High-quality harmless utilizing method of hyperaccumulator

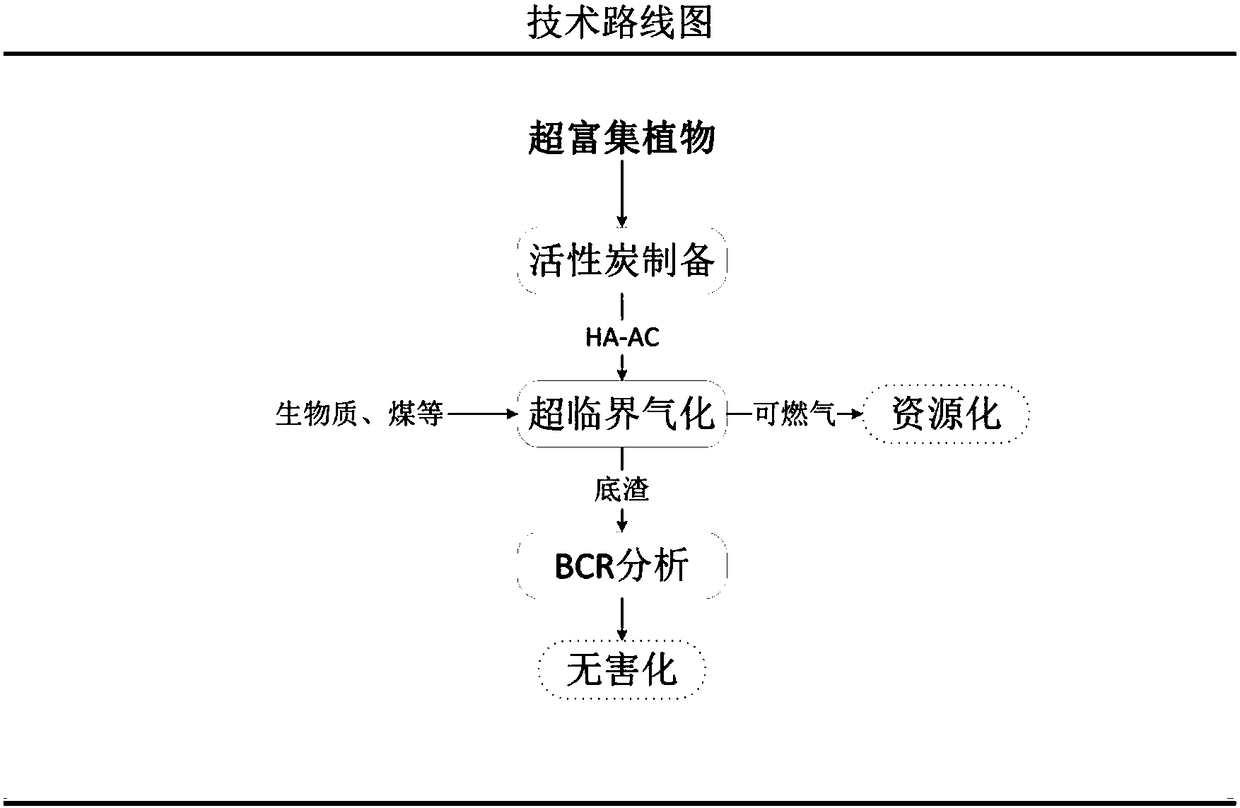

A kind of ultra-enrichment plant and harmless technology, which is applied in the field of deep processing and utilization of hyper-accumulation plants, can solve the problems of long preparation time, large-scale application limitation, reactor tube wall corrosion, etc., and achieve simple process flow and resource utilization. The effect of chemical treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

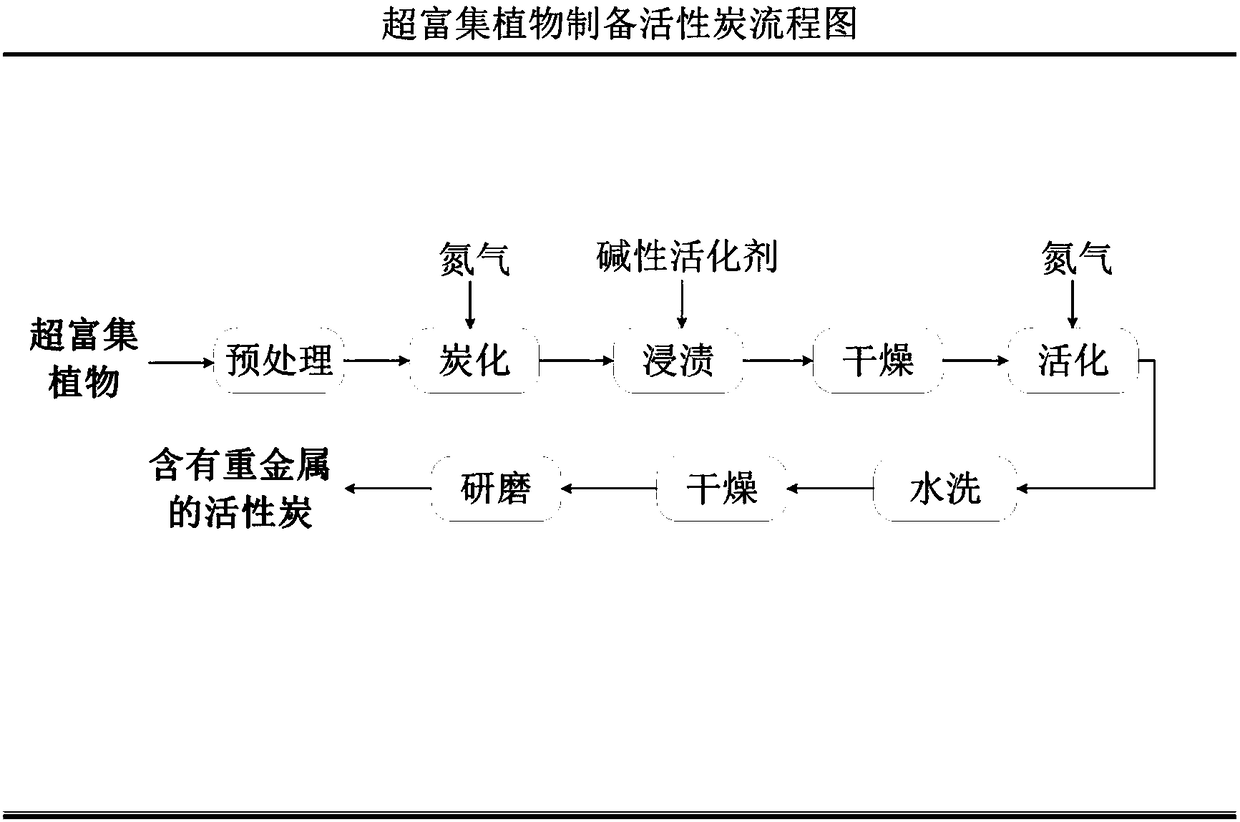

[0047] The concrete method steps of utilizing hyperaccumulator plant to prepare activated carbon are:

[0048] (1) Pretreatment: pulverize the centipede grass, dry it at 105°C for 24 hours, pass it through a 100-mesh sieve, and store it sealed for later use;

[0049] (2) Carbonization: carbonize the centipede grass pulverized material in step (1) in a nitrogen atmosphere (such as a muffle furnace, etc.), wherein the carbonization temperature is 500 ° C, and the carbonization time is 30 minutes;

[0050] (3) Impregnation: impregnate the carbonized material in step (2) with an alkaline solution with a mass fraction of 50%, and uniformly mix once every 8 hours during this period, wherein the mass ratio of the carbonized material to the alkaline activator is 1:4;

[0051] (4) Drying: After soaking for 24 hours, dry at 105°C for 12 hours to obtain a mixture of carbonized material and alkaline active agent;

[0052] (5) Activation: Activate the carbonized material and the alkaline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com