Aquaculture feeding system

An aquaculture and feeder technology, applied in fish farming, application, animal husbandry, etc., can solve the problems of feeder failure, inability to work, damage and crushing of feed particles, etc., to achieve strong adaptability, uniform feeding, and consumption. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

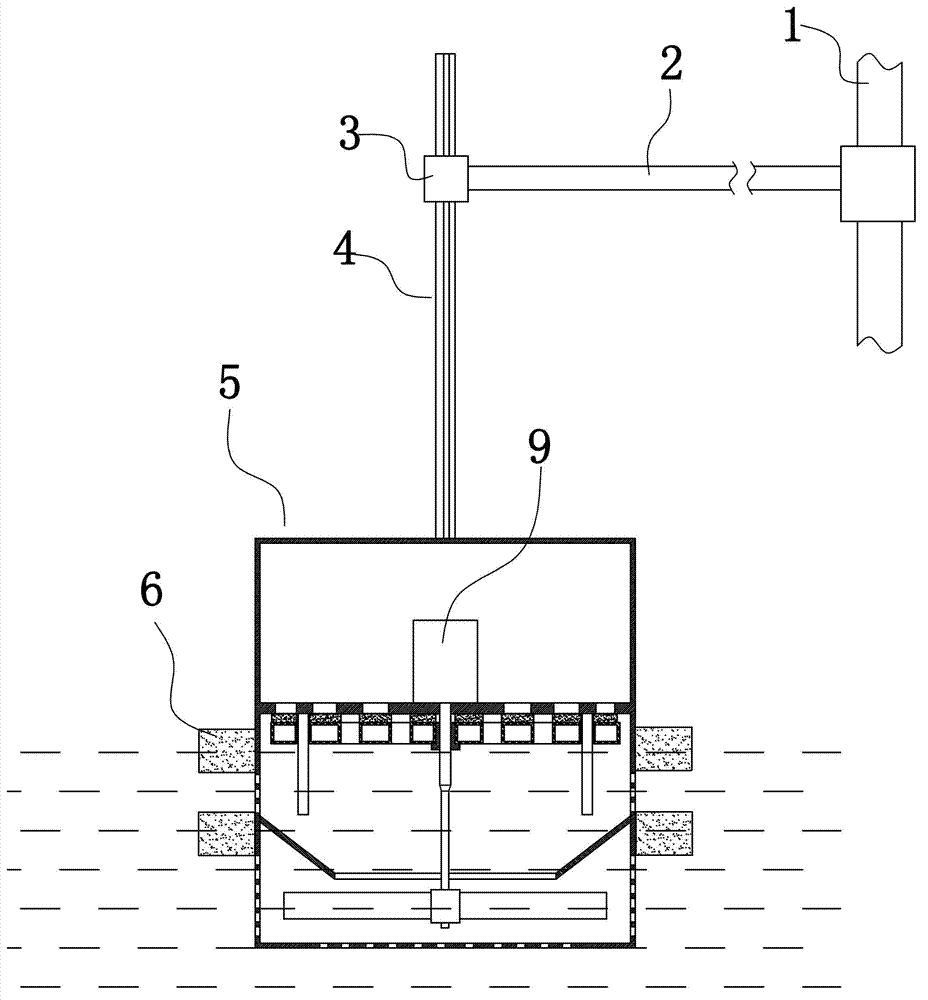

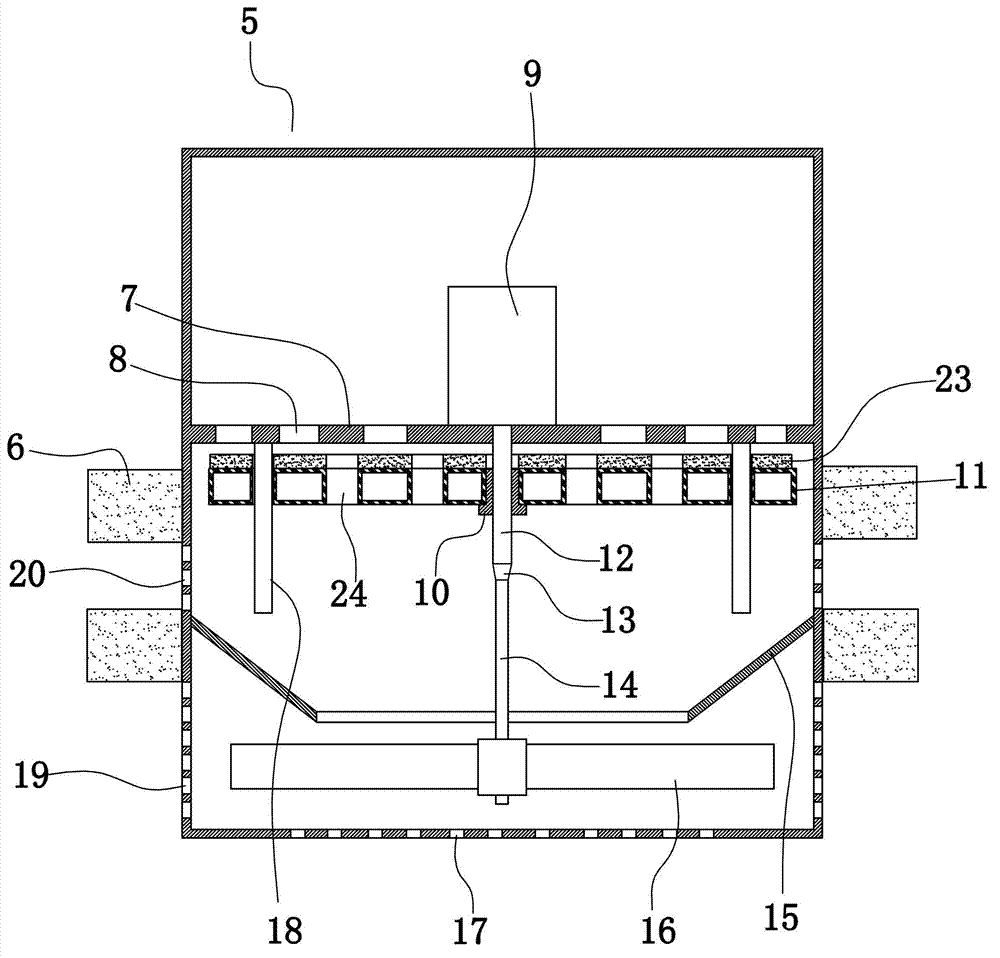

[0024] Such as figure 1 As shown, an aquaculture feeding system includes a column 1, a turnover rod 2 that can rotate around the column, a feed box 5 and a floating block 6 arranged on the outer surface of the feed box. Turnover bar 2 ends are provided with vertical guide sleeve 3, and the inwall of vertical guide sleeve is provided with vertical guide groove. A second vertical guide rod 4 is provided on the top surface of the material box 5, and a vertical guide block extending from the bottom of the second vertical guide rod to the top is provided on the side of the second vertical guide rod. The second vertical guide rod 4 can slide up and down and is arranged in the vertical guide sleeve 3, and the vertical guide block is arranged in the vertical guide groove.

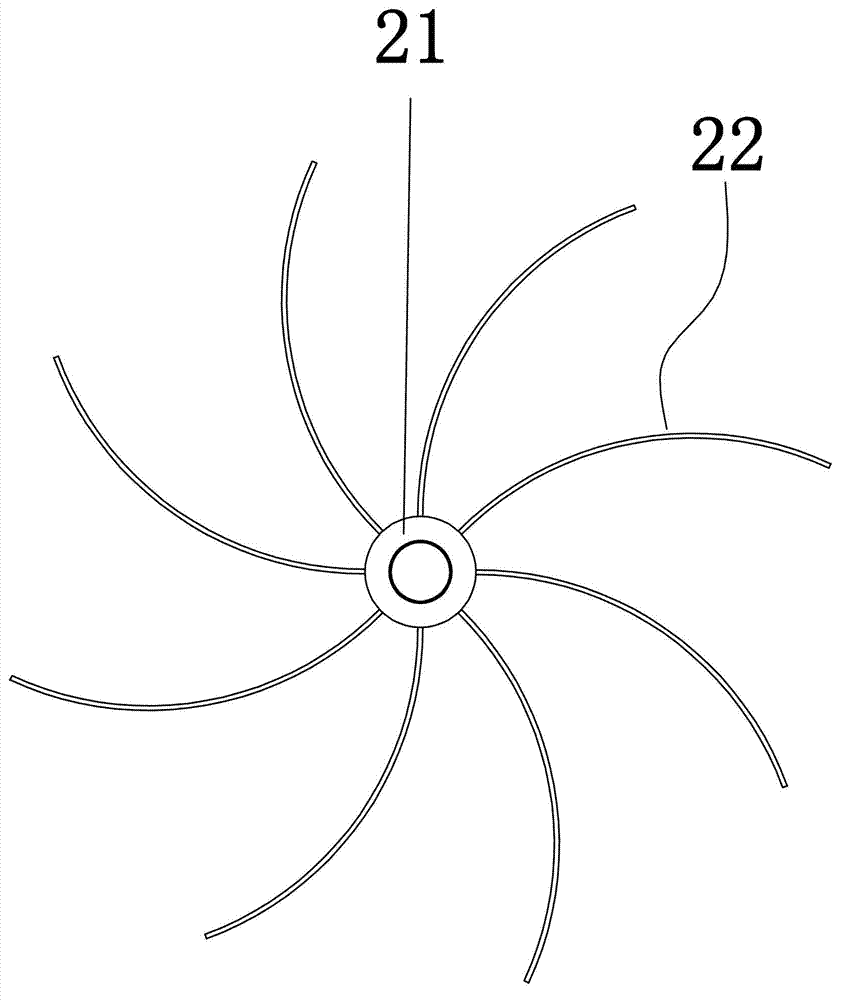

[0025] Such as figure 1 , figure 2As shown, the cross section of the feed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com