A kind of room temperature sintering method of nano-silver clad copper conductive ink

A technology of conductive ink and sintering method, which is applied in ink, household utensils, applications, etc., can solve the problems of limited substrate protection, and achieve the effects of large-scale production and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Disperse silver-coated copper nanoparticles with a diameter of 11nm (prepared according to ZL201611072652.1 method) in n-octane, prepare an ink with a solid content of 30w%, put it into an ultrasonic cleaner for 2 hours, and obtain a yellow-brown ink .

[0025] (2) Take an appropriate amount of ink on the polyethylene terephthalate (PET) film, and use the preparer to coat the film.

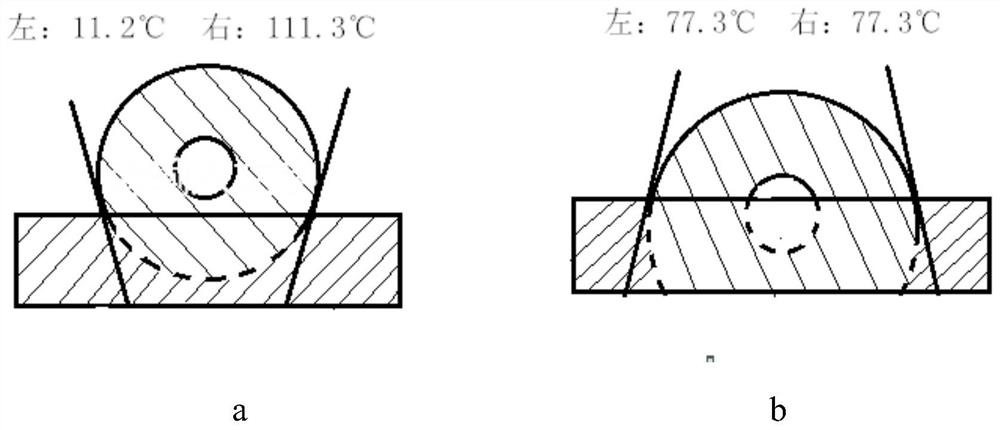

[0026] (3) Soak the film prepared in step (2) in a methanol solution of 10v% 1-amino-2-propanol for 1 min, and use alcohol amine to replace the oleylamine on the surface of the particles, so that the surface of the film changes from hydrophobic to Hydrophilic. Then wash with methanol 3 times and wipe dry.

[0027] (4) Repeat steps (2) and (3) for 3 coatings;

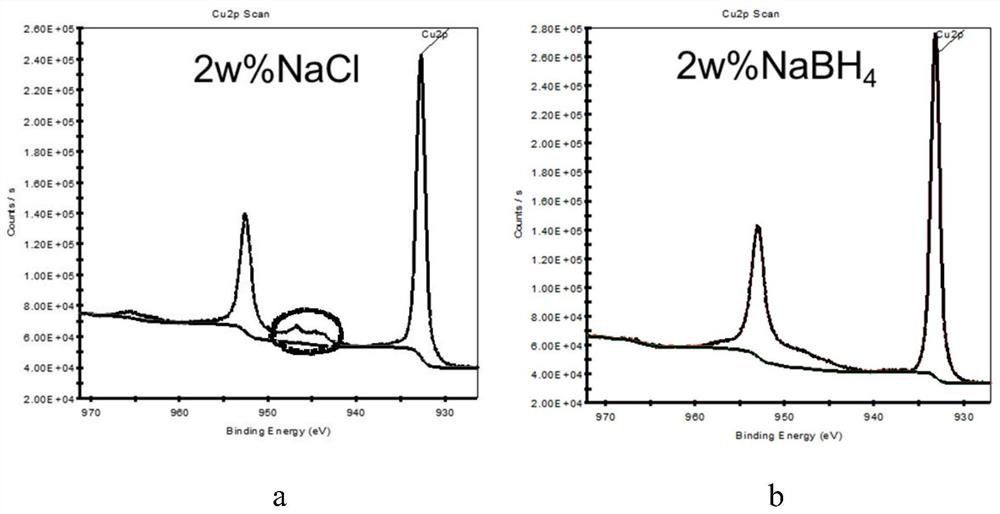

[0028] (5) Soak the film in step (4) in 2w% NaCl solution for 3 minutes, then wash it with water for 3 times, and dry it.

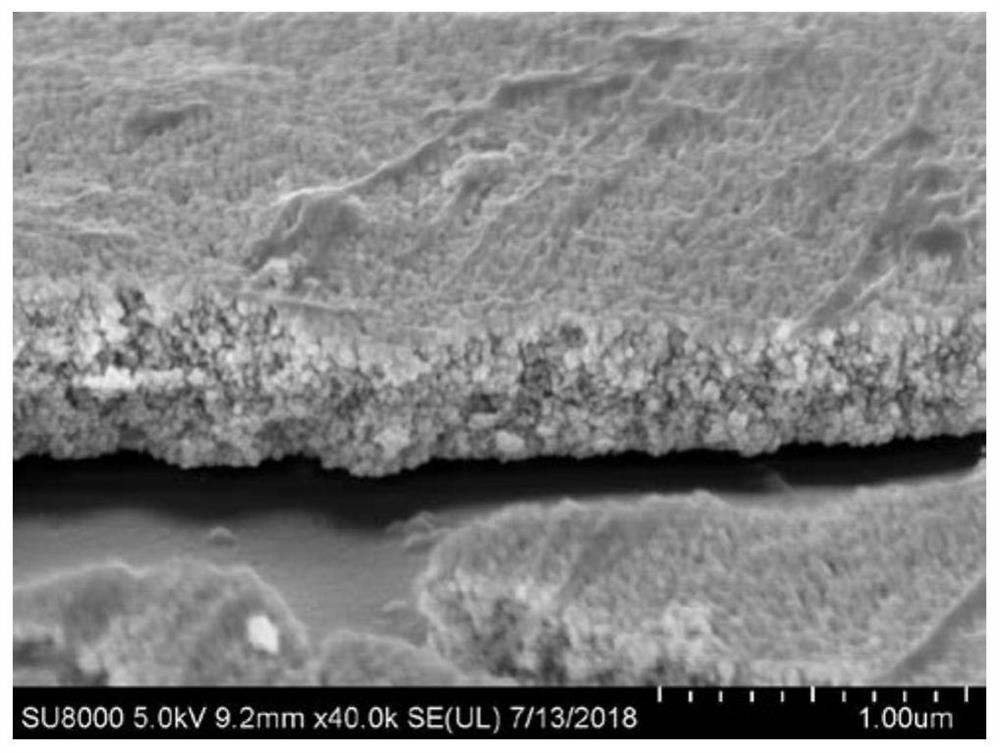

[0029] (6) The sheet resistance of the film measured by a four-probe tester is 10 Ω / □, the film thickn...

Embodiment 2

[0032] (1) Disperse silver-coated copper nanoparticles (ZL201611072652.1) with a diameter of 11nm in n-octane to prepare an ink with a solid content of 30w%, put it into an ultrasonic cleaner for 2 hours, and obtain a yellow-brown ink.

[0033] (2) Take an appropriate amount of ink on the polyethylene terephthalate (PET) film, and use the preparer to coat the film.

[0034] (3) Soak the film prepared in step (2) in a methanol solution of 10v% 1-amino-2-propanol for 1 min, and use alcohol amine to replace the oleylamine on the surface of the particles, so that the surface of the film changes from hydrophobic to Hydrophilic. Then wash with methanol 3 times and wipe dry.

[0035] (4) Repeat steps (2) and (3) for 2 coatings;

[0036] (5) Dissolving NaBH4 in NaOH solution with pH=12 to obtain NaBH4 solution with a mass fraction of 2w%.

[0037] (6) Soak the film of step (4) in the NaBH4 solution of step (5) for 3 minutes, then wash it with water for 3 times, and dry it.

[0038...

Embodiment 3

[0042] (1) Disperse silver-coated copper nanoparticles (ZL201611072652.1) with a diameter of 11nm in n-octane to prepare an ink with a solid content of 30w%, put it into an ultrasonic cleaner for 2 hours, and obtain a yellow-brown ink.

[0043] (2) Take an appropriate amount of ink on the PET film, and use the preparer to coat the film.

[0044] (3) Soak the film prepared in step (2) in a methanol solution of 10v% 1-amino-2-propanol for 1 min, and use alcohol amine to replace the oleylamine on the surface of the particles, so that the surface of the film changes from hydrophobic to Hydrophilic. Then wash with methanol 3 times and wipe dry.

[0045] (4) Repeat steps (2) and (3) for 3 coatings;

[0046] (5) Dissolving NaBH4 in NaOH solution with pH=12 to obtain NaBH4 solution with a mass fraction of 2w%.

[0047] (6) Soak the film of step (4) in the NaBH4 solution of step (5) for 2 minutes, then wash it with water for 3 times, and dry it.

[0048] (7) The sheet resistance of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com