A kind of coal pyrolysis equipment

A coal pyrolysis and equipment technology, applied in special forms of dry distillation, petroleum industry, coke ovens, etc., can solve the problems of energy waste, low degree of automation, low dust removal efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

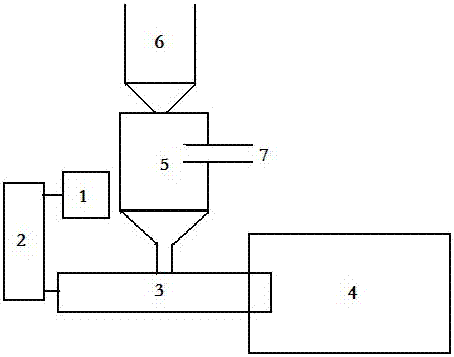

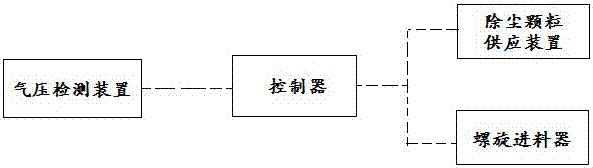

[0016] Such as figure 1 As shown, the motor 1 drives the reduction gearbox 2 to provide power for the whole device. The reduction gearbox drives the screw feeder 3 to transport the coal to the coal pyrolysis device 4 . The coal pyrolysis device 4 pyrolyzes the coal, and the generated gas enters the dust remover 5 and contacts with the dust removal particles supplied by the dust removal particle supply device 6, thereby removing dust pollutants in the gas. Coal ash is used for dust removal particles, and the cleaned gas is discharged through the conveying pipeline 7, while the dust removal particles after absorbing dust enter the screw feeder 3 and enter the coal pyrolysis device 4 again. The dust collector 5 is a moving bed dust collector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com