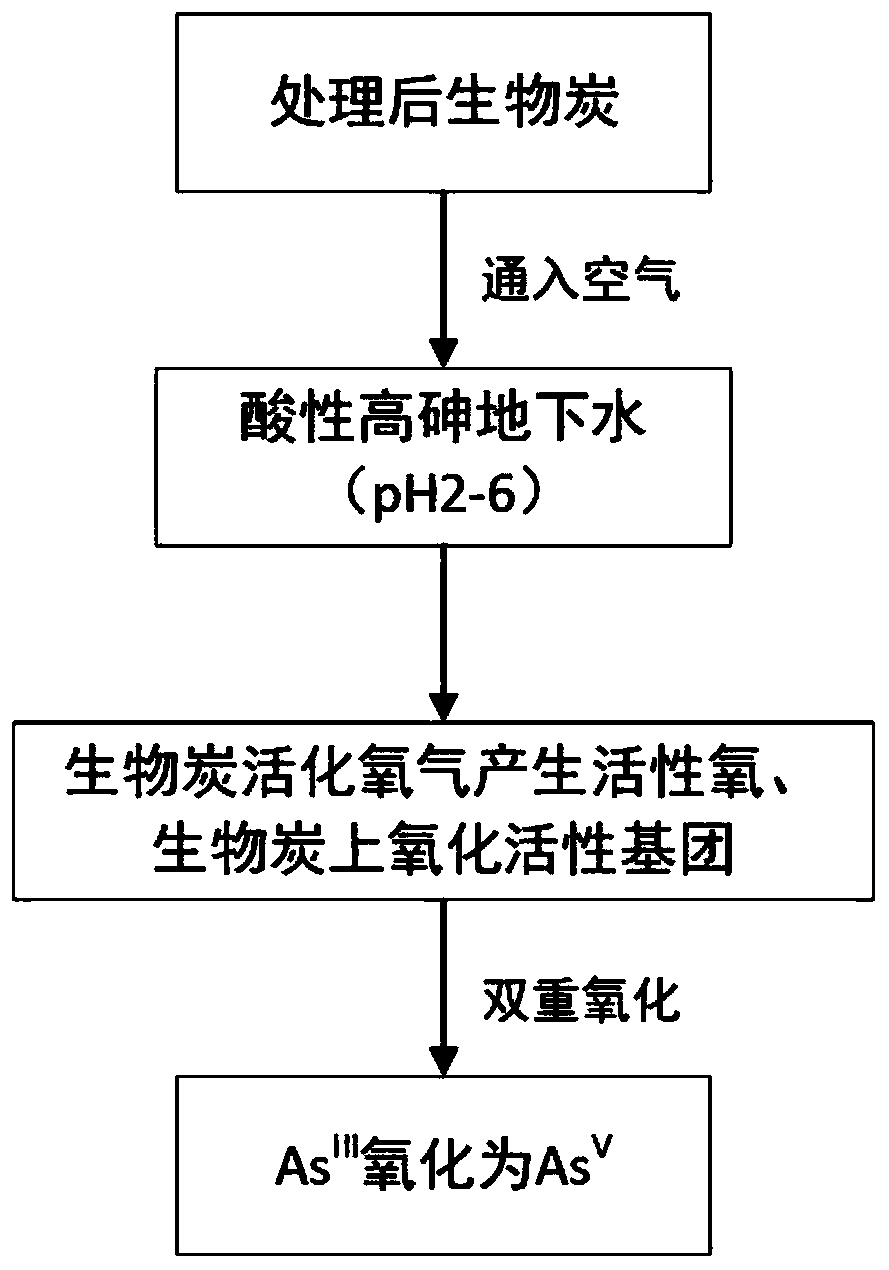

Method of using biochar for oxidizing trivalent arsenic in underground water

A trivalent arsenic and groundwater technology, applied in chemical instruments and methods, oxidized water/sewage treatment, contaminated groundwater/leachate treatment, etc., can solve problems such as high operating cost, complicated operation, and secondary pollution, and achieve Difficult to manage effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

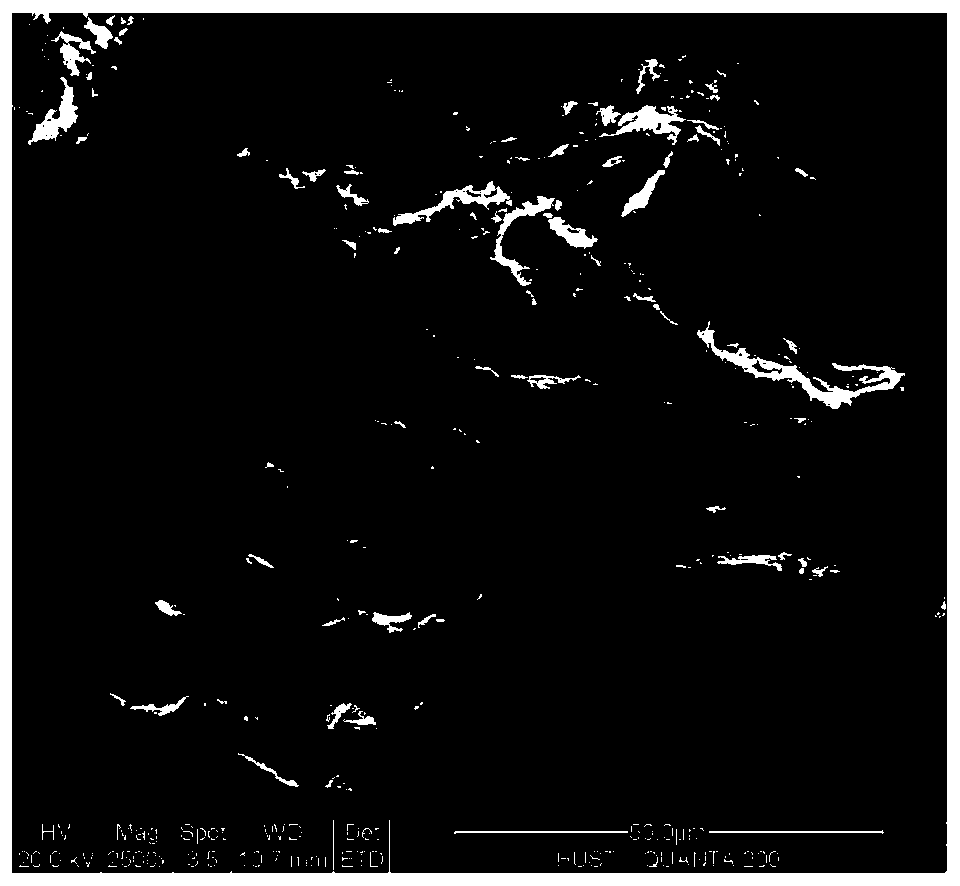

Embodiment 1

[0036] In the present invention, the rice husks of the prepared biochar are all taken from a breeding base in Hubei. The retrieved rice husks were washed several times with deionized water to remove impurities, and then placed in an electric blast drying oven for 12 hours (80°C). And seal it in a ziplock bag for later use. Then weigh 40g of rice husk into the silicon carbide reactor and cover it (isolation of oxygen), place it in a muffle furnace at 400°C for 1 hour with limited oxygen pyrolysis (no gas is introduced during the pyrolysis process), wait to cool to room temperature, The biochar was washed twice with deionized water.

[0037] The specific cleaning procedure is as follows: put in a 2L beaker, add 2L of deionized water, put it on a magnetic stirrer and stir at a speed of 600r / min for 12h, filter (medium-speed filter paper, 30-50μm), and put the obtained solid into 2L In the beaker, add 2L deionized water, stir at the same speed for 12h, and filter. The finally o...

Embodiment 2

[0039] The biochar raw material in Example 1 is corn stalks.

Embodiment 3

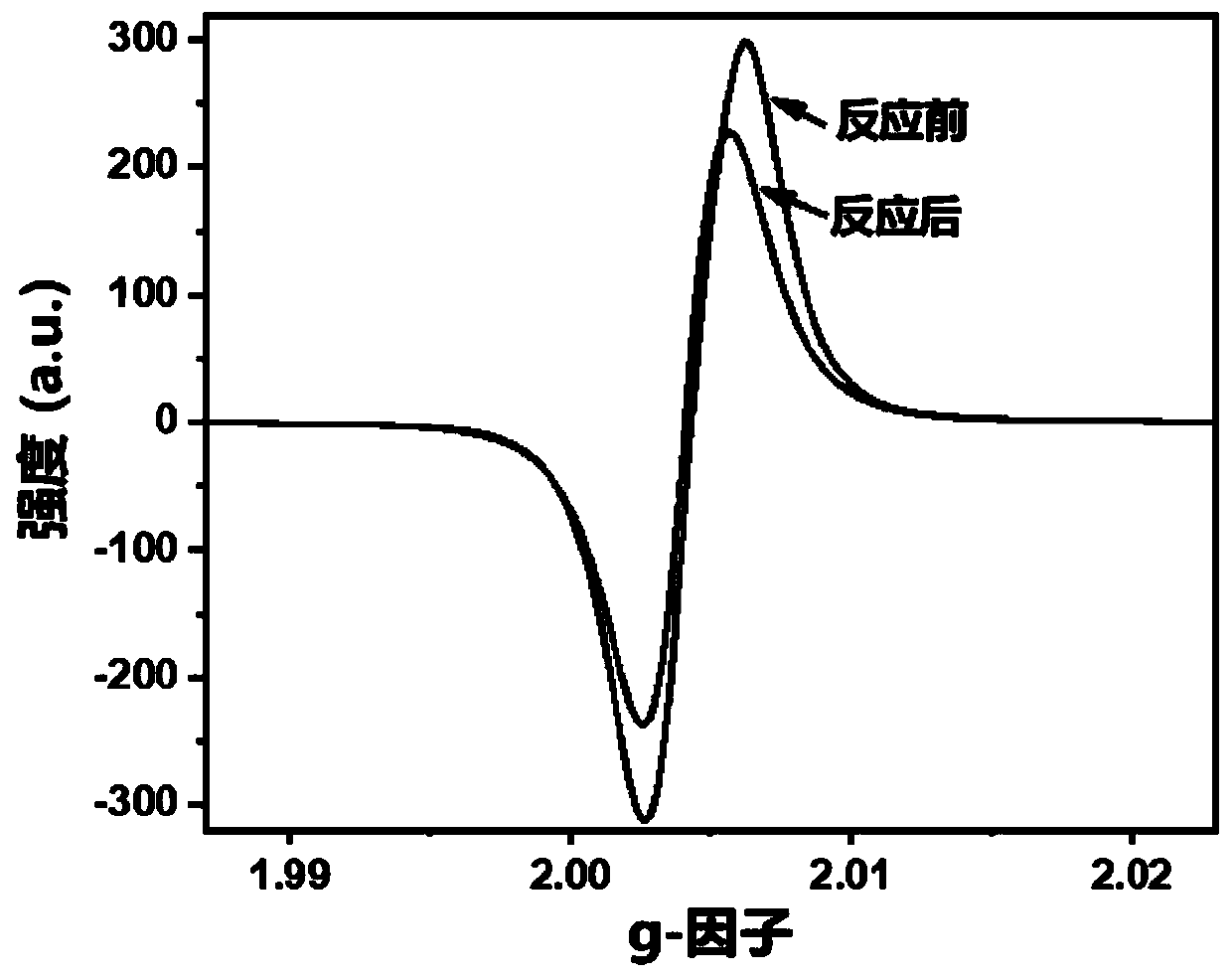

[0041] Measure 250mL containing As III Groundwater (0.01mM concentration, 750μg L –1 , pH=4) in a brown glass bottle, add 0.5g of biochar (prepared at 400°C) to it, pass 250mL of air into the reactor and seal it and place it on a magnetic stirrer at 700r min -1 The reaction was stirred at a certain speed, samples were taken at preset time points (0, 0.5, 1, 1.5, 2, 3, 4, 6, 8, 12 and 24h), and As III for analysis.

[0042] Such as Figure 6 As shown in (b), when the pH of the groundwater is 4.0, when the treated biochar is added and air is introduced at the same time, the As III The oxidation rate can reach 87.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com