Two-way DC-DC converter

A DC converter, bidirectional DC technology, applied in the direction of DC power input conversion to DC power output, high-efficiency power electronic conversion, output power conversion device, etc., can solve the problem that the circuit voltage loss cannot obtain sufficient performance, and large current flows into the switching element , Increased circuit scale and other issues, to achieve the effect of simplifying the structure, shortening the driving period, and suppressing switching loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

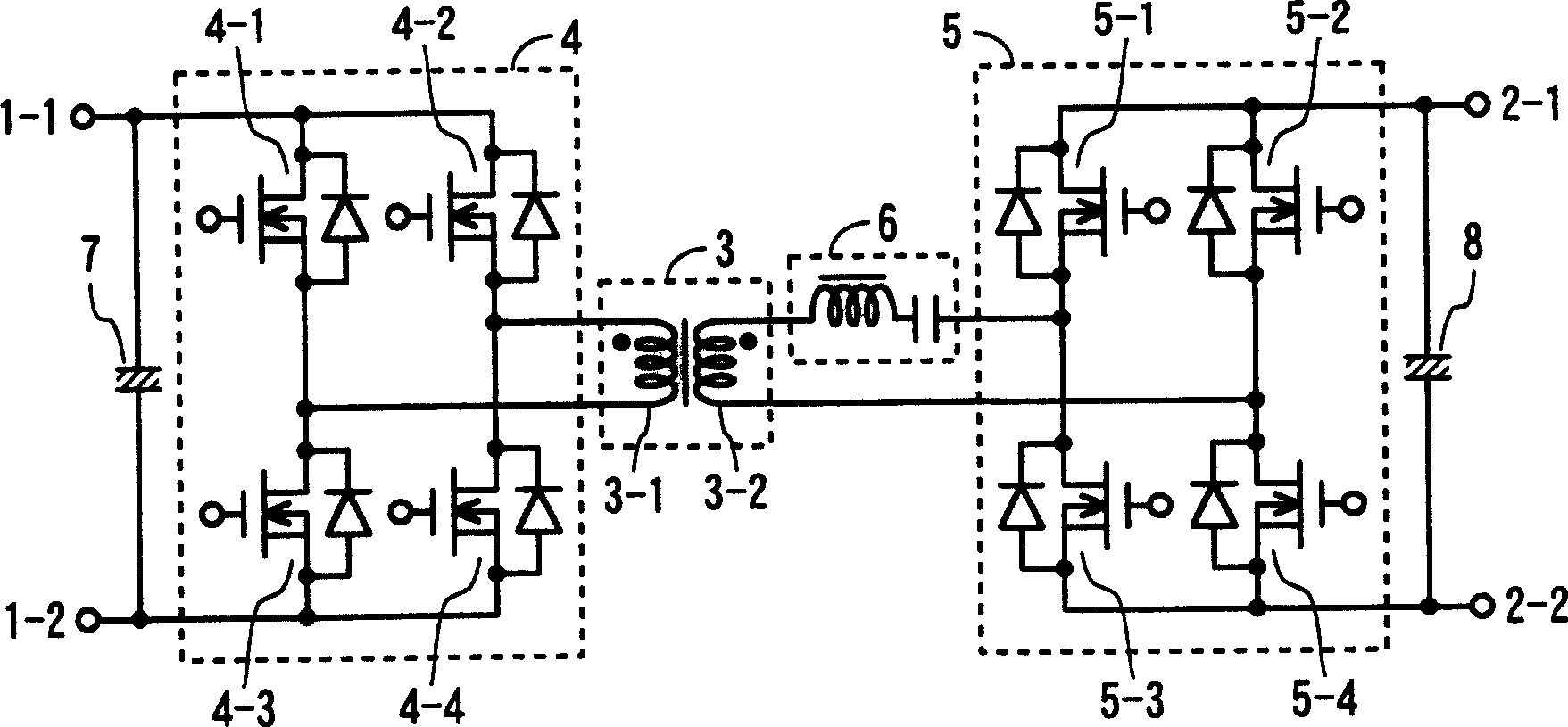

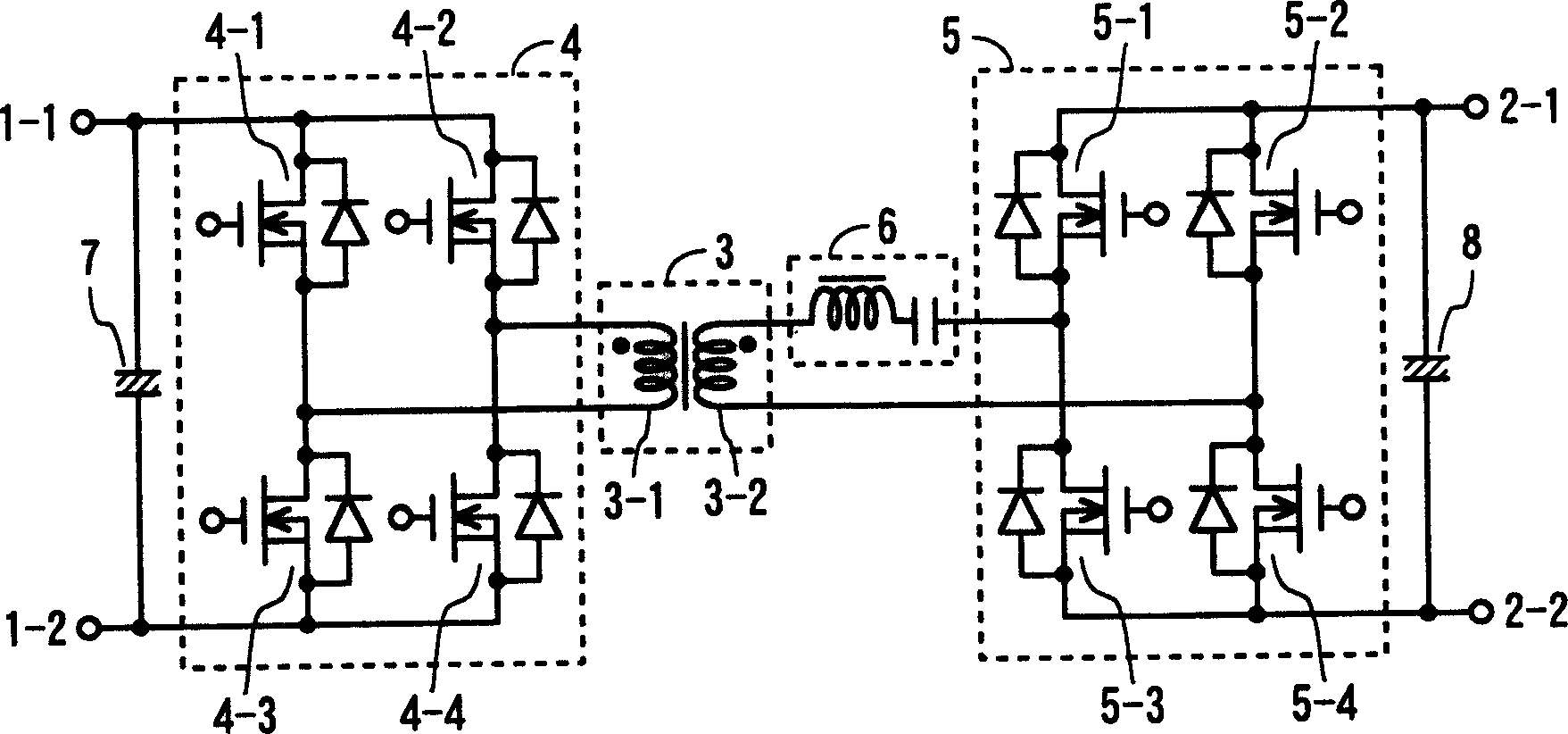

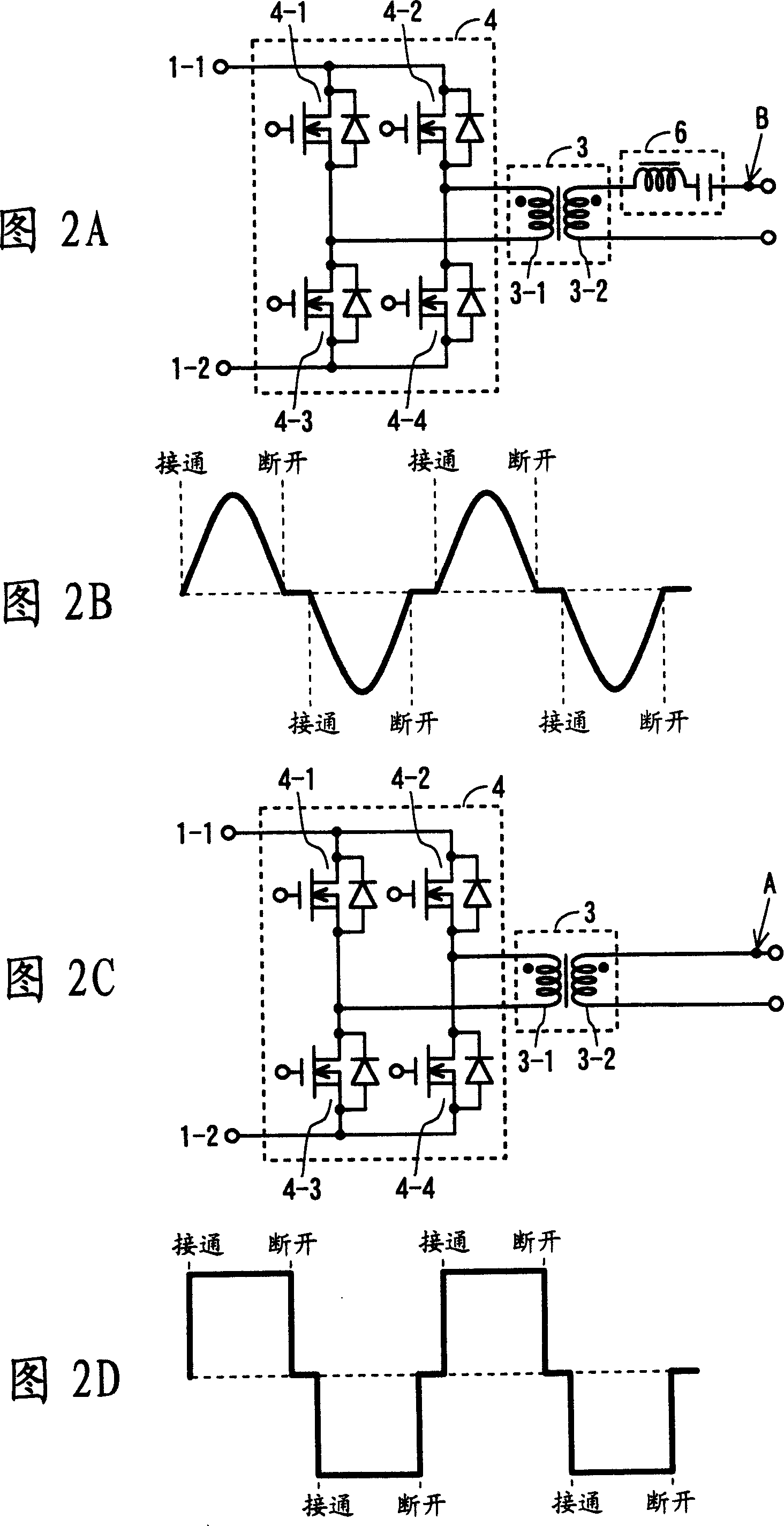

[0020] Hereinafter, the present invention will be described in detail with reference to the drawings. figure 1 It is a circuit diagram showing an embodiment of the bidirectional DC-DC converter of the present invention. In the bidirectional DC-DC converter of this embodiment, the DC power supply connected to the low-voltage side terminals 1-1 and 1-2 and the DC power supply connected to the high-voltage side terminals 2-1 and 2-2 are bidirectionally integrated through the transformer 3. . Hereinafter, the side of the low-voltage side terminals 1-1 and 1-2 may be referred to as the primary side, and the side of the high-voltage side terminals 2-1 and 2-2 may be referred to as the secondary side.

[0021] The transformer 3 includes a low-voltage winding 3-1 on the primary side and a high-voltage winding 3-2 on the secondary side. The step-up ratio of the bidirectional DC-DC converter is determined by the winding ratio of the low-voltage side winding 3-1 and the high-voltage si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com