A growth type polycrystalline diamond sintered component and its application

A polycrystalline diamond, growth-type technology, applied in the field of superhard materials, can solve the problem that the diamond layer cannot be sintered, and achieve the effects of uniform residual stress distribution, strong operability, and stable temperature field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

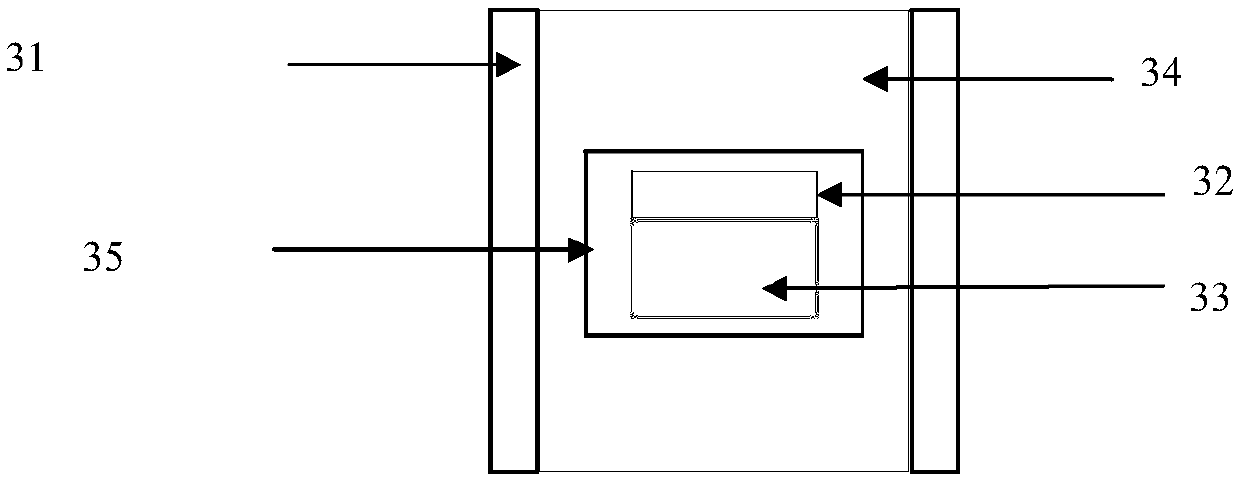

[0032] Such as image 3 As shown, in this embodiment, the sintered component used includes a heating tube 31, a metal adhesive layer 32, a diamond layer 33, an insulating tube 34, and an infiltration cavity 35.

[0033] In an implementation of this embodiment, the heating tube 31 is cylindrical, and the cylindrical heating tube 31 is located at the outermost layer of the sintering assembly. The height of the heating tube is preferably selected to be 1.2 to 10 cm. The outer diameter and height of the heating tube depend on the high-pressure space provided by the high-pressure equipment. If the space is large, the heating tube can be enlarged accordingly. The wall thickness of the heating tube 31 is selected to be between 0.15-1 cm. The upper and lower ends of the heating tube can be respectively covered with a number of conductive heating sheets, the diameter of which is equal to the outer diameter of the heating tube.

[0034] The insulating tube 34 is located inside the heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| residual stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com