Patents

Literature

105results about How to "High partition coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pharmaceutical compositions of adsorbates of amorphous drugs and lipophilic microphase-forming materials

ActiveUS20050031693A1Improve dissolve concentrationImproved dissolved concentration of drugPowder deliveryDrug compositionsDrugLipophilicity

A pharmaceutical composition comprises a solid adsorbate comprising a drug adsorbed onto a substrate and a lipophilic microphase-forming material. The solid adsorbate may also be co-administered with a lipophilic microphase-forming material to an in vivo use environment. The compositions of the present invention enhance the concentration of drug in a use environment.

Owner:BEND RES

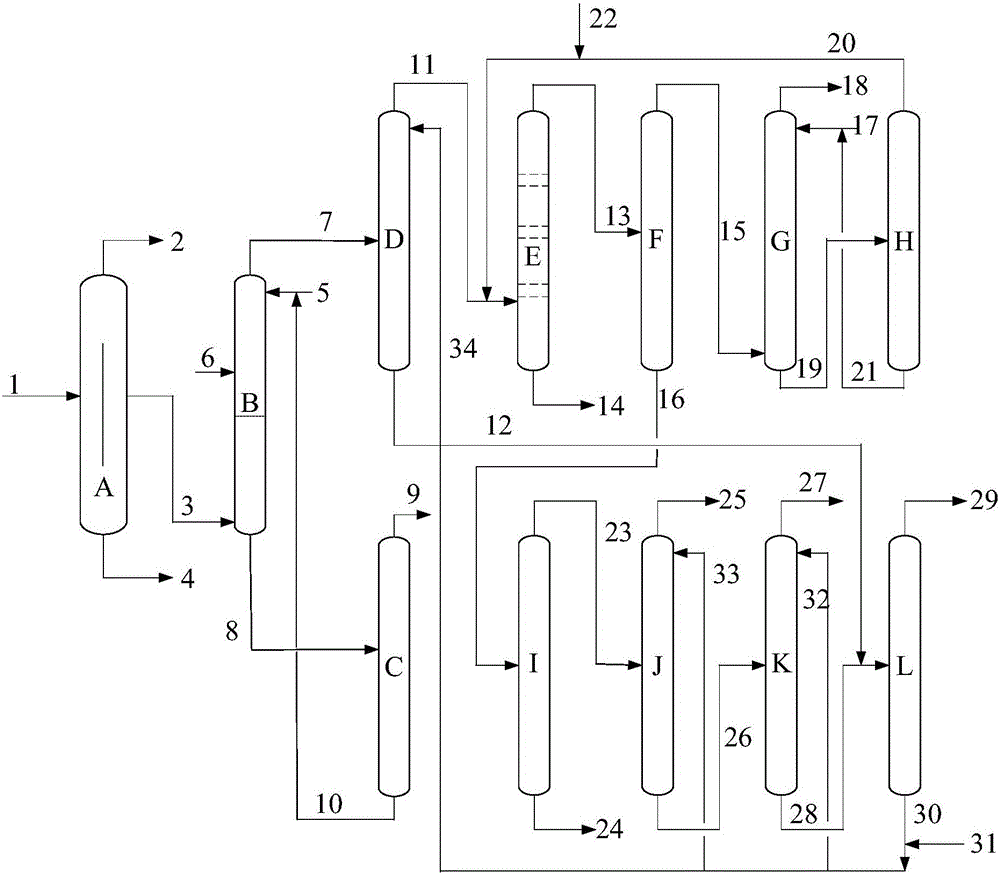

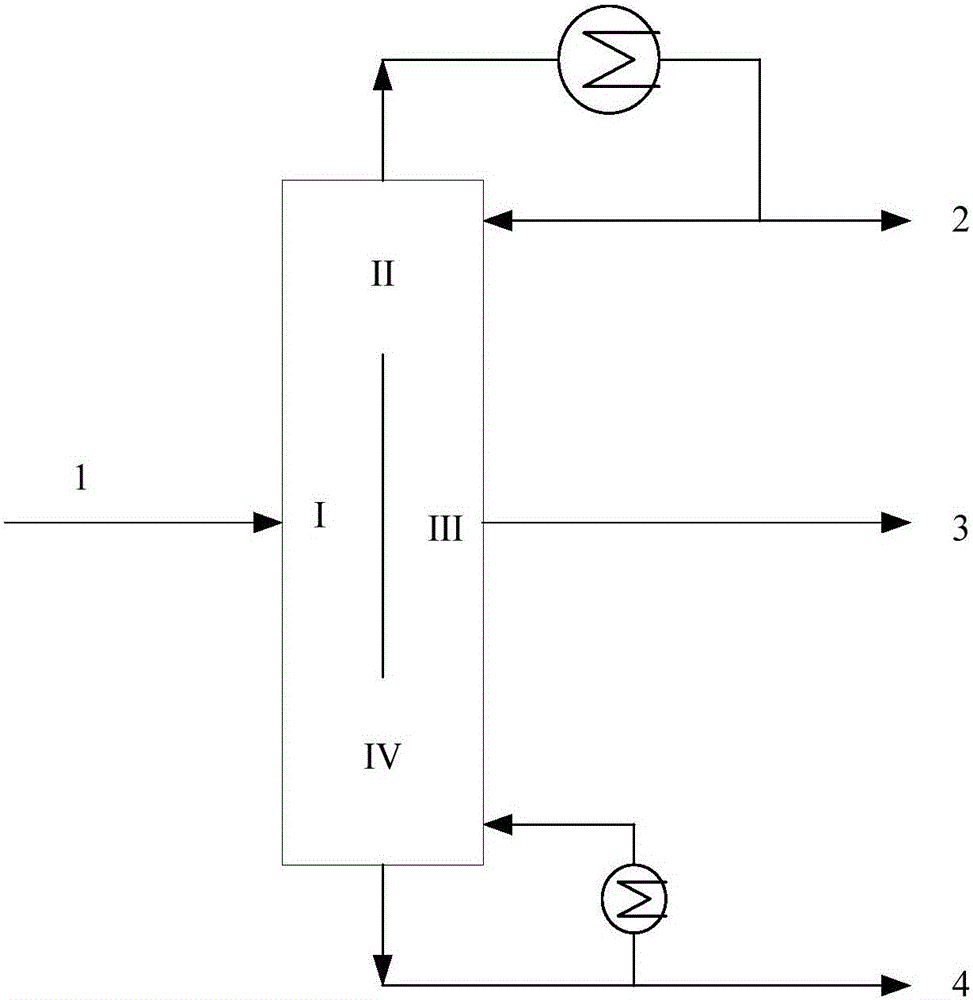

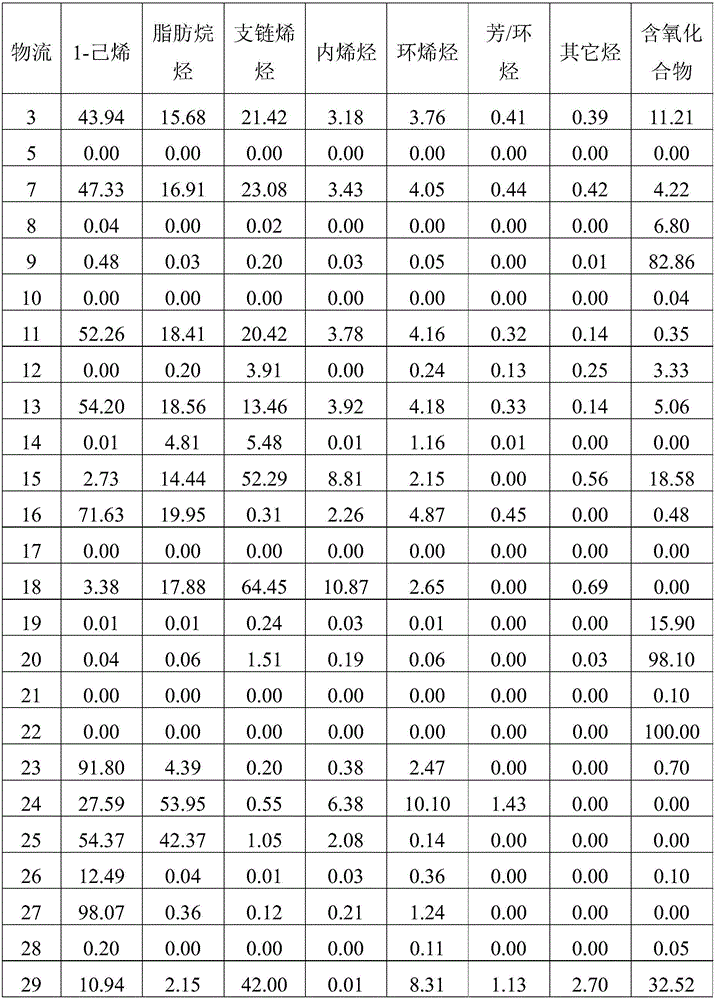

Method for separating oxygenated chemicals and 1-hexene from Fischer-Tropsch synthesis oil product

ActiveCN105777467AIncrease productionExpand product rangeOrganic compound preparationDistillation purification/separationAlkaneAlcohol

The invention relates to a method for separating oxygenated chemicals and 1-hexene from a Fischer-Tropsch synthesis oil product.The method comprises the steps that C6 fraction material flow is obtained through distillation in a predistillation tower by taking the Fischer-Tropsch synthesis oil product as a raw material, and two streams of extraction agents are fed to remove oxygenated chemicals in an extraction tower to obtain material flow rich in the oxygenated chemicals and crude C6 hydrocarbon material flow; the oxygenated chemicals contained in the crude C6 hydrocarbon material flow are further removed through a third extraction agent, tertiary olefins are converted into corresponding ethers through methyl alcohol under the action of an etherification catalyst to be removed, further purification is performed through rectification, and then C6 isoparaffin components and cycloolefin components are removed sequentially through a fourth extraction agent and a fifth extraction agent respectively to obtain 1-hexene product material flow.Compared with the prior art, the method has the advantages of being simple in technological process, low in cost and the like, and not only is 1-hexene separated and purified from the Fischer-Tropsch synthesis oil, but also the oxygenated chemicals can be separated.

Owner:YANKUANG ENERGY R&D CO LTD

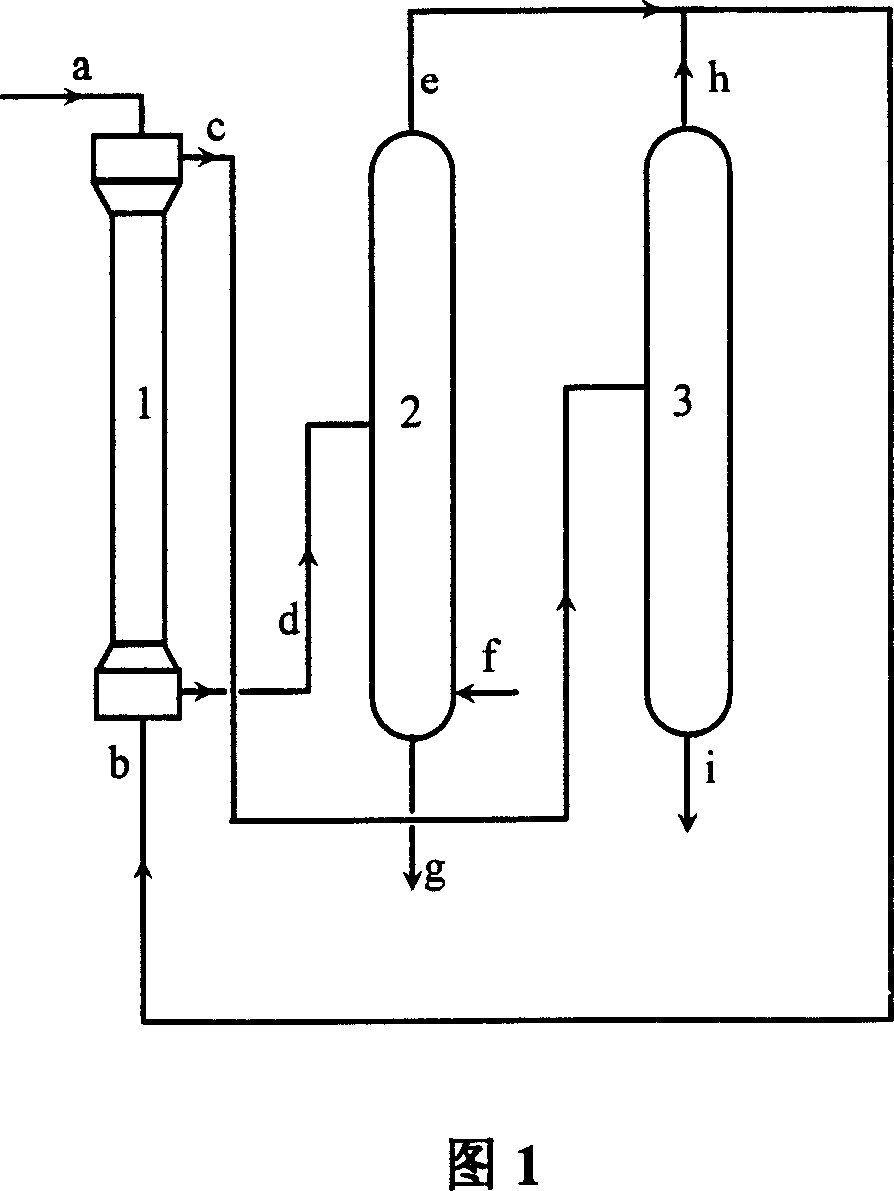

Extraction and dephenolization process of coal gasification wastewater

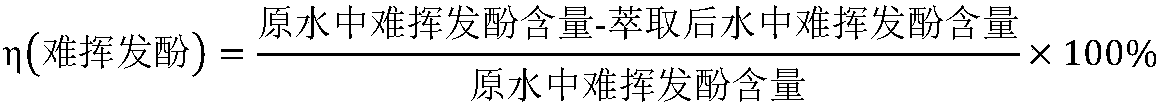

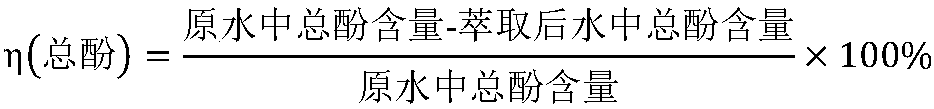

InactiveCN1834040AHigh partition coefficientSolve the problem of ineffective extraction of polyphenolsMultistage water/sewage treatmentWater/sewage treatment by extractionCoal gasification wastewaterHigh concentration

This invention discloses a method to remove high-concentration hydroxybenzenes from coal-gasification sewage, that is, coal-gasification sewage containing hydroxybenzenes and isobutyl methyl ketone as extracting solvent are mixed and separated so as to obtain solvent phase and remnant aqueous phase liquid. Solvent and crude hydroxybenzene are extracted from the solvent phase by distillation. Multiple-class reflux extraction is carried out towards remnant aqueous phase liquid and rudimental solvent is further extracted from the extract. Facilities involved in this method include a static mixer, an oil-water separator, a hydroxybenzene distillation tower and an extraction tower. Extracting coal-gasification sewage containing high-concentration hydroxybenzenes with the method provided by this invention, total hydroxybenzene extraction ratio can be as high as 92%. Besides, it also has the advantages of simple technique, soft conditions and recyclable extraction solution.

Owner:SOUTH CHINA UNIV OF TECH

Method of recovery phenol from waste water and system thereof

InactiveCN1919818ALow boiling pointSmall latent heatOrganic chemistryOrganic compound preparationOrganic solventWastewater

The invention discloses a recycling method and system in the phenolwaste water, which comprises the following steps: adopting ketone organic solvent as extractant; adopting extracting tower, organic solvent recycling tower and stripping tower to extract; distilling; stripping to obtain the product. The system is composed of extracting tower, organic solvent recycling tower, stripping tower and corresponding connecting pipe.

Owner:TSINGHUA UNIV

Adhesive preparations

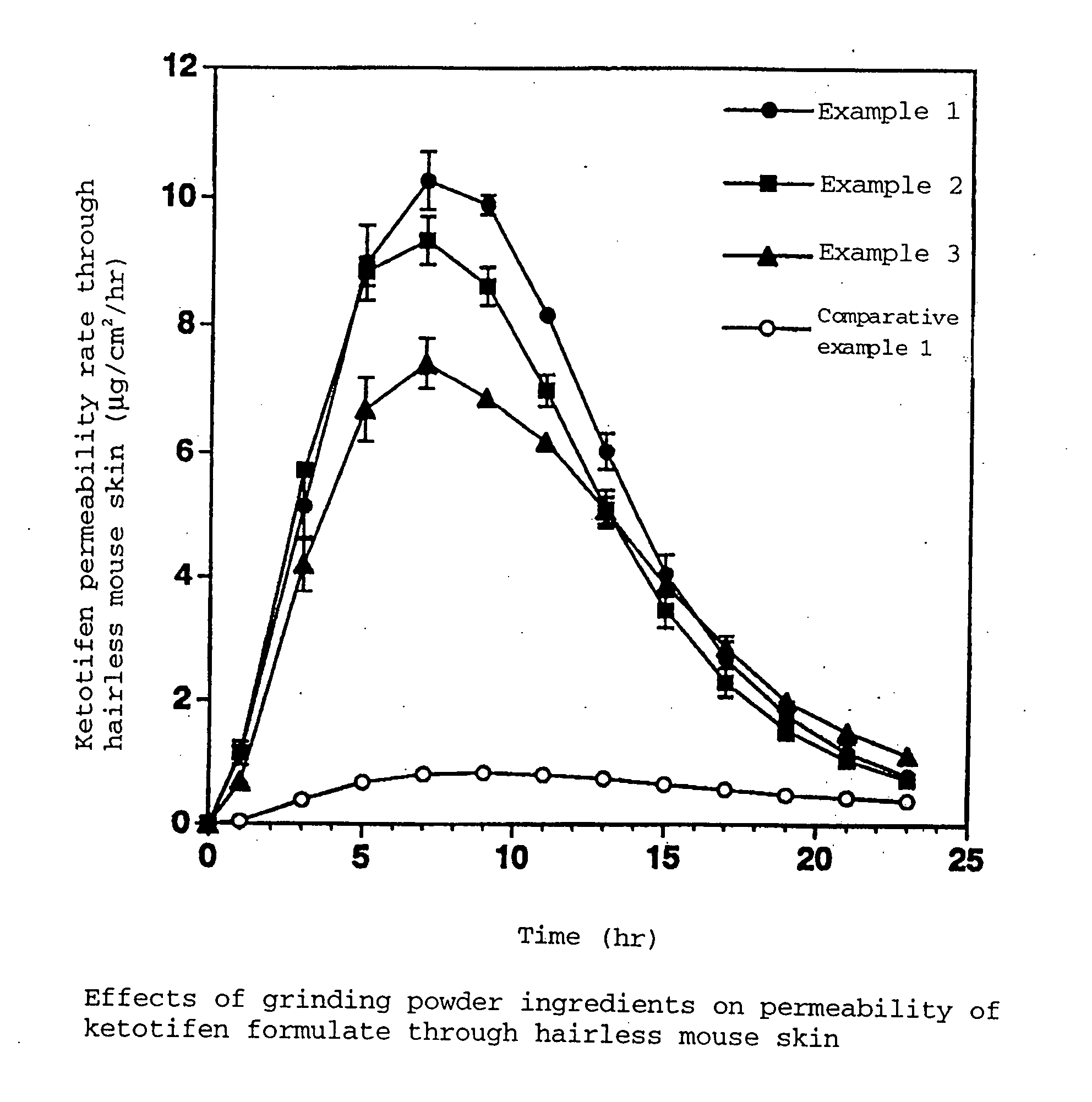

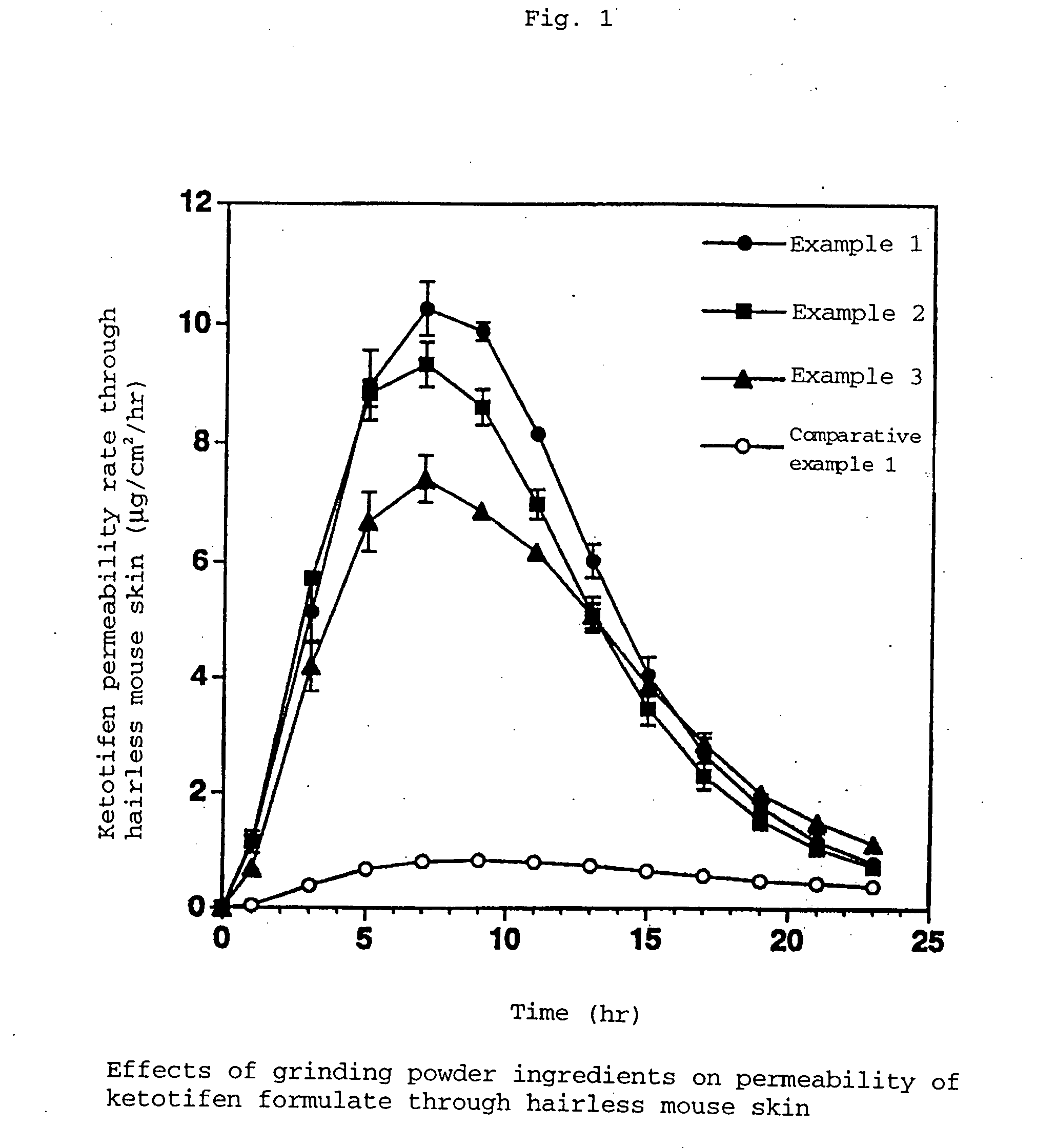

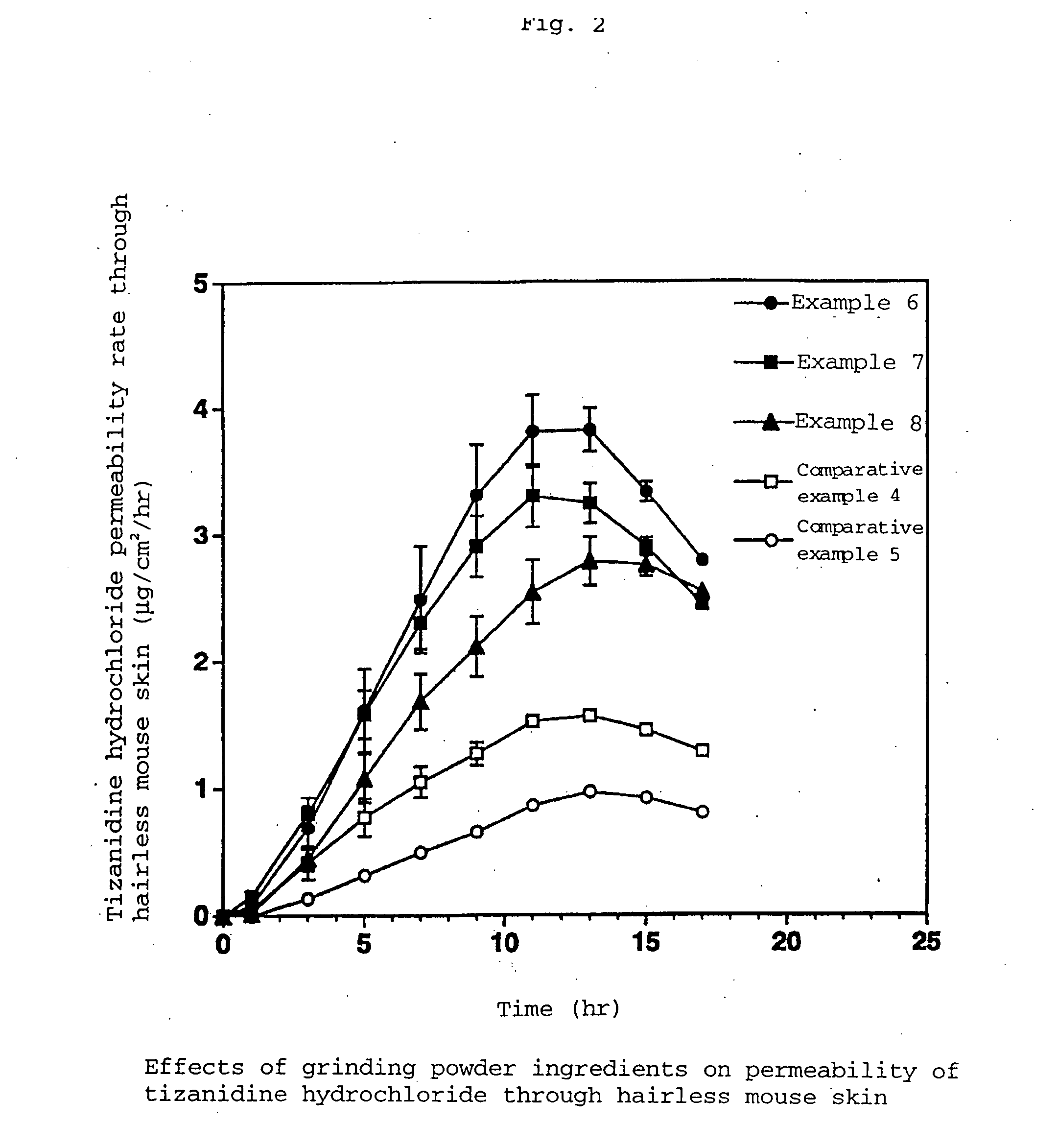

InactiveUS20070184097A1Improve drug solubilityImprove skinSynthetic polymeric active ingredientsAmine active ingredientsOrganic acidPercutaneous absorption

Adhesive preparations with improved percutaneous absorption of physiologically active substances, in particular, matrix adhesive preparations containing a base drug salt and an organic acid salt having an mean diameter of from 0.1 to 100 μm are provided.

Owner:HISAMITSU PHARM CO INC

Pharmaceutical Compositions of Amorphous Dispersions of Drugs and Lipophilic Microphase-Forming Materials

ActiveUS20080063708A1Minimize fed/fasted difference in bioavailabilityUniform bioavailabilityPowder deliveryBiocideSolubilityMedicine

A pharmaceutical composition comprises a solid amorphous dispersion comprising a low-solubility drug and a concentration-enhancing polymer and a lipophilic microphase-forming material. Alternatively, a solid amorphous dispersion comprising a low-solubility drug and a concentration-enhancing polymer is co-administered with a lipophilic microphase-forming material to an in vivo use environment.

Owner:LONZA BEND INC

Amphiphilic polypeptide DGRGGGAAAA and preparation method thereof, and novel anticancer drug delivery system and preparation method thereof

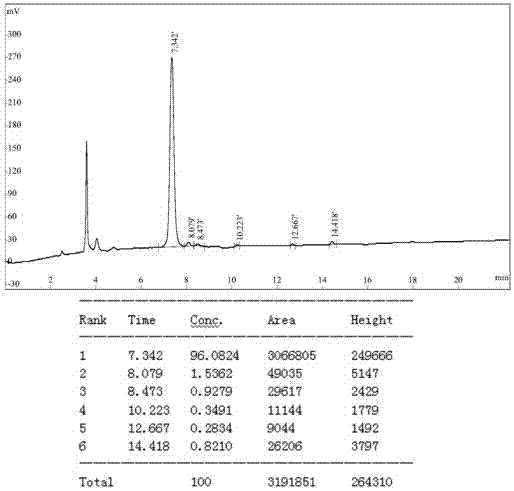

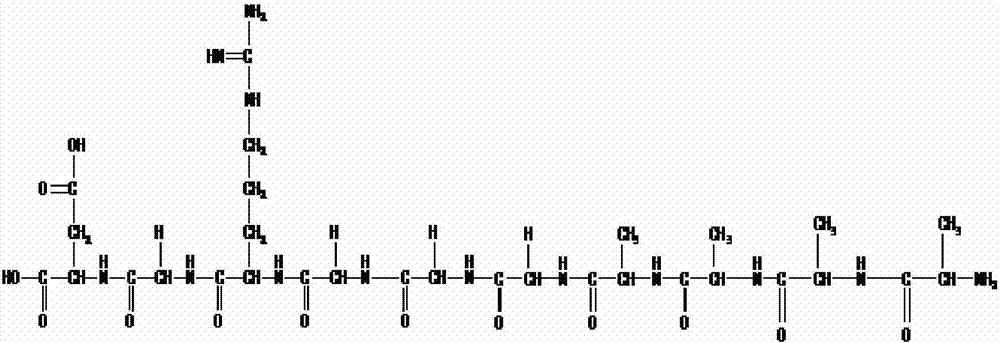

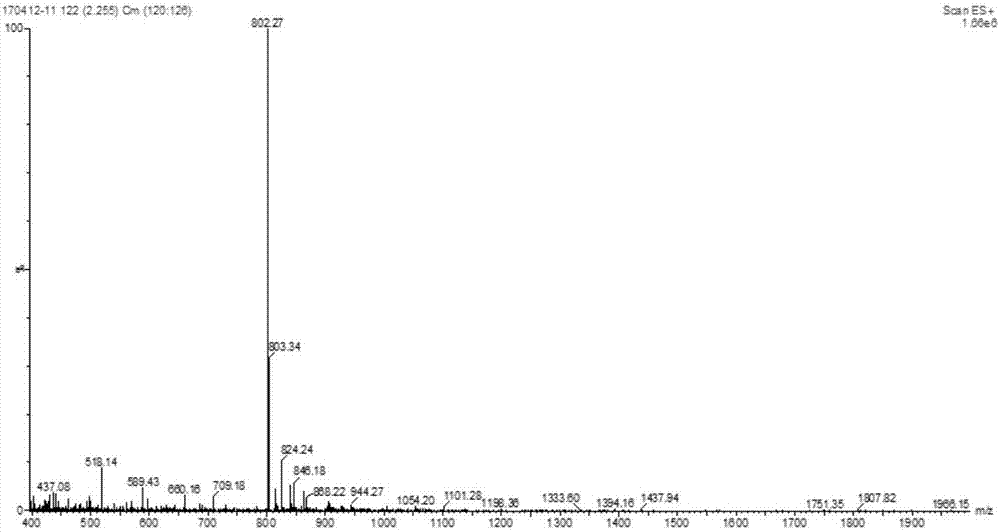

ActiveCN107365354AImprove solubilityHigh partition coefficientOrganic active ingredientsPeptide preparation methodsSide effectDelivery system

The invention discloses an amphiphilic polypeptide DGRGGGAAAA and a preparation method thereof, and a novel anticancer drug delivery system and a preparation method thereof; the preparation method of the amphiphilic polypeptide DGRGGGAAAA comprises: 1) using DMF (dimethyl formamide) as a solvent, DCM (dichloromethane) as an expanding agent and DIC (diisopropyl carbodiimide) as a catalyst to synthesize DGRGGGAAAA by a solid-phase synthetic process; 2) mixing the DGRGGGAAAA and doxorubicin (DOX), dissolving the mixture in water, subjecting the system to multiple dialysis, centrifuging the dialyzed system, and removing supernate to obtain the novel anticancer drug delivery system. The novel anticancer drug delivery system has significantly improved efficiency, and has the advantages of high targeting action, small side effect, low toxicity and the like.

Owner:ANHUI POLYTECHNIC UNIV

Compound solvent for extraction separation of tungsten and molybdenum and using method thereof

A compound solvent for extraction separation of tungsten and molybdenum is prepared by mixing extractant secondary carbon primary amine and Di-(2-ethylhexyl) phosphoric acid, wherein the volume of the secondary carbon primary amine occupies for 30-70% of the total volume, and the balance is the Di-(2-ethylhexyl)phosphoric acid. The separation of tungsten and molybdenum can be achieved by sequentially using the compound solvent to perform extracting, countercurrent washing and reextraction through (NH4)2CO3. The compound solvent replaces a single extractant to separate tungsten and molybdenum, and due to synergistic effect, the partition coefficient of molybdenum is remarkably improved, so that the content of molybdenum oxide in sodium tungstate solution is reduced to lower than 10ppm, the loss of tungsten during the molybdenum removing process is reduced to lower than 0.1%, and the recovery rate of molybdenum is larger than 95%.

Owner:HENAN UNIV OF SCI & TECH

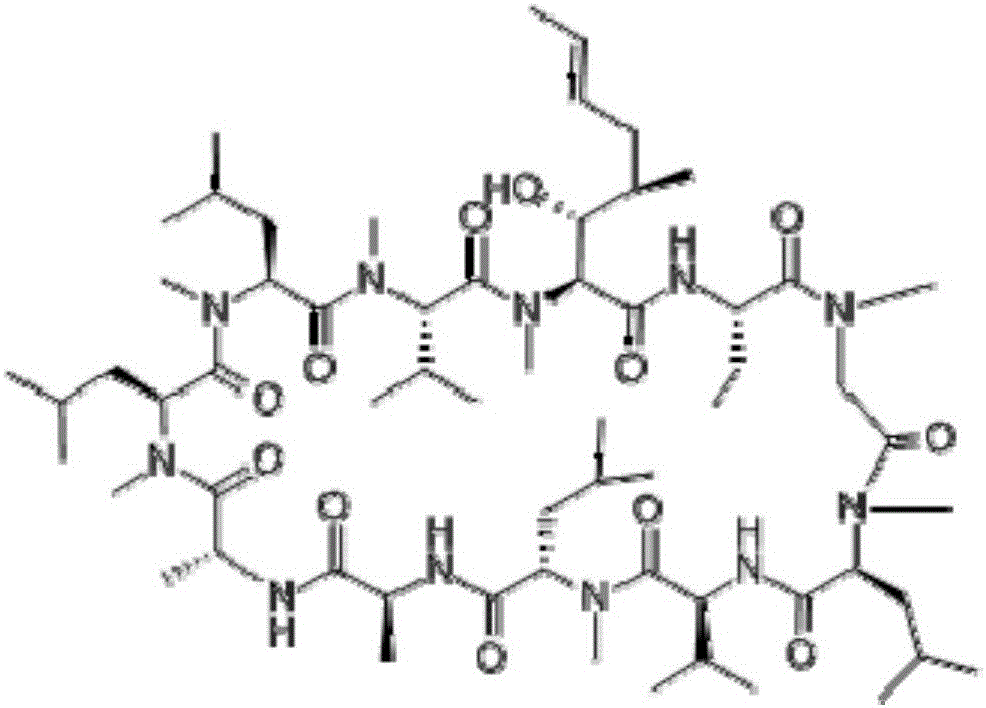

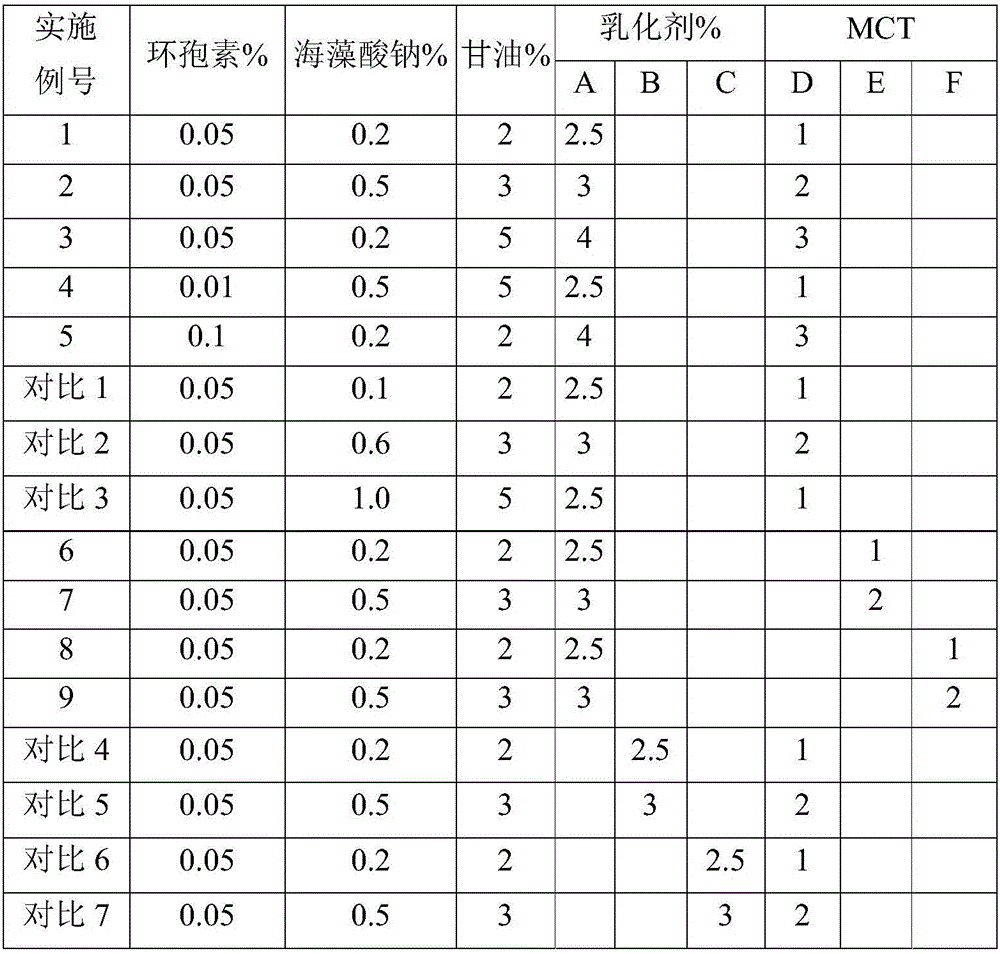

Ophthalmic ciclosporin emulsion

InactiveCN105726479AHigh partition coefficientHigh content of active ingredientsSenses disorderCyclic peptide ingredientsEmulsionCiclosporin

The invention provides ophthalmic ciclosporin emulsion. The ophthalmic emulsion is characterized by comprising the following components by weight percent: 0.02-0.1% of ciclosporin, 2.5-4% of polyoxyethylated castor oil, 1-3% of middle-chain fatty glyceride, 2-5% of glycerin, 0.2-0.5% of sodium alginate and the balance of water.

Owner:北京茗泽中和药物研究有限公司

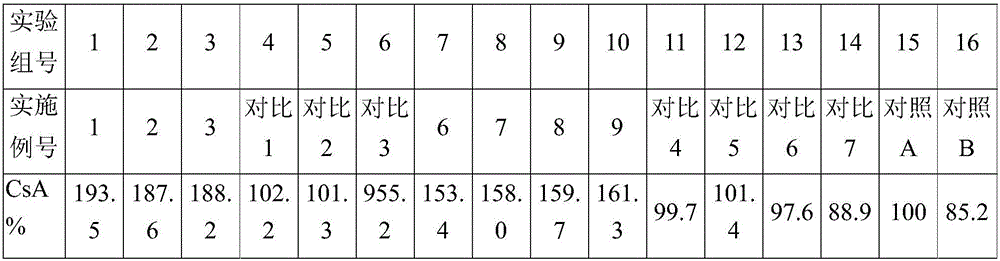

Method for removing boron and phosphorus impurity in industrial silicon by slagging refining

InactiveCN102951645AHigh partition coefficientGood removal effectSilicon compoundsMedium frequencyInductively coupled plasma

The invention discloses a method for removing the boron and phosphorus impurity in industrial silicon by slagging refining, and relates to the industrial silicon impurity removal technology. The method comprises the following steps of: 1) coating a compact SiC coating as an inner layer on the surface of a graphite crucible, and coating a Y2O3 coating on the SiC coating as an outer layer; 2) after slagging constituent is mixed, putting into a pre-processed graphite crucible; 3) opening a medium-frequency induction furnace for heating until slag charges are molten; 4) after the slag charges are molten, adding the industrial silicon into the molten slag charges, carrying out slagging refining, and reacting if power is lowered after the slag charges and silicon materials are totally molten; 5) inserting a venting pin into the molten liquid, and introducing Ar+H2O into the system to guarantee that the silicon and the slags are contacted; 6) pulling out the venting pin, and pouring the upper layer of silicon liquid of the molten liquid into a standing graphite module for cooling; 7) continuously adding silicon materials, and repeating steps 4) to 6); and 8) cutting impurity enrichment parts on the tail part and the head part of refined polysilicon, and measuring the content of residual parts of boron and phosphorus by ICP-MS (inductively coupled plasma-mass spectrum). The method has the advantages of simple technology and high industrial feasibility.

Owner:XIAMEN UNIV

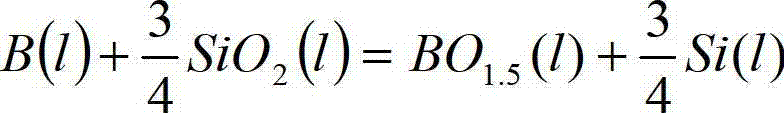

Working solution solvent system used for anthraquinone-process hydrogen peroxide production technology

ActiveCN104085859AHigh partition coefficientThe synthesis process is simplePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemistrySolubility

The invention discloses a working solution solvent system used for an anthraquinone-process hydrogen peroxide production technology. The working solution solvent system used for the anthraquinone-process hydrogen peroxide production technology comprises isooctyl acetate, heavy aromatics, trioctyl phosphate, cyclohexyl acetate and cyclohexyl propionate or comprises isooctyl acetate, heavy aromatics and trioctyl phosphate. The working solution solvent system used for the anthraquinone-process hydrogen peroxide production technology has the advantages that raw materials are simple and easily-available, production cost can be greatly reduced, hydrogen peroxide extraction distribution coefficient is high, anthraquinone solubility is high, hydrogenation efficiency is high, and therefore the working solution solvent system used for the anthraquinone process hydrogen peroxide production technology can be applied to large-scale industrial production.

Owner:北京凯迪森科技有限公司

Isolation of carboxylic acids from fermentation broth

ActiveUS6777213B2Increase contactImprove extraction efficiencyFatty oils/acids recovery from wasteFatty acid chemical modificationMicroorganismAlkene

A process for recovering carboxylic acids from an aqueous mixture such as a fermentation broth using a solvent containing at least one olefin without the need for first removing the spent microorganism cells is provided. A co-solvent which increases the partition coefficient of the solvent relative to the carboxylic acid may optionally be included. The resulting carboxylic acid is hydrogenated to produce a saturated carboxylic acid.

Owner:COGNIS IP MANAGEMENT GMBH

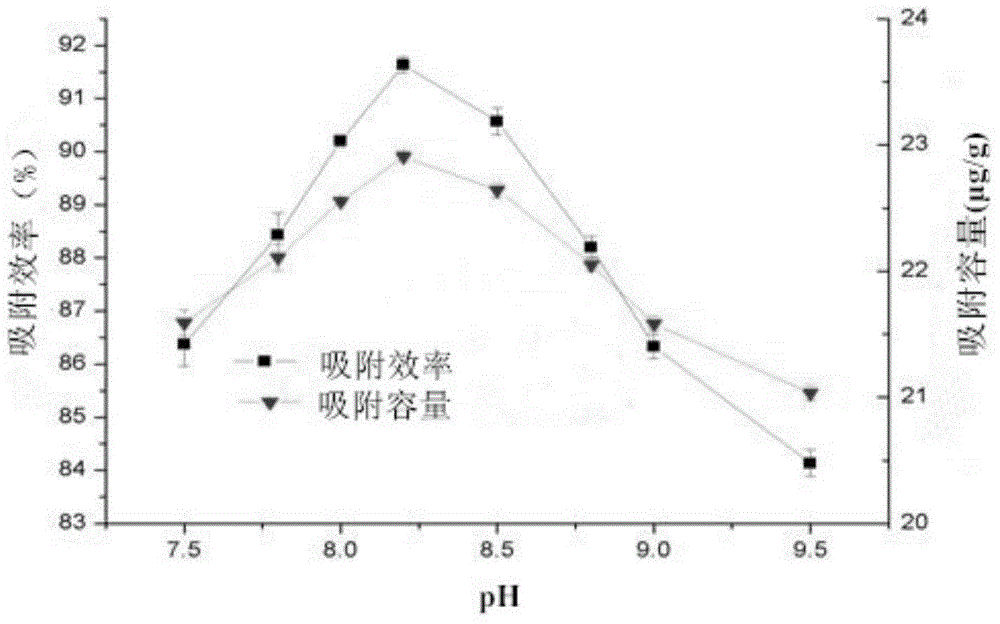

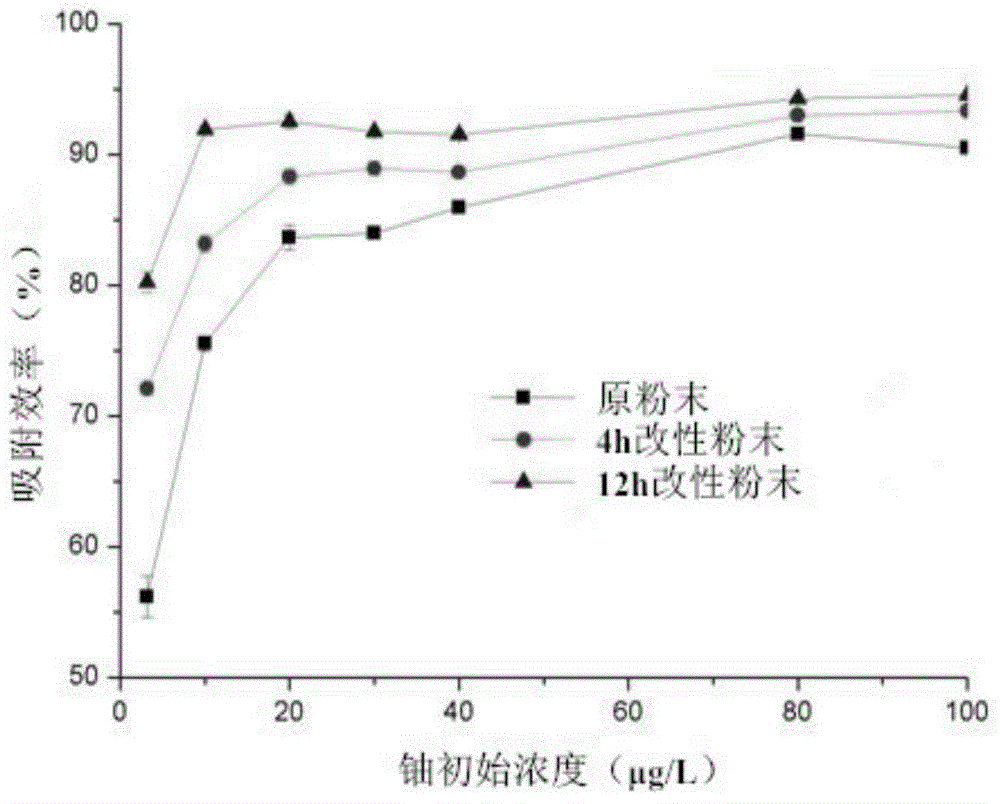

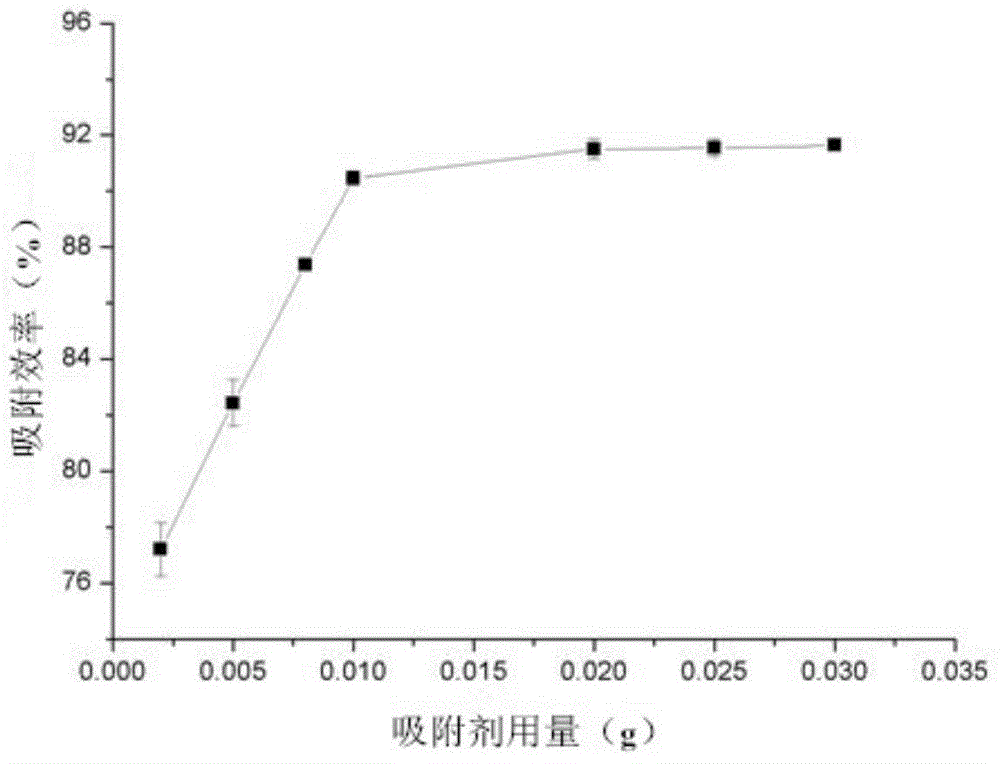

Adsorbent for removing low-concentration uranium and application thereof

InactiveCN104941591ALow costWide variety of sourcesOther chemical processesSpecial surfacesSorbentDiethylenetriamine

The invention relates to uranium adsorption for uranium-containing wastewater, in particular to an adsorbent for removing low-concentration uranium and application thereof. The adsorbent is obtained by drying and smashing plant leaves, modifying the plant leaves by a diethylenetriamine-isopropanol mixed solution and washing and drying a product. The adsorbent is applied to adsorb uranium in the uranium-containing wastewater at the pH value of 8.2 and is higher in adsorption efficiency.

Owner:NANHUA UNIV

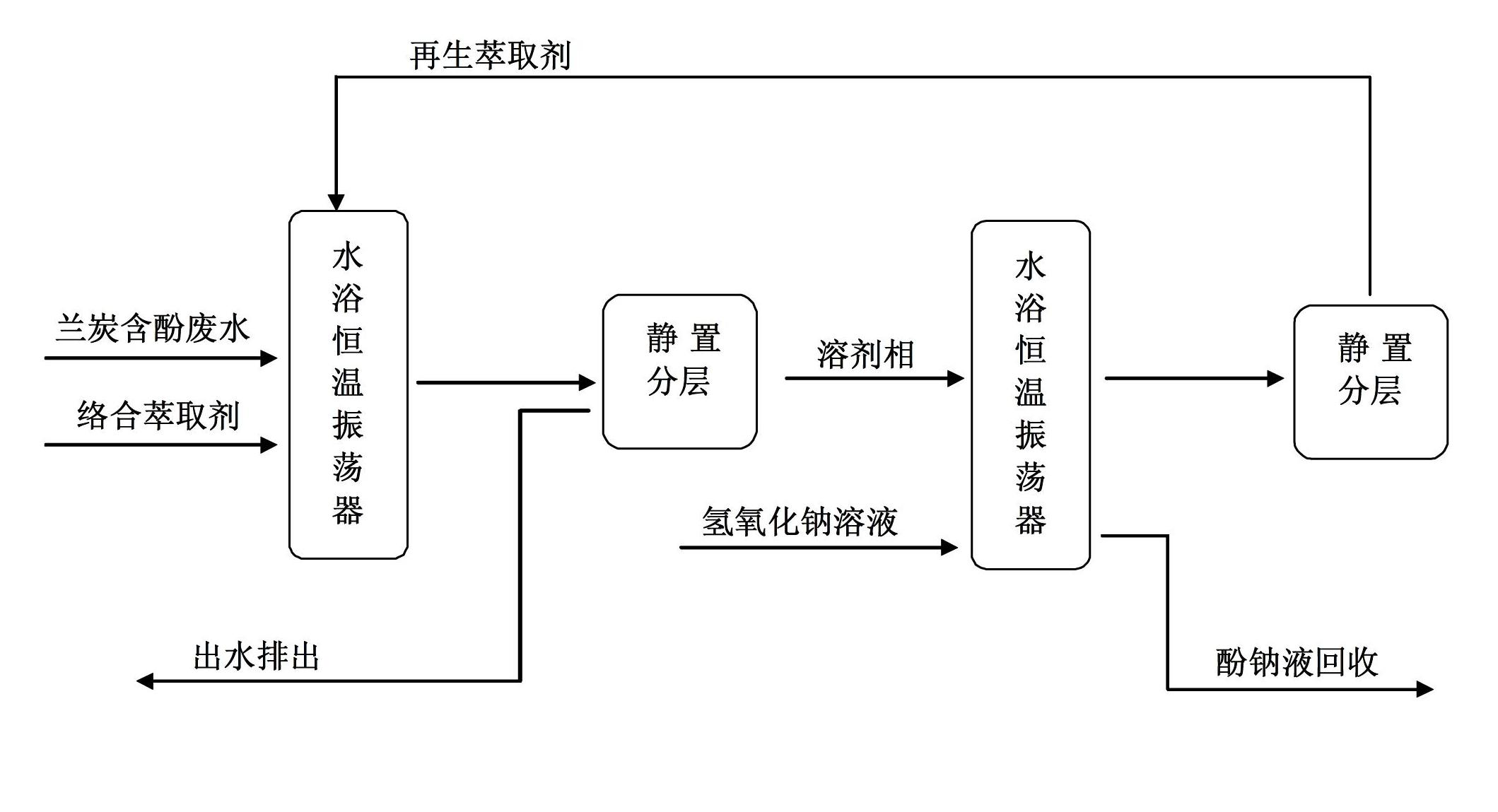

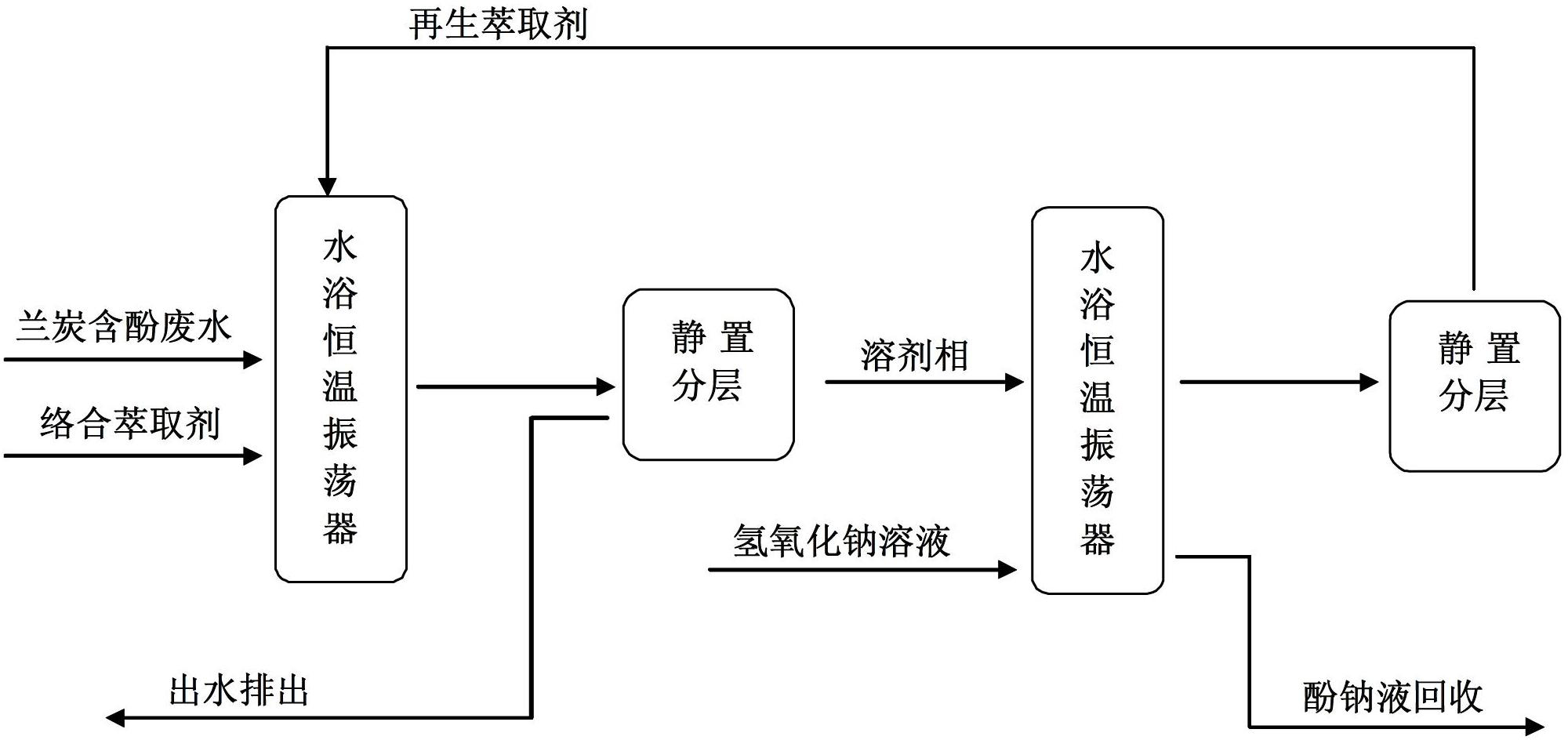

Complexation extraction dephenolization method of semi coke wastewater containing phenol

InactiveCN102642887AHigh partition coefficientImprove extraction abilityWater contaminantsWater/sewage treatment by extractionWater bathsSolvent

The invention relates to a complexation extraction dephenolization method of a semi coke wastewater containing phenol. An extractant and semi coke wastewater containing phenol are arranged in a thermostat water bath to be shaken, and stand still at a normal temperature to be subject to split phase so as to obtain a raffinate water phase and a solvent phase rich in phenols, the obtained solvent phase rich in the phenols is reextracted with back-extractant sodium hydroxide, the obtained regenerated extractant is recycled, and the obtained phenol resources are recovered. A complexation extraction method is adopted for the dephenolization process of the semi coke wastewater containing phenol, tributyl phosphate is used as a complexing agent, toluene is used as a diluent, and due to a special complexation extraction mechanism, a distribution coefficient of the complexation extraction dephenolization method is higher, the extracting power is strong, a complexation extractant has the advantage of reuse after being reextracted with alkali liquor, and valent matters in the wastewater are enriched, separated and recycled with the alkali liquor so as to realize the efficient treatment and resource recycling of phenols.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

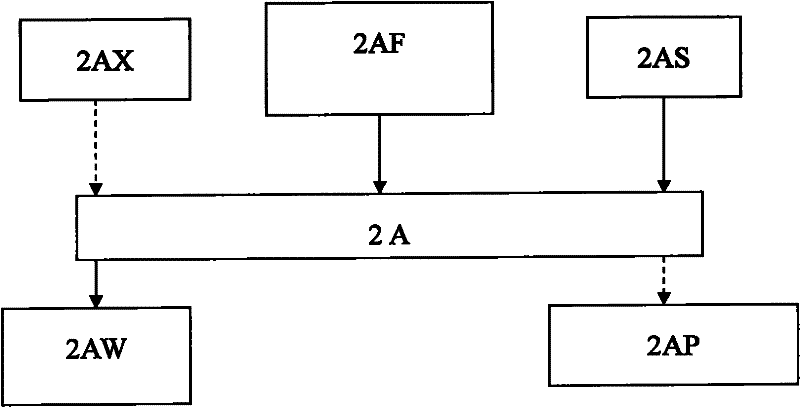

Method for improving 2A process plutonium concentration multiple in Purex flow

The invention belongs to the technical field of nuclear fuel reprocessing, and in particular relates to a method for improving 2A process plutonium concentration multiple in a Purex flow. By the method, the 2AF feed acidity is improved to be 3.8-5mol / L, and a flow ratio of 2AF to 2AX to 2AS is (7-8):1:(0.4-0.5). By the method, the plutonium concentration of the 2AP can be more than 10g / L.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

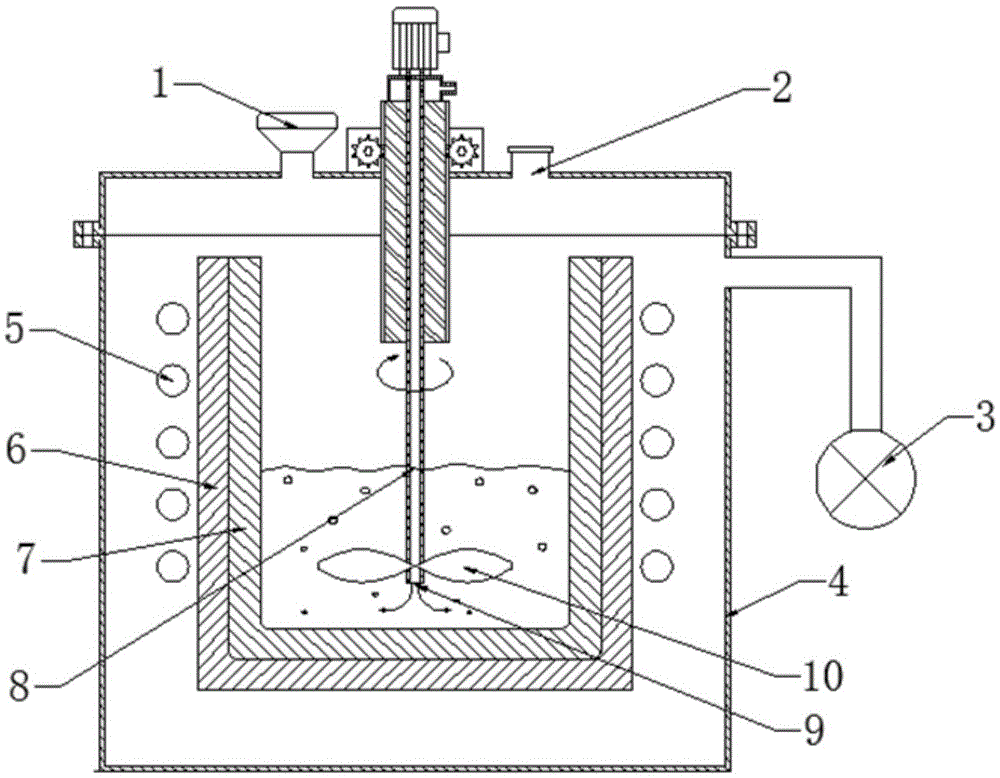

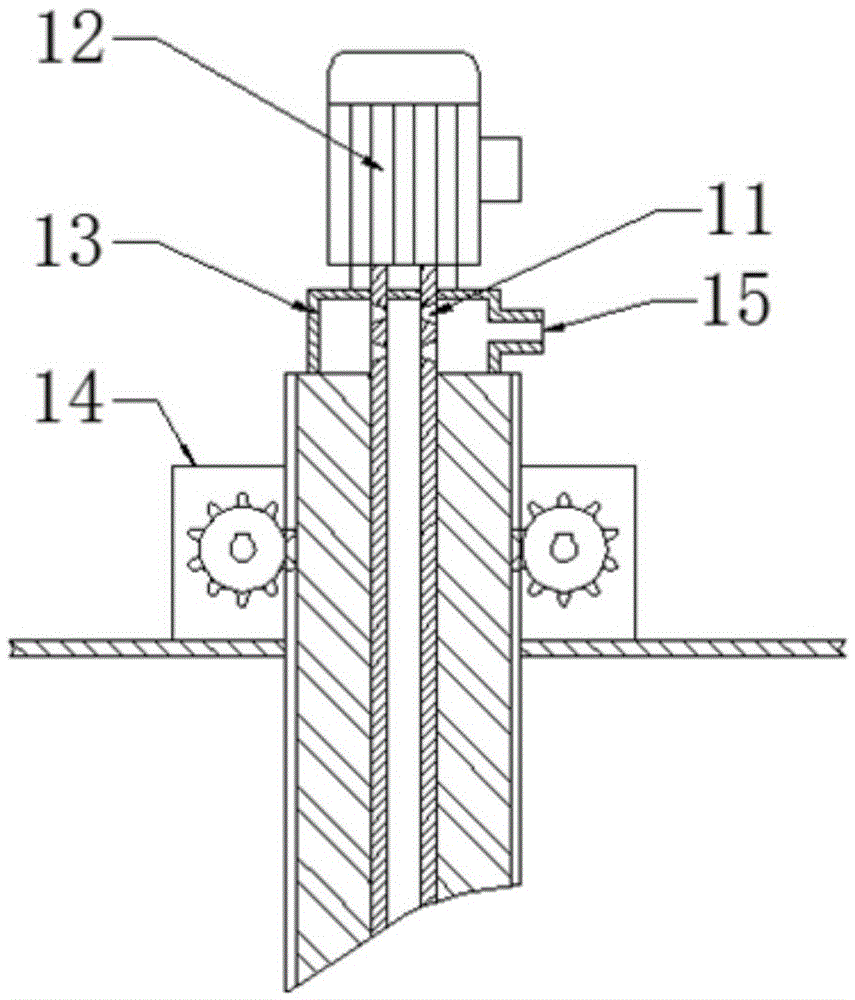

Boron removal method and device through activated slag agent

ActiveCN105540593AReduce the amount of slag agentReduce harm to the environmentSilicon compoundsSlagIntermediate frequency

The invention discloses a boron removal method and device through an activated slag agent, and belongs to the fields of semiconductor materials and metallurgy. The device is provided with a lobe pump, a furnace base, a medium-frequency induction coil, an insulating layer, a graphite crucible, a stirrer and a lifting device. The method comprises the steps that raw silicon is put into the graphite crucible from a feed port, the lobe pump is started to perform vacuumizing, a medium-frequency induction power supply is started to perform heating, and when the temperature is increased to 1500 DEG C, silicon blocks are completely molten; inert gas is charged into a furnace cavity to enable the temperature to be kept at 1550 DEG C-1650 DEG C, the slag agent is added, the stirrer is started, and first-time slagging is completed; the power of the medium-frequency induction power supply is increased to enable the temperature in the furnace cavity to reach 1700 DEG C-1800 DEG C, the feed port is opened, active components of the slag agent are put into the furnace cavity for the first time, vacuumizing is performed, the stirrer is started, the inert gas is introduced, and second-time slagging is completed; after slagging is completed, silicon liquid is poured into a receiving crucible, standing and cooling are performed, a silicon ingot is taken out, purified low-boron high-purity silicon is obtained, and then boron removal achieved through the activated slag agent is completed.

Owner:XIAMEN UNIV

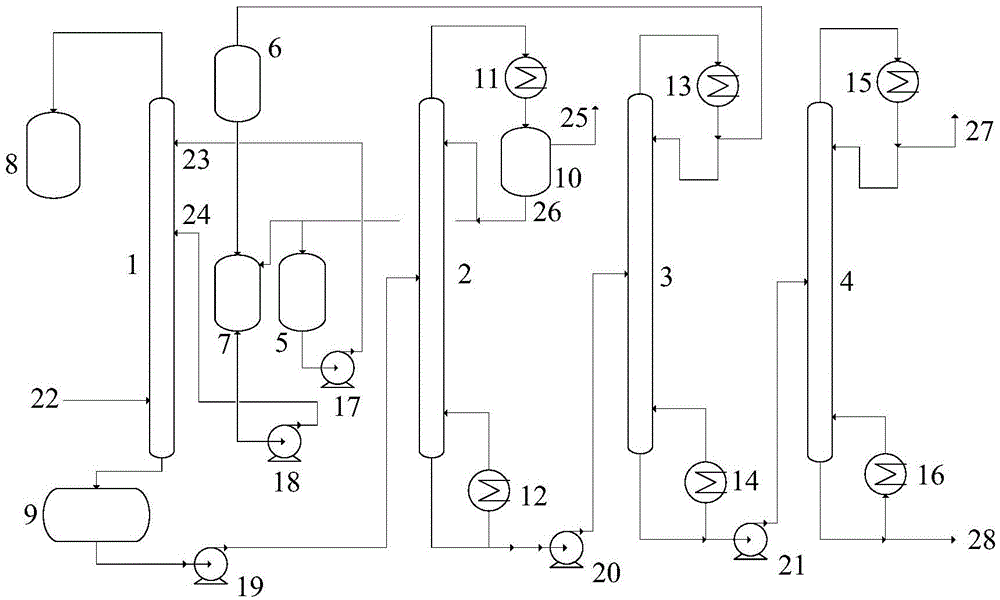

Method for extracting and recovering amide from aqueous solution

ActiveCN104803870AHigh partition coefficientInhibition of dissolutionCarboxylic acid amide separation/purificationEconomic benefitsSolvent

The invention discloses a method for extracting and recovering amide from an aqueous solution. An amide aqueous solution is added into the bottom of an extraction tower at a normal temperature, a main extraction agent is added into the top of the extraction tower, a composite solvent consisting of a main extraction agent and an auxiliary extraction agent is added into a part at the height, 0.1-0.4 times away from the top of the tower, of the extraction tower, extraction and separation are finished through countercurrent contact of liquid-liquid phases, and a raffinate phase mainly containing water and an extraction phase containing amide are obtained from the top and bottom of the tower respectively. The extraction phase containing amide passes through a main extraction agent recovery tower, an auxiliary extraction agent recovery tower and a product recovery tower in sequence to obtain the main extraction agent, the auxiliary extraction agent and an amide product from the top of the tower respectively, and the main extraction agent and the auxiliary extraction agent are recirculated for extraction of the amide aqueous solution. The method increases the distribution coefficient of amide in the extraction agent under the action of the auxiliary extraction agent, and can remarkably reduce the consumption of the extraction agent, reduce the energy consumption of subsequent rectification separation, so as to achieve remarkable economic benefits.

Owner:ZHEJIANG UNIV

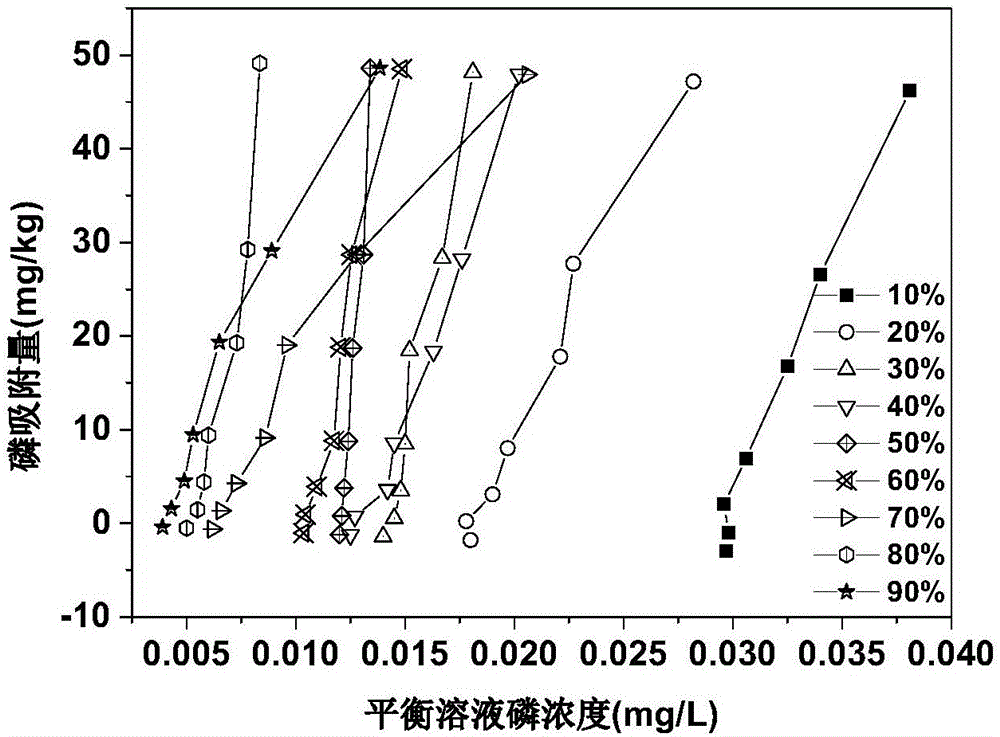

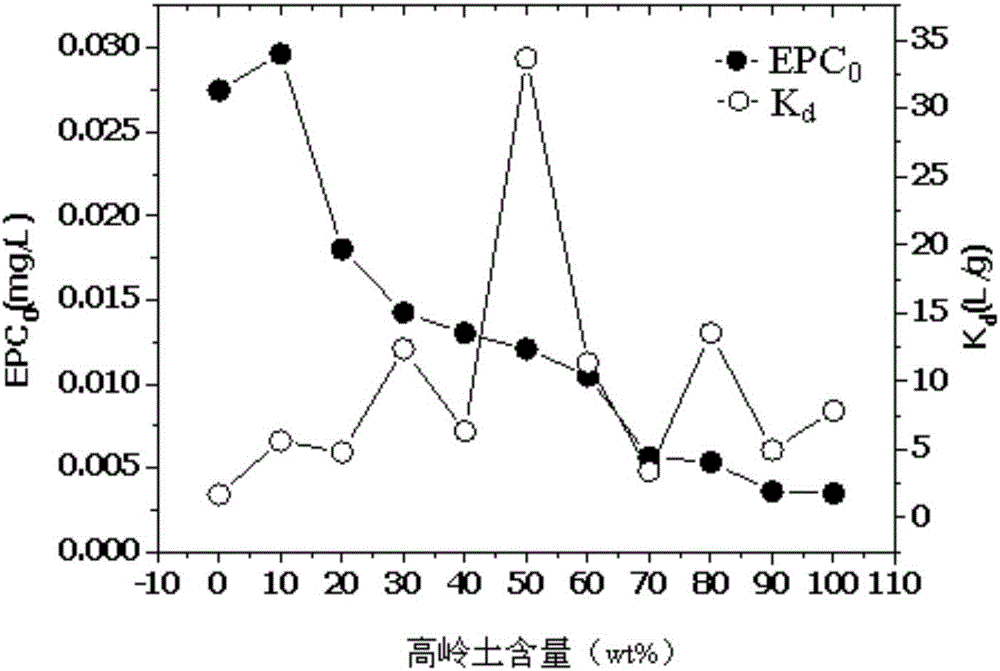

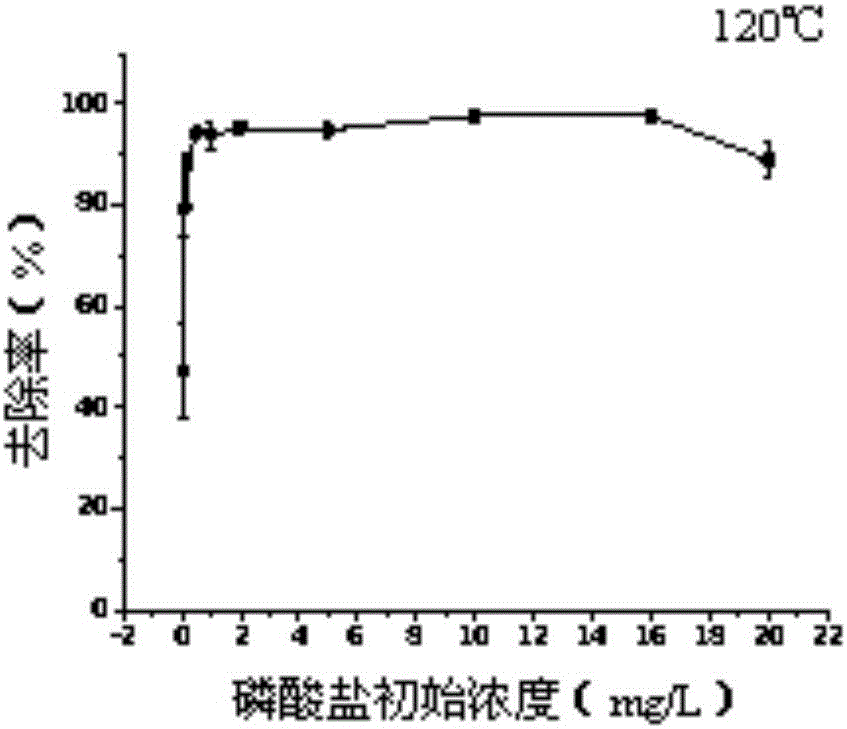

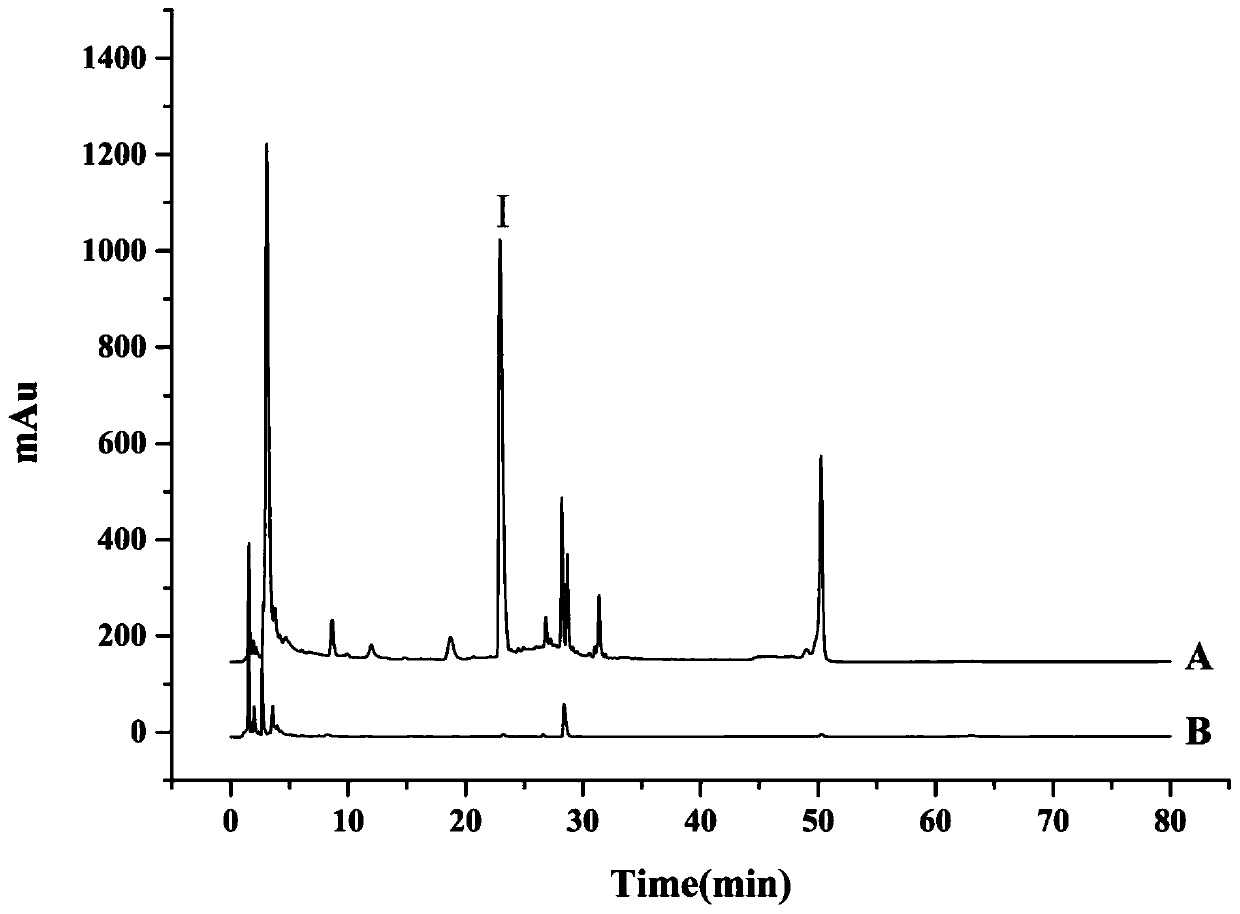

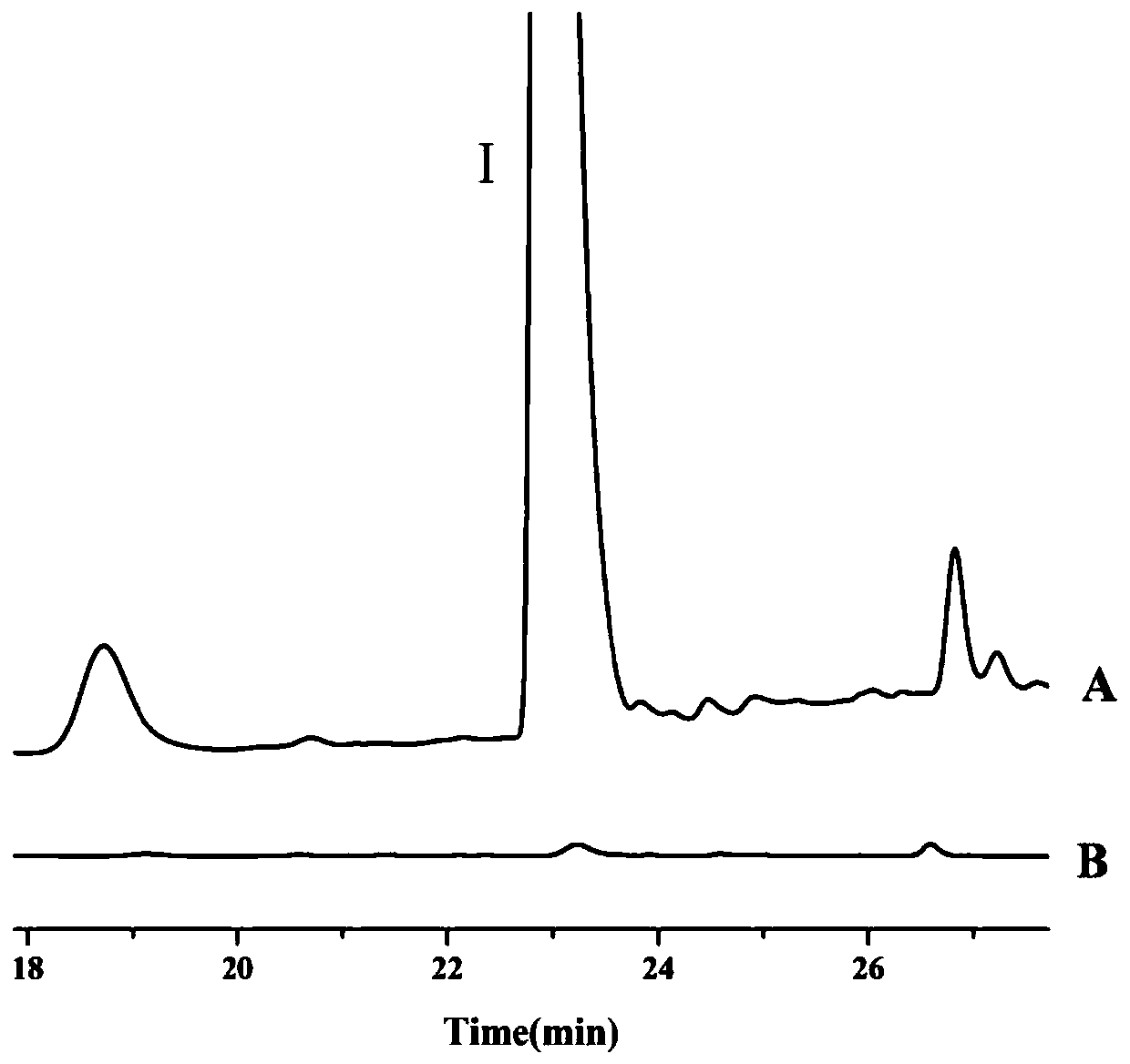

Preparation method and application of sediment-water interface phosphorus release control material

ActiveCN106277672ADecrease the adsorption-desorption equilibrium concentrationLess materialFixation/solidifcation sludge treatmentContaminated waterways/lakes/ponds/rivers treatmentIron saltsPhosphate

The invention provides a preparation method and application of a sediment-water interface phosphorus release control material. For the first time, a lake sediment and kaolin mixture is used as a basic raw material, and processes like oxidation, iron salt modification, granulation and calcination are adopted, so that adsorption-desorption balance concentration EPC0 value of the material to phosphate is remarkably lowered, linear distribution coefficient Kd value of the material is increased, and the material can effectively reduce sediment interstitial water phosphate concentration and can inhibit sediment-water interface phosphate release. The material itself has weak phosphate desorption capability and high adsorption and buffering capability, so that the material can truly realize effective obstruction and control on sediment-water interface phosphorus release. The material is low in material cost, high in social and economic benefit and safety, free of ecological risk to lake water, energy-saving and environment-friendly and has remarkable effect on controlling sediment-water interface phosphorus release in different lake areas of the Dian Lake in the process of application.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

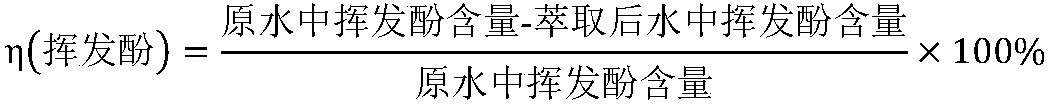

Deoiling-dephenolization combined treatment method for high-concentration phenol ammonia wastewater and system

ActiveCN110002629AHigh oil removal efficiencyImprove processing efficiencyFatty/oily/floating substances removal devicesWater contaminantsHigh concentrationRisk stroke

The invention relates to a deoiling-dephenolization combined treatment method for high-concentration phenol ammonia wastewater and a system. The treatment method comprises the following steps: (1) carrying out gas floating deoiling on a coke oven flue gas; (2) carrying out oil-water separation; (3) carrying out pressurized extraction dephenolization. A treatment system comprises a gas floating tank, an oil-water separator, an extraction device, a recycling tank and a flue gas buffer tank. As the coke oven flue gas is adopted as a foaming gas, the deoiling efficiency can be improved by virtue of nonpolar characteristics of carbon dioxide in the coke oven flue gas and the waste heat of the coke oven flue gas, and the acid gas carbon dioxide can be subjected to saturated absorption while deoiling is carried out; by changing the pH value of a solution, phenolate in wastewater can be induced to release phenolic substances of rich molecule modes, the allocation coefficient of the phenolic substances in an extraction agent can be increased, and the extraction efficiency can be improved; finally, through synergetic effects of gas floating deoiling and acidification and extraction procedures, the wastewater treatment efficiency is greatly improved, and three purposes can be achieved with one stroke.

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD +1

Method for extracting gibberellin by salting-out method

InactiveCN101531646AReduce dosageHigh partition coefficientOrganic chemistryFermentationSalting outGibberellin

The invention provides a method for extracting gibberellin from ferment filtrate by a salting-out method, comprising the following steps of adding adequate sodium chloride or sodium sulfate in gibberellin-contained ferment filtrate, separating the gibberellin out of the filtrate, and obtaining the crude extract containing the gibberellin by solid-liquid separation; wherein the yield of the crude extract is more than 98%.

Owner:迈德金生物技术(北京)有限公司

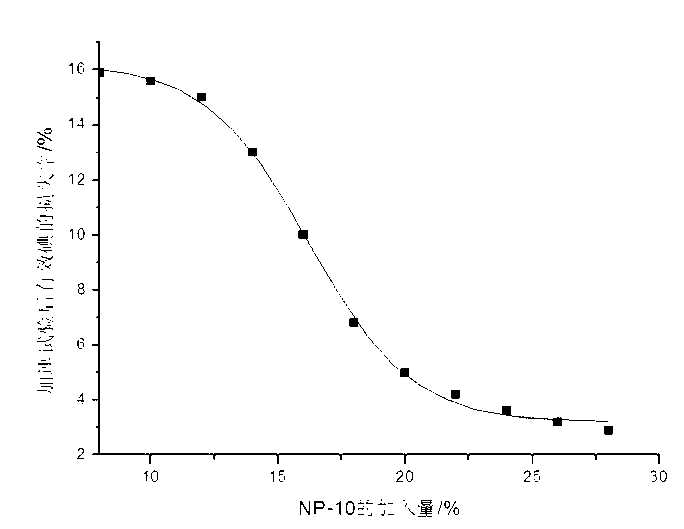

Extracting agent for efficiently removing dihydric phenols in coal gasification wastewater and extracting method

ActiveCN107697972AWide range of volume ratioEasy to controlFatty/oily/floating substances removal devicesWater contaminantsCounter currentEnvironmental chemistry

The invention belongs to the technical field of sewage treatment, and discloses an extracting agent for efficiently removing dihydric phenols in coal gasification wastewater and an extracting method.The method comprises the following steps: preparing a composite extracting agent from 16-99% by volume of methyl isobutyl ketone used as a main extracting agent and 1-84% by volume of n-pentanol usedas a synergistic extracting agent; and performing multistage counter-current extraction on coal gasification wastewater by using the composite extracting agent to obtain an extracting phase and a raffinate phase. The composite extracting agent greatly enhances the extracting effect of the dihydric phenols; and the composite extracting agent has the advantages of wide volume ratio range of the methyl isobutyl ketone and n-pentanol and simple industrial operation, and has favorable prospects in actual industrial application.

Owner:SOUTH CHINA UNIV OF TECH

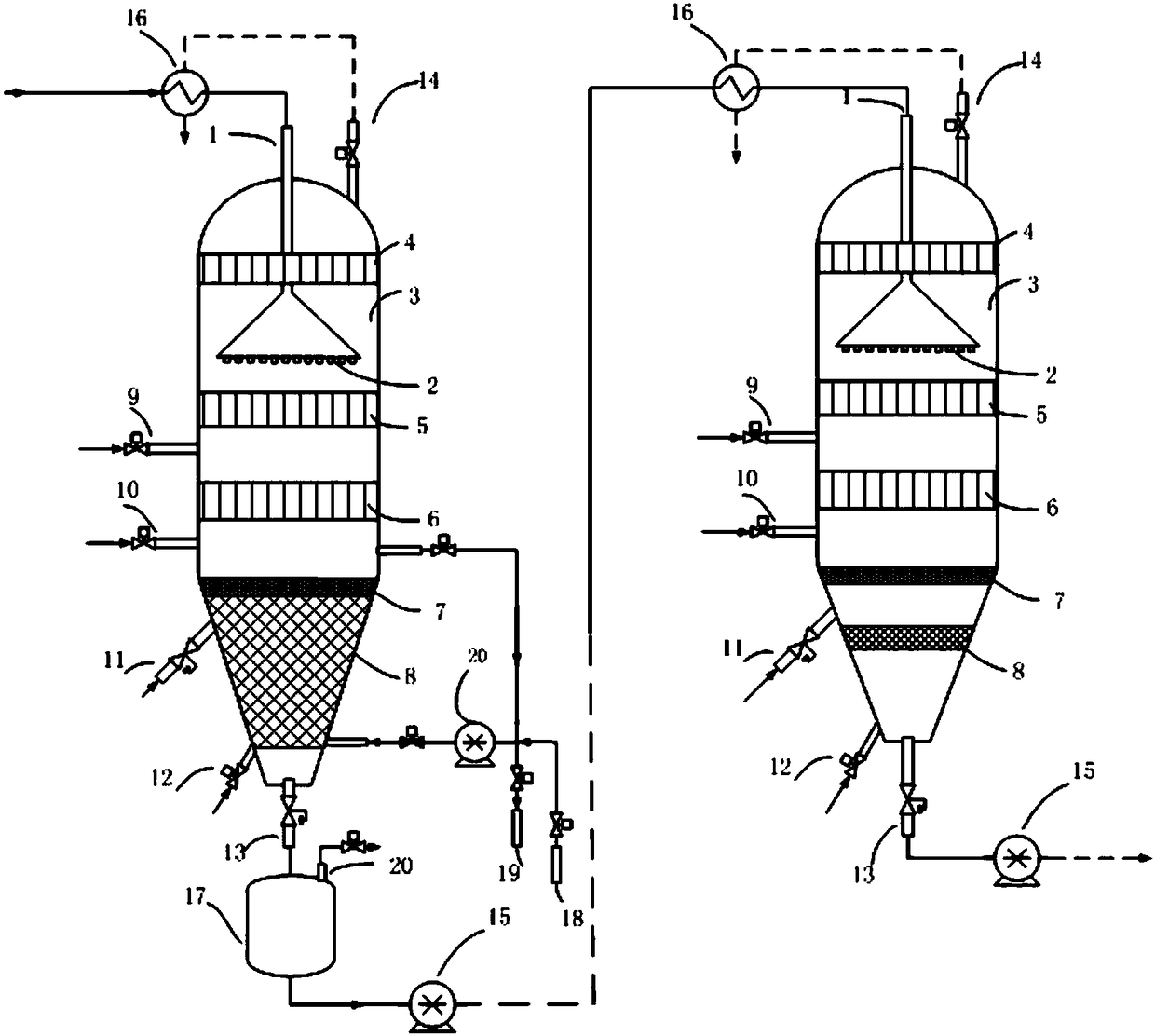

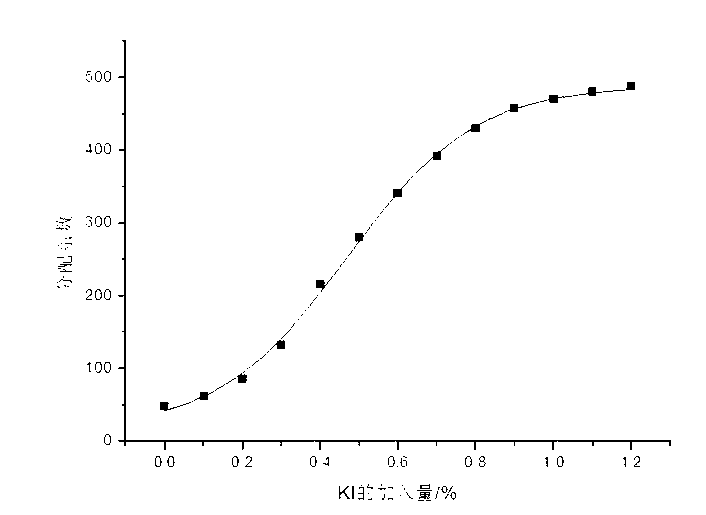

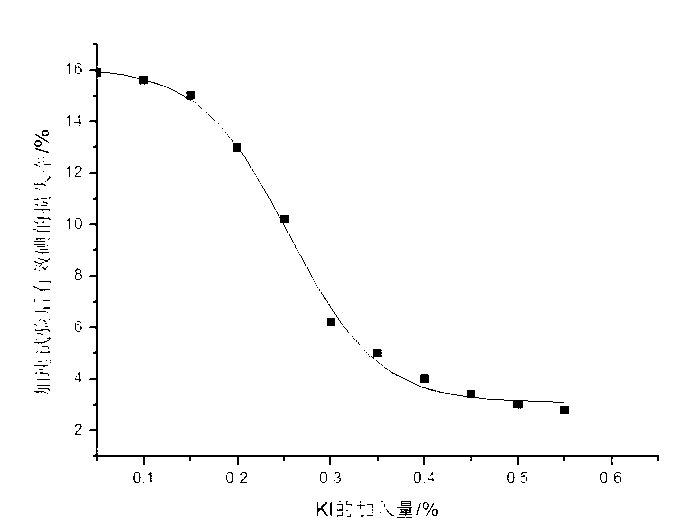

Reagent for separating amino acid enantiomer

InactiveCN1670012AAchieve enantiomer separationHigh partition coefficientSolvent extractionOrganic compound preparationChemical industryEnantiomer

The invention relates to a new pattern agent for separating amino acid enantiomer, which belongs to the mass transfer isolation technique field about chemical industry, chemical and medicine. The invention discloses the new pattern agent to solve the problem which both the low selective and small flux of chiral selectors hinder the chirality enantiomer drugs industrial mass production seriously, which comprises: mixing the chirality molecule D-dimethylbenzoyl tartaric acid or L-dimethylbenzoyl tartaric acid with the mole ratio as 1:1-40 and D2EHPA, adding octanol as deflocculating agents, and stirring to get the D-dimethylbenzoyl tartaric acid, L-dimethylbenzoyl tartaric acid or D2EHPA with unreactive chiral molecules and the mixture liquid system of intermediate complex compound from the reaction formation. The mixture liquid system is the said new pattern agent for separating amino acid enantiomer.

Owner:TSINGHUA UNIV

Treatment method of high-concentration phenolic wastewater in coal chemical industry

InactiveCN106044917ALow boiling pointReduce heat evaporationWater treatment compoundsWater contaminantsHigh concentrationChemical industry

The invention discloses a treatment method of high-concentration phenolic wastewater in coal chemical industry. The treatment method comprises the specific operating steps that a dephenolizing extraction agent methyl propyl ketone for the high-concentration phenolic wastewater in the coal chemical industry is extracted at the temperature of 30-80 DEG C to obtain an extraction phase and a raffinate phase, wherein the total phenol content in the high-concentration phenolic wastewater in the coal chemical industry is not lower than 2000 mg / L. Compared with the prior art, more energy is saved at a solvent recovery stage in the treatment method, and the energy consumption of a water tower is greatly reduced. In addition, the methyl propyl ketone has an excellent extraction effect so that the treatment method can very effectively reduce the phenolic substance content in the high-concentration phenolic wastewater.

Owner:SOUTH CHINA UNIV OF TECH

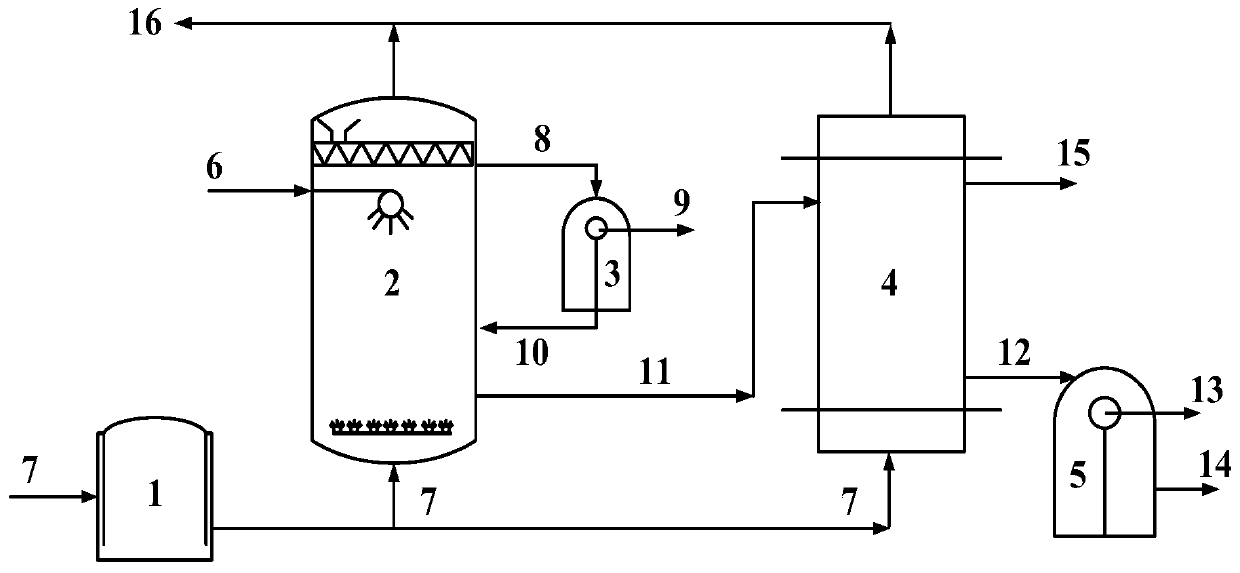

A process for continuous production of furfural from xylose

The invention provides a process for continuous production of furfural from xylose. The process includes the following steps: pretreating mother liquor containing the xylose, injecting the mother liquor into a reactor after the dispersing and atomization of the mother liquor in the upper part of a packed bed reactor, bringing the mother liquor into contact with a heat-carrying gas stream fed fromthe lower part of the reactor, carrying out the generated furfural from the reaction system by a gas stream, and extracting and separating the furfural in a base solution at the same time by the an extractant. The temperature of a xylose dehydrated reaction in the packed bed is 150-280 DEG C, and the residence time of the xylose solution in the reactor is 0.01-100 minutes. Conversion of the xyloseinto the furfural in a liquid phase reaction system, and furfural stripping separation and extraction separation are synchronously achieved in a multi-layer packed bed reactor so as to reduce steam consumption in the whole process, to reduce production of wastewater, and more importantly, to shorten the residence time of the furfural product in the liquid phase reaction system to reduce side reactions causing loss of furfural.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Aquaculture compound iodine solution and preparation method thereof

InactiveCN103210958AHigh partition coefficientImprove stabilityBiocideDisinfectantsIodine solutionsIodide

The invention relates to an aquaculture compound iodine solution. The solution comprises the following components in percentage by weight: 1.8-3% of iodine, 0.3-1% of iodide, 15-30% of a nonionic surfactant, 3.5-4.5% of hydrochloric acid with the concentration of 75% by weight, 16-26% of phosphoric acid with the concentration of 85% by weight and the balance of water. The invention further relates to a preparation method of the aquaculture compound iodine solution. The aquaculture compound iodine solution is ingenious in design, has high distribution coefficient and high stability and is suitable for large-scale popularization and application.

Owner:SHANGHAI YUKING NEW MATERIAL TECH

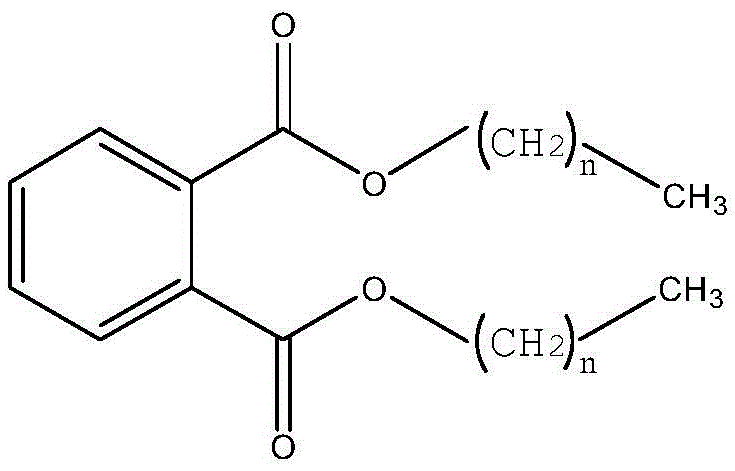

Working solution for producing hydrogen peroxide by anthraquinone process

InactiveCN105600755AHigh partition coefficientAnthraquinone SolubilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolubilityTetralin

The invention provides a working solution for producing hydrogen peroxide by an anthraquinone process. The working solution comprises a mixed solvent and a working carrier, wherein the mixed solvent is prepared from the following components in percentage by volume: 50%-80% of heavy aromatics and 20%-50% of phthalic acid; and the working carrier is a mixture of alkylanthraquinone and corresponding tetralin alkylanthraquinone. The working solution for producing hydrogen peroxide by the anthraquinone process has a relatively large distribution coefficient (100-400); the amount of an extracting agent in the extraction process can be reduced; the content of hydrogen peroxide in extraction raffinate can be reduced; the yield of hydrogen peroxide can be improved; meanwhile, the height of an extraction tower can be reduced; the equipment investment cost can be reduced; and meanwhile, the working solution has relatively high anthraquinone solubility.

Owner:CHINA TIANCHEN ENG +1

Method for removing terpene from essential oil

ActiveCN111363624AEfficient extractionReduce energy consumptionFatty-oils/fats refiningFatty-oils/fats separationSolventChemical compound

The invention provides a method for removing terpene from essential oil, and belongs to the technical field of essential oil purification. According to the method, an organic salt association extraction agent is used for association extraction, the selectivity, the partition coefficient and the extraction rate are high in the extraction process, the organic salt association extraction agent and the oxygen-containing terpenoids can form the eutectic solvent, efficient extraction of the oxygen-containing terpenoids is achieved, and then most terpenes are separated out. Through two times of backextraction processes, terpene and the oxygen-containing terpenoids can be completely separated, and the purity and the recovery rate of the obtained oxygen-containing terpenoids are very high. Meanwhile, the method provided by the invention is simple to operate, low in energy consumption and free of side reaction. Results of embodiments show that the purity of the oxygen-containing terpenoids obtained by the method for removing terpenes from essential oil provided by the invention can reach 99%, and the recovery rate can reach 95%.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for salt extraction separation of benzol-cyclohexane normal heptane

InactiveCN101172928BHigh partition coefficientHigh selectivityDistillation purification/separationExtraction purification/separationBenzeneLiquid layer

The invention provides a method for leaching and separating benzene-cyclohexane or normal heptane saliferously. Inorganic slat extraction agent is dissolved in main organic leaching agent to form saliferous organic solvent with certain concentration so as to obtain composite extraction agent. The invention is characterize in that the composite extraction agent is added according to the volume ratio of 0.5 to 2:1 of the composite extraction agent and the benzene-cyclohexane or normal heptane to form a benzene-cyclohexane or normal heptane compound system; the benzene-cyclohexane or normal heptane compound system is saliferously leached through multiple cross-flows and counter-flows so as to obtain cyclohexane with the mol concentration being larger than 96 percent, or the normal heptane with the mol concentration being larger than 73 percent; and the leaching liquid which is rich in benzene is rectified so as to obtain the benzene with the mol concentration being larger than 98 percentand the organic main extraction agent with the concentration being larger than 96 percent. The invention has the advantages that a method of adding the saliferous assistant component into the organicsolvent is adopted, so that the obtained composite leaching agent has repulsive interaction on the cyclohexane or normal heptane among the raw material components, thereby decreasing the mutual solubility and mixing the liquid layers.

Owner:HARBIN ENG UNIV

Efficient dephenolizing extractant and extraction and dephenolization method thereof

InactiveCN108046366AGuaranteed ExtractionShorten layering timeWater contaminantsWater/sewage treatment by extractionKeroseneTricresyl phosphate

The invention discloses an efficient dephenolizing extractant and an extraction and dephenolization method thereof. The extractant contains tricresyl phosphate as an active ingredient and further contains coal oil and amino compounds. A mixture of tricresyl phosphate, coal oil and the amino compounds is taken as the extractant. The complex extraction and dephenolization method adopts a special complex extraction mechanism, distribution coefficient is relatively high, extraction capacity is high, besides, the complex extractant has the advantage of being reusable after reextraction by alkali liquor, and the alkali liquor enriches, separates and recovers valuable substances in waste water, so that efficient treatment and resource recycling of phenols are realized.

Owner:CCTEG CHINA COAL RES INST

Method for salt extraction separation of benzol-cyclohexane normal heptane

InactiveCN101172928AReduce energy consumptionEasy to operateDistillation purification/separationExtraction purification/separationMutual solubilityBenzene

The invention provides a method for extracting and separating benzene-cyclohexane / n-heptane by adding salt. Dissolve the inorganic salt co-extractant in the organic main extractant to form a certain concentration of salt-containing organic solvent to obtain a composite extractant; The ratio of 2:1, adding a composite extractant to form a benzene-cyclohexane / n-heptane mixed system, the benzene-cyclohexane / n-heptane mixed system is subjected to multi-stage cross-current or countercurrent salt extraction to obtain a molar concentration greater than 96% cyclohexane or greater than 73% n-heptane and benzene-rich extract; rectify the benzene-rich extract to obtain benzene with a molar concentration greater than 98% and an organic main extract with a concentration greater than 96% agent. The invention adopts the method of adding salt auxiliary components into the organic solvent, so that the prepared composite extractant can repel the cyclohexane / n-heptane in the raw material components, reduce the mutual solubility and separate the mixed liquid.

Owner:HARBIN ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com