Plasma powder making device with grading device and powder making process thereof

A technology of classification device and pulverizing device, which is applied in solid separation, combination device, separation method, etc., can solve the problems that ultrafine particles cannot be completely separated, products are difficult to meet requirements, cannot prevent agglomeration, etc., to achieve no pollution risk, prevent The effect of particle agglomeration and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

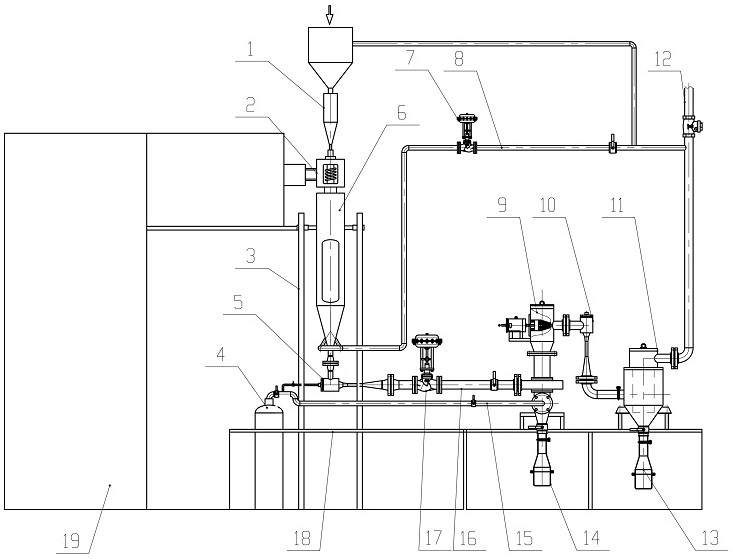

[0038] The purpose of this embodiment is to provide a plasma spheroidization technology and a technology for separating ultrafine powders by using the extremely high centrifugal force generated by the impeller rotating at high speed, specifically, using such as figure 1 The plasma powder making device with the classifying device shown is used for the powder making process. It melts the irregular raw material powder into droplets through the high-temperature heat source generated by the radio frequency induction power supply, and forms spherical powder with regular shape during the falling process, and directly enters the classification device to screen out qualified spherical powder with narrow particle size. The technical problems of spheroidization and classific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com