Processing method for comprehensively recovering high manganese asbolite

A processing method and technology for cobalt earth ore, which are applied in the field of comprehensive recovery of high manganese cobalt earth ore, can solve the problems of low recovery rate of valuable metal products, high labor intensity, environmental pollution, etc., and achieve low utilization rate and labor intensity. Large, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

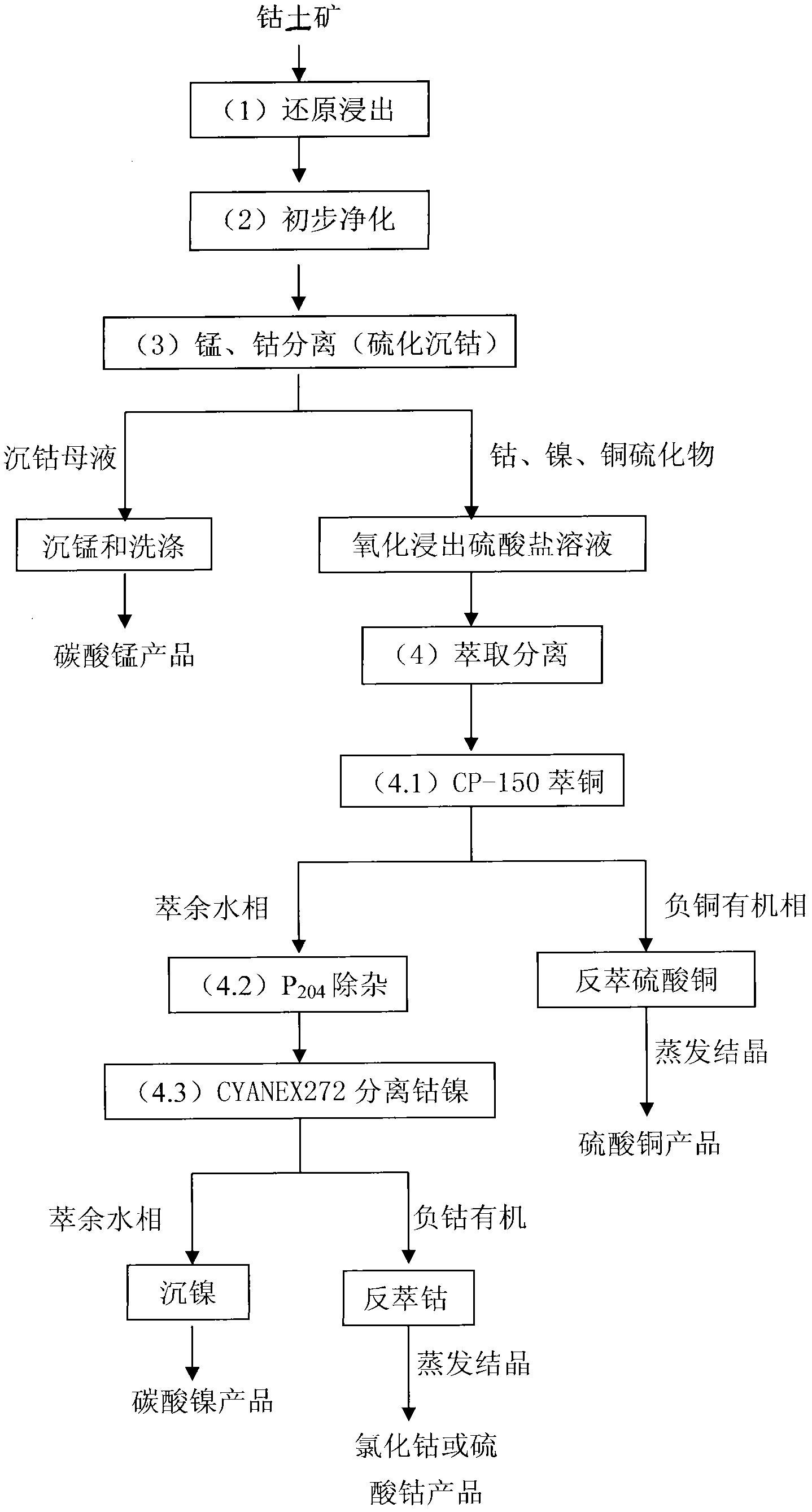

[0027] The present invention comprehensively reclaims the processing method of high manganese cobalt ore, and is made up of following processing steps:

[0028] (1) Reductive leaching step: put 1000 grams of cobalt ore crushed to 150 microns and 22% manganese into clear water at a liquid-solid weight ratio of 3:1, stir to form a slurry, and The temperature of the slurry is raised to 50°C, and then 220 grams of sodium thiosulfate and 396 grams of concentrated sulfuric acid are slowly added at the same time. The reduction leaching reaction time is controlled at about 4 hours, and the pH is always controlled during the reaction process. After the reaction is completed, filter to obtain the filtrate As a backup, the filtrate contains valuable metal ions: Mn 2+ 、Co 2+ 、Ni 2+ 、Cu 2+ and impurity metal ions: Fe 3+ , Zn 2+ 、Al 3+ , Mg 2+ , Ca 2+ 、Na + etc., discard the filter residue;

[0029] (2) preliminary purification step: the standby filtrate of step (1) gained is tran...

Embodiment 2

[0037] The present invention comprehensively reclaims the processing method of high manganese cobalt ore, and is made up of following processing steps:

[0038] (1) Reduction leaching step:

[0039] Put 1000 grams of cobalt ore crushed to 100 microns and with a manganese content of 30% into clear water at a liquid-solid weight ratio of 4:1, stir to form a slurry, and heat the slurry to 60°C, then Slowly add 300 grams of sodium thiosulfate and 540 grams of concentrated sulfuric acid at the same time, the reduction leaching reaction time is controlled at about 5 hours, and the PH1-2.5 is always controlled in the reaction process, and the filtrate is obtained by filtering after the reaction as a standby. Valuable metal ions: Mn 2+ 、Co 2+ 、Ni 2+ 、Cu 2+ and impurity metal ions: Fe 3+ , Zn 2+ 、Al 3+ , Mg 2+ , Ca 2+ 、Na + etc., discard the filter residue;

[0040] (2) Preliminary purification steps:

[0041] The standby filtrate of step (1) gained is transferred to prelim...

Embodiment 3

[0050] The present invention comprehensively reclaims the processing method of high manganese cobalt ore, and is made up of following processing steps:

[0051](1) Reduction leaching step:

[0052] Put 1000 grams of cobalt ore crushed to 75 microns and containing 43% manganese into clear water at a liquid-solid weight ratio of 5:1, stir to form a slurry, and heat the slurry to 80°C. Slowly add 430 grams of sodium thiosulfate and 774 grams of concentrated sulfuric acid, the reduction leaching reaction time is controlled at about 6 hours, and the PH1-2.5 is always controlled during the reaction process, and the filtrate is obtained by filtering after the reaction as a backup. Valence metal ion: Mn 2+ 、Co 2+ 、Ni 2+ 、Cu 2+ and impurity metal ions: Fe 3+ , Zn 2+ 、Al 3+ , Mg 2+ , Ca 2+ 、Na + etc., discard the filter residue;

[0053] (2) Preliminary purification steps:

[0054] The standby filtrate of step (1) gained is transferred to preliminary purification, preliminar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com