Process for preparing high-density zirconium diboride blocks by spark plasma sintering

A technology of discharge plasma and diboration, which is applied in the direction of chemical instruments and methods, boron/boride, metal boride, etc., can solve the problems of low relative strength, high cost, and difficult sintering, so as to shorten the sintering time, Low energy consumption and time consumption, high-efficiency sintering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

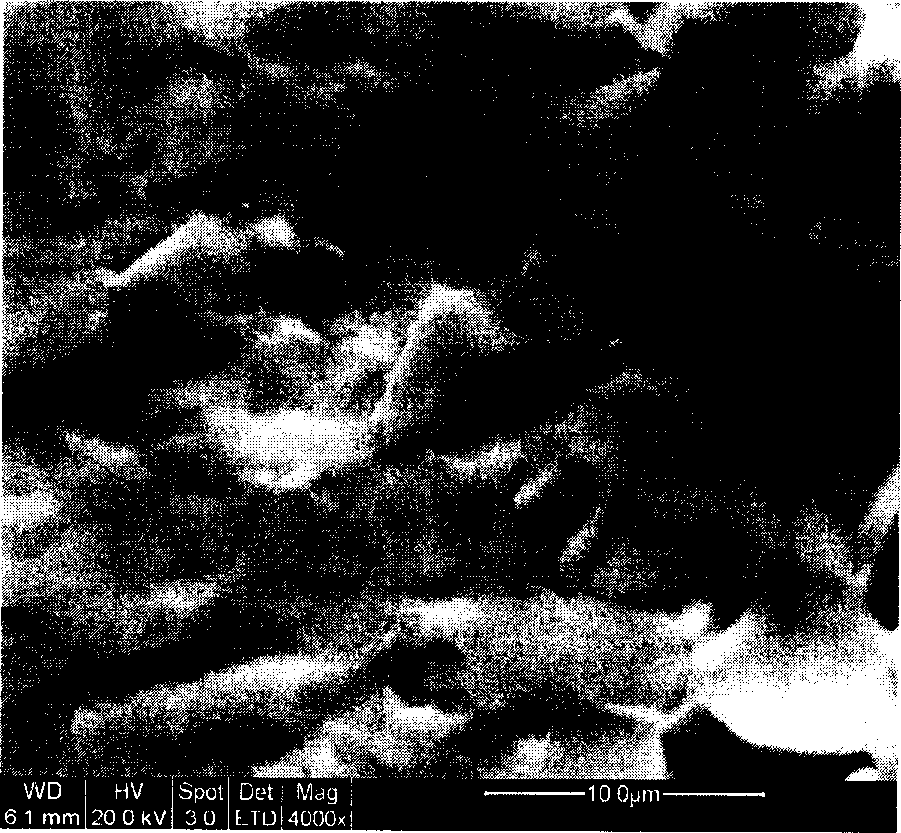

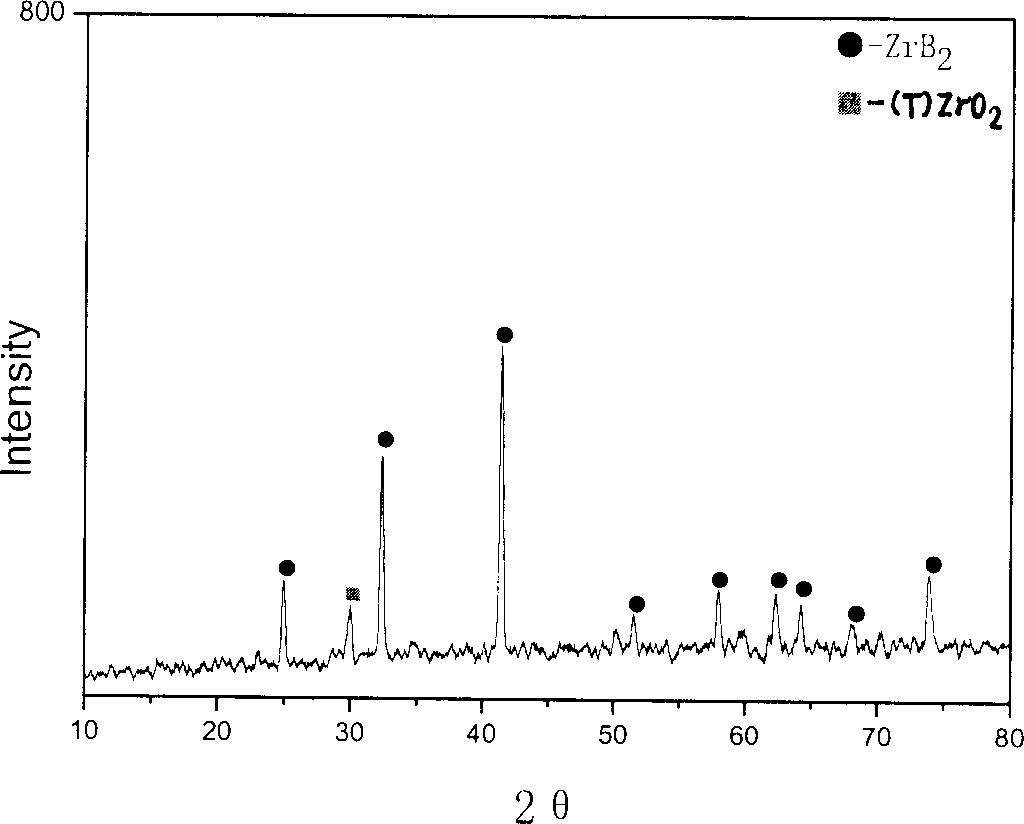

[0022] 1), Coated ZrB 2 Preparation of composite powder:

[0023] 3 g ZrB 2 Add the powder into 200ml of water, ultrasonically disperse for 5 minutes, and stir evenly to obtain ZrB 2 A slurry of powder and water; drop 200ml of 0.05mol / L zirconium hypochlorite solution into the slurry at a constant speed for 120 minutes, and drop the precipitant ammonia water with pH=11 at the same time to adjust ZrB 2 The pH value of the slurry is always 9, and the stirrer is used to stir continuously. After the zirconium hypochlorite solution is added dropwise, the stirring is continued for 1 hour, and the pH value is kept at 9, and the precursor coated ZrB of the coating layer is obtained. 2 The composite powder of the powder; the composite powder was washed three times and once with deionized water and absolute ethanol respectively, then dried at 100°C and calcined at 600°C to obtain ZrO 2 Coated ZrB 2 Coated ZrB powder particles 2 Composite powder. Coated ZrB 2 The thickness of the ...

Embodiment 2

[0027] 1), Coated ZrB 2 Preparation of composite powder:

[0028] 3 g ZrB 2 Add the powder into 200ml of water, ultrasonically disperse for 5 minutes, and stir evenly to obtain ZrB 2 Slurry of powder and water; drop 300ml of mixed solution (150ml of 0.12mol / L aluminum nitrate and 150ml of 0.2mol / L yttrium nitrate) into the slurry at a constant speed in 180 minutes, and drop the precipitant of pH=11 at the same time Ammonia regulates ZrB 2 The pH value of the slurry is always 9. Stir continuously with a stirrer. After the mixed solution is added dropwise, continue to stir for 1 hour, and keep the pH value at 9 to obtain the precursor of the coating layer coated ZrB 2 The composite powder of the powder; the composite powder was washed three times and once with deionized water and absolute ethanol respectively, then dried at 80°C and calcined at 500°C to obtain Al 2 o 3 and Y 2 o 3 co-coated ZrB 2 Coated ZrB powder particles 2 Composite powder. Coated ZrB 2 The thickne...

Embodiment 3

[0032] Get 2.0g coated zirconium diboride composite powder (the coating layer is 10% ZrO 2) into a graphite mold with an inner diameter of 10 mm, and the surrounding and upper and lower surfaces are lined with graphite paper, and the powder is compacted with an axial pressure of 30 MPa, and the pressure is maintained for 10 minutes. Put the pre-compressed mold into the spark plasma sintering equipment, apply an axial pressure of 50MPa, and under the protection of an inert atmosphere, raise the temperature to 1600°C at a heating rate of 50°C / min for 5 minutes, then cool with the furnace. The density of the sintered zirconium diboride bulk material is 97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com