Preparation method and application of sediment-water interface phosphorus release control material

A sediment and water interface technology, applied in chemical instruments and methods, water/sludge/sewage treatment, polluted waterway/lake/pond/river treatment, etc., can solve the problems of high phosphorus release risk and high ecological risk , to achieve the effect of improving adsorption capacity and adsorption strength, cheap materials, increasing porosity and specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The sediment-water interface phosphorus release control material described in this example is prepared by the following method:

[0042] (1) Collect lake bottom mud as raw material, freeze-dry, grind and sieve to obtain sediment powder with a particle size of not less than 100 mesh, and set aside; take kaolin, dry, grind and sieve to obtain kaolin powder with a particle size of not less than 100 mesh body, spare;

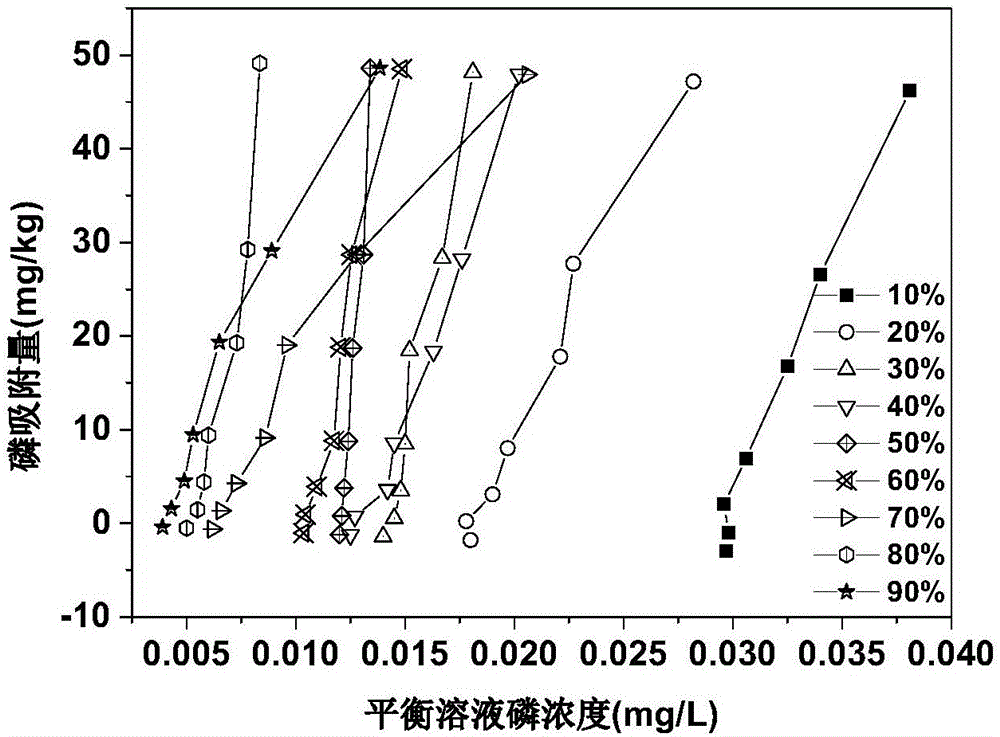

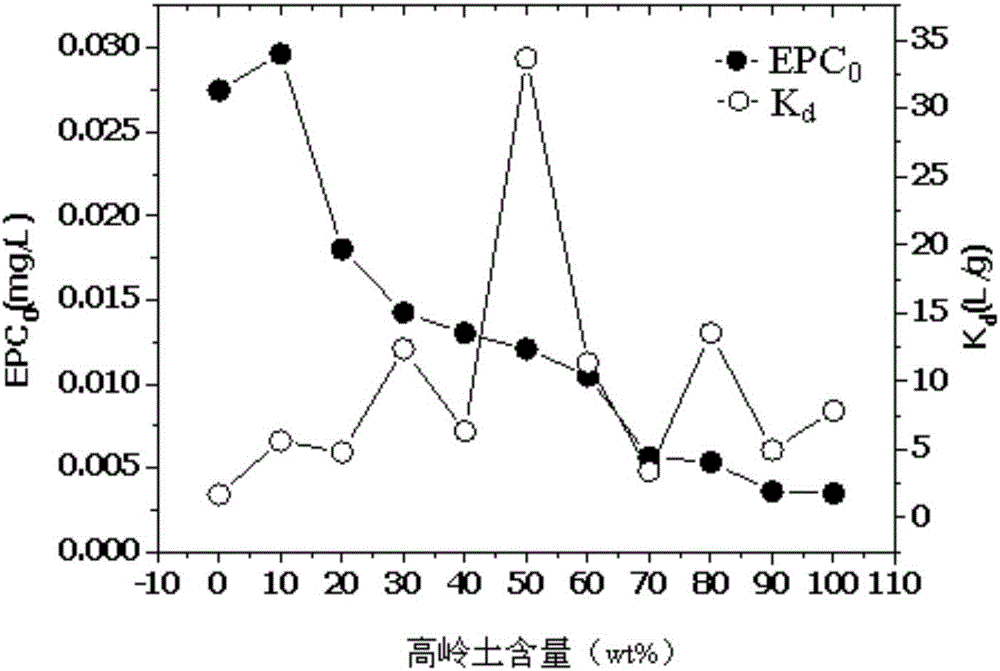

[0043] (2) Fully mix the sediment powder and kaolin powder in proportion to form a mixed powder, the amount of the kaolin accounts for 10wt% of the total mass of the mixed powder, and set aside;

[0044] (3) Utilize 5mol / L HNO 3 The aqueous solution oxidizes the mixed powder, and the HNO 3 The mass ratio of the aqueous solution to the mixed powder is 50:1, then placed in a blast drying box and evaporated to dryness, taken out and cooled to room temperature;

[0045] Then use 0.2mol / L FeSO 4 The aqueous solution is used to modify the oxidized mixed powder,...

Embodiment 2

[0048] The sediment-water interface phosphorus release control material described in this example is prepared by the following method:

[0049] (1) Collect lake bottom mud as raw material, freeze-dry, grind and sieve to obtain sediment powder with a particle size of 150-200 mesh, and set aside; take kaolin, dry, grind and sieve to obtain a particle size of 150-200 mesh Kaolin powder, spare;

[0050] (2) Fully mix the sediment powder and kaolin powder in proportion to form a mixed powder, the amount of the kaolin accounts for 80wt% of the total mass of the mixed powder, and set aside;

[0051] (3) Utilize 5mol / L HNO 3 The aqueous solution oxidizes the mixed powder, and the HNO 3 The mass ratio of the aqueous solution to the mixed powder is 50:1, then placed in a blast drying box and evaporated to dryness, taken out and cooled to room temperature;

[0052] Then use 0.2mol / L FeSO 4 The aqueous solution is used to modify the oxidized mixed powder, and the FeSO 4 The mass rati...

Embodiment 3

[0055] The sediment-water interface phosphorus release control material described in this example is prepared by the following method:

[0056] (1) Collect lake bottom mud as raw material, freeze-dry, grind and sieve to obtain sediment powder with a particle size of 120-300 mesh, and set aside; take kaolin, dry, grind and sieve to obtain a particle size of 120-300 mesh Kaolin powder, spare;

[0057] (2) Fully mix the sediment powder and kaolin powder in proportion to form a mixed powder, the amount of the kaolin accounts for 70wt% of the total mass of the mixed powder, and set aside;

[0058] (3) Utilize 5mol / L HNO 3 The aqueous solution oxidizes the mixed powder, and the HNO 3 The mass ratio of the aqueous solution to the mixed powder is 50:1, then placed in a blast drying box and evaporated to dryness, taken out and cooled to room temperature;

[0059] Then use 0.2mol / L FeSO 4 The aqueous solution is used to modify the oxidized mixed powder, and the FeSO 4 The mass rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com