Process for purifying calcium fluoride from floated fluorite mine

A technology for purifying calcium fluoride from fluorite ore after flotation, applied in the direction of calcium/strontium/barium fluoride, calcium/strontium/barium halide, etc. Low content, unable to meet the quality standards of calcium fluoride for nuclear use, etc., to achieve the effect of simple process and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

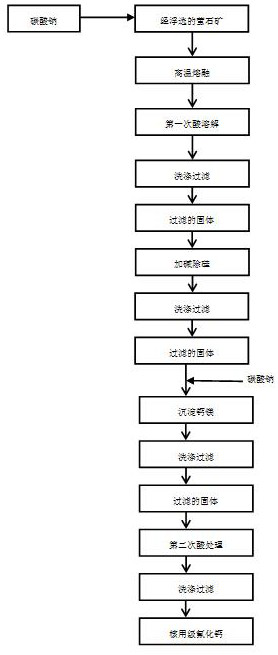

Image

Examples

Embodiment Construction

[0015] A process for purifying calcium fluoride from fluorite ore after flotation, comprising the following steps:

[0016] (1) Evenly mix the flotation fluorite ore powder with anhydrous sodium carbonate, and the mass of anhydrous sodium carbonate powder is 10% of the mass of fluorite powder.

[0017] (2) First cover a layer of sodium carbonate powder with a thickness of 3mm on the bottom of the nickel plate, then cover a layer of flotation fluorite powder and sodium carbonate powder mixture with a thickness of 75mm on the sodium carbonate powder, and finally cover the mixture with another layer Sodium carbonate powder with a thickness of 2mm; put the nickel plate into a high-temperature furnace to heat up at a heating rate of 10°C / min, heat to 840-860°C, keep the temperature constant for 3-6 hours, cool to room temperature naturally, and break to 200 meshes.

[0018] (3) Add the crushed fluorite powder to a hydrochloric acid solution with a concentration of 20% and a volume ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com