Non-sintered brick prepared from river and lake silt and preparation process thereof

A technology of non-sintered bricks and preparation technology, which is applied in the field of building materials, can solve the problems of unguaranteed product quality, complicated process, waste of energy, etc., and achieve the effects of prolonging the service life, saving earth and rock resources, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

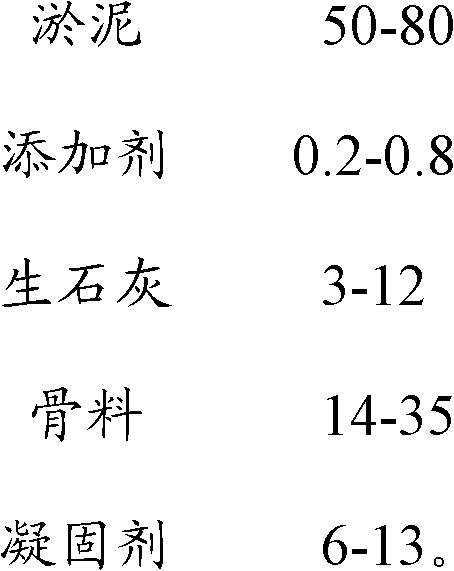

[0045] In the present embodiment, the raw materials for preparing the described non-fired bricks are composed as follows in parts by weight:

[0046]

[0047] Wherein, the additive comprises the following components in parts by weight:

[0048]

[0049] The parts by weight of the metal salt compound is the parts by weight of the metal ions contained therein.

Embodiment 2

[0051] In the present embodiment, the raw materials for preparing the described non-fired bricks are composed as follows in parts by weight:

[0052]

[0053]

[0054] Wherein, the additive comprises the following components in parts by weight:

[0055]

[0056] The parts by weight of the metal salt compound is the parts by weight of the metal ions contained therein.

Embodiment 3

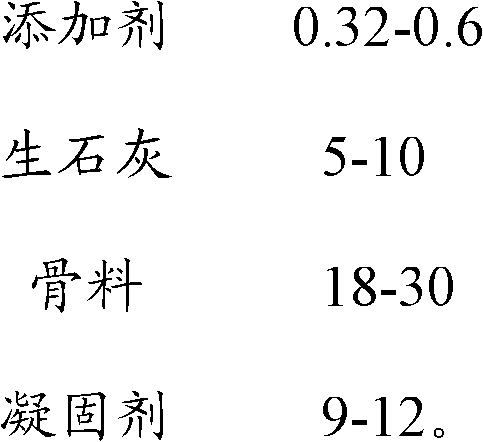

[0058] In the present embodiment, the raw materials for preparing the described non-fired bricks are composed as follows in parts by weight:

[0059]

[0060] Wherein, the additive comprises the following components in parts by weight:

[0061]

[0062] The parts by weight of the metal salt compound is the parts by weight of the metal ions contained therein.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com