Method for preparing NaY zeolite

A technology of zeolite and zeolite directing agent, which is applied in the field of inorganic non-metal, can solve the problems of low zeolite output, high energy consumption, equipment corrosion, etc., and achieve the effects of high crystallinity, high whiteness and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

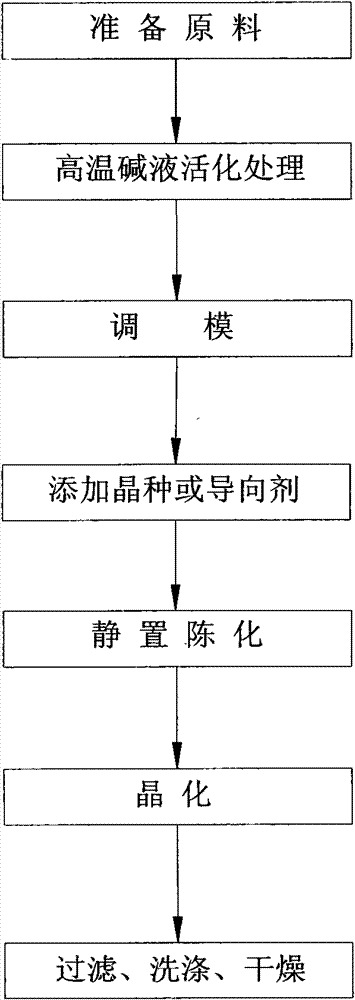

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Using bentonite from Liaoning as raw material, its components and the contents of each component are: SiO 2 =71.96%; Al 2 o 3 = 15.04%; Fe 2 o 3 = 0.23%; TiO 2 =0.11%; CaO=1.02%; MgO=2.69%; Na 2 O = 1.14%; K 2 O = 0.86%; H 2 O = 5.52%.

[0033] First, add 680 grams of bentonite that has been prepared into the sodium hydroxide solution. The sodium hydroxide solution is made by dissolving 360 grams of sodium hydroxide in 2000 ml of water. After stirring evenly, place it in a high-pressure reactor. Stir for 5 hours under the condition of 150°C, then cool down to below 50°C, add 1500 ml of water, stir for 10 minutes, so that the molar ratio between the materials in the lye is: Na 2 O:Al 2 o 3 : SiO 2 :H 2O=4.5:1:8.1:200 to prepare NaY zeolite. Then add 350 ml of NaY zeolite structure-directing agent, stir for 30 minutes, stop stirring, let stand and age for 6 hours, then start stirring, raise the temperature to 100°C, crystallize for 12 hours, filter...

Embodiment 2

[0034] Embodiment 2: the bentonite raw material that adopts is the same as embodiment 1. The difference between this embodiment and embodiment 1 is that the temperature conditions of the high-temperature lye activation treatment are different, that is, the temperature conditions in the autoclave are different from those of embodiment 1.

[0035] First, add 680 grams of bentonite that has been prepared into the sodium hydroxide solution. The sodium hydroxide solution is made by dissolving 360 grams of sodium hydroxide in 2000 ml of water. After stirring evenly, place it in a high-pressure reactor. Stir for 5 hours at 200°C, then cool down to below 50°C, add 1500 milliliters of water (the molar ratio conditions are the same as in Example 1), and stir for 10 minutes; add 350 milliliters of directing agent, stop stirring after 30 minutes, and let Set aside to age for 6 hours, then start stirring, raise the temperature to 100°C, crystallize for 12 hours, filter after cooling, wash, ...

Embodiment 3

[0036] Embodiment 3: the bentonite raw material that adopts is the same as embodiment 1.

[0037] First, add 680 grams of bentonite that has been prepared into the sodium hydroxide solution. The sodium hydroxide solution is made by dissolving 400 grams of sodium hydroxide in 2000 ml of water. After stirring evenly, place it in a high-pressure reactor. Stir for 5 hours at 200°C, then cool down to below 50°C, add 2500 ml of water, stir for 10 minutes, so that the molar ratio between the materials in the lye is: Na 2 O:Al 2 o 3 : SiO 2 :H 2 O=5:1:8.1:250 to prepare NaY zeolite. Then add 500 ml of NaY zeolite structure directing agent, stir for 30 minutes, stop stirring, let stand and age for 6 hours, then start stirring, raise the temperature to 100°C, crystallize for 12 hours, filter and wash after cooling, and then After drying, the finished product of NaY zeolite is obtained. The product is detected by "X-ray diffraction analysis", and the crystallinity of the sample is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com