Ceramic rolling device and method

A technology of ceramic rollers and ceramics, applied in the field of materials, can solve the problems of lack of plastic deformation and limited processing of ceramic materials, and achieve the effect of simple devices and steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

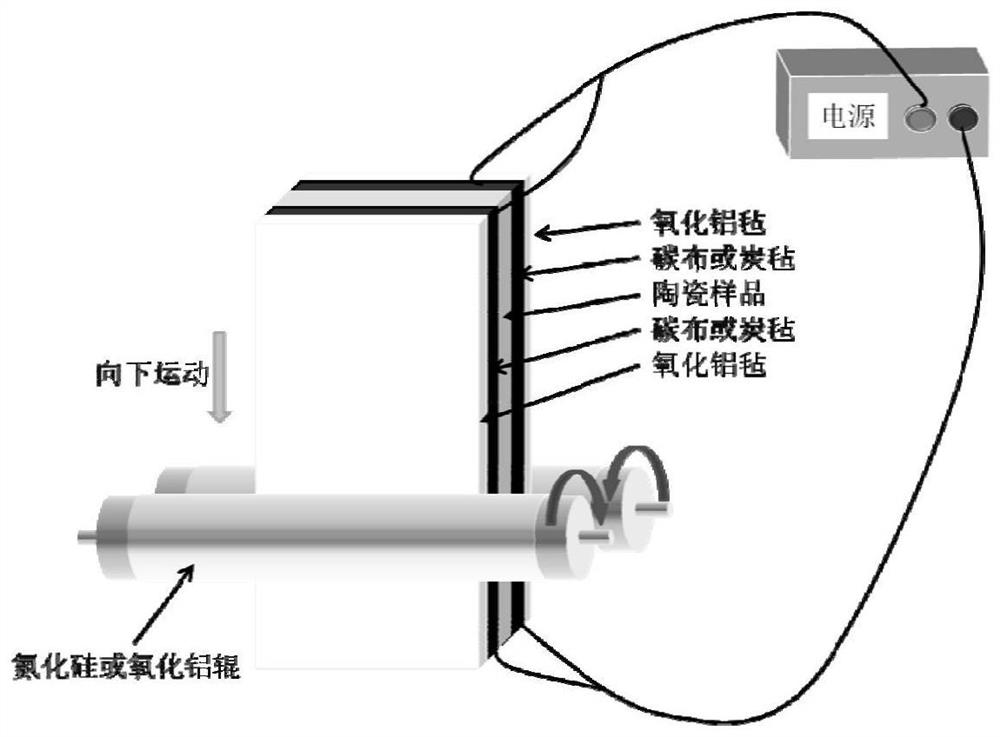

[0033] The vertically placed ceramics are rolled by the front and rear two pressing rolls in the ceramic rolling device. The material of the pressure roller is silicon nitride ceramics, and the dimensional accuracy is ±0.02mm. The double roller spacing of the roller press is adjustable from 0-5mm, and the accuracy is ±0.1mm. The length of the pressing roller is 100mm. The rotational speed of the roller press is 0-10 rpm. Among them, the ceramic to be rolled is a zirconia ceramic plate, the purpose of which is to roll the zirconia ceramic plate, plastic deformation occurs, the thickness is reduced, and the length and width are changed accordingly. Specific methods include:

[0034] 1. Place the zirconia between two carbon cloths, and then between two larger alumina felts, so that the carbon cloth will not directly contact the ceramic roller. The size of the zirconia plate is 10×1×100mm; the carbon cloth is 20mm wide and 150mm long, which can wrap the zirconia plate; the wid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com