A process for continuous production of furfural from xylose

A technology of xylose and furfural, which is applied in the field of continuous production of furfural from xylose, can solve the problems of economic efficiency limitation and achieve the effect of suppressing the loss of furfural

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Add H to 10wt% xylose solution 2 SO 4 , prepared into 5-10wt% dilute sulfuric acid-xylose solution, and then add extractant NaCl to saturation.

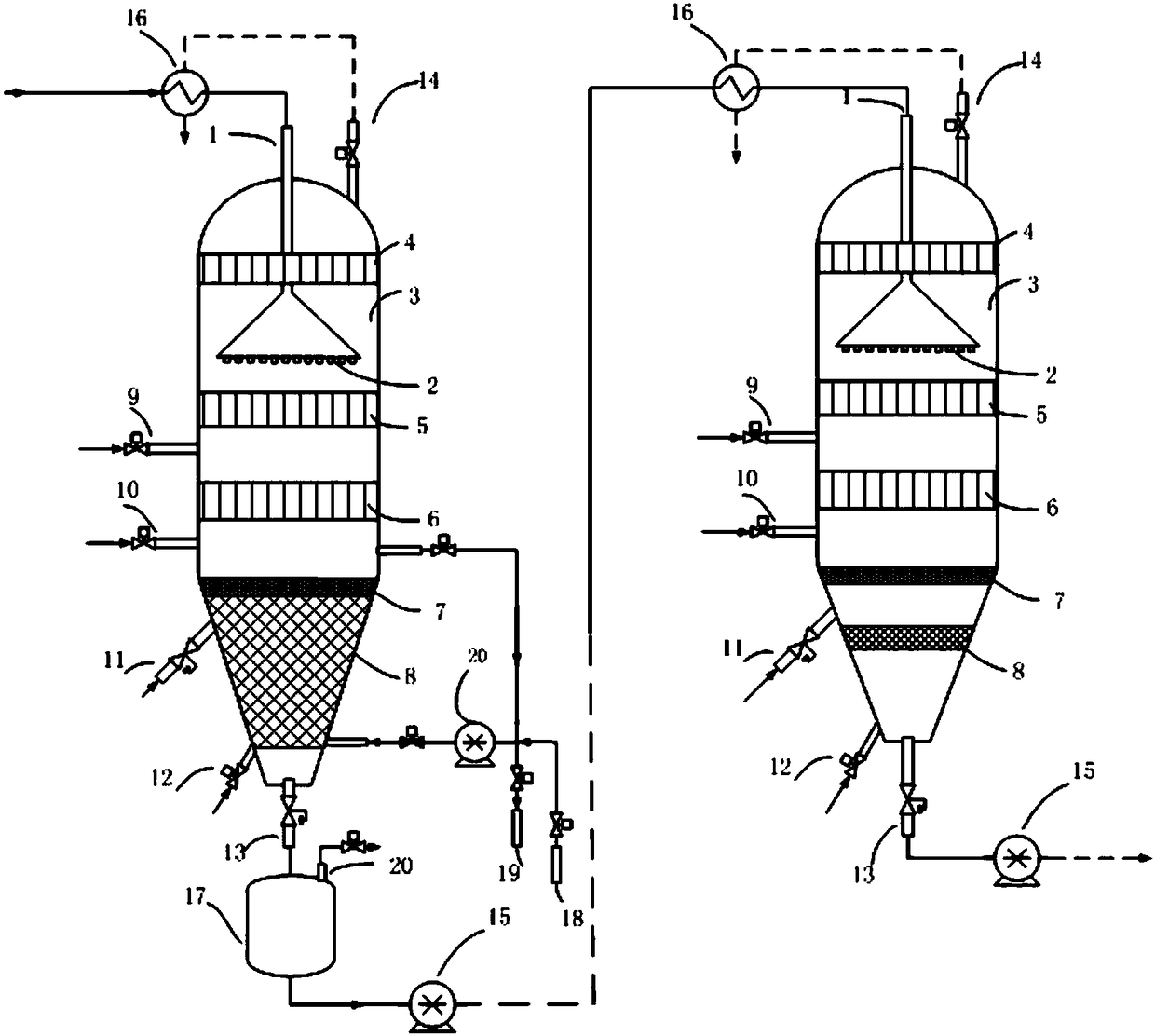

[0047] Use HZSM-5 molecular sieve catalyst (Si / Al=25) to load on the inner wall of porous ceramics (cordierite material, 100 mesh) to make solid acid with filling molding treatment. The solid acid filler is stacked inside the packed bed reaction tube, such as figure 1 Support catalyst packing 6 positions. Use wire mesh packing to place in the upper part of the packed bed reactor, such as figure 1 Defoaming filler 4 positions. Metal powder sintered plates with a pore size of 5 microns are used as dispersed carrier gas fillers, and the lower part of the reactor, such as figure 1 Disperse the carrier gas packing in 7 positions. Porous ceramics (cordierite material, 400 mesh) are directly used as extractant dispersion filler, placed at the bottom of the reactor, such as figure 1 Disperse organic solvent filler 8 positions. ...

Embodiment 2

[0050] Add acetic acid to 10wt% xylose solution to prepare 5wt% dilute acetic acid-xylose solution.

[0051] The faujasite molecular sieve catalyst is used to support the inner wall of porous ceramics (cordierite material, 100 mesh) to make a solid acid with filling molding treatment. The solid acid filler is stacked inside the packed bed reaction tube, such as figure 1 Support catalyst packing 6 positions. Use wire mesh packing to place in the upper part of the packed bed reactor, such as figure 1 Defoaming filler 4 position position. Metal powder sintered plates with a pore size of 5 microns are used as dispersed carrier gas fillers, and the lower part of the reactor, such as figure 1 Disperse the carrier gas packing in 7 positions. Porous ceramics (cordierite material, 400 mesh) are directly used as extractant dispersion fillers and placed at the bottom of the reactor, as shown in figure 8 for dispersion of organic solvent fillers.

[0052] The prepared xylose mother l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com