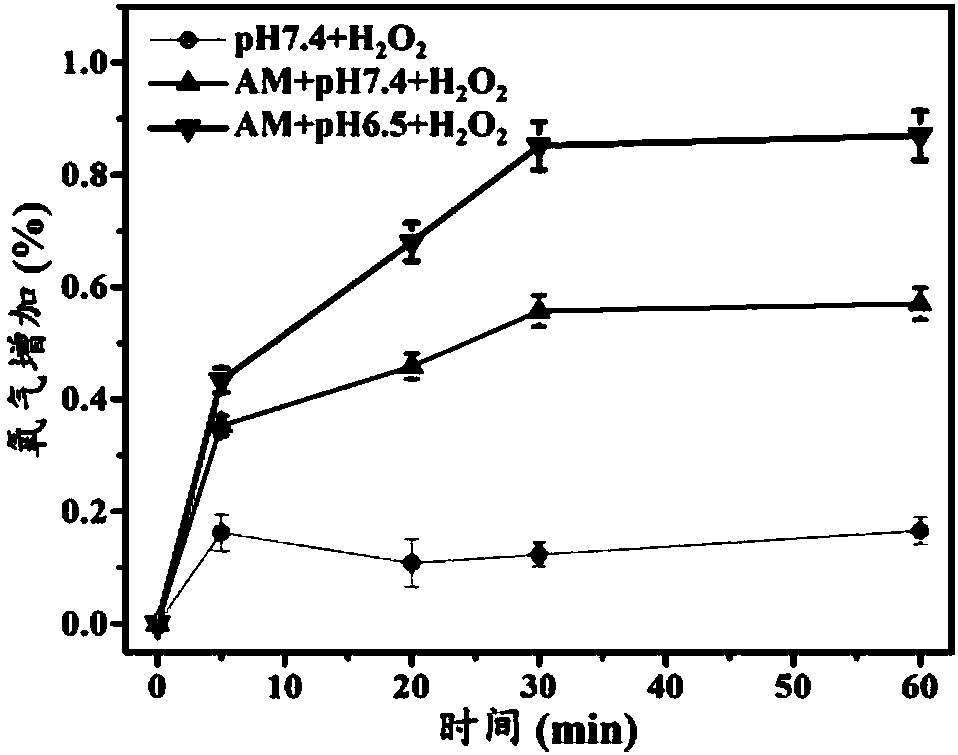

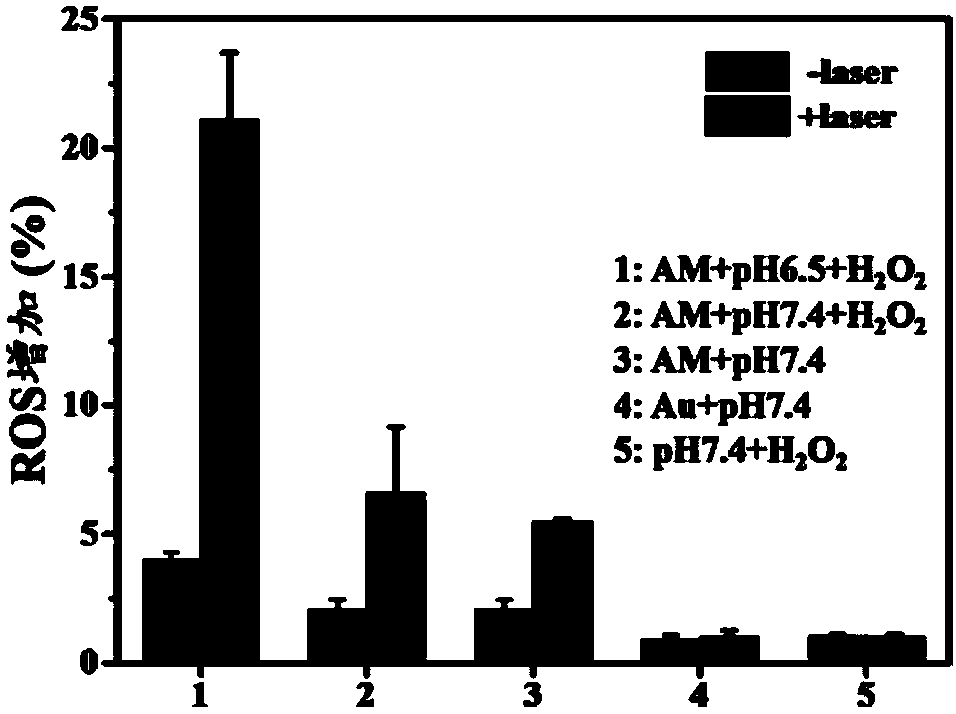

Gold nanocage-manganese dioxide composite nanoparticle as well as preparation method and application thereof

ActiveCN107670040AImprove hypoxic microenvironmentGive full play to the photodynamic effectPhotodynamic therapyGeneral/multifunctional contrast agentsTumor targetManganese

The invention discloses a gold nanocage-manganese dioxide composite nanoparticle as well as a preparation method and application thereof, and relates to the technical field of nanoparticle photodynamic therapy. The composite nanoparticle comprises a gold nanocage inner core and a manganese dioxide shell layer. The preparation method is characterized in that potassium permanganate is reduced by a one-step reduction method; the manganese dioxide shell layer covers the surface of the gold nanocage, wherein the gold nanocage inner core achieves a photodynamic curative effect under the triggering of near-infrared light; the manganese dioxide shell layer is degraded in tumor microenvironment and releases oxygen, so that the tumor oxygen deficiency is relieved, and the photodynamic curative effect is enhanced; on the other hand, the opto-acoustic and magnetic resonance bimodule imaging can also be realized. The problem of insufficient photodynamic curative effect caused by factors such as tumor oxygen deficiency and photodynamic oxygen consumption of a nanometer photosensitizer used in the prior art is solved. The photodynamic curative effect of the gold nanocage-manganese dioxide composite nanoparticle is obvious; the gold nanocage-manganese dioxide composite nanoparticle can be applied to tumor targeted oxygenation photodynamic diagnosis and treatment integration.

Owner:SHENZHEN INST OF ADVANCED TECH

Method for farming loaches on large scale

InactiveCN103704158AGuaranteed scaleEnsure controllable farmingClimate change adaptationAnimal feeding stuffFisheryPond loach

The invention discloses a method for farming loaches on a large scale, and belongs to the farming field. The method has the advantages that selected excellent parent loaches are subjected to artificial spawning and breeding, so that the quality of laid loach eggs can be guaranteed, a survival rate can be increased, the egg laying period can be shortened owing to an artificial spawning mode, and the farming efficiency can be improved; the eggs are hatched by the aid of flowing water current, so that the eggs can be lifted by the flowing water current and can be prevented from settling at the bottoms of ponds, death of loach eggs at the bottoms of the ponds due to oxygen deficiency can be prevented, and the survival rate of the loach eggs can be increased; the quantity of the loaches capable of being hatched in the unit volume of the hatching ponds can be increased, the cost can be saved, and the hatching efficiency can be improved; the loaches can be assuredly and controllably farmed on the large scale by the aid of the method via ultimate reasonable feeding and cultivating management.

Owner:TONGXIANG HENGSHENG LOACH CULTURE PROFESSIONAL COOP

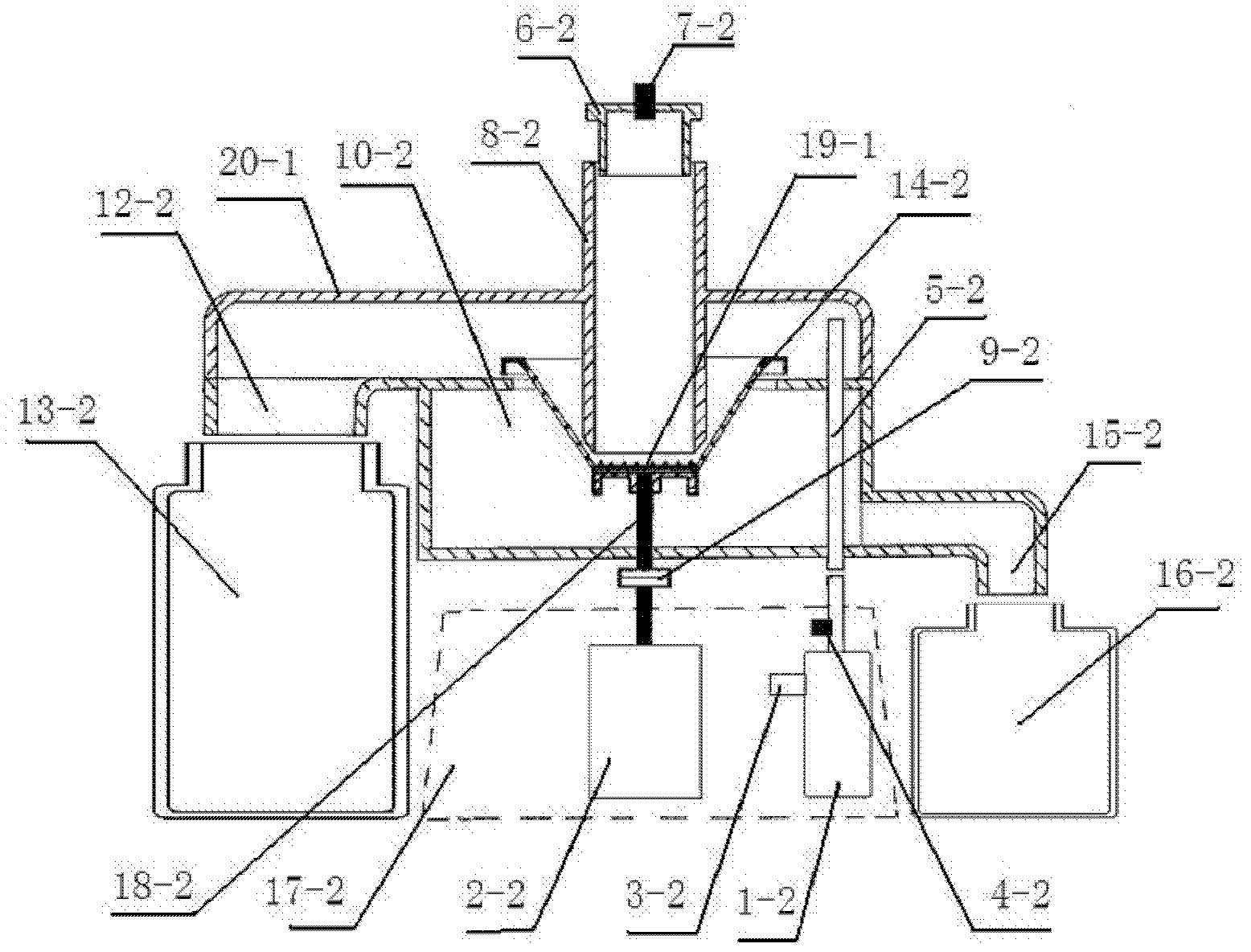

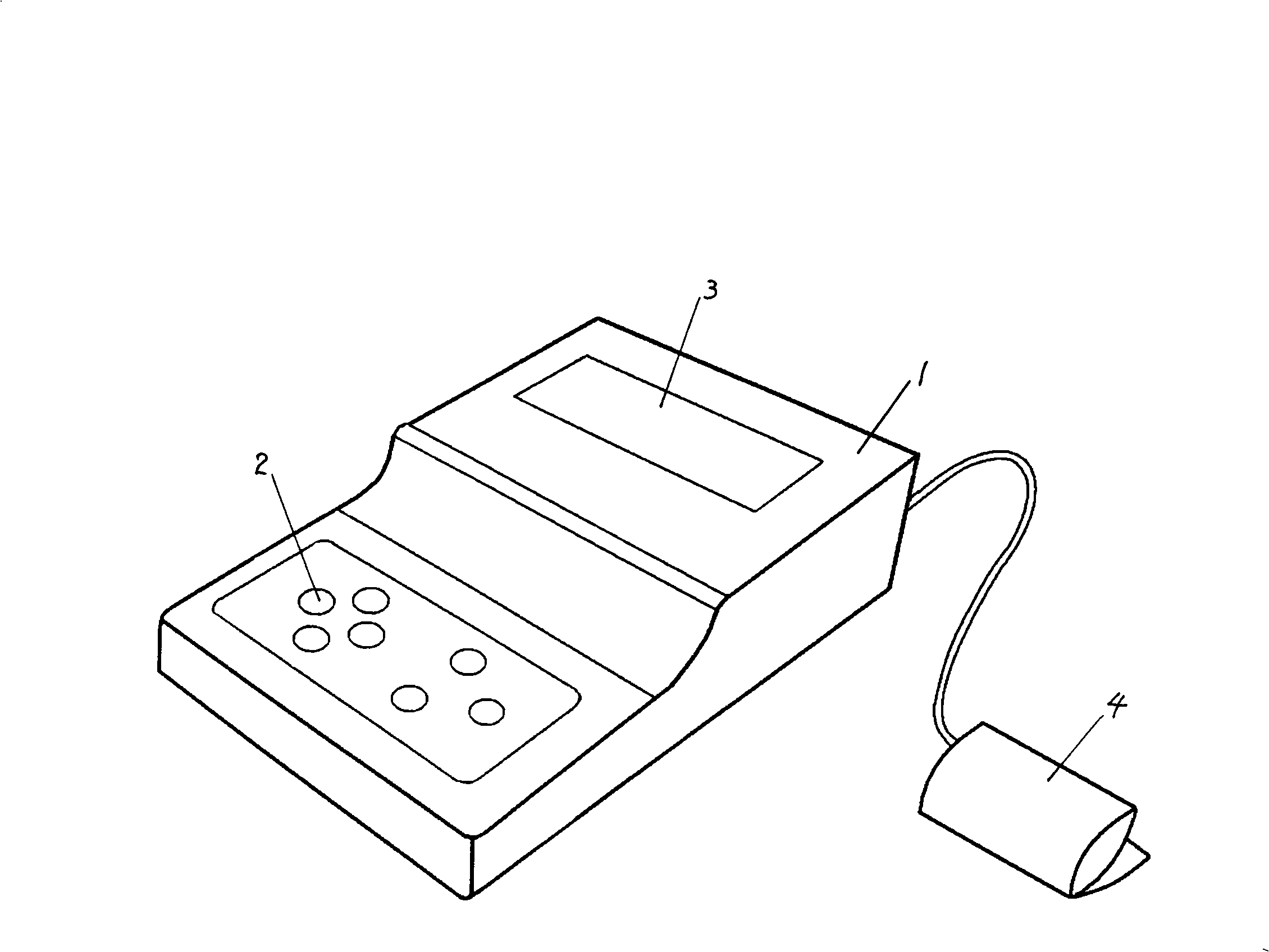

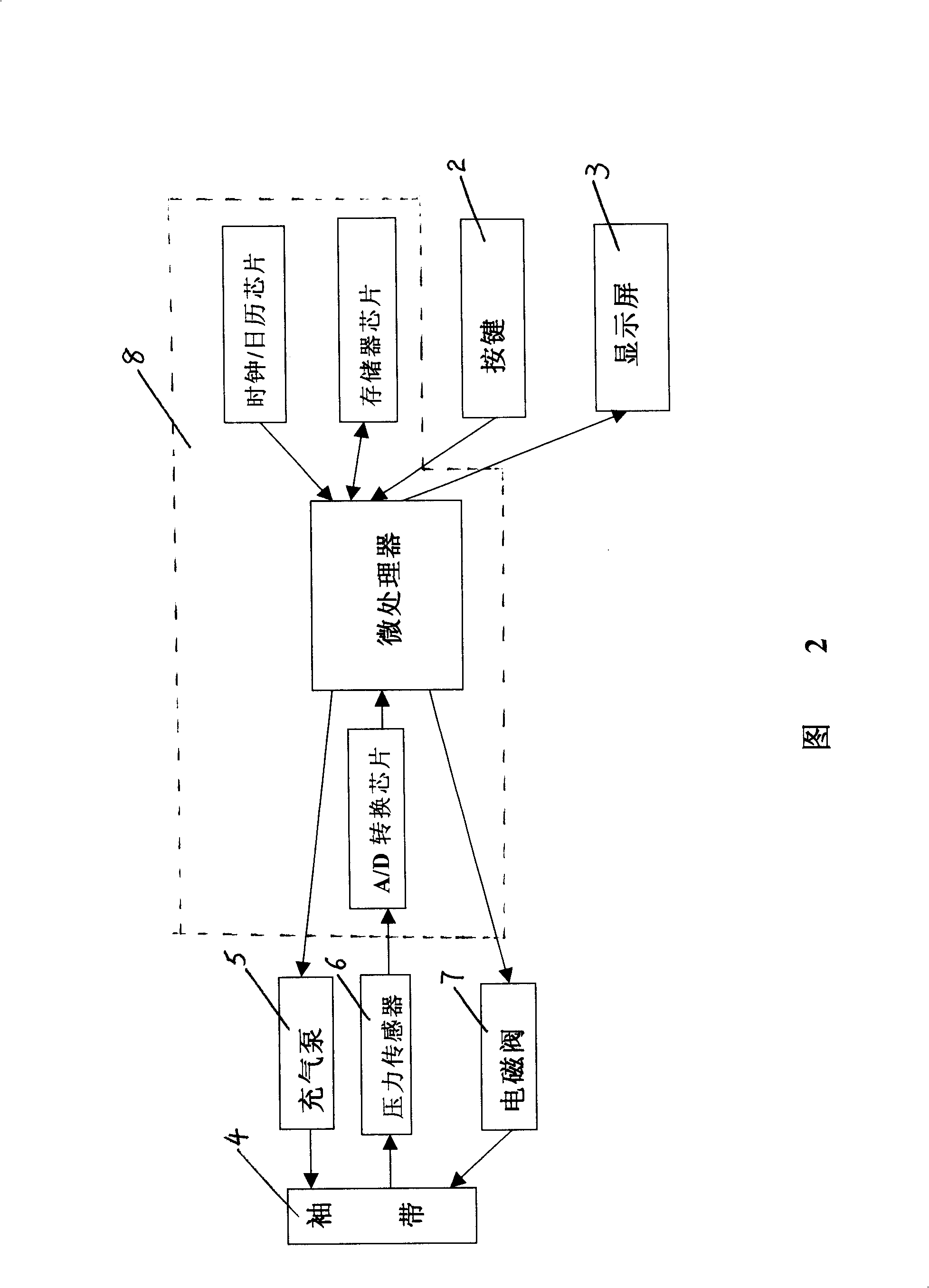

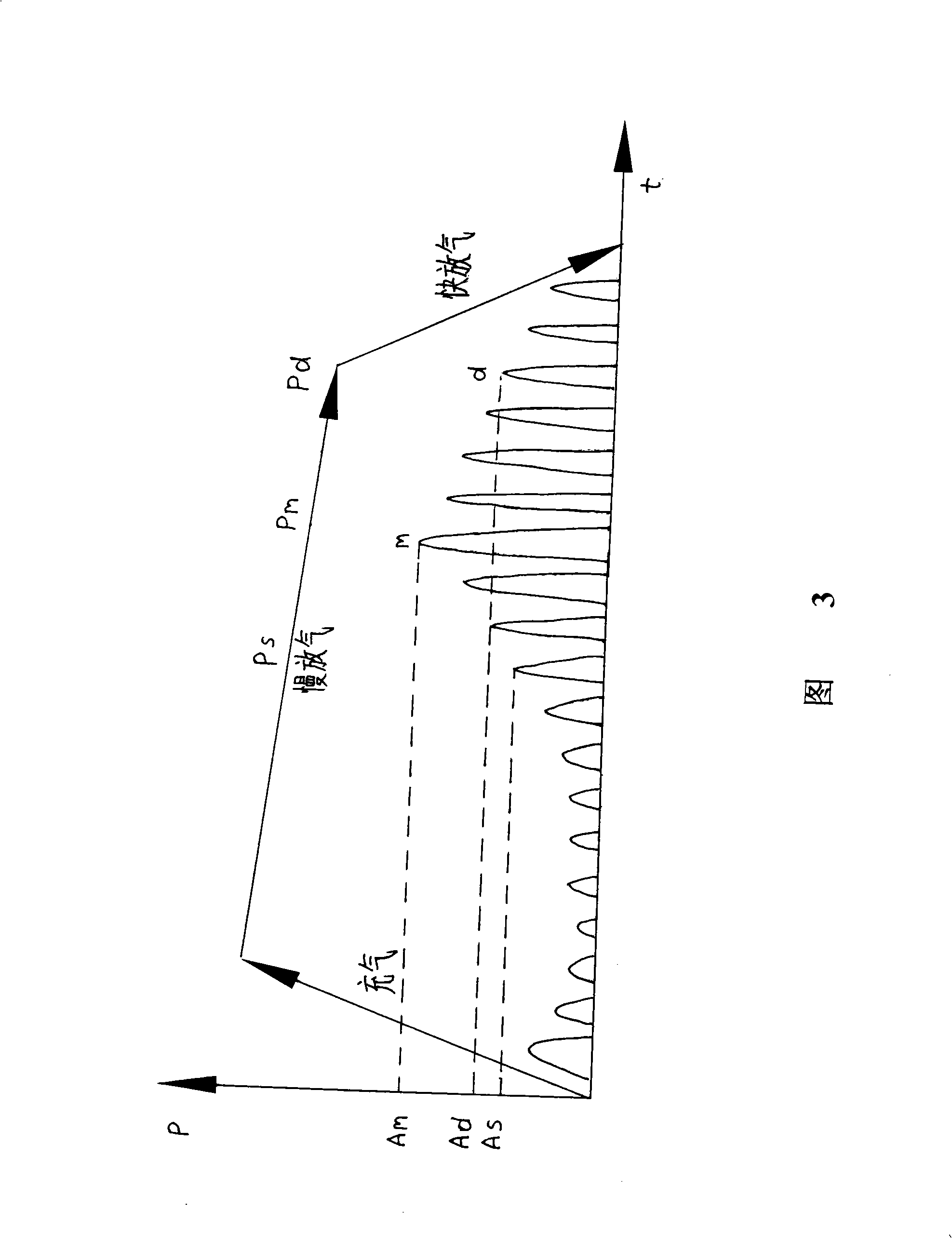

Cerebrovascular and cardiovascular health care therapeutic instrument

InactiveCN101317805AStimulate anti/resistance to ischemiaStimulate hypoxic potentialChiropractic devicesMovement coordination devicesClosed loopRisk stroke

The invention discloses a healthcare therapeutic apparatus of cardiovascular diseases, which is composed of a shell, a keypad arranged on the shell, a display, a cuff connected with the shell, an inflator pump arranged in the shell, a pressure sensor, an electromagnetic valve and a control circuit. The pressure sensor is connected with the cuff and used for detecting gas pressure and pressure oscillatory wave in the cuff. The detection signal output end of the pressure sensor is connected with the signal input end of a control circuit. The control circuit executes closed-loop control on the gas in the cuff via the inflator pump, the pressure sensor and the electromagnetic valve. The healthcare therapeutic apparatus can effectively stop the limb blooding of a user at intervals by repeatedly pressing hard upon the limb of the user, thus inspiring the anti-ischemia / ischemia or oxygen deficiency resistant potential of organism tissue cells, improving the viability and operational capacity of the organism, an organ or tissues under the condition of the oxygen deficiency, having a remarkable effect on preventing cardio-cerebrovascular diseases and treating ischemic mind-brain diseases, and reducing the incidence of sudden death and stroke. Therefore, the healthcare therapeutic apparatus of the cardiovascular diseases is suitable for a family and an individual.

Owner:吉训明 +4

Nonvolatile memory element, manufacturing method thereof, design support method therefor, and nonvolatile memory device

ActiveUS8437173B2Facilitates formation of conductive pathReduce voltageSolid-state devicesSemiconductor/solid-state device manufacturingLow voltageEngineering

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

Paper pouring channel tube for casting and shaping technique thereof

InactiveCN101508005AReduce pollutionSave energyFoundry mouldsPaper recyclingFiberResource utilization

The invention relates to a paper pouring channel pipe for forging, which is made of waste paper pulp, sintered filling materials, binding materials, reinforcing agent and moisture-proof agent materials. The new concepts and mechanisms completely different from the prior art are applied to the paper pouring channel pipe, namely the pouring channel pipe is not made of the prior used refractory materials such as pottery, porcelain and the like, and non-fireproof paper pulp fibers are taken as a main component which is added with the sintered filling materials and the like, carbonized and sintered under the using conditions of high temperature and oxygen deficiency to form a carbon sinter with high fire resistance degree and the paper pouring channel pipe which achieves the molten iron scouring resistance and fire resistance degree capable of meeting the current forging process requirements. The paper pouring channel pipe has the advantages of regenerative resource utilization, no forging, energy conservation, environment pollution reduction, socket joint, no sand leakage, convenient use, little dust during cutting, light weight, little resource consumption, no easy damage at normal temperature, crispness after high temperature treatment, easy stripping, easy cleaning, little hard solid waste after pouring, abrasion reduction of a sand regenerating device, improvement on the quality of regenerated sand, reduction on the defective index of forged pieces, no carburization problem for the forged pieces, and the like.

Owner:曹敏道

Manufacturing method of semiconducter device

An IrOx film is formed as a first conductive oxide film on a PLZT film by a reactive sputtering method. Thereafter, thermal treatment by, for example, RTA is performed in an atmosphere containing oxygen having partial pressure of less than 5% of atmospheric pressure. As a result, crystallization of the PLZT film is promoted, and annealing treatment is performed for the IrOx film. Thereafter, furnace annealing at 600° C. or higher, for example, 650° C. is performed for 60 minutes in, for example, an O2 atmosphere as recovering annealing to recover oxygen deficiency in the PLZT film. Subsequently, an IrO2 film is formed as a second conductive oxide film on the IrOx film by a sputtering method.

Owner:FUJITSU SEMICON LTD

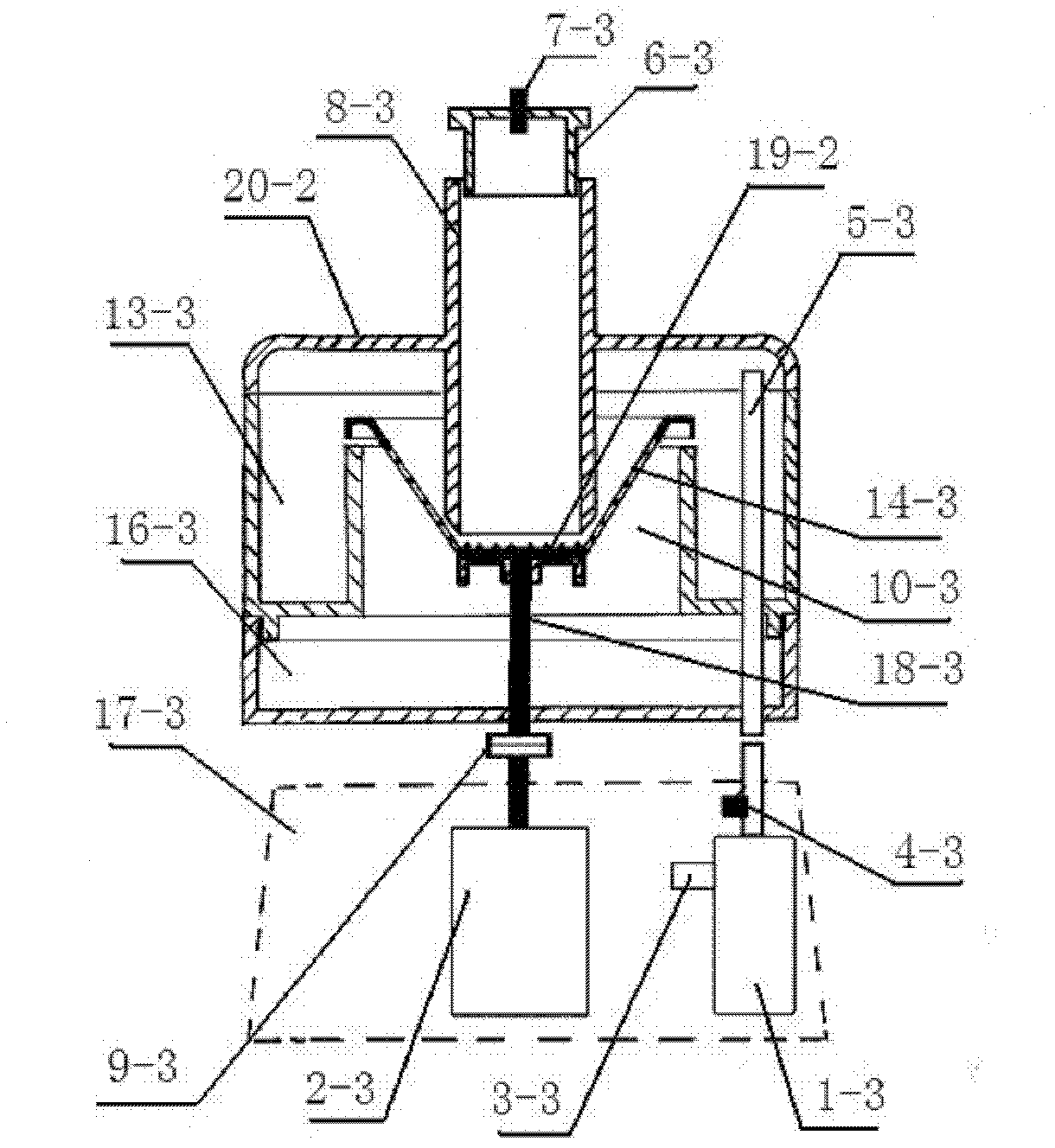

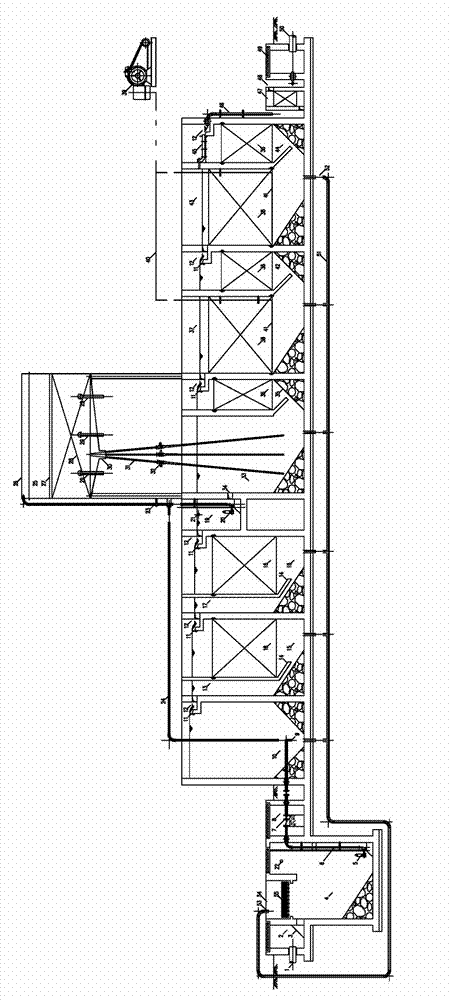

Municipal life wastewater treatment system with high efficiency and low energy consumption

ActiveCN102775025AImprove biodegradabilityHigh removal rateMultistage water/sewage treatmentFiltrationPhosphate

The invention relates to a municipal life wastewater treatment system with high efficiency and low energy consumption. The system comprises a reinforcement pretreatment part, a jet-type aeration biological filter part and a composite-type biological contact oxidation pond part. Multistage oxygen deficiency treatment, anaerobic treatment, aerobic treatment, sedimentation and filtration are adopted, reinforcement pretreatment and partial oxygen deficiency-anaerobic treatment are carried out on the wastewater, most organic pollutant can be removed and degraded, and the biodegradability of the wastewater is improved, partial aerobic treatment, oxygen deficiency treatment, anaerobic treatment, sedimentation and filtration treatment are carried out on the jet-type aeration biological filter pond, a great amount of organic pollutant, ammonia nitrogen and phosphate is removed, partial aerobic treatment, oxygen deficiency treatment, anaerobic treatment, sedimentation and filtration treatment are carried out on the composite-type biological contact oxidation pond, partial organic pollutant remained in the wastewater is removed and degraded, so that the pollutant removing rate of the domestic wastewater is improved. The system is small in occupied area, low in investment, low in operation cost and convenient in maintenance and management, and reaches the standard A of Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant (GB18918-2002).

Owner:陈秋竹

Semiconductor device

ActiveUS20110284845A1Low reliabilityImprove reliabilityTransistorSemiconductor/solid-state device detailsSemiconductorOxygen deficiency

An insulating layer containing a silicon peroxide radical is used as an insulating layer in contact with an oxide semiconductor layer for forming a channel. Oxygen is released from the insulating layer, whereby oxygen deficiency in the oxide semiconductor layer and an interface state between the insulating layer and the oxide semiconductor layer can be reduced. Accordingly, a semiconductor device where reliability is high and variation in electric characteristics is small can be manufactured.

Owner:SEMICON ENERGY LAB CO LTD

Resistance change element and semiconductor device including the same

ActiveUS20100059730A1Increase resistanceLower resistanceSolid-state devicesBulk negative resistance effect devicesElectrical resistance and conductanceOxygen deficiency

To use a resistance change element having an MIM structure, which is obtained by stacking a metal, a metal oxide, and a metal, as a switching element, it is necessary to achieve OFF resistance higher than that required in a memory element by a factor of at least 1000. On the other hand, when a resistance change element is used as a memory element and when the difference between the ON resistance and the OFF resistance is a large value, high performance, for example, a short readout time, can be achieved. The present invention therefore provides a resistance change element capable of maintaining low ON resistance and achieving high OFF resistance. High OFF resistance can be achieved while low ON resistance is maintained by adding a second metal that is not contained in a metal oxide, which is a resistance change material, the second metal being capable of charge-compensating for metal deficiency or oxygen deficiency.

Owner:NEC CORP

Planting method of submerged plants

InactiveCN103210759ASolve churnOvercomes the inability to penetrate wrapping materialsCultivating equipmentsSeaweed cultivationPlant soilObserved Survival

The invention relates to a planting method of submerged plants. According to the planting method, the submerged plants, planting soil, wrapping materials, ropes and clay are adopted. The planting method comprises the following steps of when the submerged plants are planted, wrapping stems and roots of the submerged plants by using the planting soil, wrapping the bottom of the planting soil by using the clay, and wrapping the outer sides of the planting soil and the clay by using the wrapping materials, wherein the bottoms of root systems of the submerged plants are not wrapped by the wrapping materials; and meanwhile, binding the outer sides of the wrapping materials by using the ropes, and carrying out dispersed planting on the wrapped and bound submerged plants. According to the planting method, as the wrapping materials are adopted, the loss of the planting soil after the plants are subjected to dispersed planting is overcome, so that the floating-up rate of the submerged plants is greatly reduced. As the clay is adopted for bottom sealing, the problem of loss of the planting soil after the plants are subjected to dispersed planting is solved, the defect that the root systems of the plants cannot pass through the wrapping materials is overcome, and therefore the survival rate of the submerged plants is greatly improved. The water-permeable wrapping materials are adopted, and the contact between the root systems of the plants and oxygen in water is enhanced, so that the roots of the plants cannot be rotten due to oxygen deficiency, and therefore the survival rate of the submerged plants is increased.

Owner:TONGJI UNIV +1

Semiconductor device

ActiveUS9263589B2Low reliabilityImprove reliabilityTransistorSemiconductor/solid-state device manufacturingElectricitySemiconductor

An object of the present invention is to manufacture a semiconductor device where fluctuation in electrical characteristics is small and reliability is high in a transistor in which an oxide semiconductor is used. An insulating layer from which oxygen is released by heating is used as a base insulating layer of an oxide semiconductor layer which forms a channel. Oxygen is released from the base insulating layer, whereby oxygen deficiency in the oxide semiconductor layer and an interface state between the base insulating layer and the oxide semiconductor layer can be reduced. Thus, a semiconductor device where fluctuation in electrical characteristics is small and reliability is high can be manufactured.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com