Rotary compressor

A compressor and rotary technology, used in rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve the problems of vibration in the wiring direction, broken pipes and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

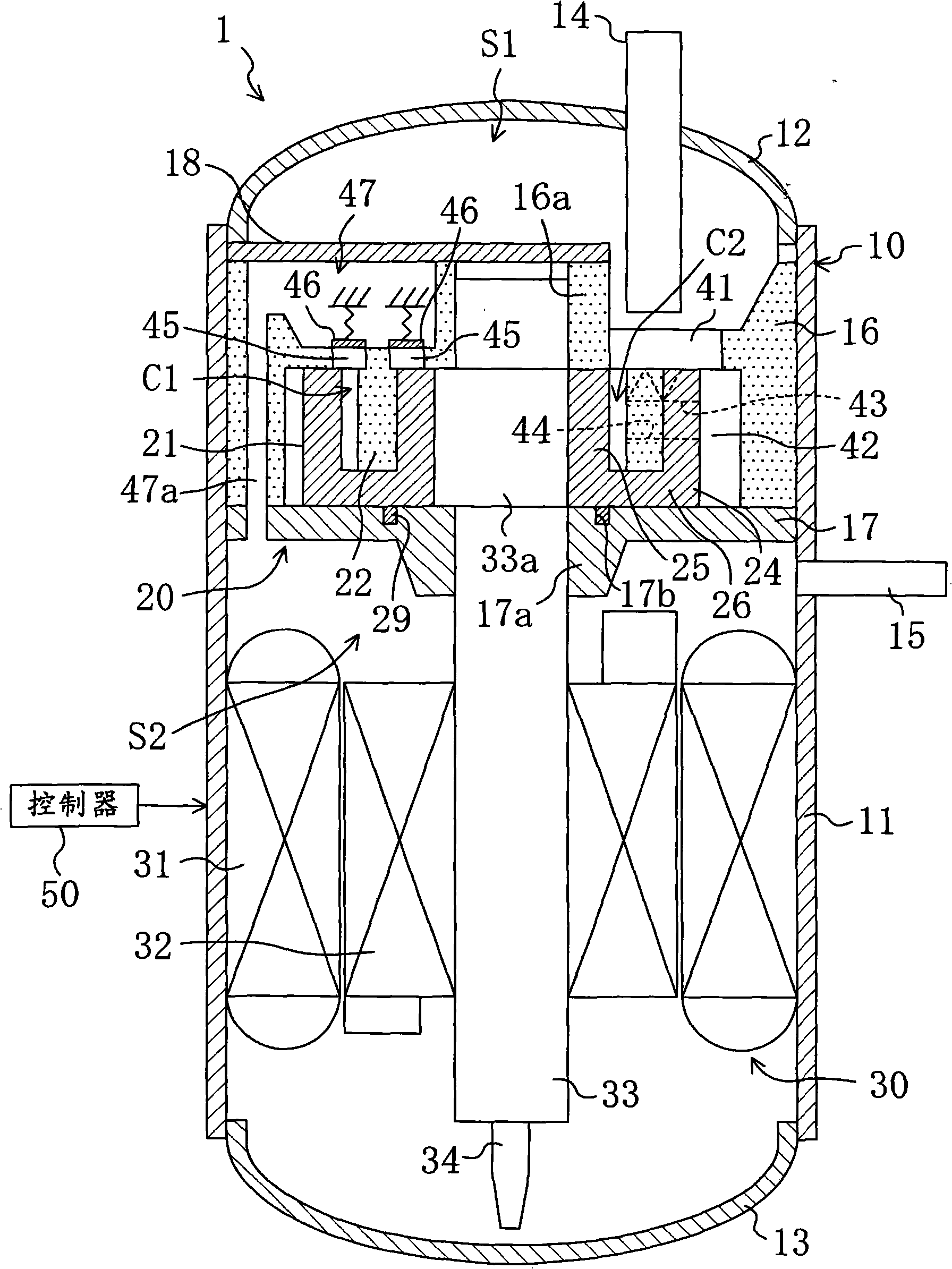

This first embodiment is as follows figure 1 The rotary compressor shown. The compressor 1 accommodates a compression mechanism 20 and a motor 30 for driving the compression mechanism 20 in a housing 10, and is configured as a fully enclosed type. The compressor 1 is used, for example, in a refrigerant circuit of an air conditioner (ari condit-ioning), to compress refrigerant sucked from an evaporator and sprayed to a condenser.

[0044] The casing 10 is composed of a cylindrical body 11 and an upper end plate 12 and a lower end plate 13 respectively fixed to the upper end and the lower end of the body 11 . The suction pipe 14 penetrates the upper end plate 12 , and the discharge pipe 15 penetrates the trunk portion 11 .

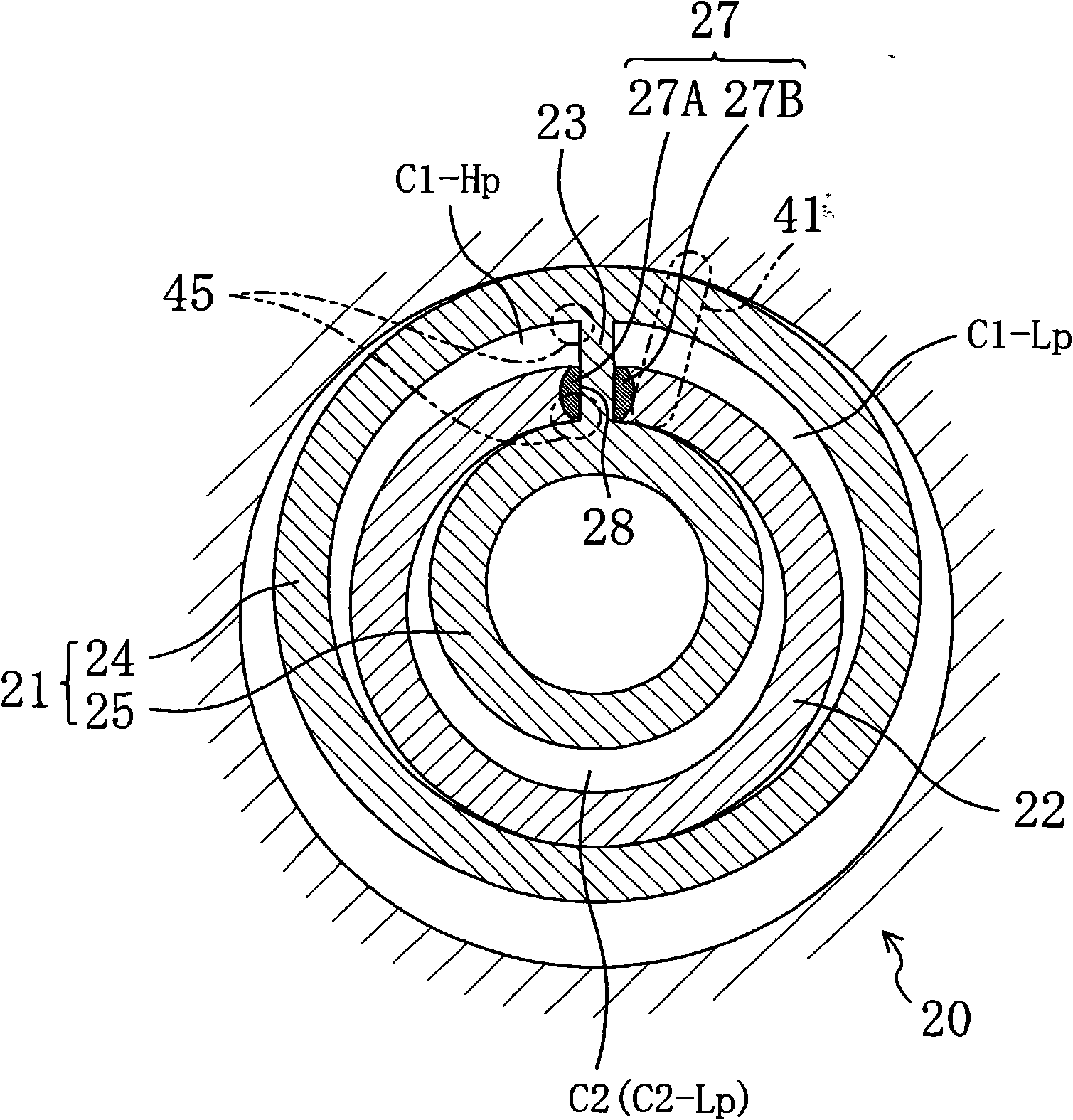

[0045] The compression mechanism 20 includes an upper cover 16 , a lower cover 17 and a cylinder 21 fixed on the casing 10 . The cylinder 21 has annular cylinder chambers C1 and C2 and is disposed between the upper cover 16 and the lower cover 17 . The u...

no. 2 approach

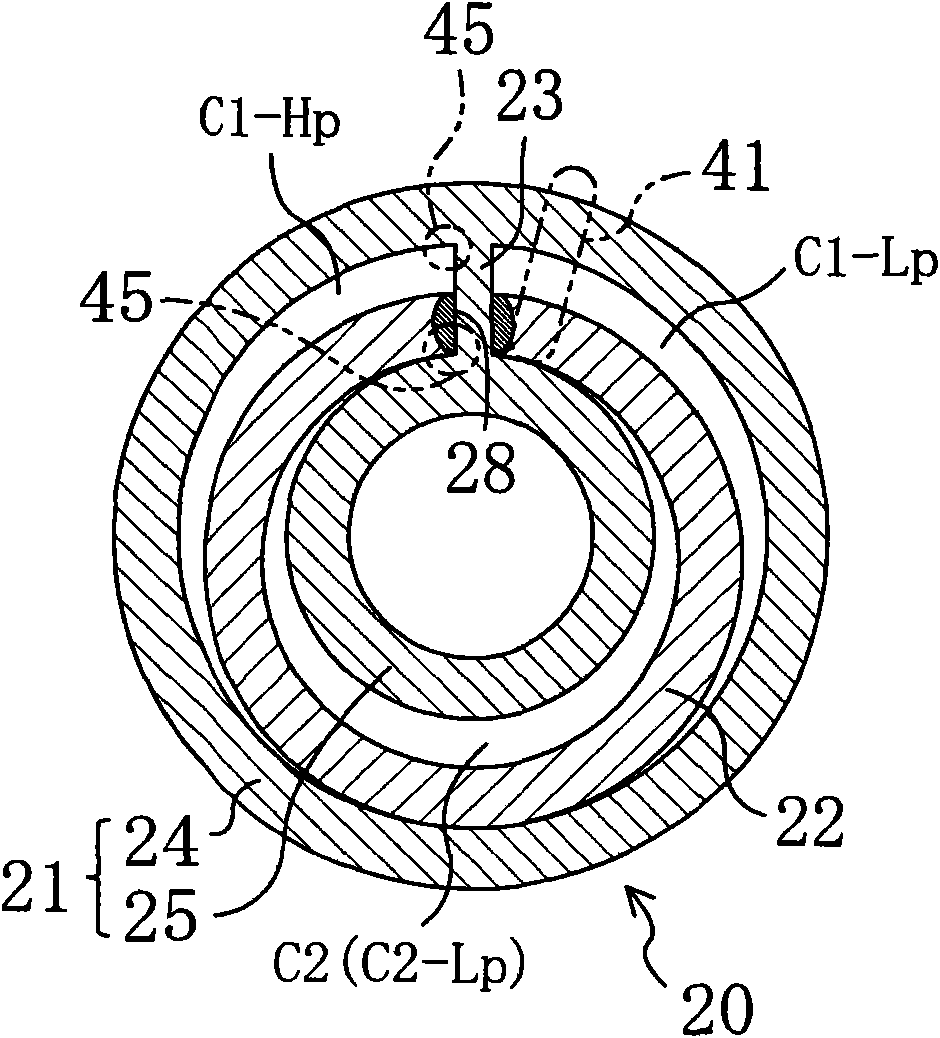

This second embodiment, such as Figure 7 and Figure 8 As shown, the configuration of the compression mechanism 20 in the first embodiment is changed. That is, in the present embodiment, the ring-shaped piston 52 is configured on the movable side and the cylinder 21 is on the fixed side, and the ring-shaped piston 52 rotates eccentrically with respect to the cylinder 21 .

[0088] The compression mechanism 20 includes an upper cover 16 and a piston body 55 . The upper cover 16 is integrally formed with the cylinder 21 . The piston body 55 is configured to rotate eccentrically relative to the cylinder 21 . In addition, in this embodiment, the lower cover 17 is omitted.

[0089] The cylinder 21 includes an annular outer cylinder portion 24 and an inner cylinder portion 25 formed coaxially with each other. The outer cylinder portion 24 and the inner cylinder portion 25 are provided on the lower surface of the end plate 26 of the upper cover 16 . Also, annular cylinder chamb...

no. 3 approach

This third embodiment, such as Figure 10 and Figure 11 As shown, the compression mechanism 20 of the first embodiment is configured to perform two-stage compression of refrigerant. That is, in the compression mechanism 20 of this embodiment, the outer cylinder chamber C1 constitutes the low-stage compression chamber, and the inner cylinder chamber C2 constitutes the high-pressure side compression chamber.

[0099] The compressor 1 is used, for example, to use carbon dioxide (CO 2) is a refrigerant, a refrigerant circuit that performs a cycle of two-stage compression and one-stage expansion. Although not shown in the figure, this refrigerant circuit is connected by refrigerant piping in order of a compressor 1 , a gas cooler, a receiver, an intercooler, an expansion valve, and an evaporator. In this refrigerant circuit, the high-pressure refrigerant discharged from the inner cylinder chamber C2 of the compressor 1 flows in the order of the radiator, liquid receiver, expansi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com