Bio-organic fertilizer capable of efficiently degrading full-biodegradable mulching film with PBAT and starch as raw materials and preparation method of bio-organic fertilizer

A technology for bio-organic fertilizer and degrading plastic film, which is applied in the field of bio-organic fertilizer preparation, can solve the problems of affecting farmland soil quality, uncontrollable degradation speed of fully biodegradable plastic film, and high recovery cost, achieving obvious promotion effect and reducing crop production cost. , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

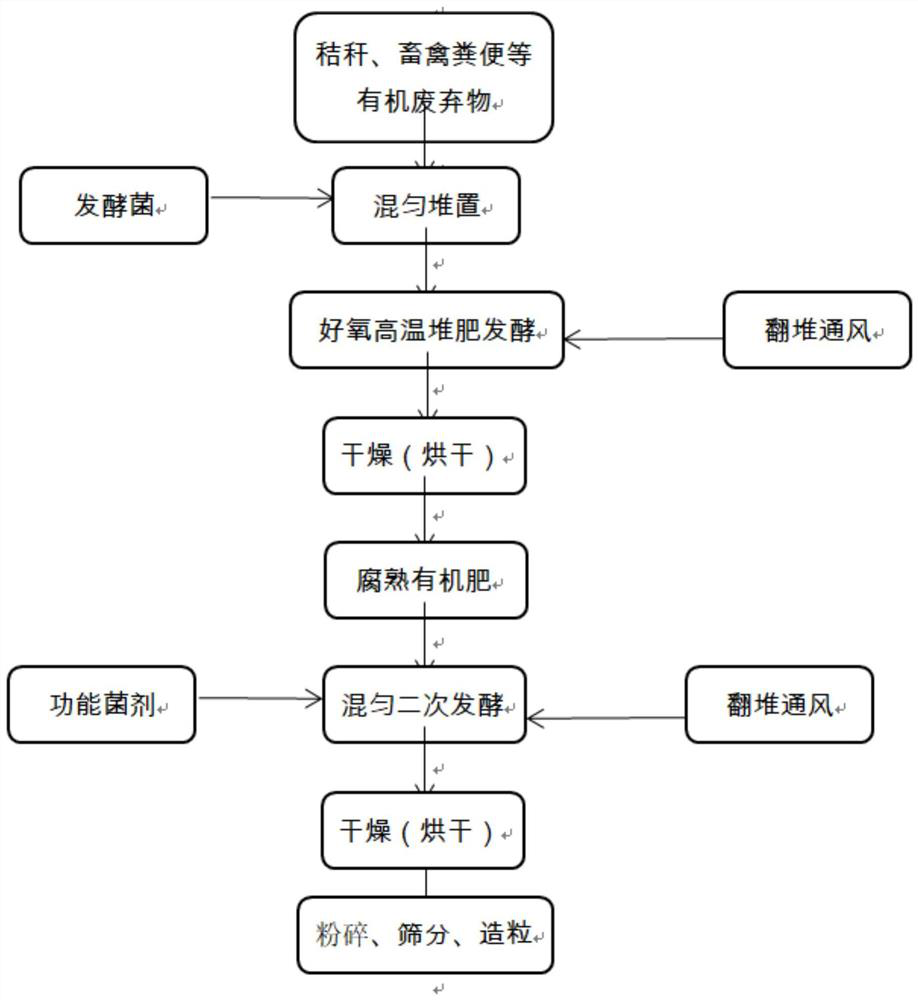

[0033] Such as figure 1 As shown, a method for preparing a bio-organic fertilizer with high-efficiency degradation to the full biodegradable mulch film with PBAT and starch as raw materials may include the following steps:

[0034] Step (1): The raw material straw is pulverized into 1-3 cm and mixed evenly with animal manure, urea, trace elements and antiviral agent in parts by weight of 18:25:4:1:1. The antiviral agent used in the present invention was purchased from Zhongnong Lvkang (Beijing) Biotechnology Co., Ltd.

[0035] Step (2): Take the material obtained in step (1), add 7 parts of fermentation bacteria and a pH regulator and mix evenly, adjust the pH to 6-8, and stack in strips.

[0036]Step (3): Take the material obtained in step (2) and carry out aerobic high-temperature composting fermentation, the water content is 50% to 60%, the highest fermentation temperature is 40 to 65°C, the fermentation time is 15 days, and the compost is turned every 4 days 1 time.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com