Preparation method of rice straw black carbon

A technology of rice straw and black carbon, which is used in carbon preparation/purification, special form dry distillation, petroleum industry, etc., can solve problems such as equipment corrosion, waste of resources and environment, and secondary environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

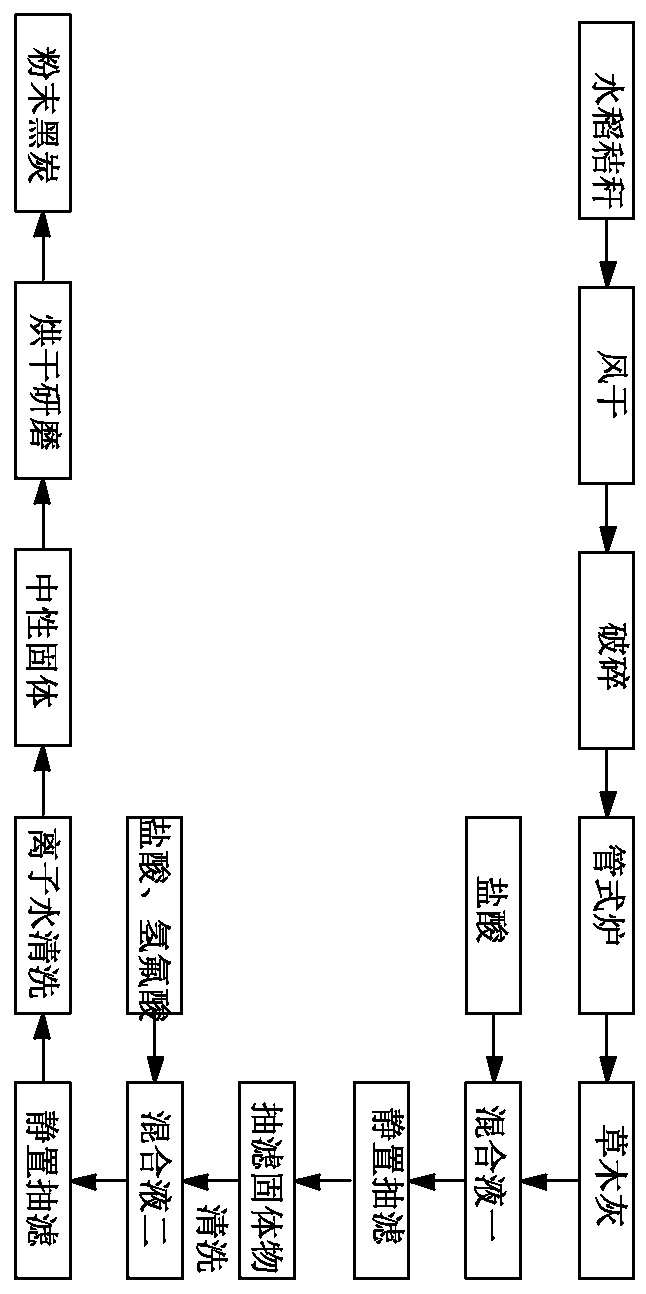

[0013] The present invention will be further described below in conjunction with the drawings:

[0014] Such as figure 1 A method for preparing rice straw black charcoal includes the following steps: (1) the rice straw is sent into a tube furnace for thermal decomposition to obtain plant ash; (2) the plant ash is added with hydrochloric acid to obtain a mixed liquid one; (3) ), the mixed liquid is subjected to static suction filtration to obtain the suction-filtered solid; (4), the solid is suction-filtered for cleaning, and hydrofluoric acid and hydrochloride are added to obtain the mixed liquid two (5), and the mixed liquid two is subjected to static suction The solids obtained after filtration are washed with ionized water to obtain neutral solids; (6). The central neutral solid is dried and ground to obtain powdered black carbon; the rice straw is air-dried and crushed and then sent to the tube furnace; hydrochloric acid and hydrogen Fluoric acid is mixed and added in a rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com