Patents

Literature

47results about How to "Easy to cause secondary pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

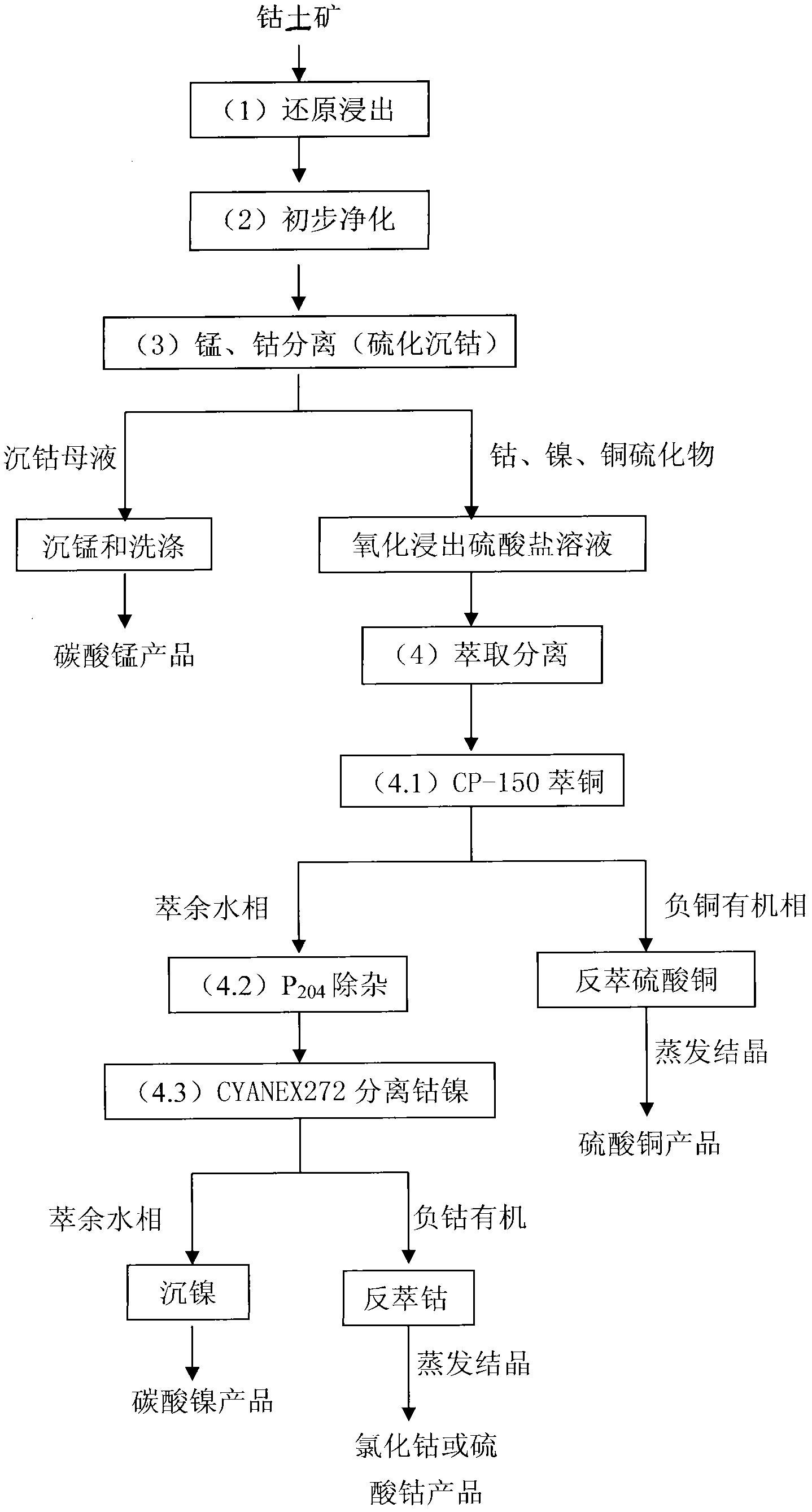

Processing method for comprehensively recovering high manganese asbolite

InactiveCN102021331AIncrease costLow recovery rateProcess efficiency improvementManganeseHydrometallurgy

The invention discloses a processing method for comprehensively recovering high manganese asbolite, belonging to the field of hydrometallurgy. In the processing method, the high manganese asbolite is processed through four processing steps comprising (1) reduction leaching, (2) primary cleaning, (3) manganese and cobalt separation and (4) extraction separation to obtain a product manganese carbonate, copper sulfate, nickel carbonate or cobaltous sulfate. The processing method has the advantages that the source of raw materials is wide, the process and equipment are simple, the operation is stable, the energy consumption is low, the production cost is low, the practicability is wide, and the economic effect and the society effect are obvious.

Owner:HAINAN ZHONGDAO ENERGY DEV

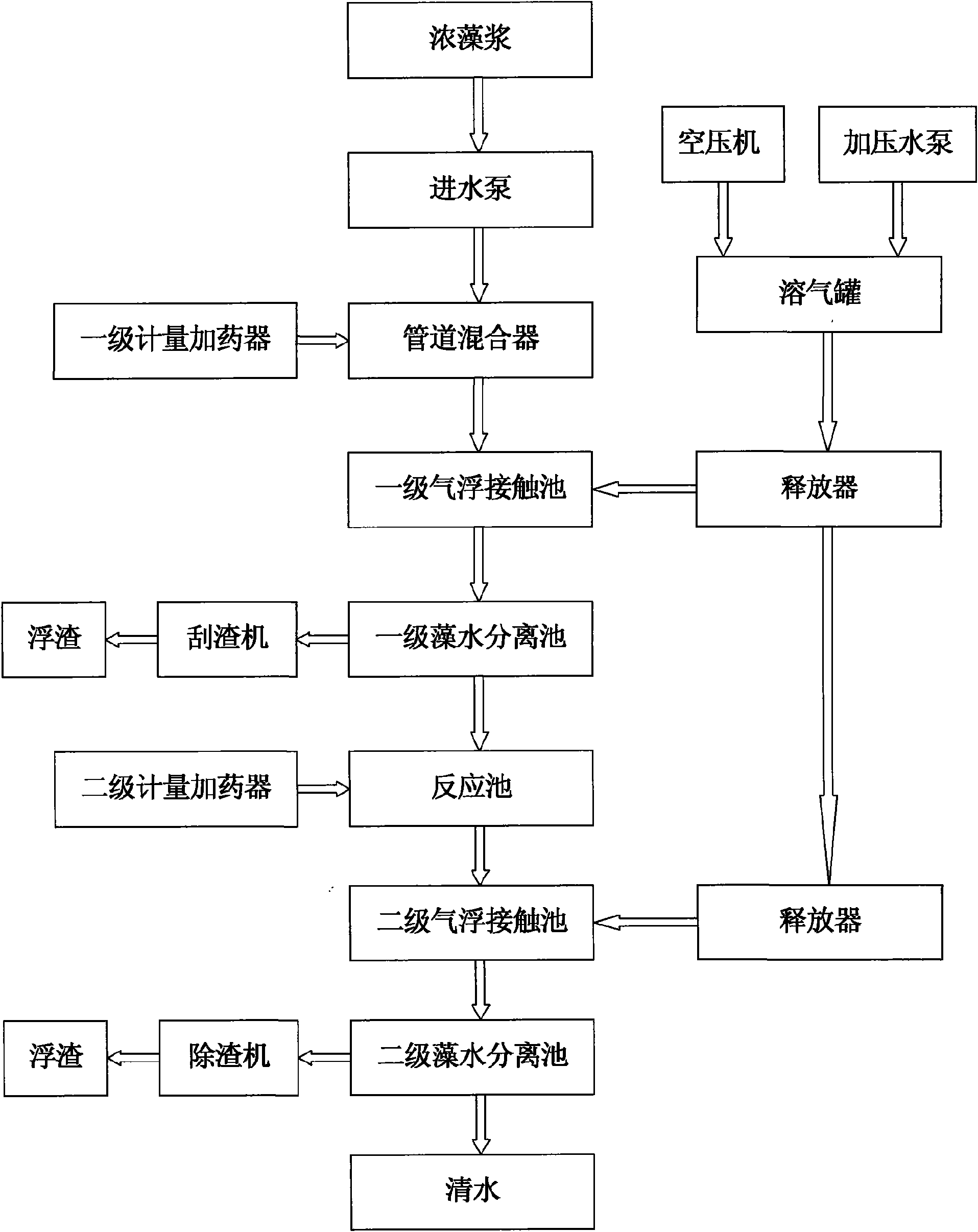

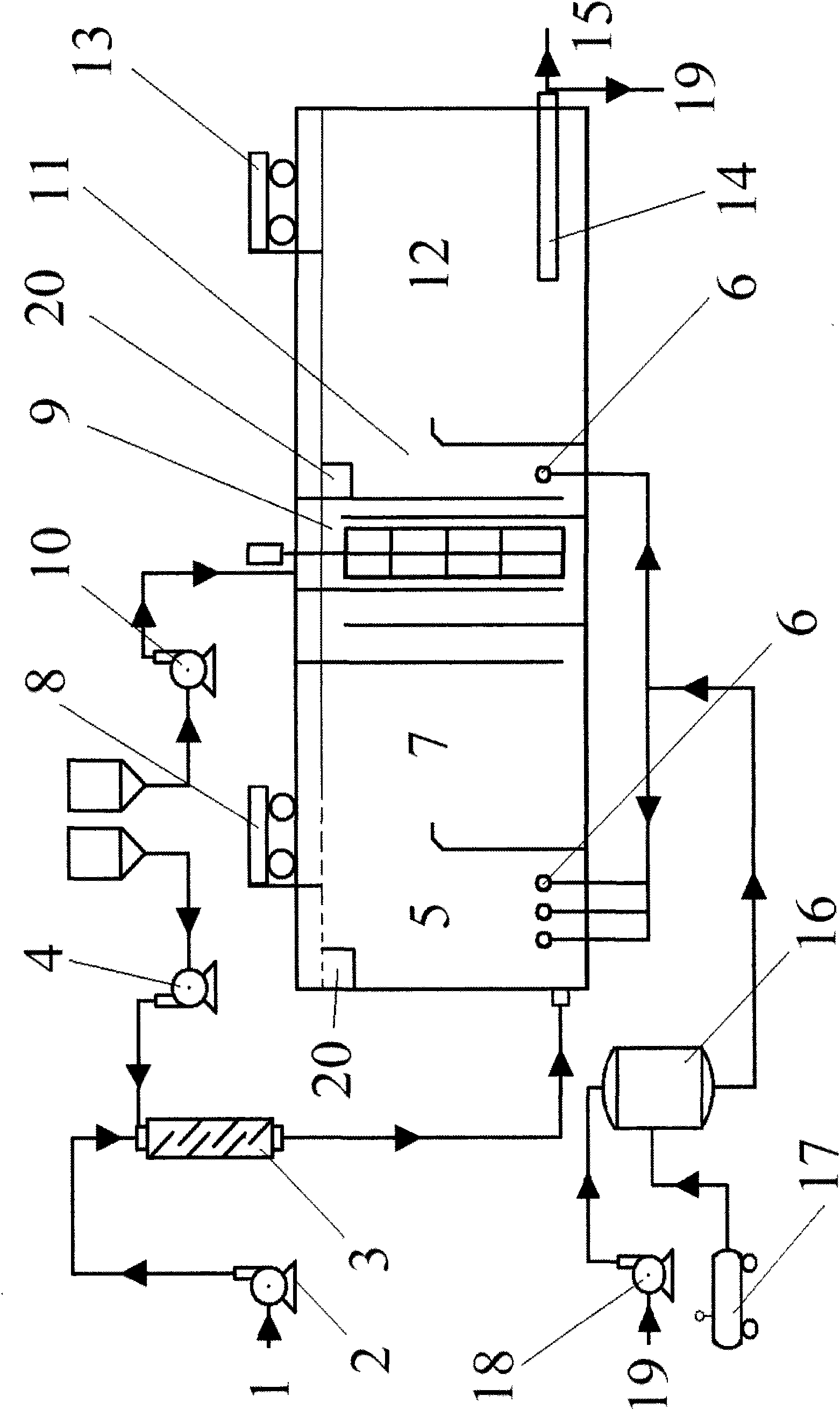

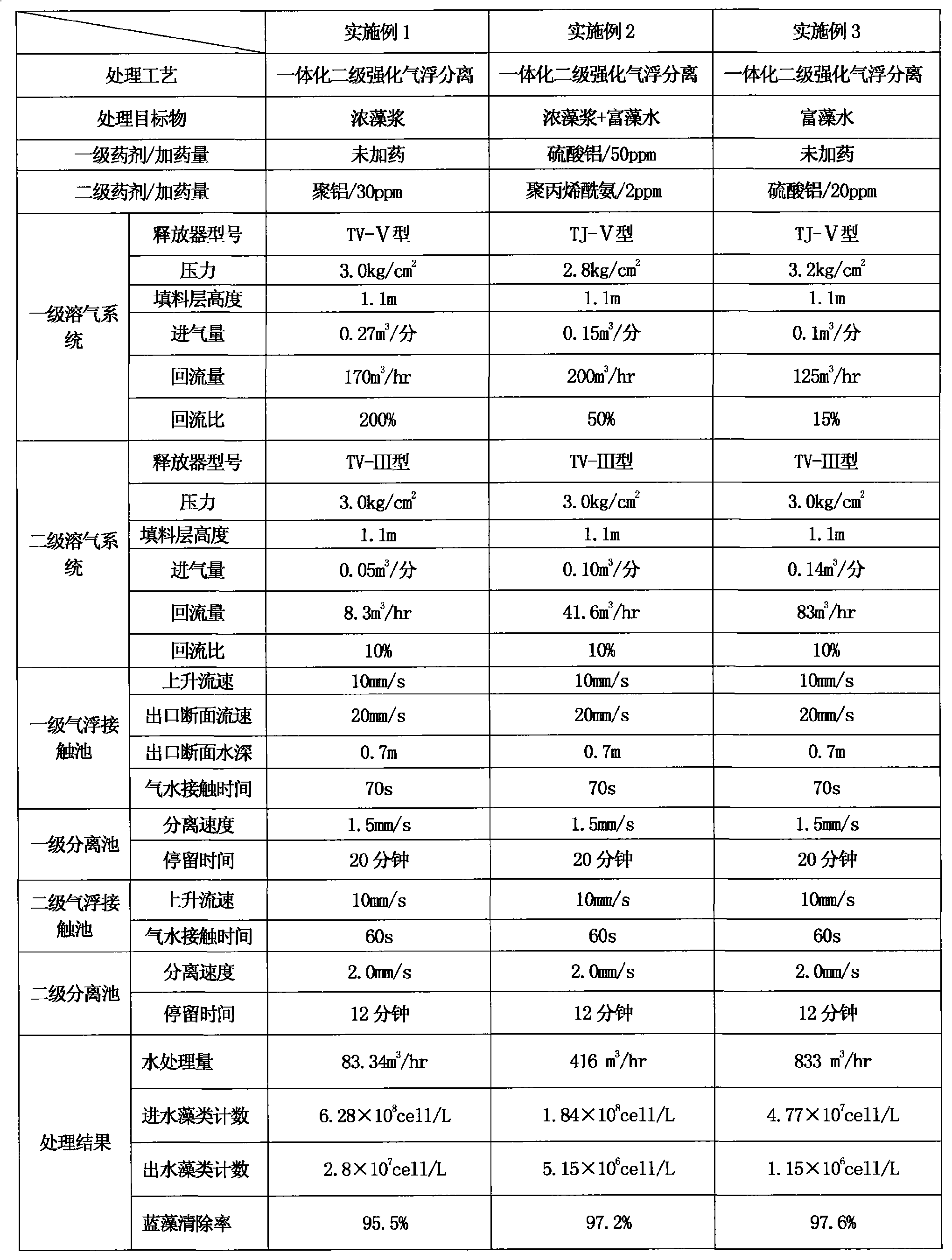

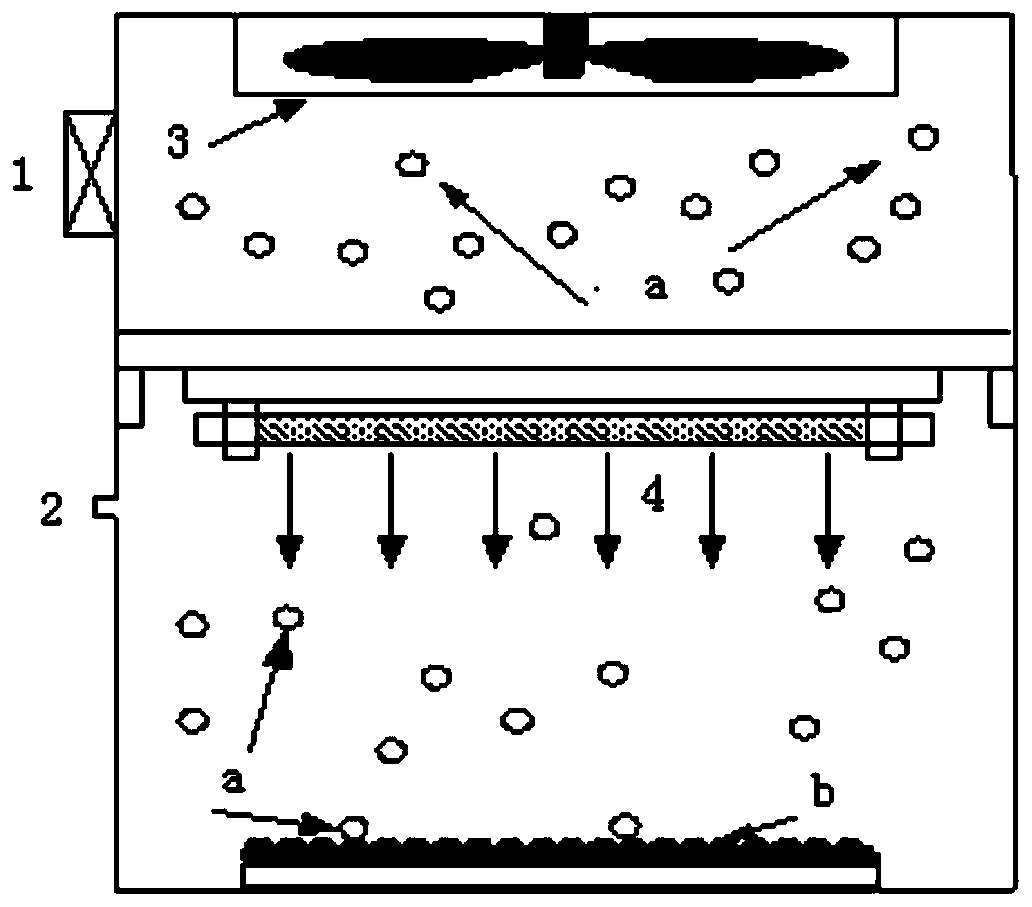

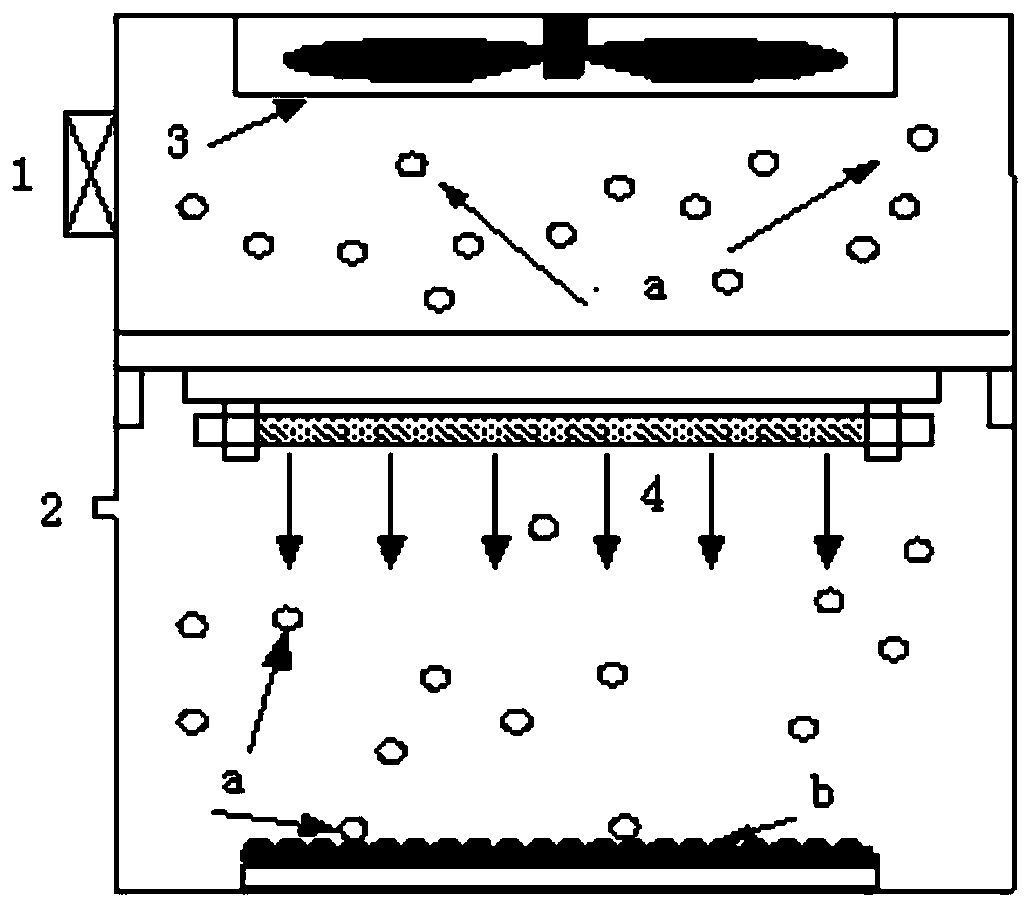

Technique and device for integrated two-stage strengthened air-flotation separation of dense algae slurry

ActiveCN101602551ARealize solid-liquid separationReduce total nitrogenMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationMicro bubbleHigh density

The invention relates to a technique for integrated two-stage strengthened air-flotation separation of dense algae slurry. The technique comprises that: collected dense algae slurry first enters a first-stage air-flotation tank where algae and high-density micro-bubbles have contact with and adhere to each other so as to separate algae and water and remove about 50 to 80 percent of algae, and then water enters a second-stage strengthening air-flotation tank, is added with an appropriate amount of flocculant, and then is subjected to air-flotation treatment again so as to remove the remaining algae and other suspended substances in the water. The invention not only applies to the disposal of dense algae slurry, but also can be used to treat algae-rich water low in algae content. The invention has the advantages of effectively removing blue-green algae in water, transferring nitrogen, phosphorus and other nutrient loads in water, purifying water, preventing the explosion of blue-green algae and providing an effective method and a device for controlling the pollution of lakes and reservoirs.

Owner:WUXI DELINHAI ENVIRONMENTAL PROTECTION TECH CO LTD

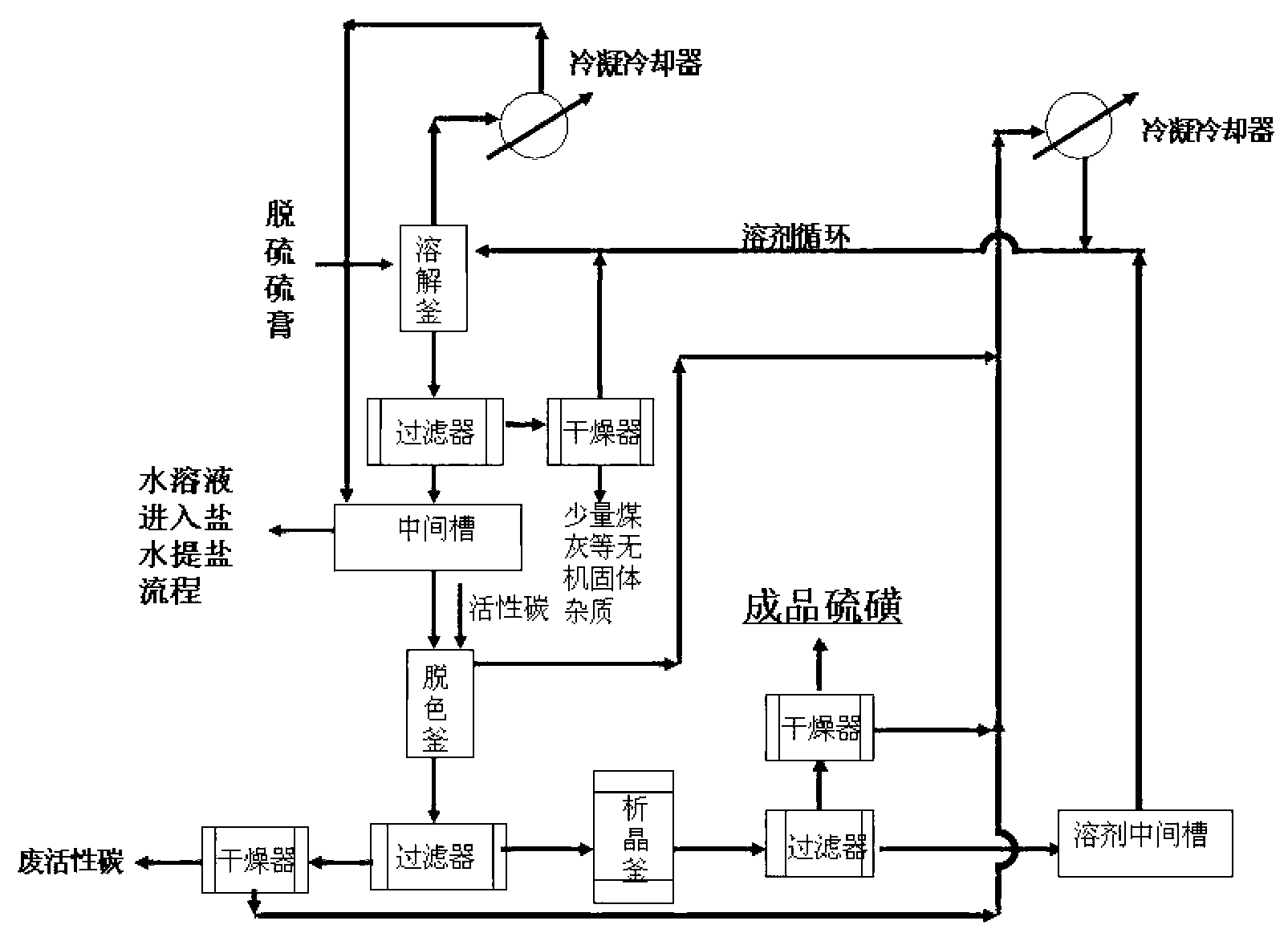

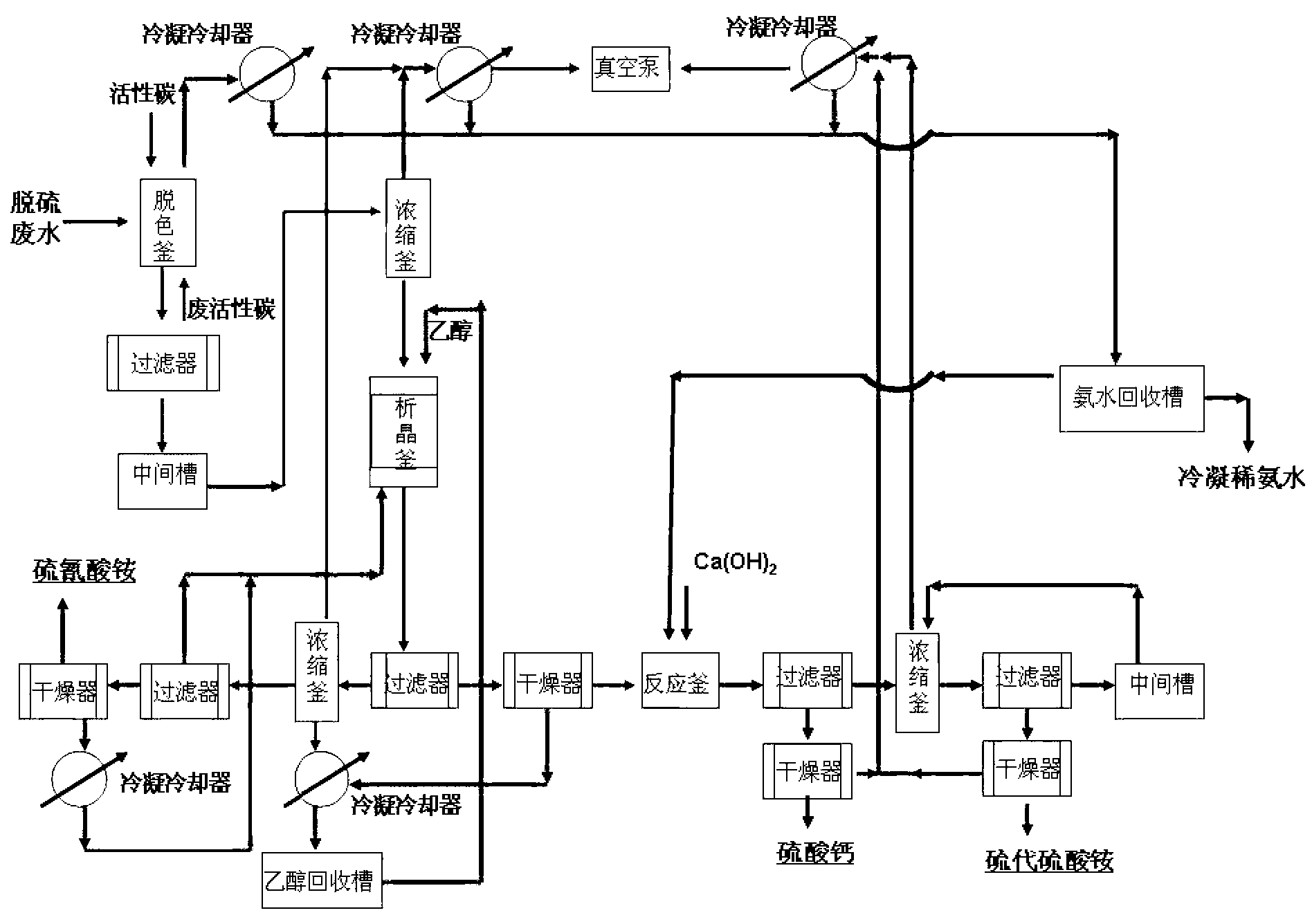

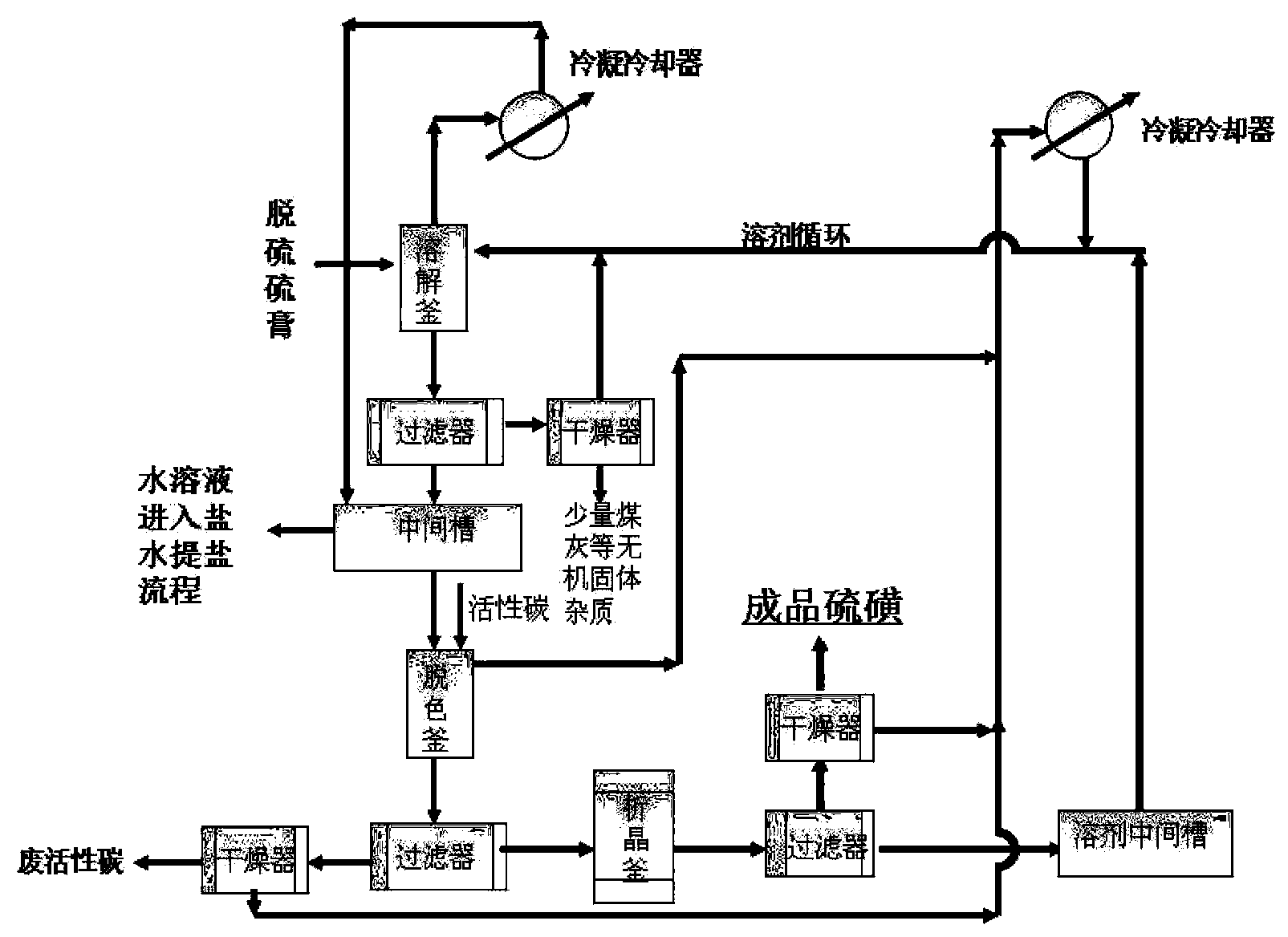

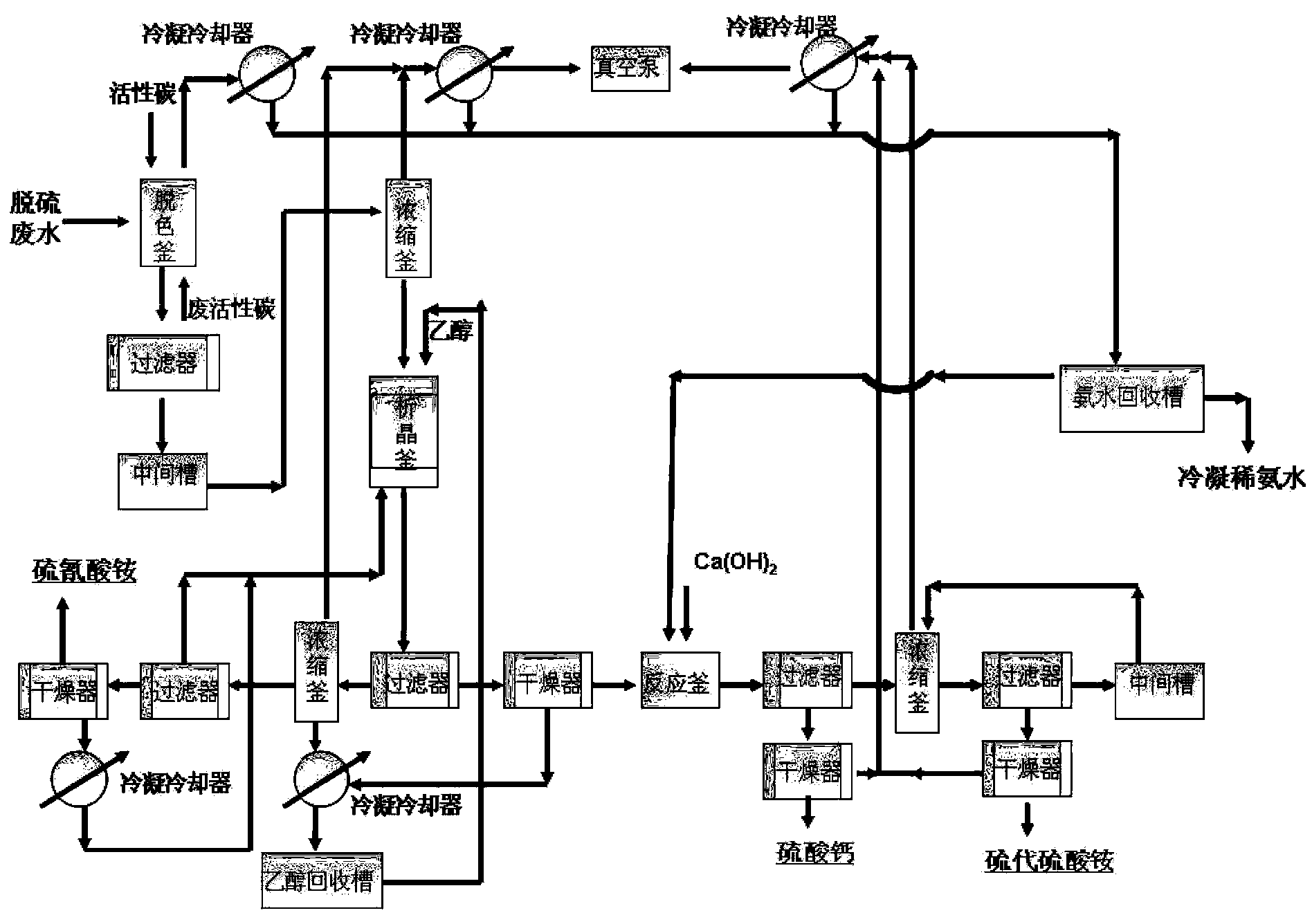

Method for processing sulfur paste as coke oven gas desulfuration by-product

ActiveCN103264991AThorough treatmentNo secondary pollutionCalcium/strontium/barium sulfatesThiosulfates/dithionites/polythionitesResource utilizationImpurity

The invention relates to a method for processing sulfur paste as a coke oven gas desulfuration by-product. The method is characterized in that a sulfur paste processing procedure comprises the steps of dissolving sulfur and removing impurities, decoloring and removing impurities, lowering temperature and crystallizing, drying the product and the like; and a waste liquid treatment procedure comprises the steps of decoloring and removing impurities, carrying out vacuum concentration on filtrate containing salt, separating ammonium thiocyanate, concentrating the ammonium thiocyanate ethyl alcohol filtrate for crystallization, drying an ammonium thiocyanate product, separating ammonium sulfate, concentrating the ammonium thiosulfate filtrate for crystallization, drying the ammonium thiosulfate product, and the like. The method can be used for thoroughly processing the sulfur paste and the waste liquid containing sulfur, the recycling rate of the product is high, no mixed salt and waste water are discharged without cause secondary pollution, so that the method is clean and environment-friendly. The method also has the outstanding characteristics of strong adaptive capacity, large production elasticity, high resource utilization ratio and the like.

Owner:张建利

Porous carbon material and its preparation method

The invention discloses a porous carbon material and its preparation method. The preparation method provided by the invention successively comprises steps of: raw material and auxiliary material selection, pulverization, spheroidization, grading, burdening, mixing, molding, roasting and the like. Green petroleum coke and green pitch coke are creatively used as raw materials. A filtration materialprepared after spheroidization of a green coke powder has large contractility, high strength, uniform pore distribution, smooth pore path, high filtration precision and good transmissivity, is not easy to block during the purification process, is easy to regenerate, and has long service life. The porous carbon material prepared in the invention can be widely used as a filtration material, a thermal insulation material, a conductance electrode and the like.

Owner:ZIGONG YUXING CARBON PRODS

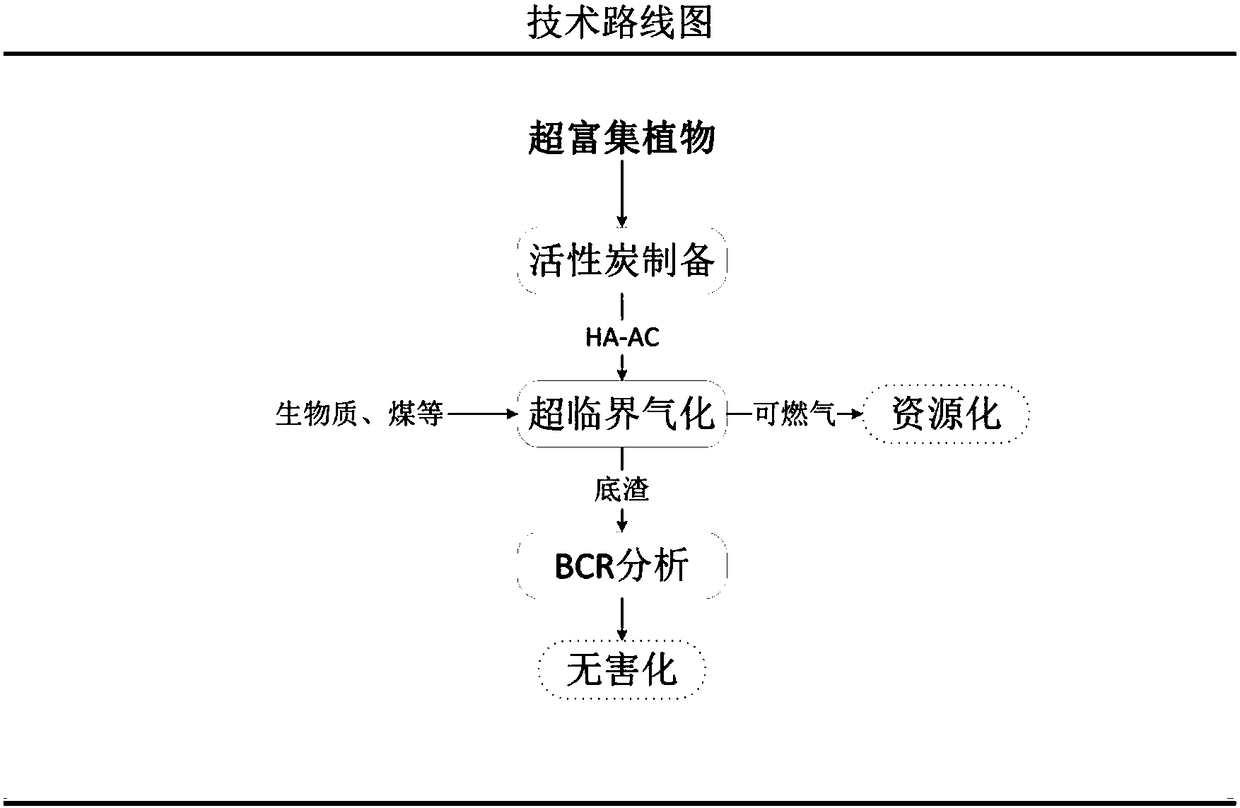

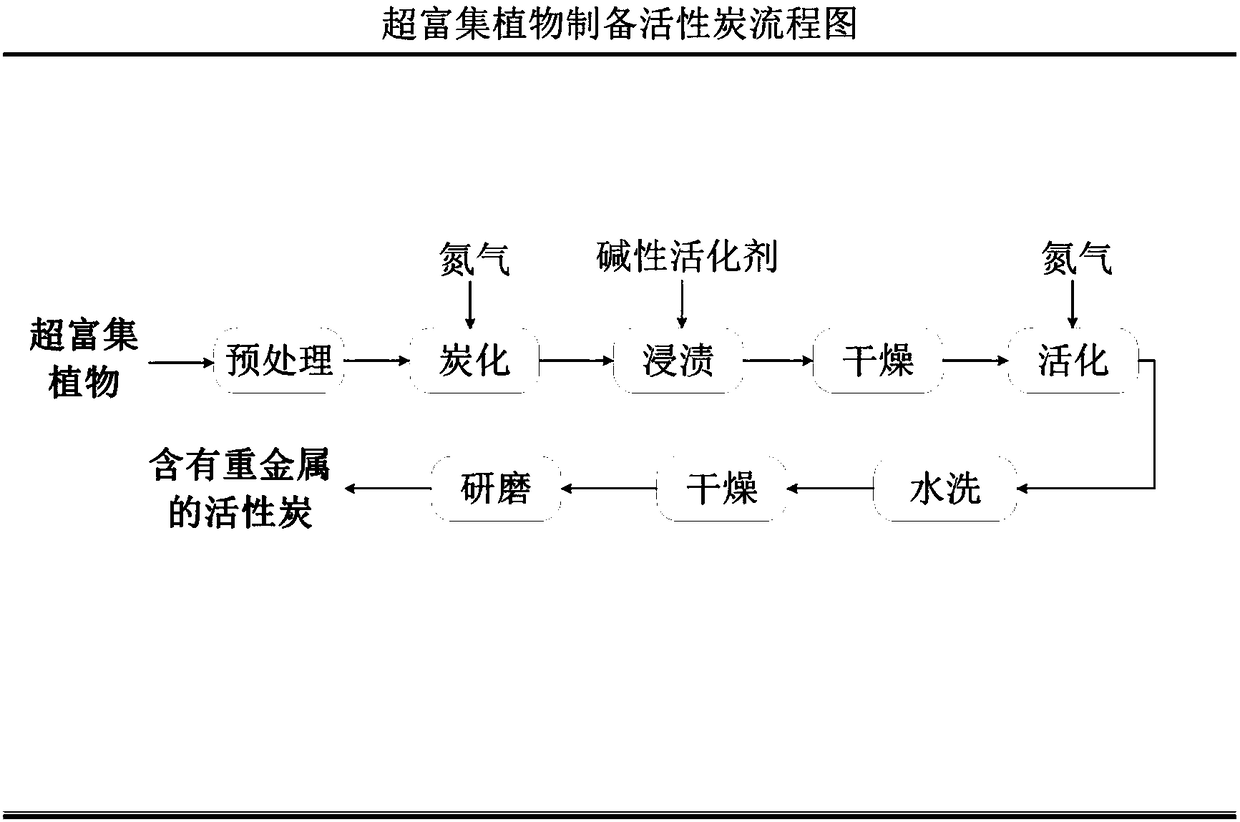

High-quality harmless utilizing method of hyperaccumulator

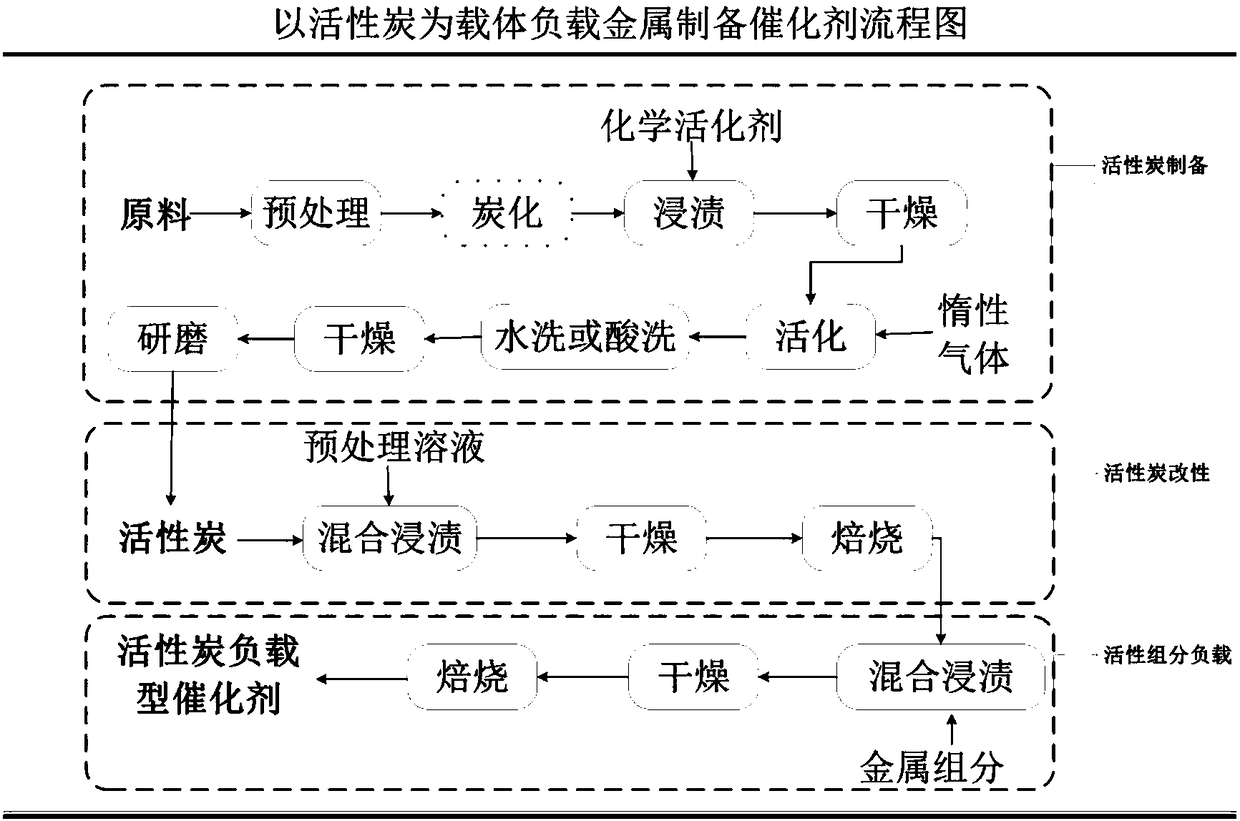

ActiveCN108485692ARealize resource processingSimple processProcess control/regulationProductsActivated carbonChemistry

The invention discloses a high-quality harmless utilizing method of a hyperaccumulator. The high-quality harmless utilizing method comprises the following steps: smashing and drying the hyperaccumulator, and sieving through a sieve of which the density is 100 meshes; carbonizing at a carbonization temperature being 450 to 550 DEG C and in carbonization time being 25 to 35 minutes, thus obtaining acarbonized material; immersing the carbonized material by using an alkaline solution of which the mass percentage is 45 to 55 percent; drying at 90 to 120 DEG C for 10 to 15 hours after immersing for20 to 28 hours, thus obtaining an amorphous particulate carbon block; activating the amorphous particulate carbon block into an activated carbon coarse product under a nitrogen atmosphere, wherein the activating temperature is 750 to 850 DEG C, and the activation time is 25 to 35 minutes; drying for 10 to 15 hours, thus obtaining metal-containing activated carbon with a catalytic effect; grindingthe activated carbon, thus obtaining an activated product HA-AC; adding 5 to 15 percent of the activated carbon product HA-AC to biomass or other reaction raw materials; putting a swelled material ina supercritical reaction kettle, and carrying out sealing reaction at the reaction temperature being 380 to 600 DEG C and the reaction pressure being 22.1 to 30 MPa, thus obtaining a hydrogen-rich gas. The high-quality harmless utilizing method disclosed by the invention has the advantages that additional metal loading is not required, a complicated preparation technology and a longer preparationperiod are not required, heavy metal can be fully stabilized, and secondary pollution can be avoided.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Deodorization method and deodorant

InactiveCN107137742AGrowth inhibitionAvoid it happening againBiocideFungicidesMicroorganismOdor source

The invention provides a deodorization method and a deodorant, relating to the technical field of deodorization. The deodorization method comprises the steps of spraying a chemical deodorant to an odor source so as to reduce the number of odor-producing microorganisms, and feeding a microbial deodorant to the odor source sprayed with the chemical deodorant after a preset time, wherein the chemical deodorant includes one or more of thiobacteria, lactic acid bacteria, saccharomycetes and spore bacteria; and the chemical deodorant includes one or more of acid, alkali and a strong oxidant. The chemical deodorant is capable of inactivating the odor-producing microorganisms and preventing the continuous production of odor. The microbial deodorant is fed to the odor source after a preset time and is capable of transferring odor substances into the microbial deodorant, oxidizing and decomposing the odor substances and generating an environment beneficial to the survival of the odor-producing microorganisms, so that the odor reproduced by the odor-producing microorganisms can be fundamentally and thoroughly avoided. The microbial deodorant is capable of decomposing odor substances into environment-friendly products such as water and carbon dioxide and does not produce odor.

Owner:杨鹏 +1

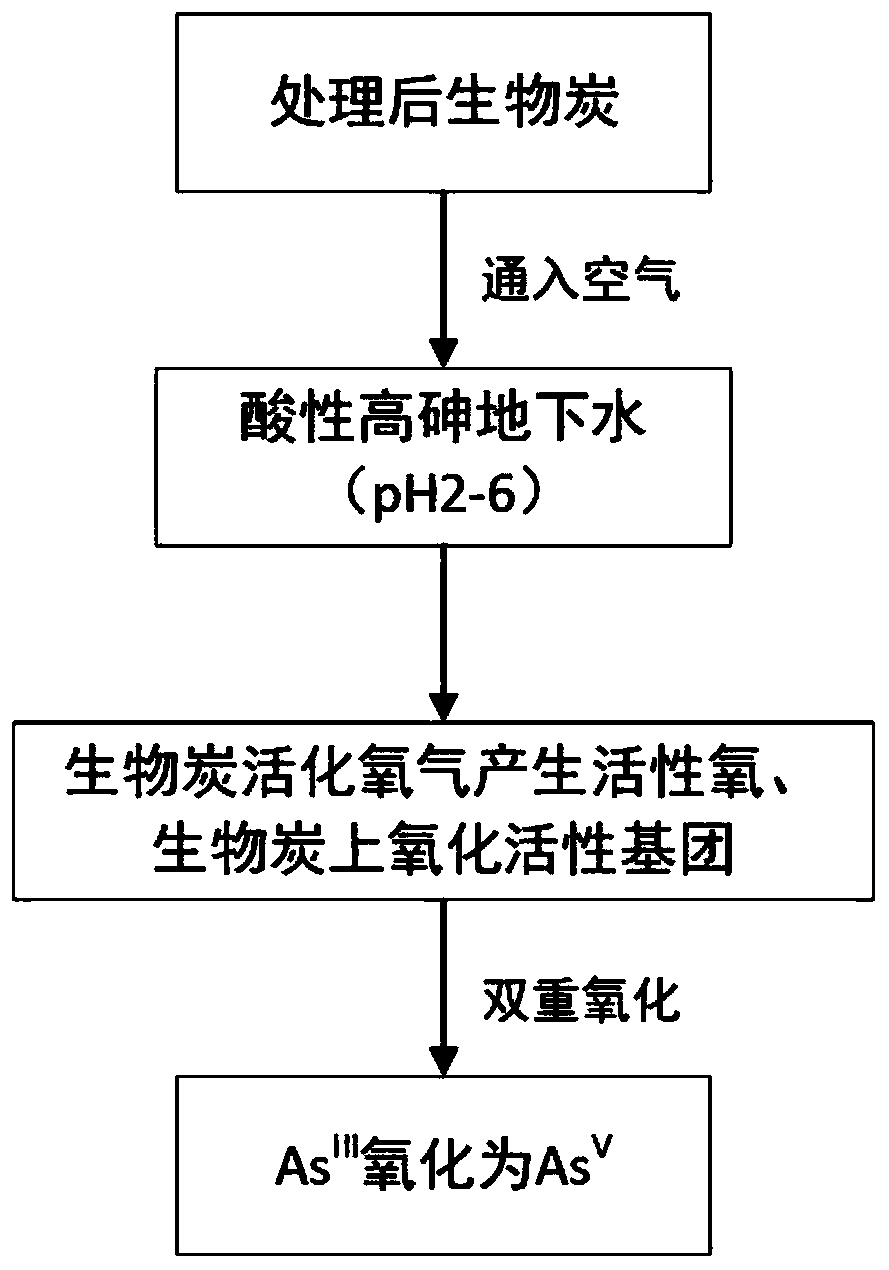

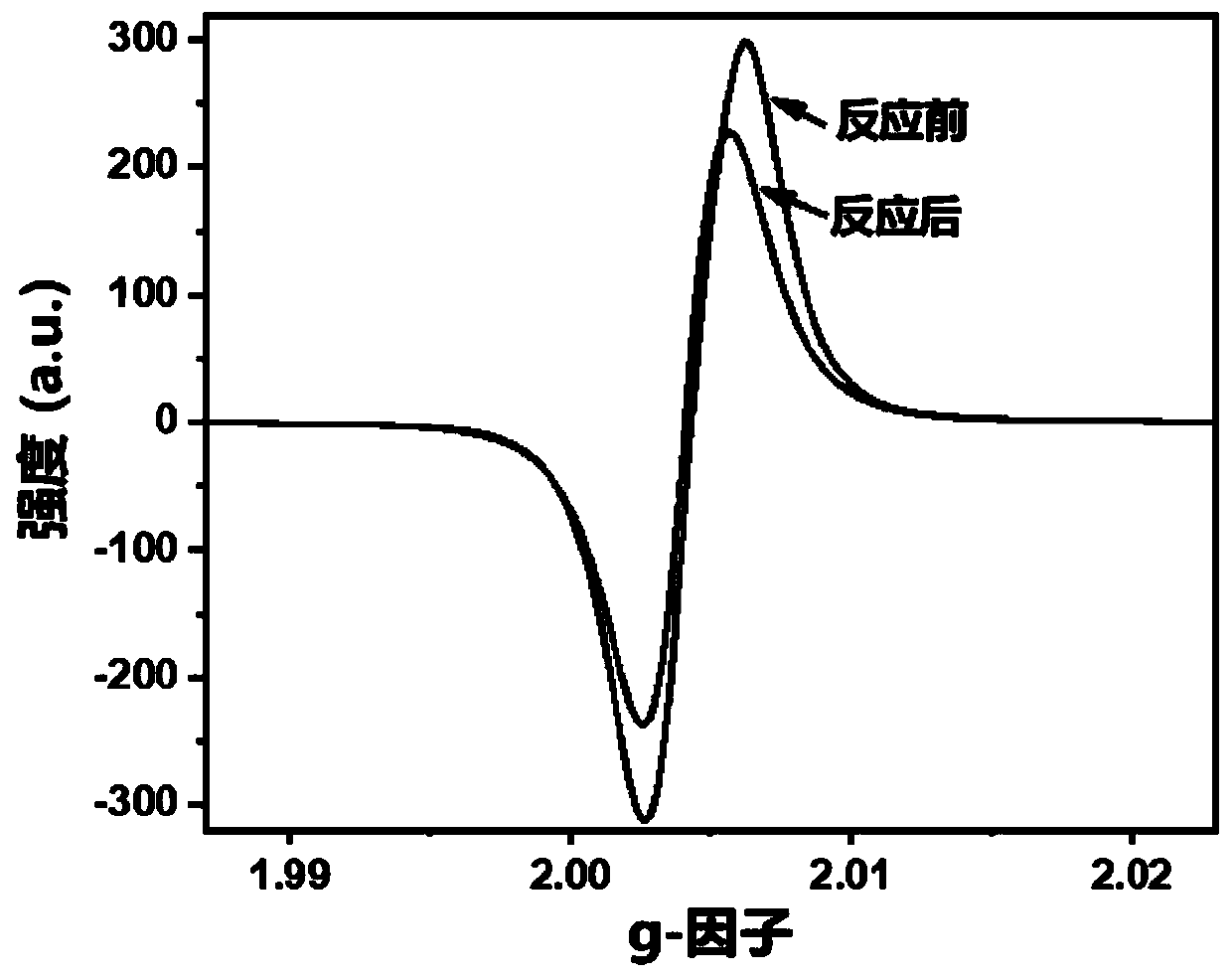

Method of using biochar for oxidizing trivalent arsenic in underground water

ActiveCN110204030ALow efficiencyEasy to cause inputWater contaminantsBiofuelsGroundwater remediationProduct gas

The invention belongs to the field of remediation of underground water and discloses a method of using biochar for oxidizing trivalent arsenic in underground water. The method includes the steps of adding the biochar into the underground water containing the trivalent arsenic (AsIII), introducing oxygen-containing gas at the same time, and carrying out stirring for a reaction for 1-3 days so thatthe AsIII in the underground water can be oxidized into pentavalent arsenic (AsV), wherein the biochar is obtained by adopting agricultural and forestry waste as a raw material for pyrolysis for 30-150 minutes at 400-500 DEG C under an oxygen isolation condition and then washing an obtained solid with deionized water. Through the cooperative effect of the biochar and the oxygen-containing gas andthe improvement of a pyrolysis preparation process and the like of the key biochar, the problems can be effectively solved that secondary pollution is likely to be caused, the operation cost is high,the operation is complicated, external minerals need to be added, and the efficiency is low. According to the method of using the biochar for oxidizing the AsIII in the underground water in site, an economical, efficient and environment-friendly treatment method is provided for oxidizing the AsIII in the underground water.

Owner:HUAZHONG UNIV OF SCI & TECH

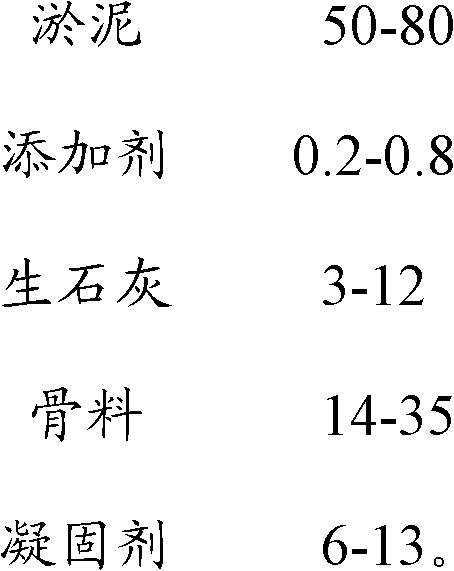

Non-sintered brick prepared from river and lake silt and preparation process thereof

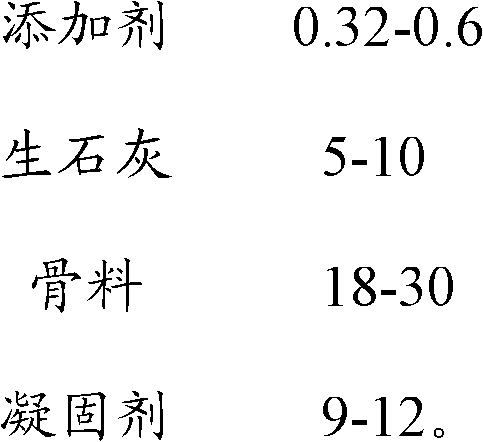

The invention relates to a non-sintered brick prepared from river and lake silt and a preparation process thereof. The brick is prepared from silt, quicklime, an additive, an aggregate, a solidifying agent and an appropriate amount of water. The process comprises dewatering silt, adding the additive and the quicklime, uniformly stirring, standing for a period of time, adding the aggregate and the solidifying agent, performing extrusion-molding, and naturally airing. The process has advantages of effective resource utilization, strong process operability and no secondary pollution. The obtained brick has high compressive strength and flexural strength, and long service life.

Owner:无锡晨海环保科技股份有限公司

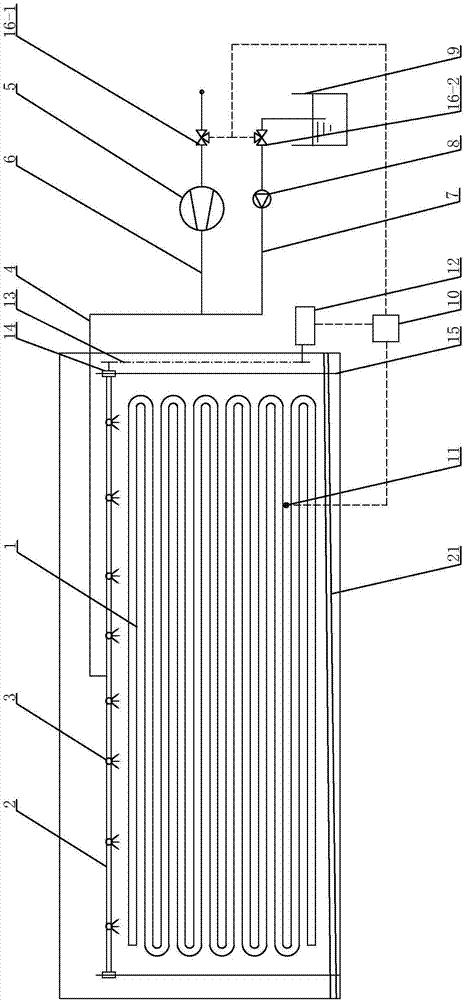

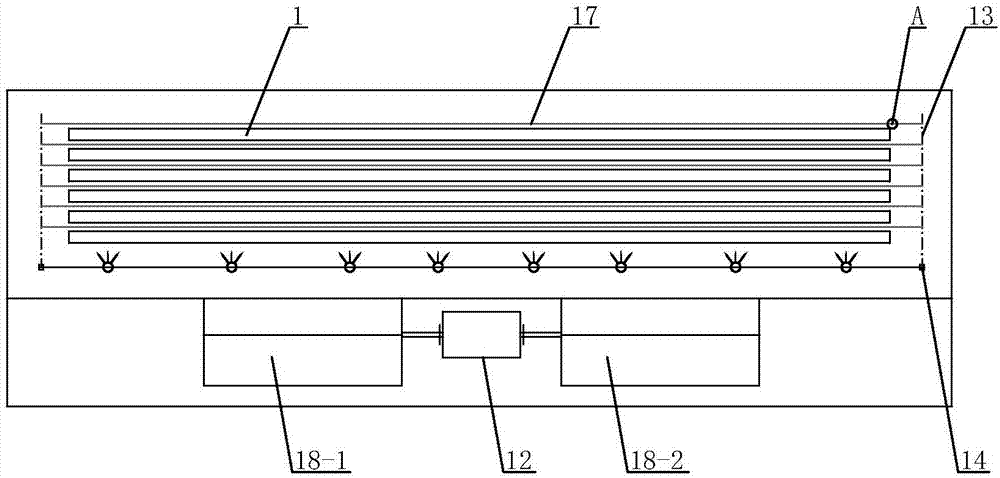

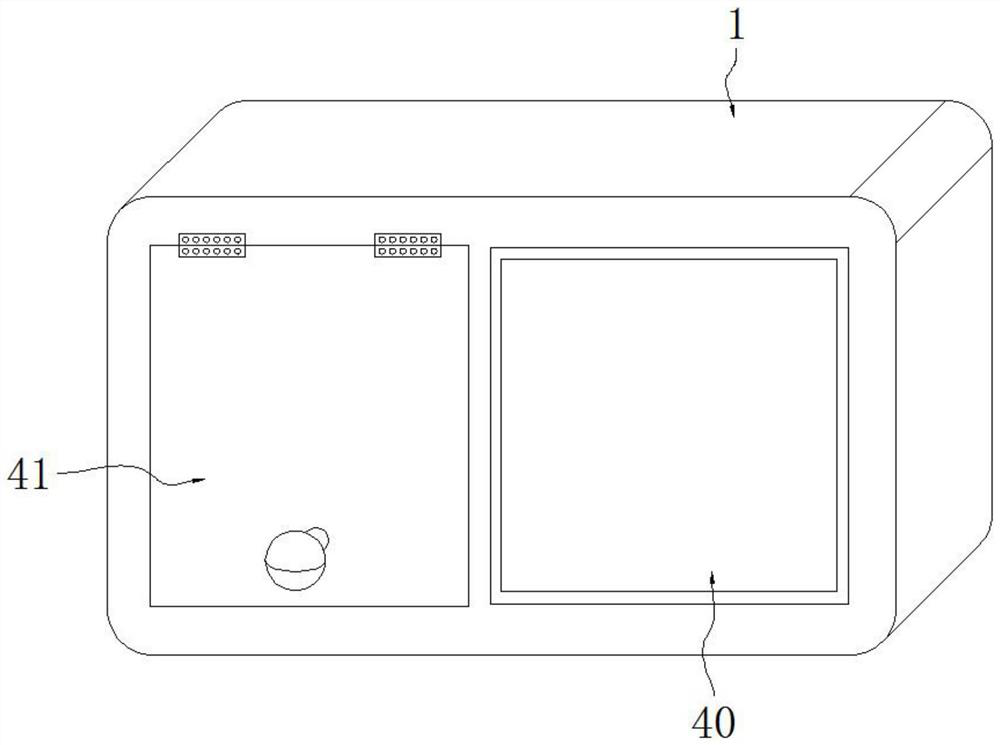

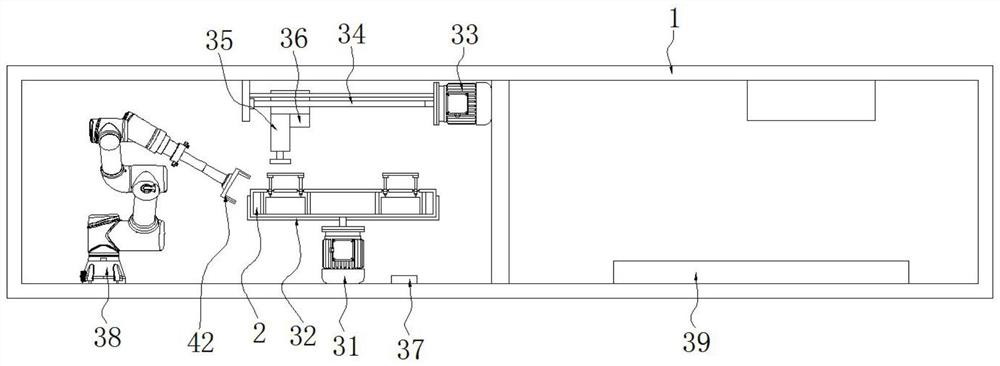

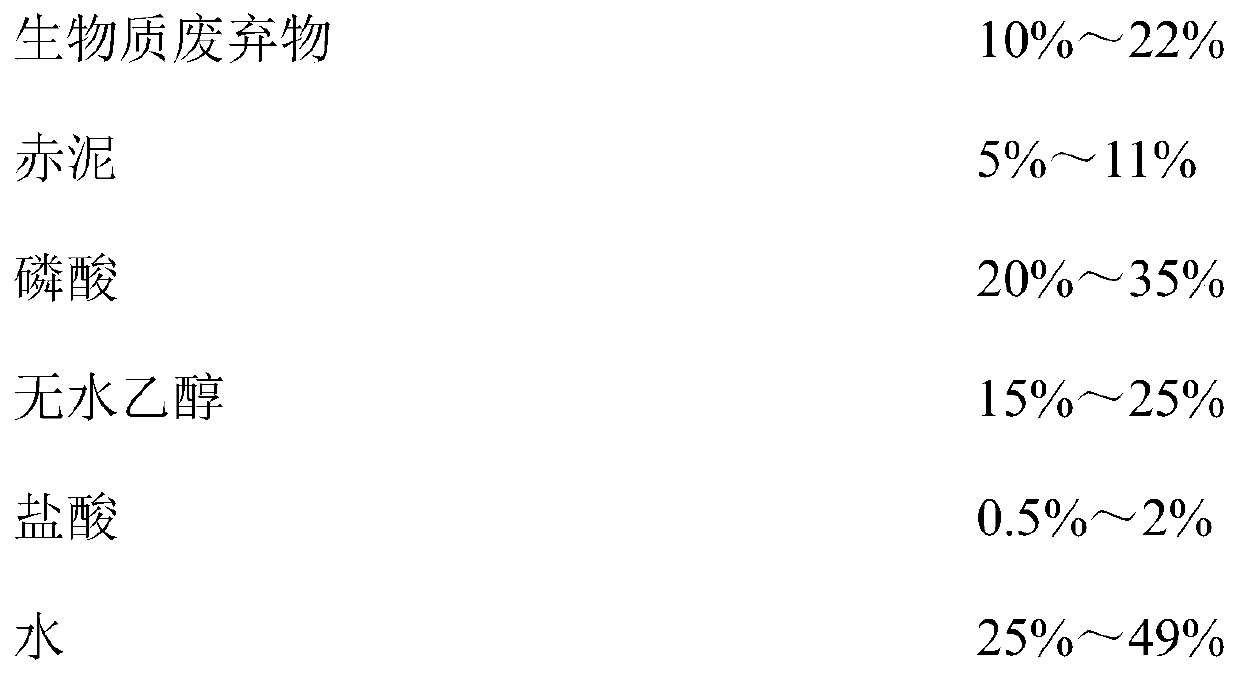

Washing device of fan coil

InactiveCN107477680AEasy to cause secondary pollutionStrong subjectivityCleaning heat-transfer devicesSpace heating and ventilation safety systemsEngineeringSewage

A cleaning device for a fan coil unit. The invention belongs to the field of fan coil cleaning. The purpose of the present invention is to provide a cleaning device for fan coils, which can automatically clean the fan coils and ensure the cleanliness of the air from the fan coils. The device of the present invention is composed of coil pipe, nozzle array pipe, nozzle, conveying pipeline, compressor, suction pipeline, water suction pipeline, water pump, detergent storage tank, controller, dirt detection device, motor, transmission mechanism, slider, guide Rod, valve one, valve two, brush rod, volute one, volute two, air outlet blade, air outlet blade adjustment device, groove and hair brush. The invention utilizes high-pressure air flow washing, brush contact wiping and cleaning, and detergent atomization and spraying technologies, and uses the electric signal loop of the controller to control and adjust the equipment, thereby realizing automatic cleaning of the fan coil unit and ensuring efficient dust removal and cleaning. Sterilize. The invention is suitable for the heating and cooling system of the terminal wind disk.

Owner:QINGDAO UNIV

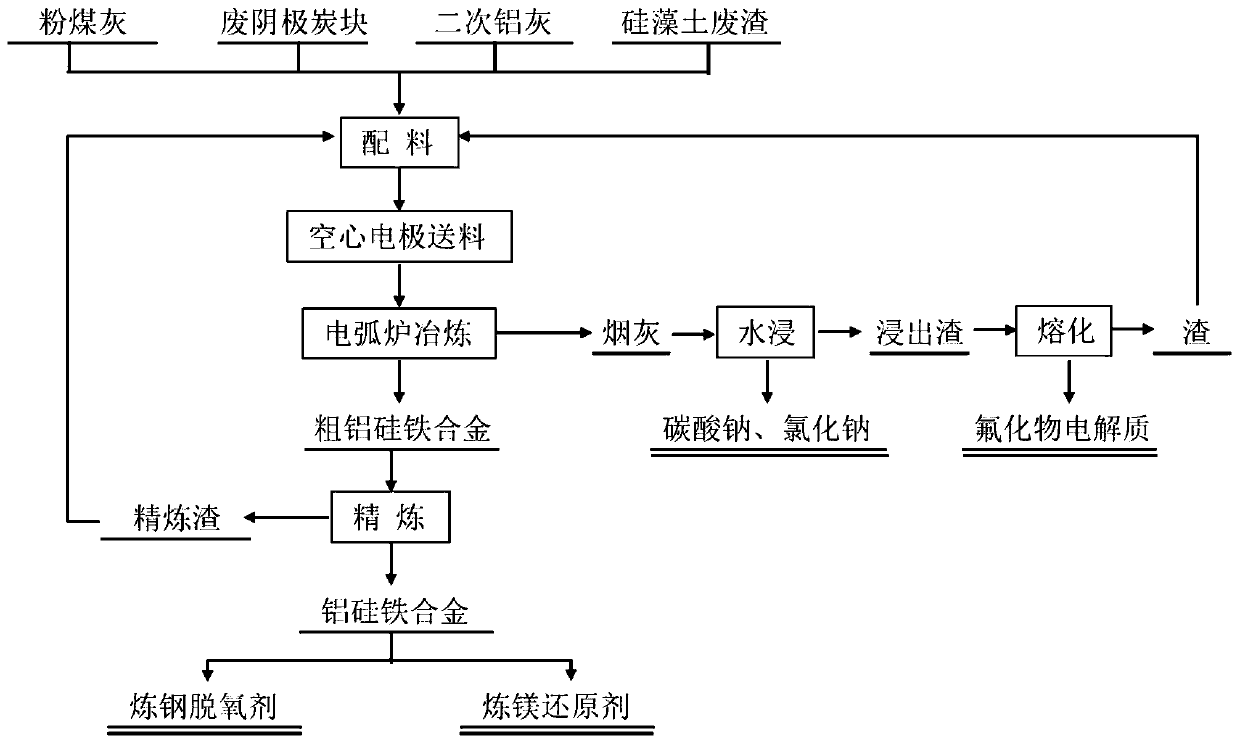

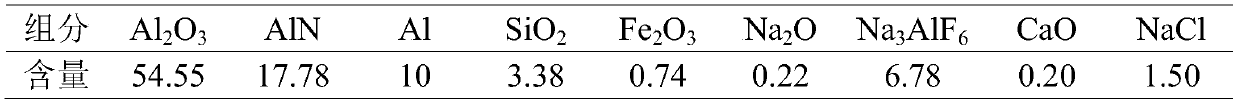

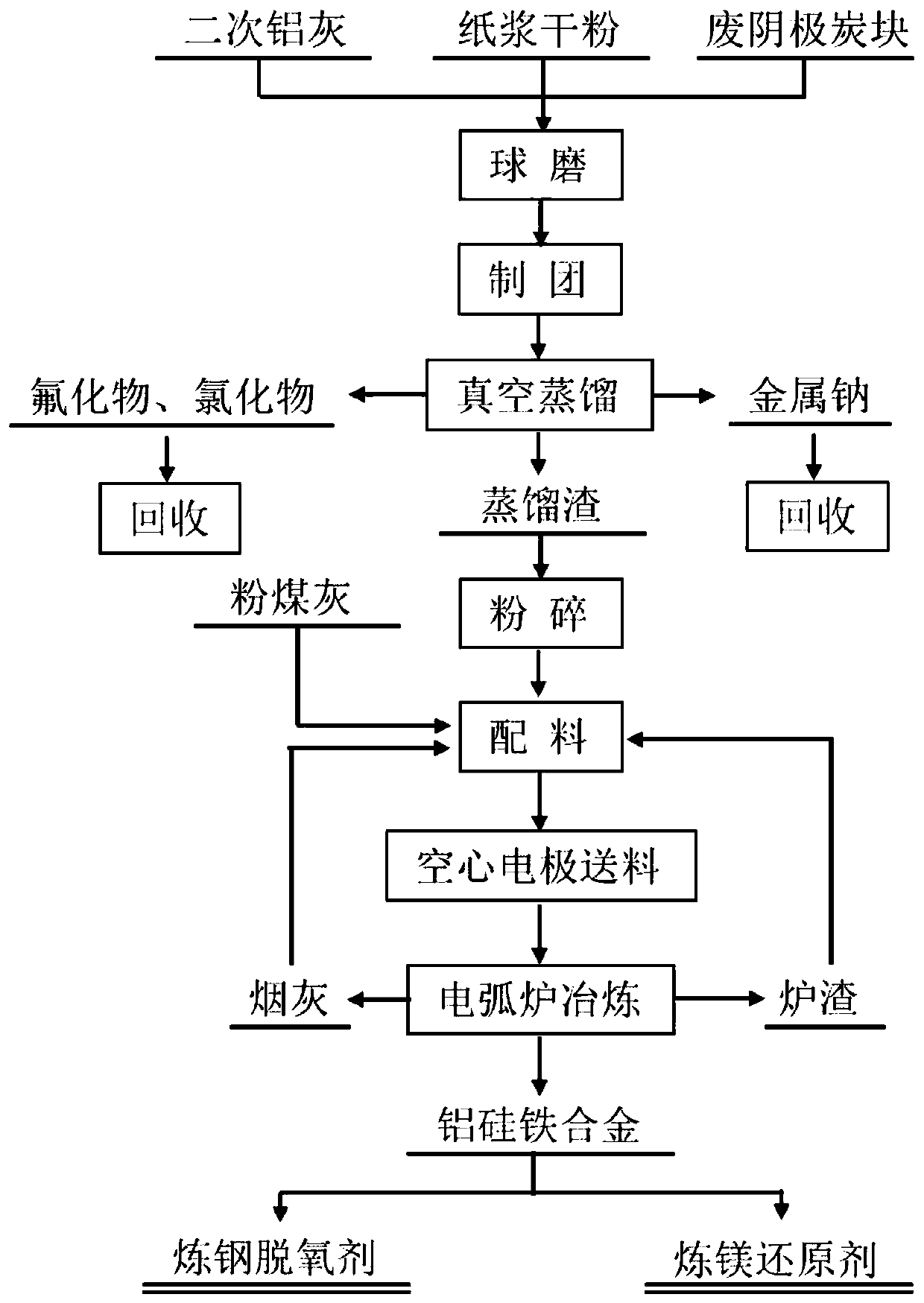

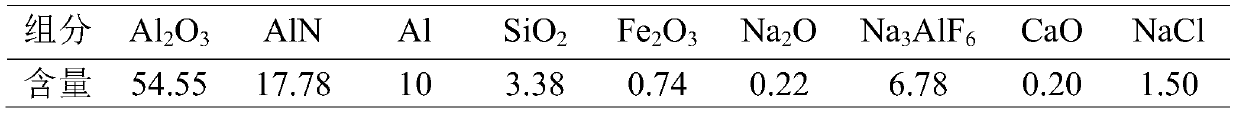

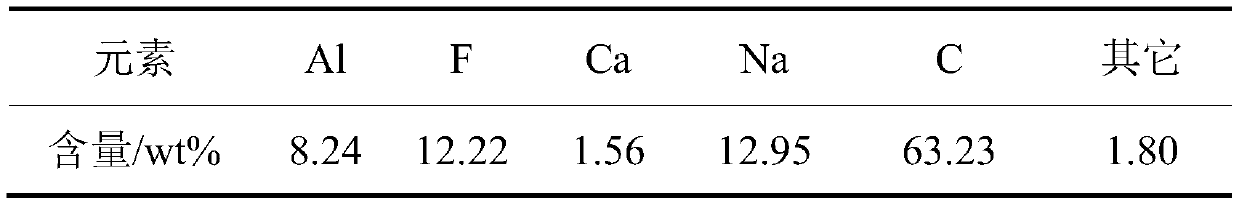

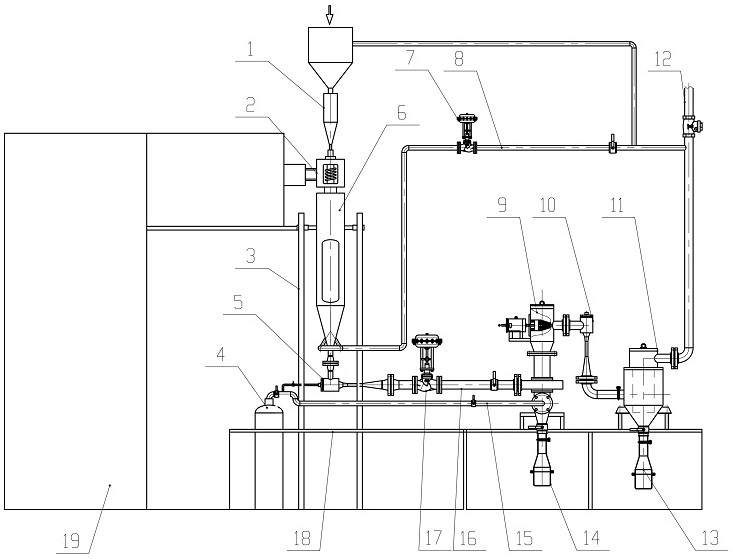

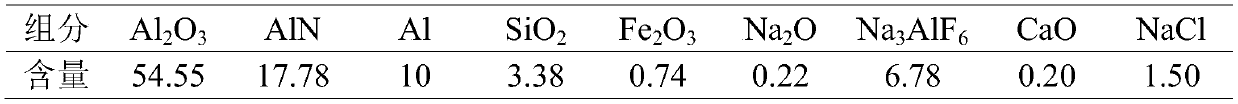

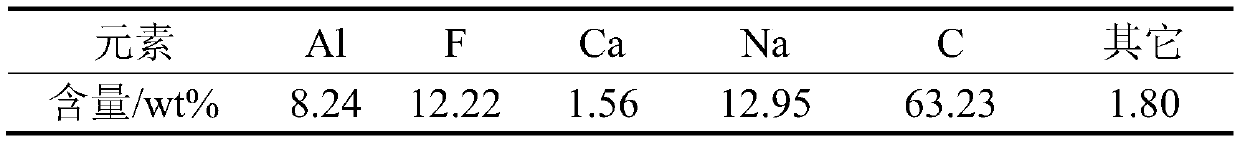

Method for preparing silicon-iron alloy by using aluminum ash as raw material and feeding material by hollow electrode

ActiveCN110129565AAchieve pyrolysisEasy to cause secondary pollutionProcess efficiency improvementDecompositionKeatite

The invention provides a method for preparing a silicon-iron alloy by using aluminum ash as a raw material and feeding material by a hollow electrode. According to the method, secondary aluminum ash is used as a raw material, an aluminum electrolysis cell waste cathode carbon block serves as a reducing agent, fly ash serves as an additive to adjust the content of aluminum in the raw materials, diatomaceous earth waste residues serve as additives to adjust the content of silicon in the raw materials, and high-temperature reduction in an electric arc furnace takes aluminum oxide and silicon oxide as main materials so as to prepare a certain-component aluminum-silicon-iron alloy; the hollow electrode is used for conveying powdery materials, so that the smelting process of the whole electric arc furnace can be enhanced, reduction of oxides and volatilization of fluoride are promoted, particularly, decomposition of the toxic substance aluminum nitride and the cyanide is accelerated, the production efficiency is improved, the production cost is reduced, and comprehensive utilization of various dangerous waste and solid waste is realized in the same process.

Owner:NORTHEASTERN UNIV

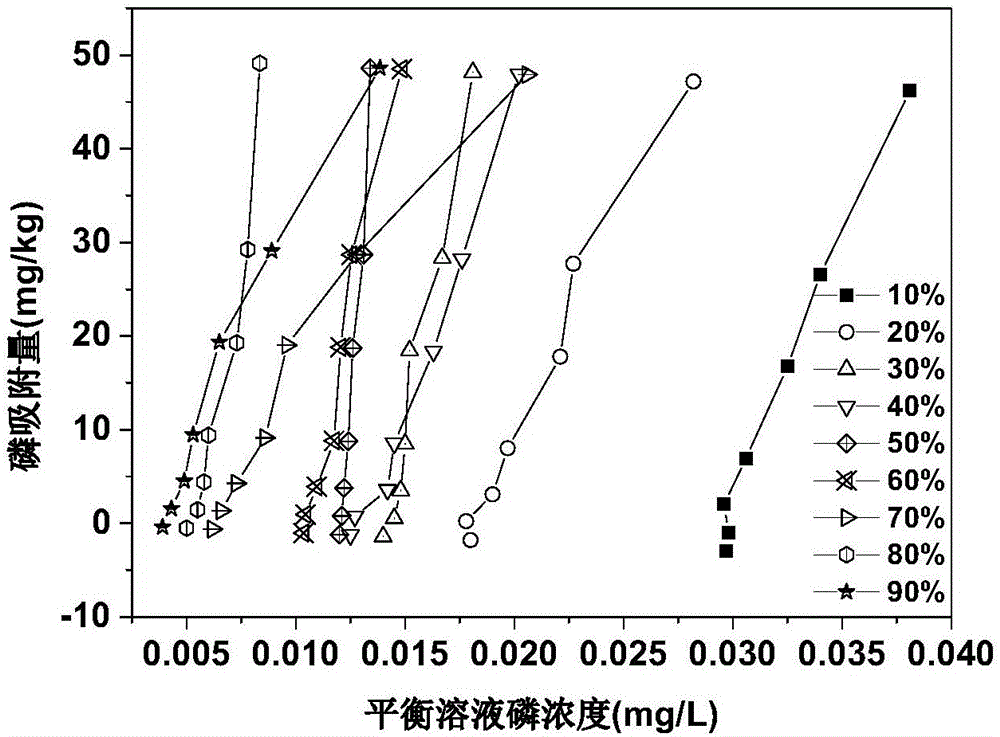

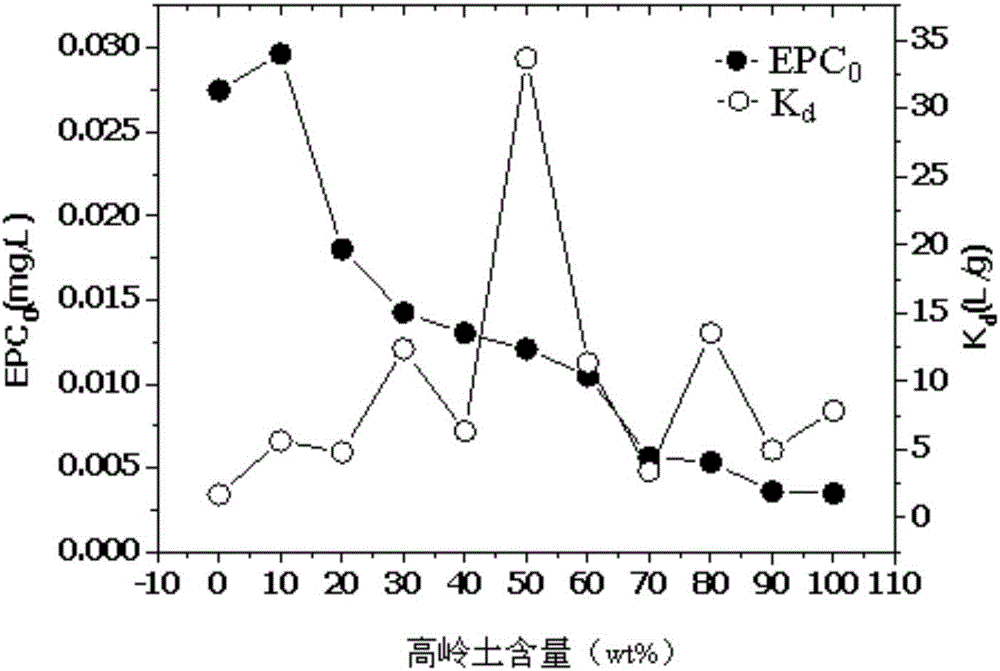

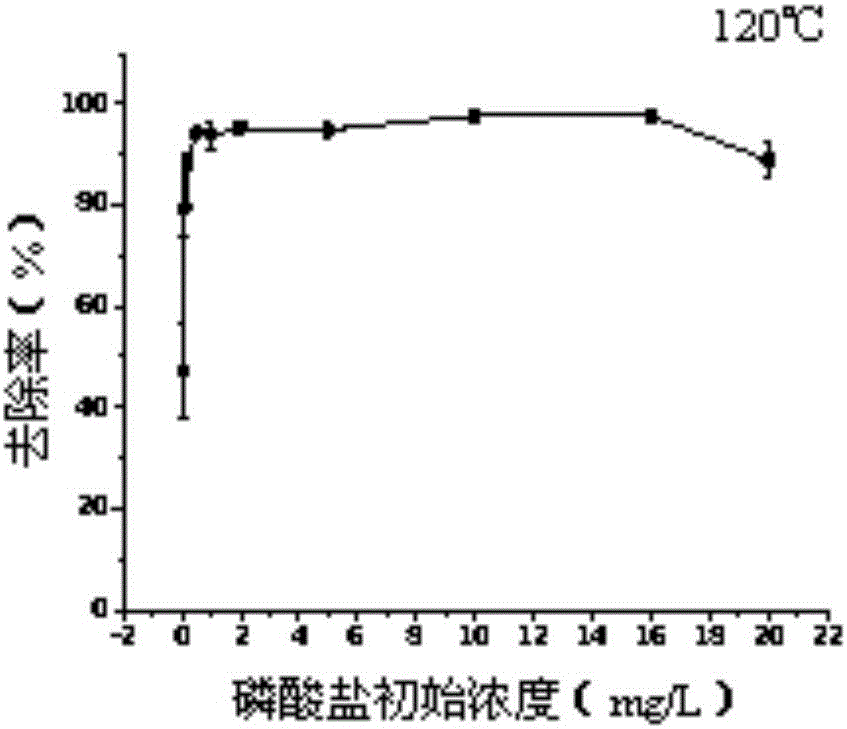

Preparation method and application of sediment-water interface phosphorus release control material

ActiveCN106277672ADecrease the adsorption-desorption equilibrium concentrationLess materialFixation/solidifcation sludge treatmentContaminated waterways/lakes/ponds/rivers treatmentIron saltsPhosphate

The invention provides a preparation method and application of a sediment-water interface phosphorus release control material. For the first time, a lake sediment and kaolin mixture is used as a basic raw material, and processes like oxidation, iron salt modification, granulation and calcination are adopted, so that adsorption-desorption balance concentration EPC0 value of the material to phosphate is remarkably lowered, linear distribution coefficient Kd value of the material is increased, and the material can effectively reduce sediment interstitial water phosphate concentration and can inhibit sediment-water interface phosphate release. The material itself has weak phosphate desorption capability and high adsorption and buffering capability, so that the material can truly realize effective obstruction and control on sediment-water interface phosphorus release. The material is low in material cost, high in social and economic benefit and safety, free of ecological risk to lake water, energy-saving and environment-friendly and has remarkable effect on controlling sediment-water interface phosphorus release in different lake areas of the Dian Lake in the process of application.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

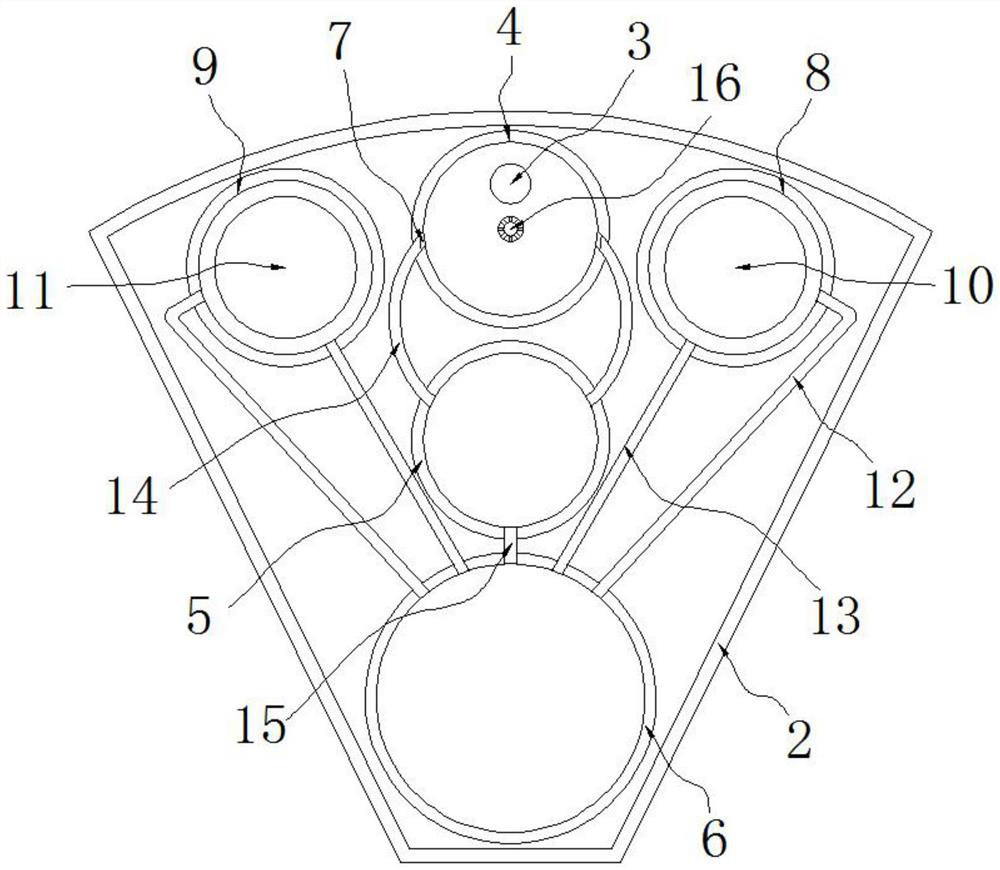

Water quality monitoring equipment and monitoring system based on micro-fluidic disc chip

ActiveCN114152606AReduce volumeLess reagent consumption and less wasteMaterial analysis by observing effect on chemical indicatorPreparing sample for investigationMicrofluidic chipIntegrated automation

The invention provides water quality monitoring equipment and a monitoring system based on a micro-fluidic disc chip, the water quality monitoring equipment comprises a shell, the micro-fluidic disc chip and a digestion unit, a centrifugal center point is arranged in the micro-fluidic disc chip, and a digestion pool, a quantitative pool, a reaction pool, a B reagent preset pool and a C reagent preset pool are fixedly mounted in the micro-fluidic disc chip; and a liquid bag reagent TP-B and a liquid bag reagent TP-C. The water quality monitoring equipment and the monitoring system based on the micro-fluidic disc chip are reasonable in design, and can realize micro-fluidization of water quality detection, integrated automation of multi-step reaction, integration of high-temperature closed digestion and presetting and storage of reagents; therefore, the developed laboratory and the portable micro-volume low-power-consumption micro-fluidic chip water quality detection system have the outstanding advantages of small volume, extremely low reagent consumption and waste liquid consumption, extremely low power consumption, short reaction period and the like, and can lead the development direction of rapid standardization water quality instruments in the laboratory.

Owner:WUHAN NEWFIBER OPTOELECTRONICS TECH

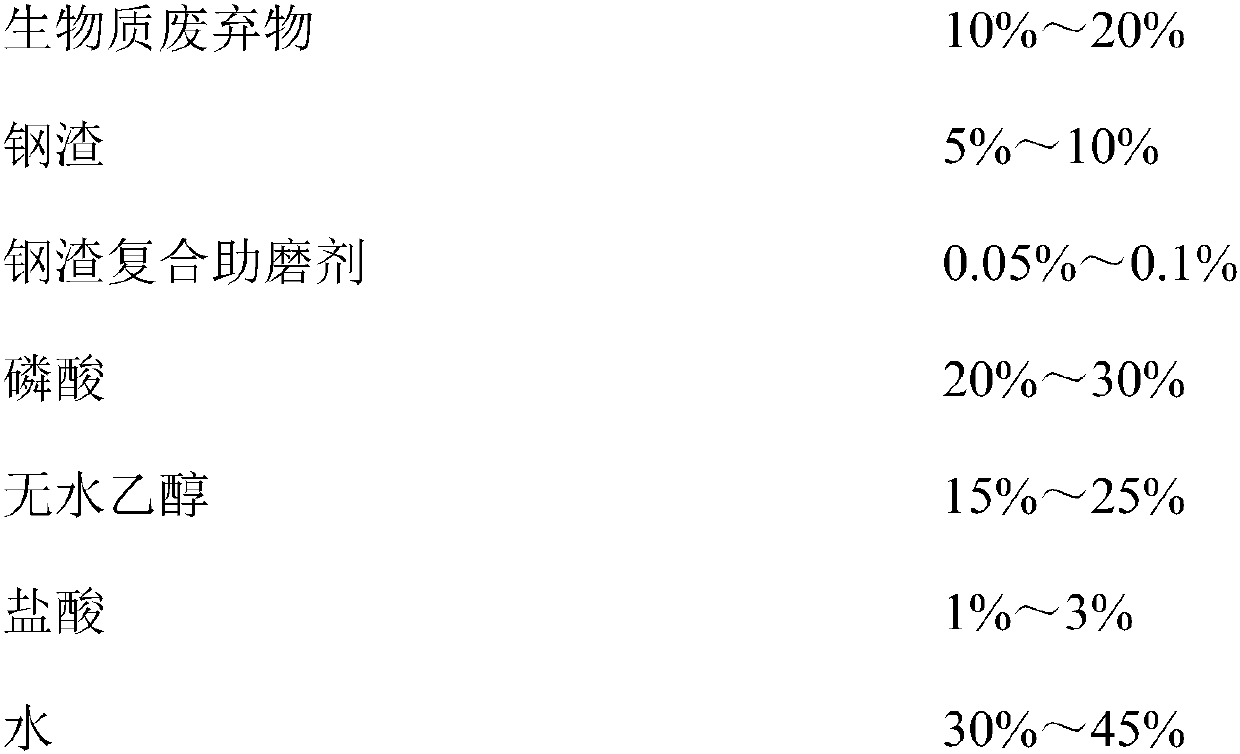

Steel-slag-based biomass activated carbon for degrading formaldehyde and preparation method of activated carbon

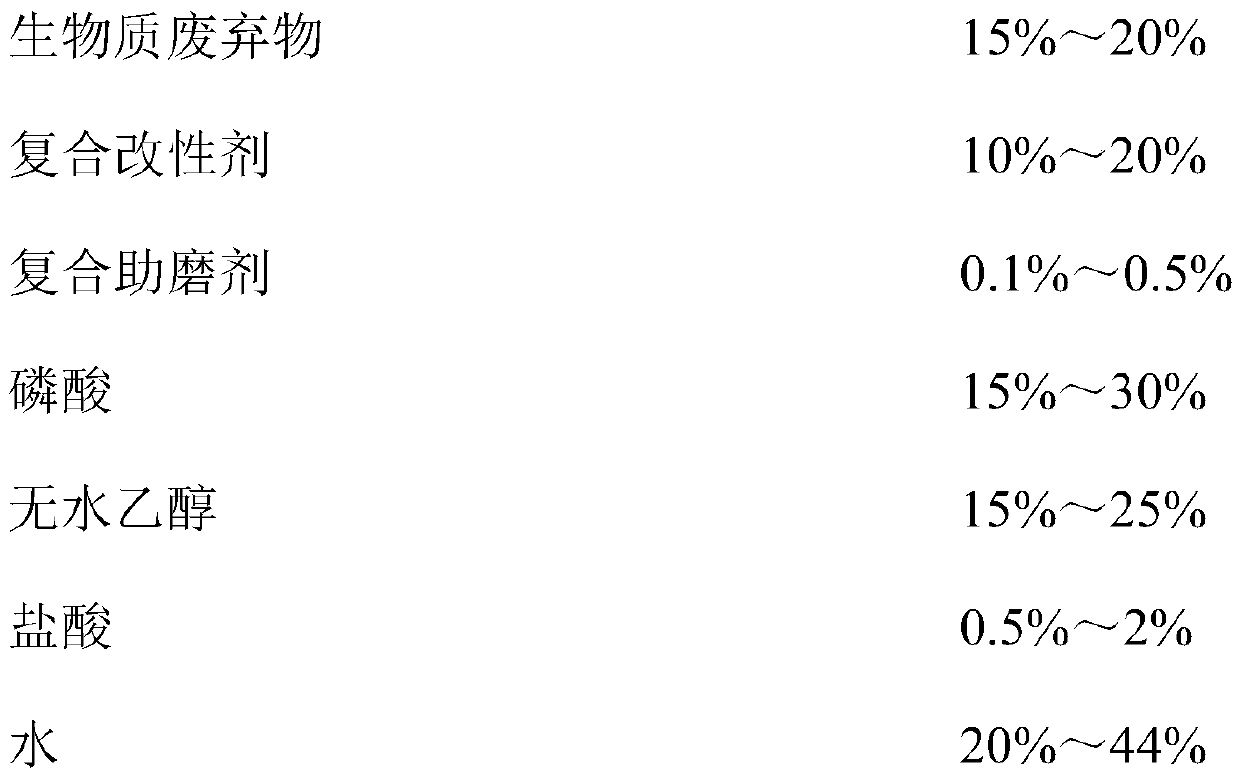

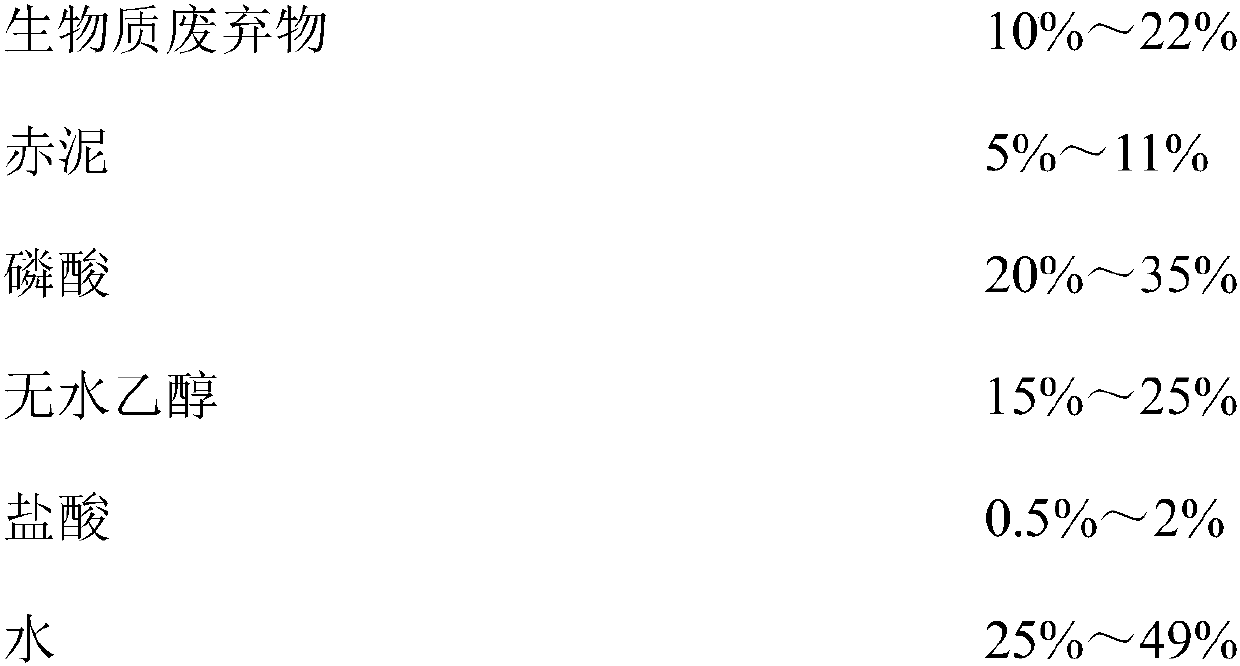

InactiveCN109734090AReduce manufacturing costPromote sustainable developmentCarbon compoundsSlagPhosphoric acid

The invention discloses steel-slag-based biomass activated carbon for degrading formaldehyde and a preparation method of the activated carbon, and belongs to the field of solid waste utilization. Thesteel-slag-based biomass activated carbon comprises biomass waste, steel slag, steel slag compound grinding aids, phosphoric acid, absolute ethyl alcohol, hydrochloric acid and water. The biomass waste includes one or more of fruit shells, fruit kernels and straws, and the steel slag includes one or more of heat stuffy slag, electric furnace slag and wind chopped slag. The steel slag and the biomass waste are compounded to prepare the steel-slag-based biomass activated carbon, the biomass waste is modified by metallic oxide in the steel slag, high value-added application of the steel slag andthe biomass waste is widened, and a new idea of 'danger control by waste' is achieved. Compared with a current technique of physically mixing steel slag and activated carbon to modify the activated carbon, a grind-aiding technique and a chemical combination technique are combined, and the performance and stability of the steel-slag-based biomass activated carbon are greatly improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

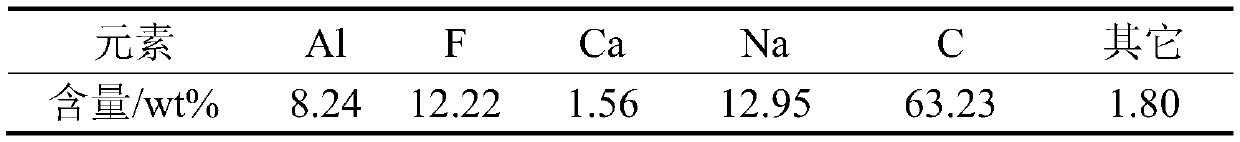

Method for preparing aluminum-silicon-iron alloy by virtue of aluminum-ash pre-treatment carbothermic reduction

ActiveCN110144457ARealize high temperature volatile separationEasy to cause secondary pollutionProcess efficiency improvementElectric arc furnaceDecomposition

The invention provides a method for preparing an aluminum-silicon-iron alloy by virtue of aluminum-ash pre-treatment carbothermic reduction. The method comprises the following steps that secondary aluminum ash, waste cathode carbon blocks and paper pulp dry powder are uniformly mixed and are made into powder, then the mixture is pressed into pellets, and is subjected to high-temperature vacuum distillation, so that fluoride and chloride in the aluminum ash as well as fluoride and metal sodium in the waste cathode carbon blocks are volatilized and then are separated from the aluminum ash and the waste cathode carbon blocks respectively, and meanwhile, cyanide in the waste cathode carbon blocks is decomposed; then distillation residues are smashed, the smashed distillation residues are matched and mixed with fly ash, high-temperature reduction is conducted on a material mainly composed of aluminum oxide and silicon dioxide in an electric arc furnace by taking fixed carbon in the waste cathode carbon blocks as a reducing agent so as to prepare the aluminum-silicon-iron alloy with certain components; and meanwhile, decomposition of aluminum nitride in the aluminum ash and complete decomposition of the cyanide in the waste cathode carbon blocks are completed in the high-temperature reduction process, and the comprehensive utilization of various kinds of dangerous waste and solid waste is realized in the same process.

Owner:NORTHEASTERN UNIV

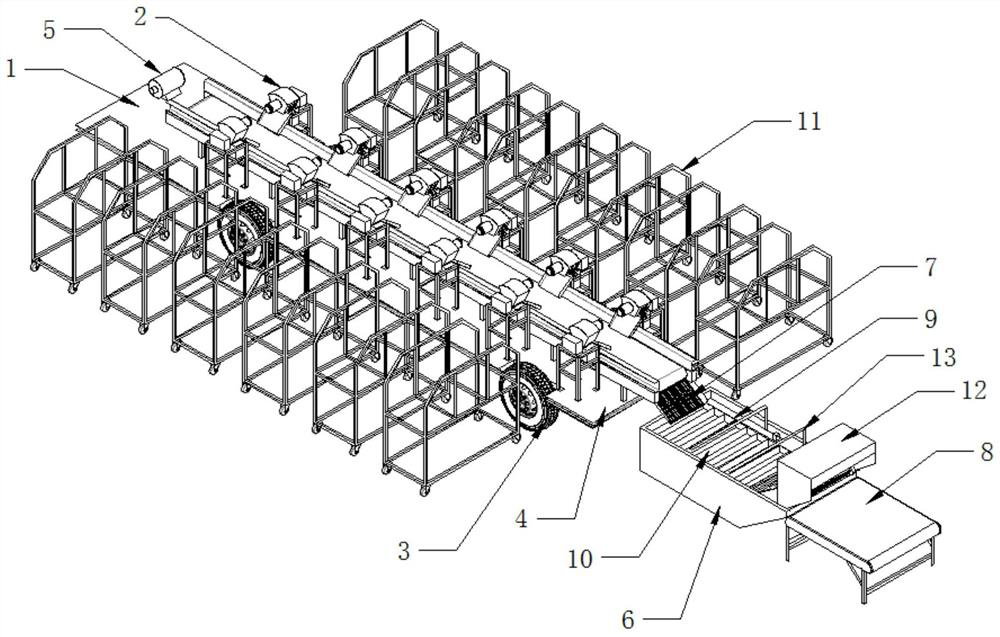

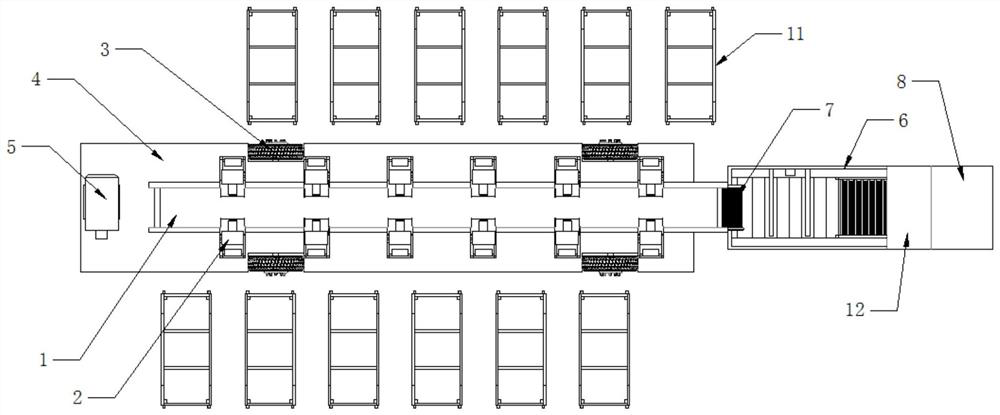

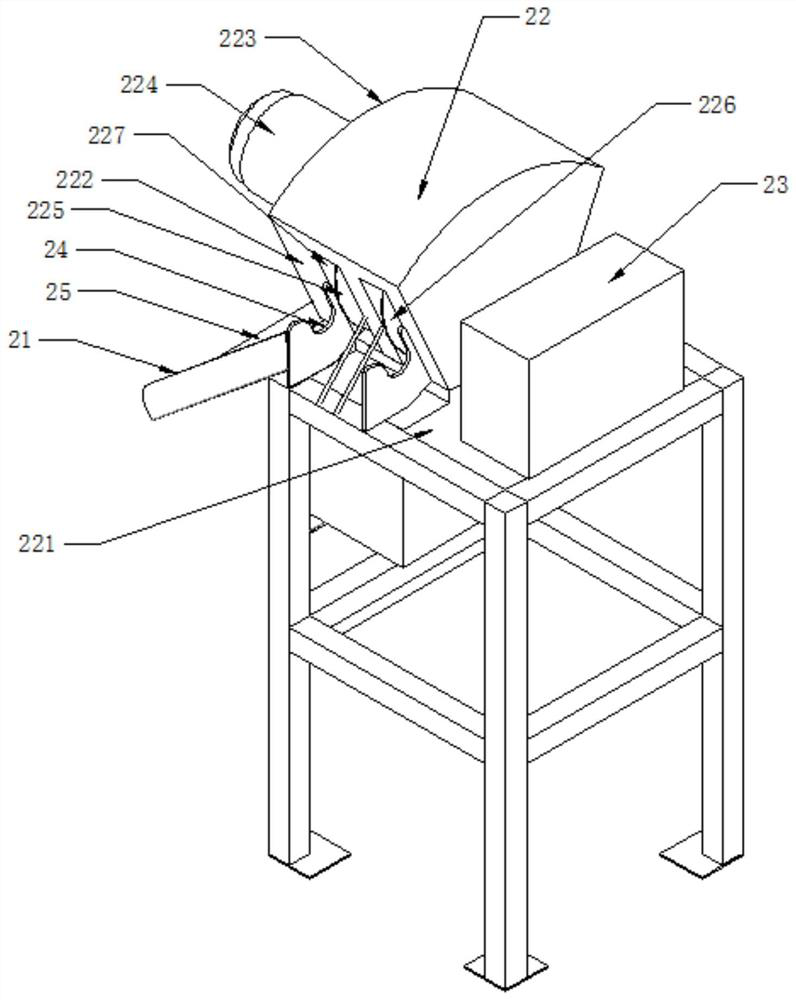

Movable automatic production equipment for healthy sugarcane seed stems

PendingCN113119215AReduce shipping costsReduce sugarcane wastageSeed arrangmentsSortingAgricultural engineeringAgricultural science

The invention discloses movable automatic production equipment for healthy sugarcane seed stems. The equipment comprises a conveyor belt and a sugarcane seed cutting device, wherein a seed outlet of the sugarcane seed cutting device is formed above the conveyor belt, and the conveyor belt and the sugarcane seed cutting device are fixed to a support with wheels; and a seed soaking device is further arranged at the conveying tail end of the conveyor belt and comprises a seed soaking groove, a net chain conveyor belt is arranged in the seed soaking groove, a conveying net belt which obliquely conveys upwards is arranged at the tail end of the net chain conveyor belt, conveying chains which coaxially drive are further arranged at the two sides of the net chain conveyor belt and the conveying net belt, conveying partition plates perpendicular to the conveying direction of the conveyor belt and the conveying net belt are arranged on the conveying chains, the conveying partition plates are arranged above the conveyor belt and the conveying net belt, and gaps are reserved between the bottoms of the conveying partition plates and the conveyor belt and between the bottoms of the conveying partition plates and the conveying net belt. According to the production equipment, fresh sugarcane stems which are cut down can be processed on site, so that the freight can be reduced, the sugarcane loss can be reduced, and the quality of healthy sugarcane seed stems can also be improved.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Thermal-insulating heat-preservation wall material and preparation method thereof

The invention provides a thermal-insulating heat-preservation wall material and a preparation method thereof. The thermal-insulating heat-preservation wall material comprises river sludge, expanded perlite, waste building grains, silicate, a wood fiber, light ceramsite, magnesium silicate, floating beads, glass wool, an adhesive and a permeation agent. Due to the addition of inorganic components,such as the river sludge, the expanded perlite, the silicate, the light ceramsite, the magnesium silicate and the floating beads, into the wall material, the addition of organic components such as thewaste building grains, the wood fiber and the glass wool, and reasonable proportioning of the components, and in addition the preparation method provided by the invention, the wall material is relatively good in heat preservation property and relatively good in environment protection when being compared with a conventional wall heat-preservation material.

Owner:HEFEI SHANGHAN DECORATION ENG CO LTD

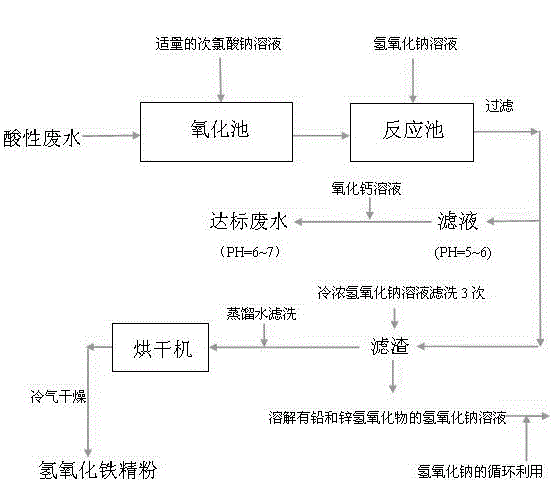

Production method for preparing ferric hydroxide by utilizing ferrite-containing waste water

InactiveCN104402145ALow priceStrong oxidation abilityIron oxides/hydroxidesMultistage water/sewage treatmentFerric hydroxideCold air

The invention discloses a production method for preparing ferric hydroxide by utilizing ferrite-containing waste water. The production method comprises the following steps: introducing acid waste water into an oxidation pond, and continuously adding a NaClO solution with the concentration of active Cl- being greater than or equal to 5.2% while stirring, so that ferrous ions in the waste water are completely oxidized into ferric ions; introducing the obtained completely-oxidized waste water into a reaction tank, and continuously adding a sodium hydroxide solution while stirring until the pH is equal to 5-6; filtering a solution in the reaction tank to obtain filter residues and a filter liquor; filter-pressing the obtained filter residues in a filter-pressing machine, filtering and washing the filter residues by using a sodium hydroxide solution with the concentration of 0.1 mol / L, and after filtering, filtering the obtained filter residues with water; feeding the obtained filter residues in a dryer for cold air drying to obtain ferric hydroxide fine powder. Ferric hydroxide with higher purity is prepared from the waste water containing the ferrite ions by using a low-cost and environment-friendly sodium hypochlorite oxidizing agent, so that a great deal of disadvantages in a traditional method are avoided.

Owner:NANTONG UNIVERSITY

Method for sterilizing and disinfecting Dendrobium officinale capsules

ActiveCN103749036AImprove sterilization effectImprove the success rate of sowingSeed immunisationAlcoholPetal

The invention relates to a method for sterilizing and disinfecting Dendrobium officinale capsules, belonging to the field of biotechnology. The method comprises the steps of firstly, selecting healthy and fully grown Dendrobium officinale capsules, removing tori and residual petals; secondly, cleaning the selected Dendrobium officinale capsules with scrubbing solution, airing until the surfaces of the capsules have no moisture, soaking with alcohol with weight percentage of 75%, wiping and setting aside; thirdly, placing the treated capsules into a closed vessel 4 hours before sowing, and igniting dichlord isocyanurice acid aerosol with mass concentration of 2% at 8-12g / m3 and placing into the closed vessel for sterilization. The method has the beneficial effects of having good sterilizing and disinfecting effect and no harm to health of human body and promoting Dendrobium officinale seed germination in advance.

Owner:YUNNAN GAOSHAN BIOLOGICAL AGRI

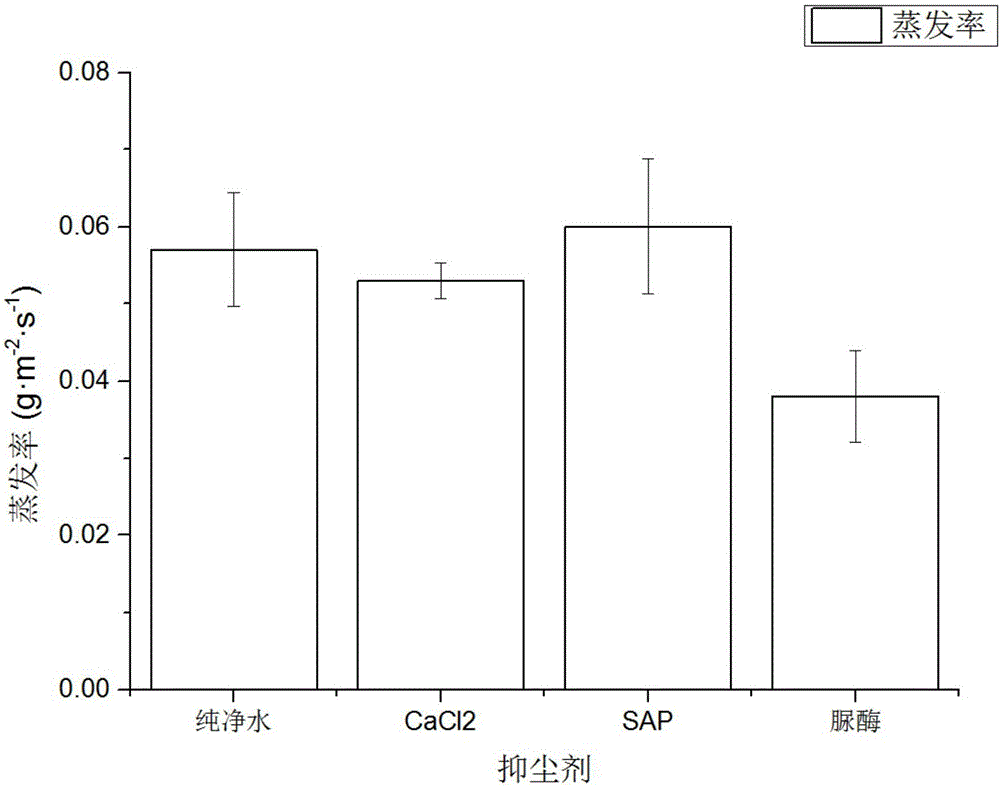

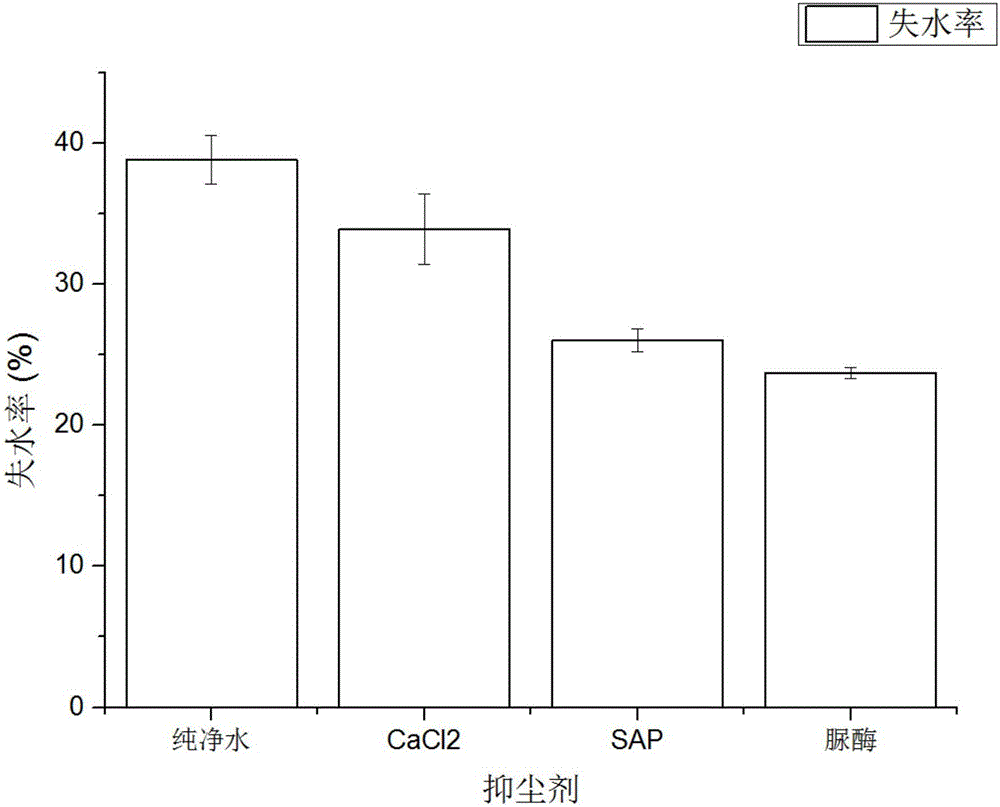

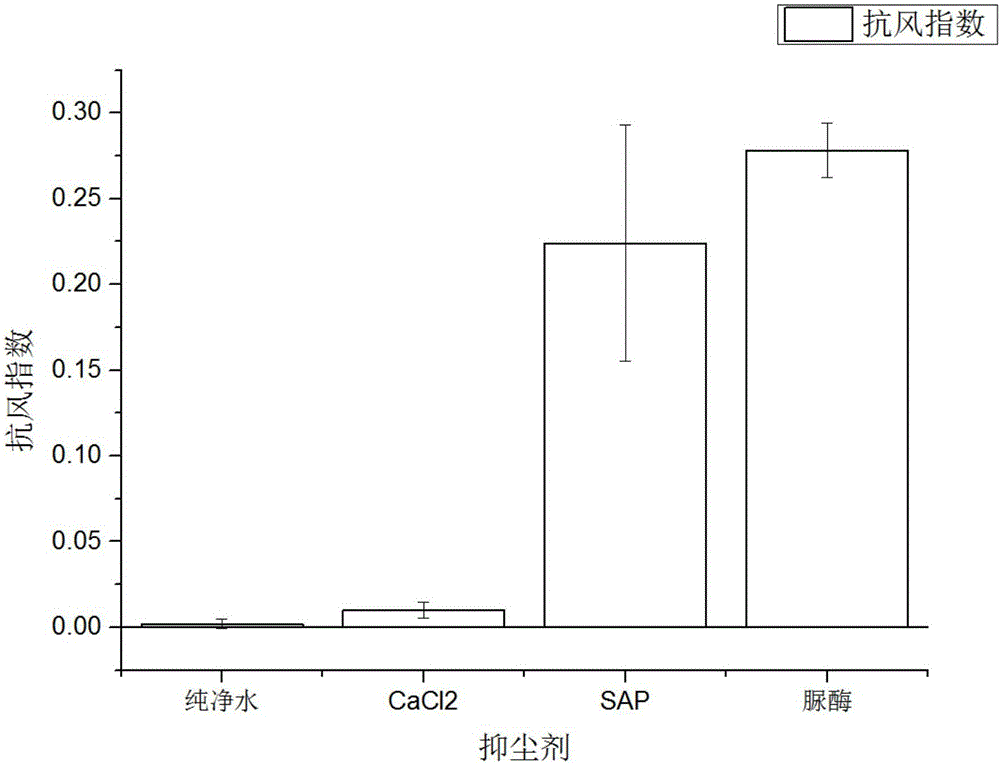

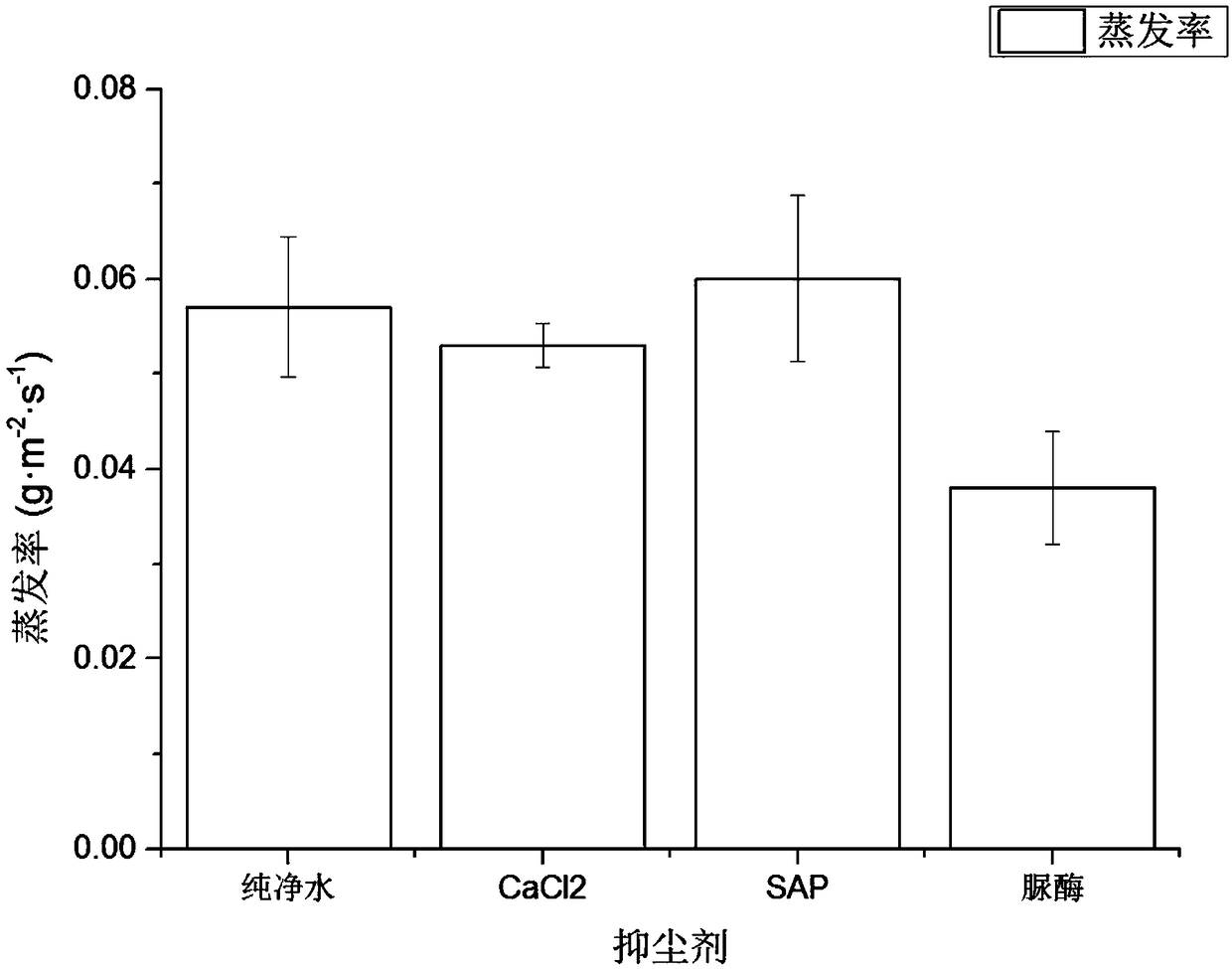

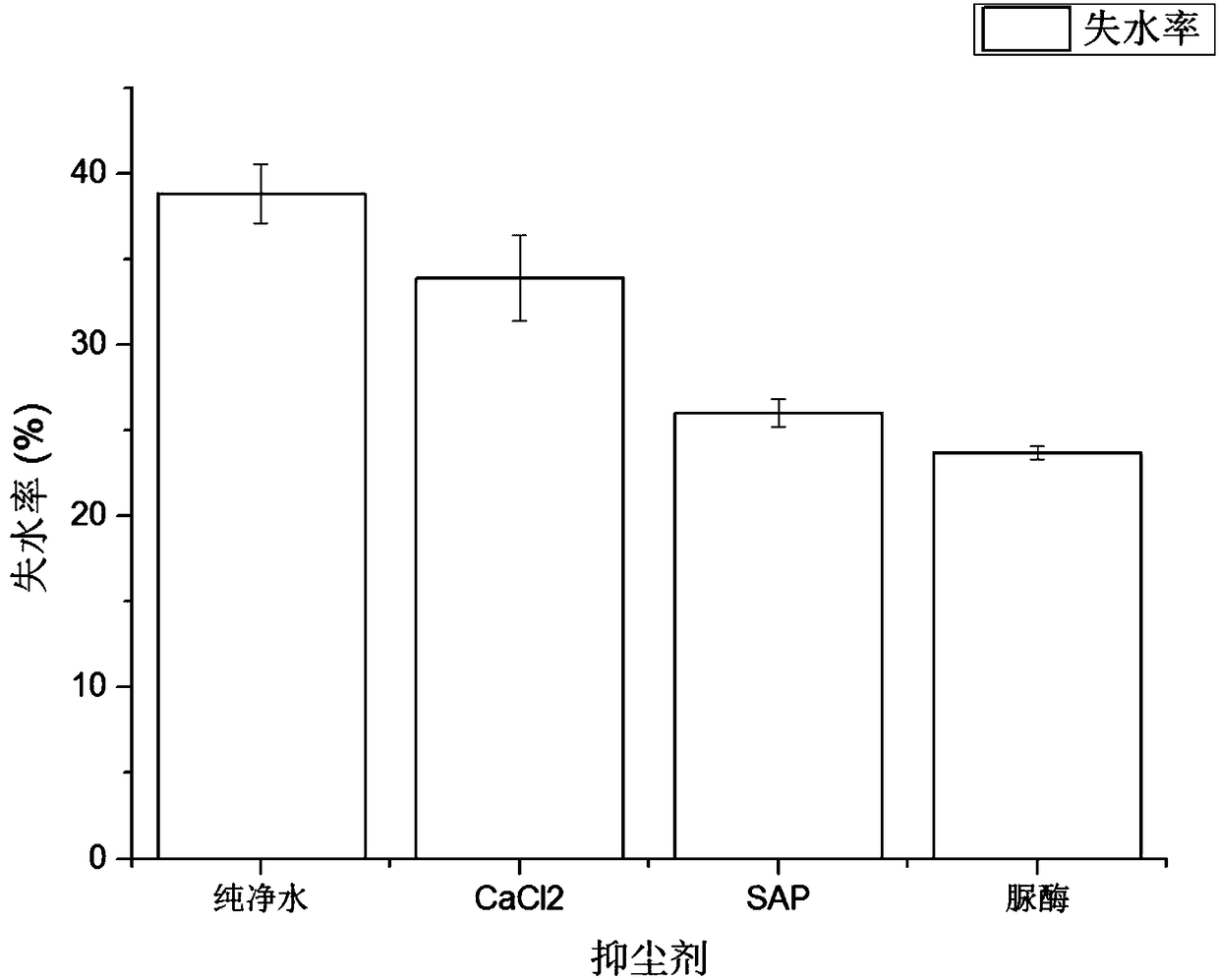

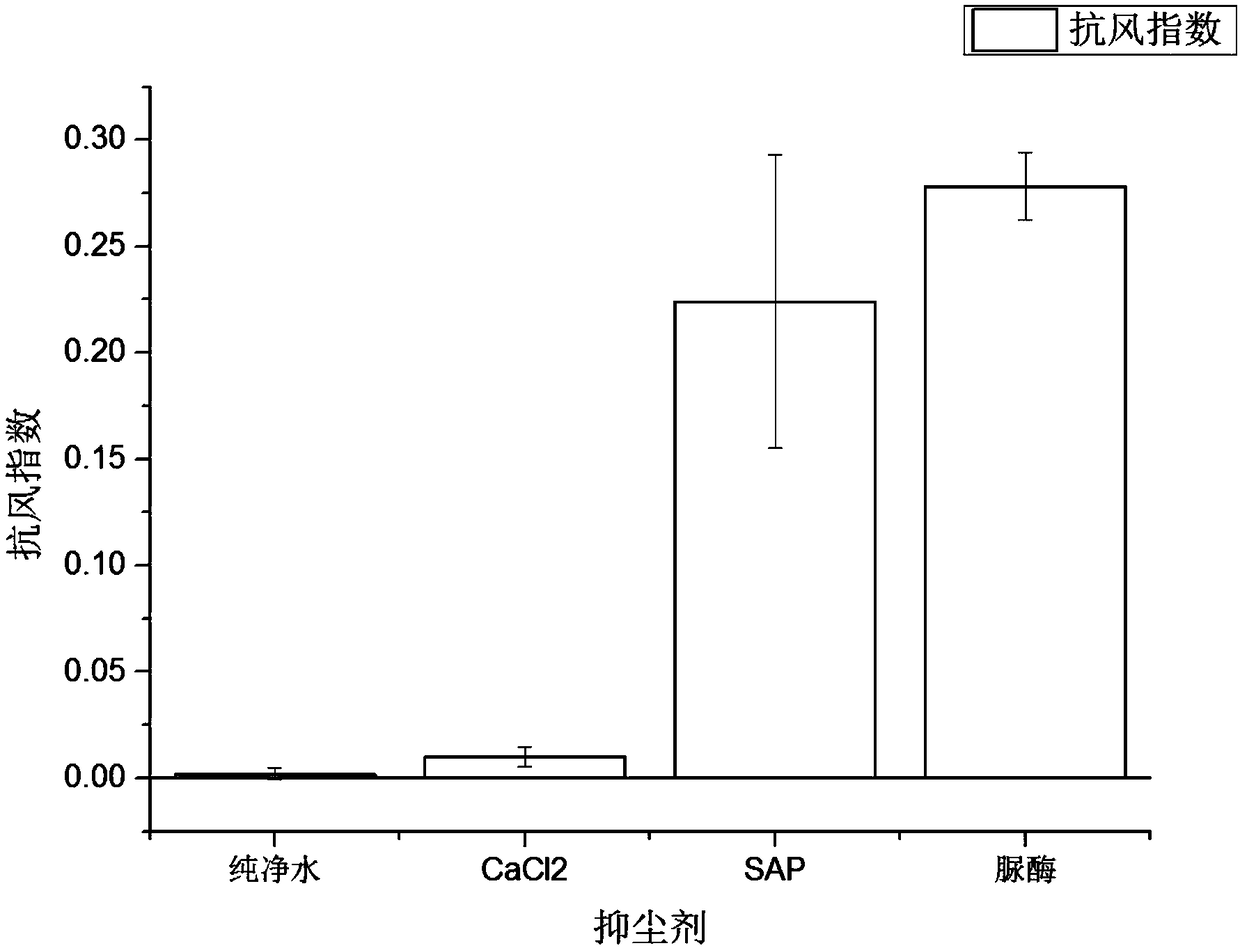

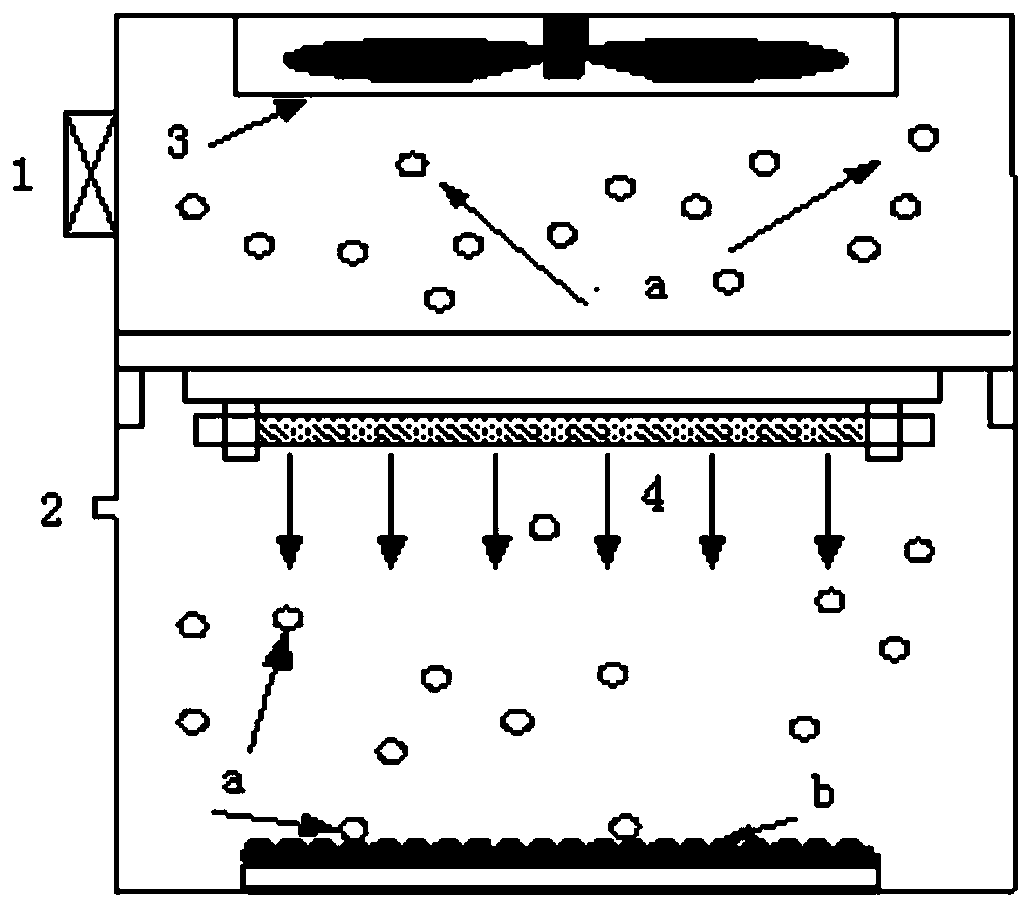

Multifunctional compounded flying dust suppressant prepared on basis of active enzyme

ActiveCN106753248AEnhanced inhibitory effectLong duration of actionOther chemical processesActive enzymeMoisture absorption

The invention discloses a multifunctional compounded flying dust suppressant prepared on the basis of an active enzyme. The multifunctional compounded flying dust suppressant is prepared from the following raw materials in percentage by weight: 0.28-0.32% of bioactive enzyme, 0.07-0.12% of high-polymer water-absorbing resin, 4.50-5.00% of CO(NH2)2, 4.40-4.50% of CaCl2, 2.20-2.30% of CaO and the balance of water. The bioactive enzyme is urease which is an artificially extracted plant enzyme. The application method of the dust suppressant comprises the following steps: dissolving powder materials in water according to the percentage by weight, uniformly mixing, spraying the mixture on the road surface and stockpile surface, wherein the amount of the mixture is 1-3L for every 1m<2> of the municipal road, and the amount of the mixture is 3-6L for every 1m<2> of the stockpile. By utilizing the principles of moisture absorption, moisture retention, bonding, biodegradation and biological calcification, the dust suppressant effectively enhances the flying dust suppression effect, and has the advantages of long acting duration time, lower secondary flying dust, high reaction speed, high temperature resistance and environment friendliness.

Owner:SOUTHEAST UNIV

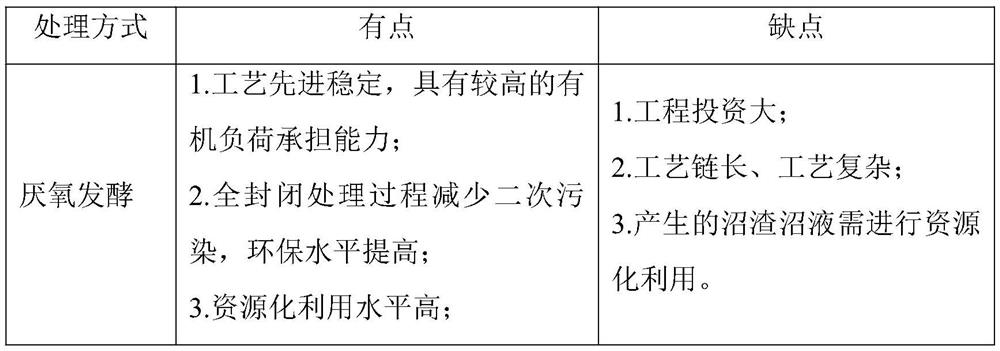

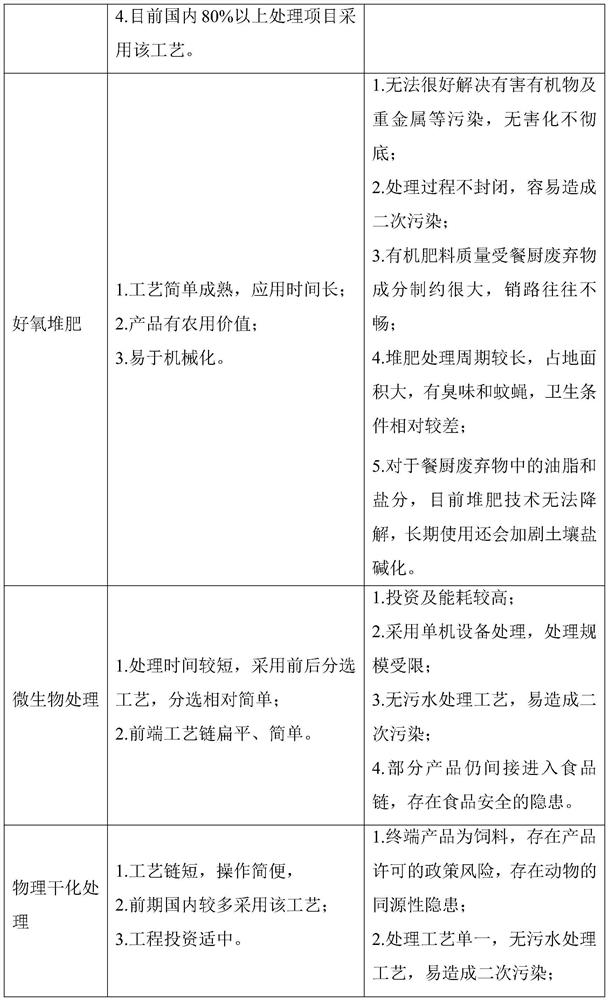

Kitchen waste enzymolysis treatment process

PendingCN112746090AReduce barrier effectAvoid Breeding SituationsPeptide preparation methodsFermentationNutritionProcess engineering

The invention discloses a kitchen waste enzymolysis treatment process. The kitchen waste enzymolysis treatment process comprises the following steps of (1) physical crushing, (2) cooking, (3) three-phase separation, (4) biological enzymolysis, (5) multi-stage filtration, (6) resin treatment, (7) solid drying and blending, (8) liquid blending, and (9) filling, packaging and warehousing. By the adoption of the process, only one-time temperature rise is needed, the treatment time is 8-10h, a product can be stored for 6-12 months at the room temperature through an anticorrosion method after nutrients are preserved, the product is not prone to being rotted and attracting mosquitoes, the production process is short, the automation degree is high, and potential safety hazards such as food entering do not exist.

Owner:NANNING DONG HIGHER BIO TECH

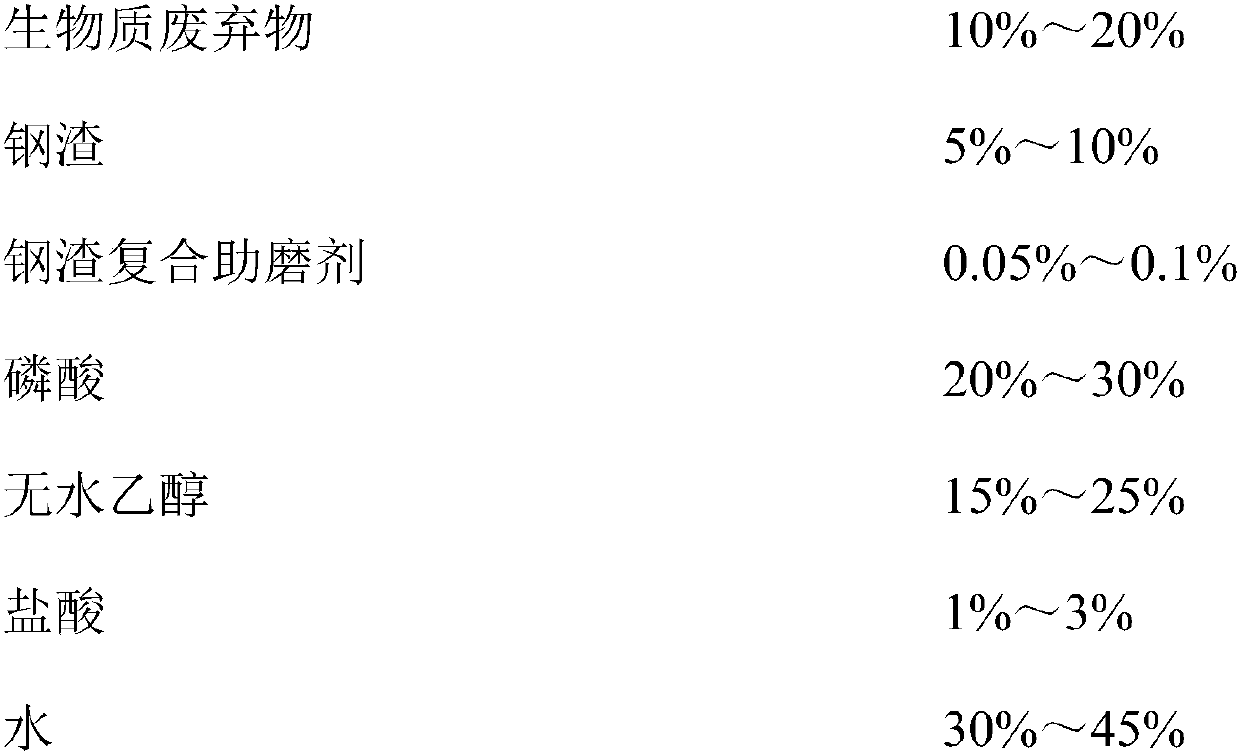

Composite modified biomass activated carbon for degrading formaldehyde and preparation method of activated carbon

ActiveCN109775706AExtended service lifePromote degradationCarbon compoundsAir quality improvementResource utilizationRed mud

The invention discloses composite modified biomass activated carbon for degrading formaldehyde and a preparation method of the activated carbon and belongs to the field of solid waste resource utilization. The composite modified biomass activated carbon comprises biomass waste, a composite modification agent, a composite grinding aid, phosphoric acid, absolute ethyl alcohol, hydrochloric acid andwater. The biomass waste comprises one or more of fruit shells, kernels and straw; the composite modification agent is a mixture of Bayer-process red mud and coal gangue. The Bayer-process red mud, the coal gangue and the biomass waste material are compounded for preparing the composite modified biomass activated carbon, a metal oxide in the mixture of the Bayer-process red mud and the coal gangueis used for modifying the biomass waste material, the service life of the activated carbon is prolonged, the mechanical strength of the activated carbon is improved, the production cost of the activated carbon is decreased by 50-60%, the high additional value application range of the Bayer-process red mud, the coal gangue and the biomass waste material is enlarged, and a new idea of using waste to treat dangers is achieved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A method for treating coke oven gas desulfurization by-product sulfur paste

ActiveCN103264991BThorough treatmentNo secondary pollutionThiosulfates/dithionites/polythionitesCalcium/strontium/barium sulfatesResource utilizationImpurity

Owner:张建利

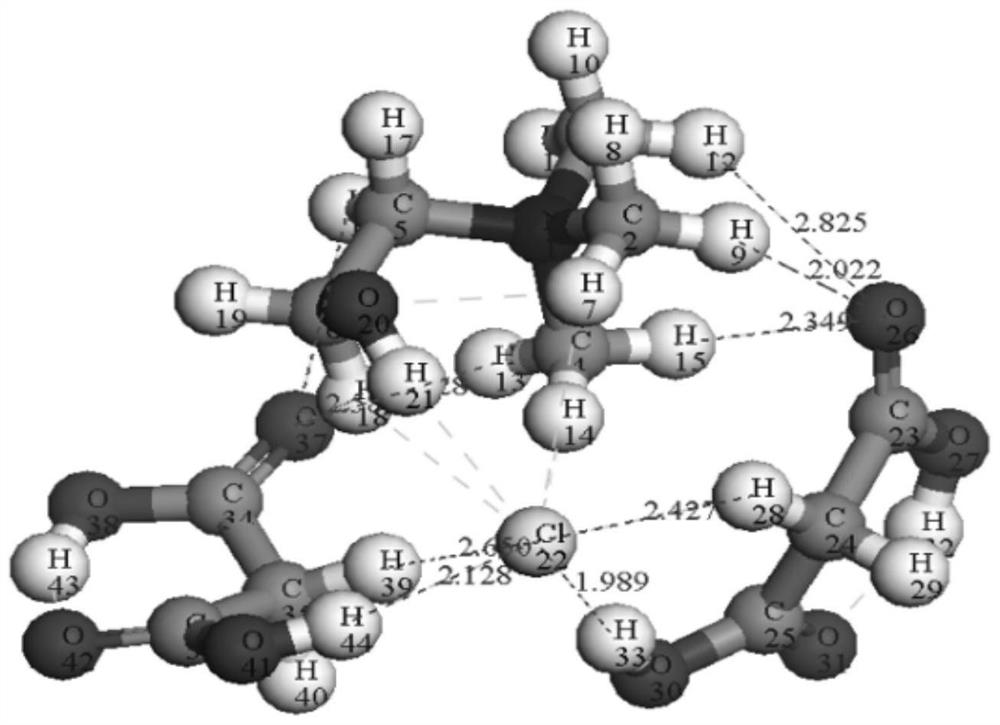

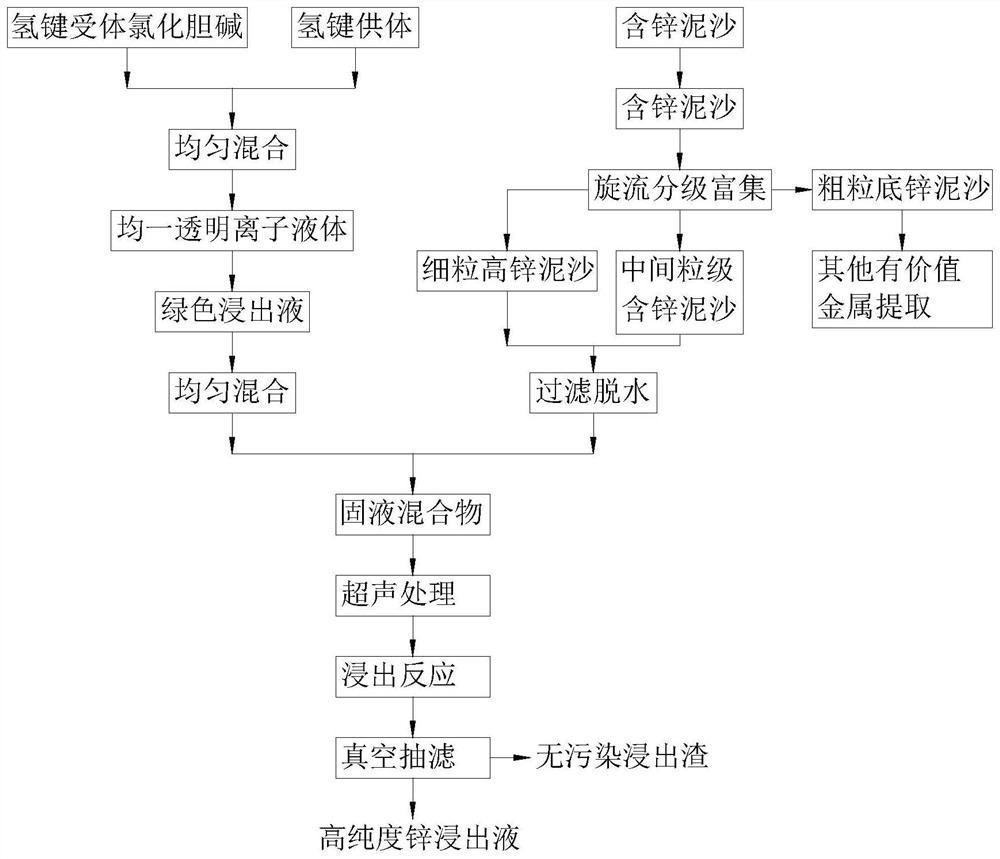

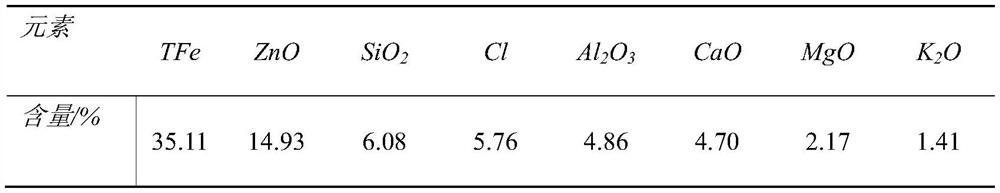

Rotational flow grading-ionic liquid-ultrasonic synergistic selective zinc immersion method

ActiveCN114317984AHigh purityReduce manufacturing costProcess efficiency improvementPregnant leach solutionSludge

The invention discloses a method for selective zinc immersion through cyclone classification-ionic liquid-ultrasonic cooperation, and belongs to the technical field of hydrometallurgy. The method comprises the steps of graded enrichment of zinc-containing dust mud, synthesis of ionic liquid and selective leaching of zinc. According to the method, the special-shaped hydrocyclone is used for pretreating the zinc-containing dust sludge to obtain fine-grain zinc-rich dust sludge, so that efficient leaching of zinc is facilitated, and meanwhile, opening and dispersing of floccules in the zinc-containing dust sludge are facilitated; the ionic liquid and ultrasonic synergistic leaching system has selective dissolving capacity on ZnO, the obtained zinc-containing leaching solution is high in purity, and the problems that components are complex, separation is difficult and the like in a traditional leaching system are solved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

A multifunctional compound fugitive dust inhibitor based on active enzyme preparation

ActiveCN106753248BCorrosiveIncrease the residual rateOther chemical processesActive enzymeMoisture absorption

The invention discloses a multifunctional compounded flying dust suppressant prepared on the basis of an active enzyme. The multifunctional compounded flying dust suppressant is prepared from the following raw materials in percentage by weight: 0.28-0.32% of bioactive enzyme, 0.07-0.12% of high-polymer water-absorbing resin, 4.50-5.00% of CO(NH2)2, 4.40-4.50% of CaCl2, 2.20-2.30% of CaO and the balance of water. The bioactive enzyme is urease which is an artificially extracted plant enzyme. The application method of the dust suppressant comprises the following steps: dissolving powder materials in water according to the percentage by weight, uniformly mixing, spraying the mixture on the road surface and stockpile surface, wherein the amount of the mixture is 1-3L for every 1m<2> of the municipal road, and the amount of the mixture is 3-6L for every 1m<2> of the stockpile. By utilizing the principles of moisture absorption, moisture retention, bonding, biodegradation and biological calcification, the dust suppressant effectively enhances the flying dust suppression effect, and has the advantages of long acting duration time, lower secondary flying dust, high reaction speed, high temperature resistance and environment friendliness.

Owner:SOUTHEAST UNIV

Bayer-process red mud modified biomass activated carbon for degrading formaldehyde and preparation method thereof

InactiveCN109809404AReduce manufacturing costPromote sustainable developmentCarbon compoundsDispersed particle separationBiomassChemistry

The invention discloses Bayer-process red mud modified biomass activated carbon for degrading formaldehyde and a preparation method thereof and belongs to the field of resource utilization of solid wastes. The Bayer-process red mud modified biomass activated carbon comprises biomass waste, red mud, phosphoric acid, absolute ethyl alcohol, hydrochloric acid and water. The biomass waste comprises one or more of shells, pits and straws. The red mud is Bayer-process red mud. The Bayer-process red mud modified biomass activated carbon is prepared by compounding the Bayer-process red mud and biomasswaste materials; metal oxide in the Bayer-process red mud is used for carrying out modification treatment on the biomass waste materials and the production cost of the modified activated carbon is reduced by 50 to 60 percent; high-additional-value application of the Bayer-process red mud and the biomass waste materials is expanded and a novel concept of treating dangerous materials with waste isrealized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

A kind of carbonylation catalyst reaction waste liquid treatment method

ActiveCN104478063BEasy to operateEasy to cause secondary pollutionWater treatment compoundsWater contaminantsPtru catalystCopper oxide

The invention relates to an oxo catalyst reaction waste liquid treatment method. The method adopting an intermittent heterogeneous phase technology to process a waste liquid comprises the following steps: adding an iron oxide immobilized metal catalyst into an oxo catalyst reaction waste liquid, stirring at 30-80DEG C for 1-6h, filtering, and separating, wherein the oxo catalyst reaction waste liquid is a reaction waste liquid obtained after the preparation of acetylacetonatocarbonyl rhodium from dimethyl formamide (DMF); the pH value of the waste liquid is 1-6, and the waste liquid contains 5-20mass% of the DMF and 0.2-2mass% of acetylacetone; the iron oxide immobilized metal catalyst comprises a iron oxide immobilized metal single substance active component, the metal oxide is one or more of iron oxide, copper oxide, cobalt oxide and cerium oxide , and the metal single substance active component is one or more of ruthenium, palladium, platinum, gold and nickel; and the mass proportion of iron oxide in the catalyst is 40-95%, the mass proportion of other metal oxides in the catalyst is 20-60%, and the mass proportion of the metal simple substance active component in the catalyst is 1-10%.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

Porous carbon material and its preparation method

The invention discloses a porous carbon material and its preparation method. The preparation method provided by the invention successively comprises steps of: raw material and auxiliary material selection, pulverization, spheroidization, grading, burdening, mixing, molding, roasting and the like. Green petroleum coke and green pitch coke are creatively used as raw materials. A filtration materialprepared after spheroidization of a green coke powder has large contractility, high strength, uniform pore distribution, smooth pore path, high filtration precision and good transmissivity, is not easy to block during the purification process, is easy to regenerate, and has long service life. The porous carbon material prepared in the invention can be widely used as a filtration material, a thermal insulation material, a conductance electrode and the like.

Owner:ZIGONG YUXING CARBON PRODS

Plasma powder making device with grading device and powder making process thereof

PendingCN112935269AEasy to cause secondary pollutionImprove efficiencyCombination devicesGas current separationDust controlEngineering

The invention belongs to the technical field of material preparation, and particularly discloses a plasma powder making device with a grading device and a powder making process thereof. The powder making device comprises a plasma torch, a reactor, the grading device and a cyclone bag-type dust collector. The upper portion of the plasma torch is connected with a powder feeder, and the side surface of the plasma torch is connected with a high-frequency induction power supply. The upper end of the reactor is connected with the plasma torch, and the lower end of the reactor is connected with a first ejector. The side surface of the bottom of the grading device is connected with the first ejector through a pipeline, the bottom of the grading device is connected with a fine powder collecting tank, the side surface of the top of the grading device is connected with a second ejector, and the grading device is further provided with a dispersion air pipe. The cyclone bag-type dust collector is connected with the second ejector. According to the device, the plasma spheroidizing technology and the technology that ultra-high centrifugal force generated by an impeller rotating at a high speed is used for separating superfine powder are utilized, and the device has the beneficial effects that the structure is simple, use is convenient, plasma spheroidizing and powder separation are integrated, the powder making efficiency is high, and the powder making effect is good.

Owner:苏州汉霄等离子体科技有限公司

A kind of disinfection and sterilization method of dendrobium officinale capsule

ActiveCN103749036BSolve disinfection problemsImprove sterilization effectSeed immunisationDendrobium candidumAlcohol

The invention relates to a method for sterilizing and disinfecting Dendrobium officinale capsules, belonging to the field of biotechnology. The method comprises the steps of firstly, selecting healthy and fully grown Dendrobium officinale capsules, removing tori and residual petals; secondly, cleaning the selected Dendrobium officinale capsules with scrubbing solution, airing until the surfaces of the capsules have no moisture, soaking with alcohol with weight percentage of 75%, wiping and setting aside; thirdly, placing the treated capsules into a closed vessel 4 hours before sowing, and igniting dichlord isocyanurice acid aerosol with mass concentration of 2% at 8-12g / m3 and placing into the closed vessel for sterilization. The method has the beneficial effects of having good sterilizing and disinfecting effect and no harm to health of human body and promoting Dendrobium officinale seed germination in advance.

Owner:YUNNAN GAOSHAN BIOLOGICAL AGRI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com