Separate low pressure coal economizer of elliptical fin heat pipe

A low-pressure economizer and elliptical fin technology, which is applied in the field of boiler waste heat recovery and energy-saving equipment, can solve the problems of boiler low-pressure economizer tube row wear, large heat exchanger volume, and high resistance, so as to improve cycle heat efficiency and heat transfer Good performance and low flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

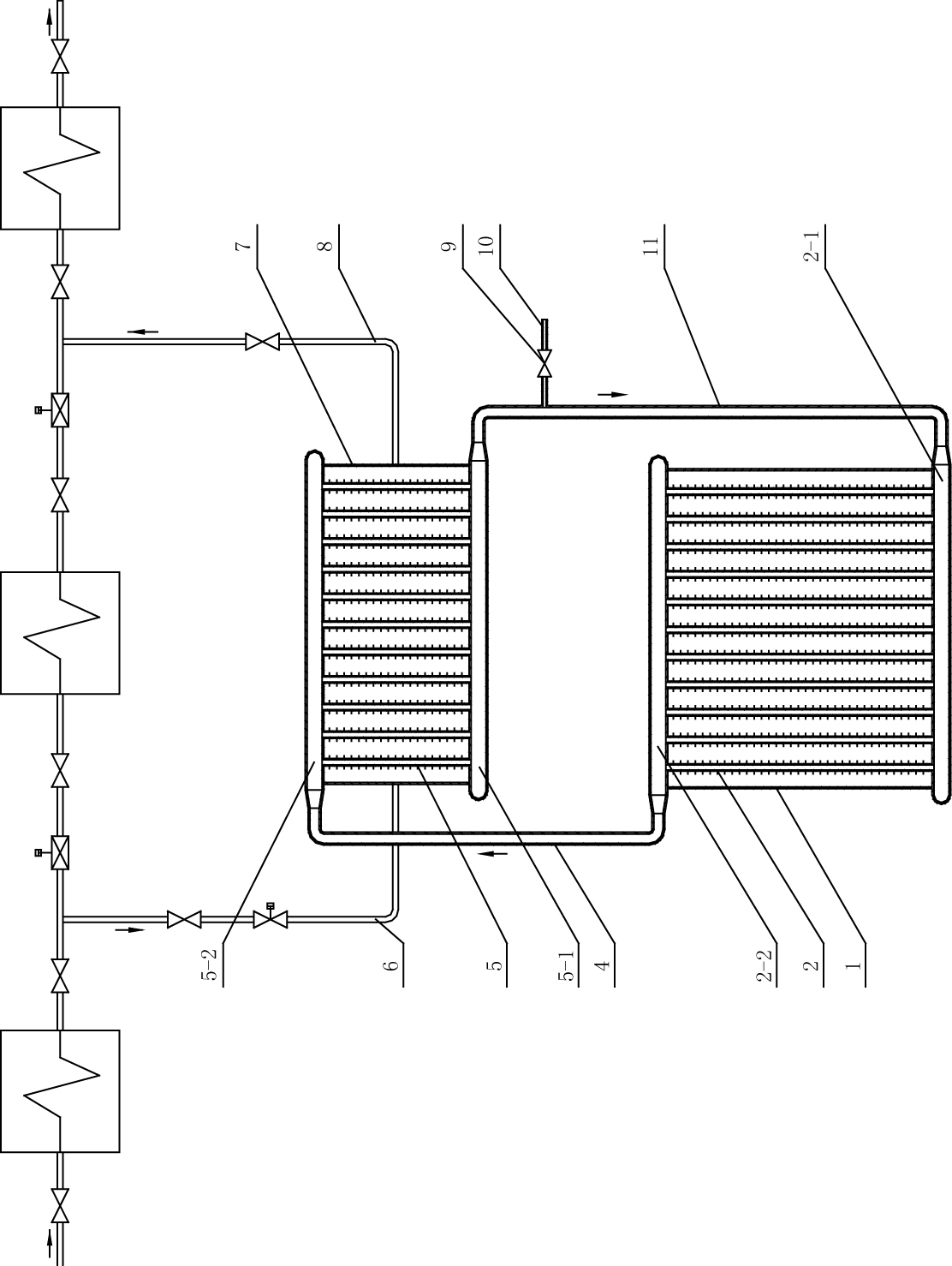

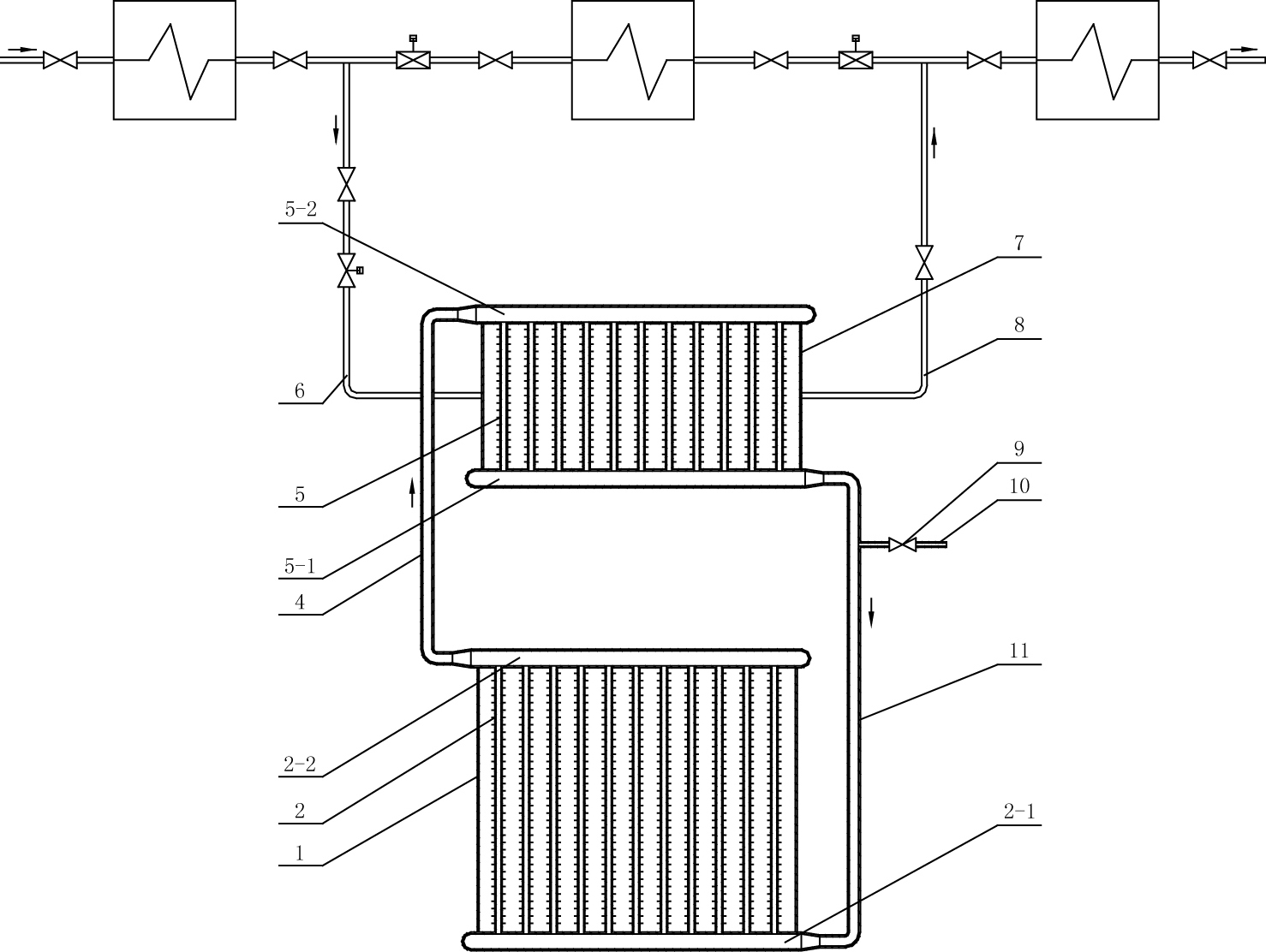

[0008] Specific implementation mode 1: Combination figure 1 The low-pressure economizer of the separated elliptical fin heat pipe of this embodiment includes an elliptical fin heat pipe evaporation section tube panel 2, an elliptical fin heat pipe condensing section tube panel 5, a steam air duct 4, and a return pipe 11. The tube panel 2 of the evaporation section of the finned heat pipe is composed of a number of parallel elliptical fin heat pipes, a condensate inlet header 2-1 and a steam outlet header 2-2. Each of the elliptical finned heat pipe evaporation section tube panels 2 The two ends of the elliptical fin heat pipe are respectively communicated with the condensate inlet header 2-1 and the steam outlet header 2-2. The elliptical fin heat pipe condensation section tube panel 5 is composed of a plurality of parallel elliptical fin heat pipes and condensation The water outlet header 5-1 and the steam inlet header 5-2 are composed. The two ends of each oval fin tube in th...

specific Embodiment approach 2

[0009] Specific implementation manner two: combination figure 1 The low-pressure economizer of the separated elliptical fin heat pipe of this embodiment will be described. It also includes an exhaust pipe 10 and an exhaust valve 9. The exhaust valve 9 is arranged on the exhaust pipe 10, and the exhaust pipe 10 is located on the water pipe. 11 is above and communicates with the water pipe 11. The non-condensable gas in the condensation section can be released through the exhaust pipe 10 to ensure the heat transfer performance of the separated heat pipe. The other components and connection relationships of this embodiment are the same as those of the first embodiment.

specific Embodiment approach 3

[0010] Specific embodiment 3: In the separated elliptical fin heat pipe low-pressure economizer of this embodiment, the elliptical fin heat pipe is a copper tube or a steel pipe. The other components and connection relationships of this embodiment are the same as those of the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com