Method for calcining cement by carbide slag replacing whole limestone

A calcium carbide slag and limestone technology is applied in the field of inorganic non-metallic materials to achieve the effects of reducing heat consumption, reducing CO2 emissions and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

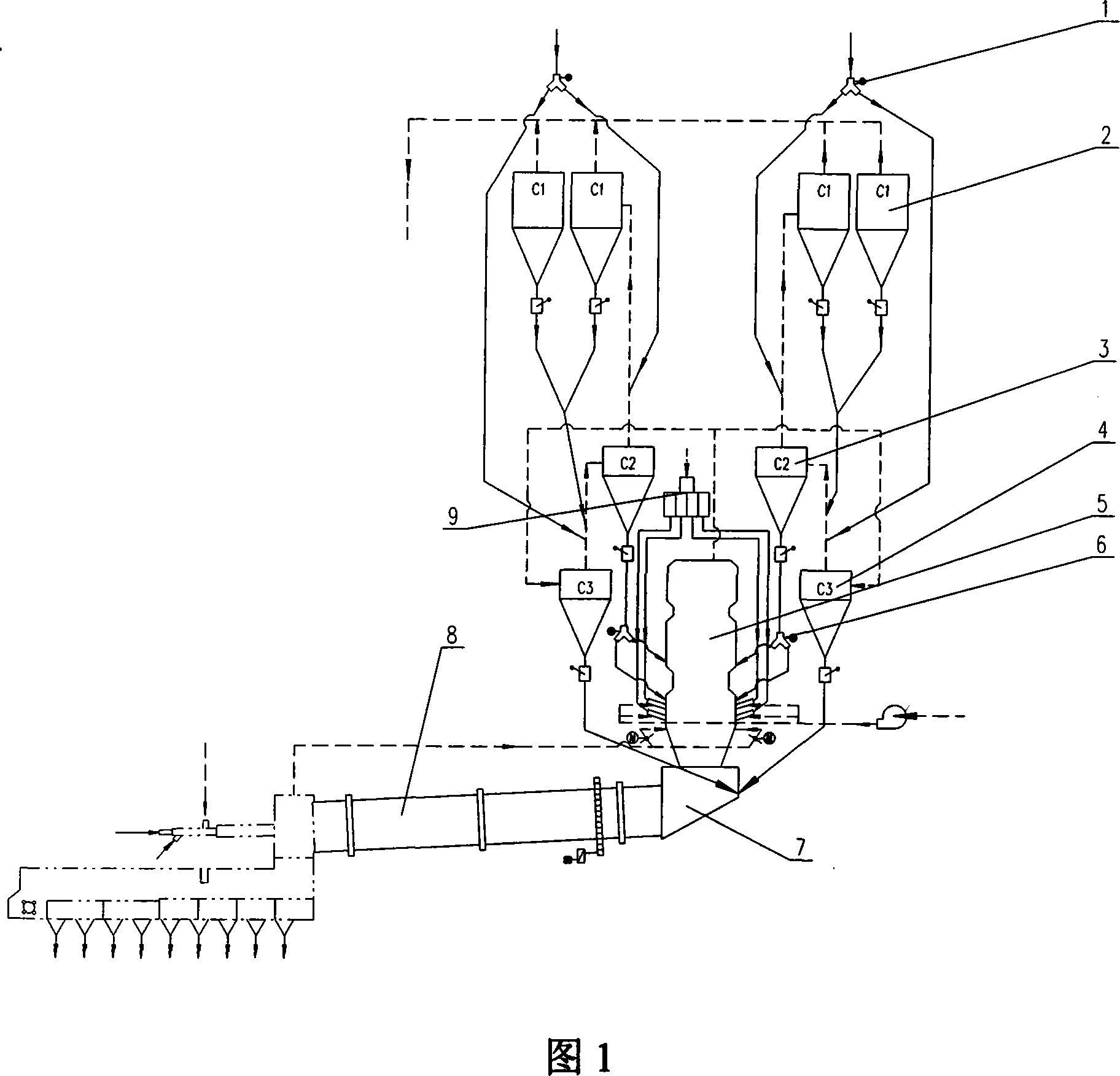

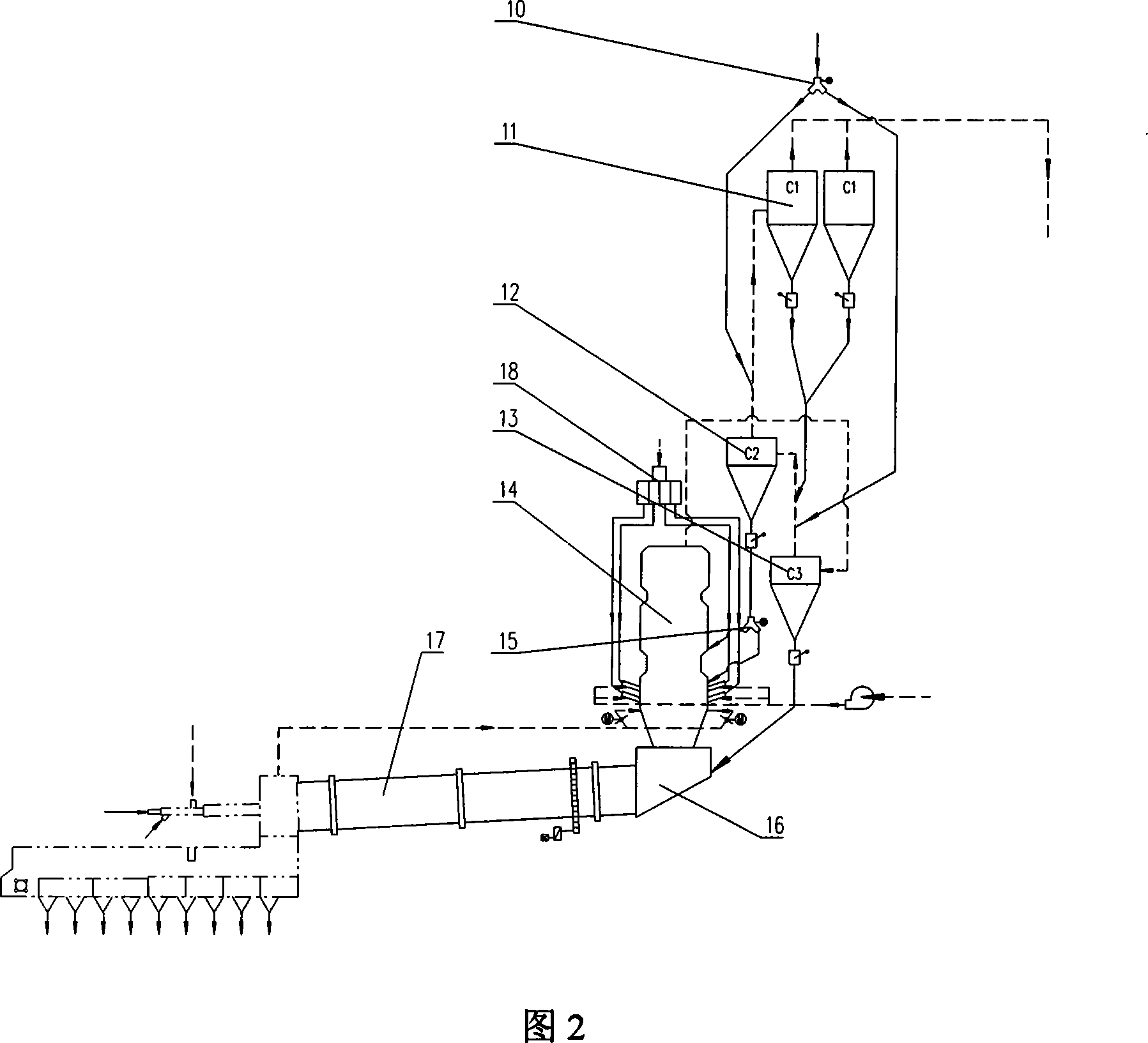

[0029] With reference to accompanying drawing 1 and Fig. 2.

[0030] Calcium carbide slag is used to replace limestone to calcined cement. Carbide slag is used as calcareous raw material, and dry method pre-decomposition cement production technology is adopted outside the kiln. Its characteristics are: 100% use carbide slag to replace limestone to calcined cement clinker. The process includes,

[0031] (1) Carbide slag preheating and pre-decomposition

[0032] The cyclone preheater and calciner system are used to preheat and pre-decompose the carbide slag raw meal. The decomposition temperature of carbide slag is 380-550°C, and the outlet temperature of the calciner is 550-750°C;

[0033] The calcium carbide slag preheater system adopts a two-stage or three-stage cyclone preheater. Moreover, the secondary preheater and the tertiary cyclone preheater can be switched. The preheater system can be a single series or a double series cyclone preheater system.

[0034] (2) Combina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com