Waste heat recovery and comprehensive utilization system of industrial furnace group

A waste heat recovery and industrial furnace technology, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problem of unbalanced waste heat recovery and waste heat utilization, achieve timely and flexible heat collection, high heat exchange efficiency, and equipment use long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

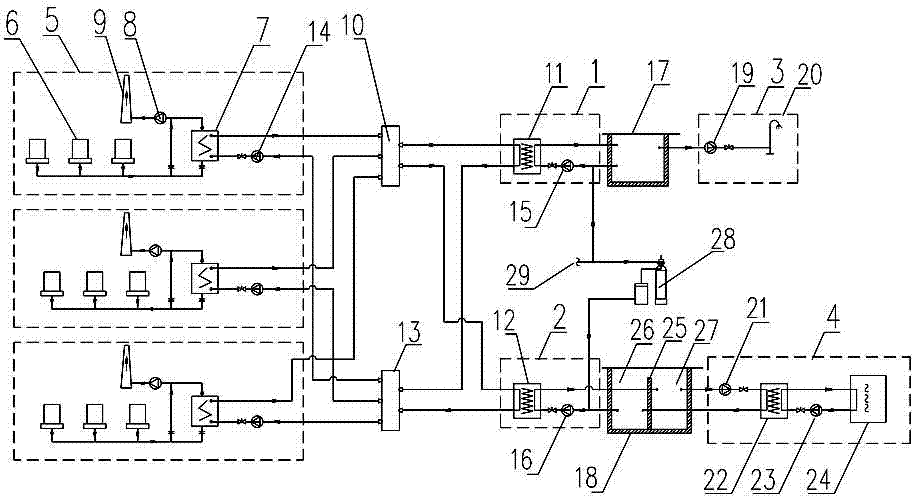

[0021] Such as figure 1 As shown, the industrial furnace group waste heat recovery comprehensive utilization system according to the present invention includes heat collection units, first and second heat exchange units 1, 2, first and second heat supply units 3, 4; The unit is composed of a plurality of heat collection subunits 5 connected in parallel; each of the heat collection subunits 5 includes a plurality of flame kilns 6 using gas, fuel oil or / and coal as raw materials, and the plurality of kiln furnaces 6 The smoke outlets are collected by pipes and then communicated with the chimney 9 through the heat pipe heat exchanger 7 hot fluid passages and the induced draft fan 8; The inlet of the water tank 10 is connected; the outlet of the water collector 10 is respectively connected with the inlets of the heat fluid channels of the plate heat exchangers 11 and 12 of the first and second heat exchange units 1 and 2 through pipes, and the first and second heat exchangers The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com