3D printing preparation method for injection mold

An injection mold, 3D printing technology, applied in the direction of additive manufacturing, process efficiency improvement, additive processing, etc., can solve the constraints of 3D printing technology application, forming process, forming efficiency and stability can not meet production needs, mold steel cracking and other issues to achieve precise manufacturing, improve forming quality, and reduce cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

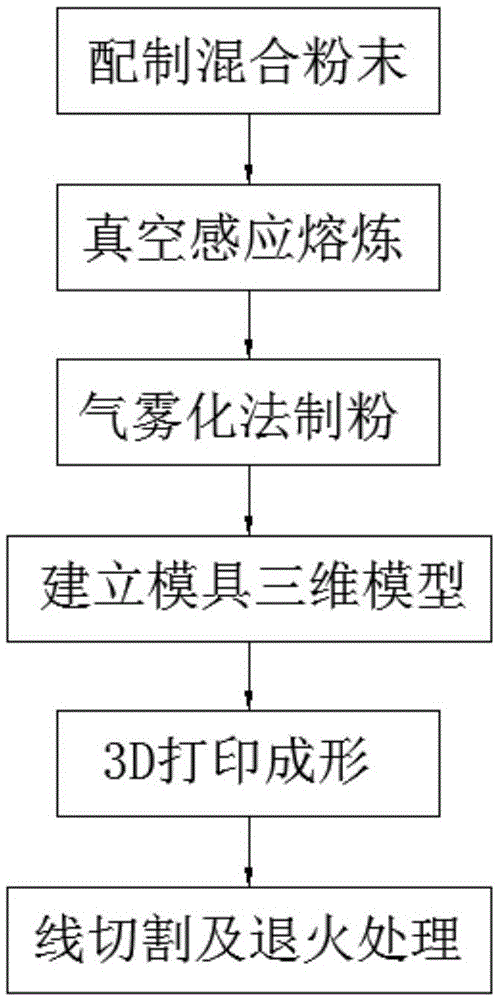

Image

Examples

Embodiment 1

[0028] (1) Configure the mixed powder, and then carry out vacuum induction melting to the mixed powder to form a mold steel billet, wherein the components contained in the mixed powder and the weight percentages of each component are as follows: 0.4% of C element, 0.75% of Si element, Mn element 0.45%, Cr element 14%, V element 0.3%, the balance is Fe element;

[0029] (2) Argon atomization is used to carry out gas atomization powder production on the above-mentioned smelted alloy. The obtained powder is spherical or quasi-spherical, with a particle size distribution of 15-30 μm and an oxygen content of less than 800 ppm to obtain a powder with good fluidity ;

[0030] (3) set up a three-dimensional CAD model of parts on a computer, convert the three-dimensional model into STL format and import it into the selective laser melting rapid prototyping equipment;

[0031] (4) Fill the powder prepared by gas atomization into the selective laser melting rapid prototyping equipment, ...

Embodiment 2

[0034] (1) Configure mixed powder, and then vacuum induction smelt the mixed powder to form a mold steel billet, wherein the components contained in the mixed powder and the weight percentages of each component are as follows: 0.45% of C element, 0.725% of Si element, Mn element 0.4%, Cr element 14.8%, V element 0.25%, the balance is Fe element;

[0035] (2) Use argon gas atomization to carry out gas atomization powder production on the above-mentioned smelted alloy, the obtained powder is spherical or quasi-spherical, the particle size distribution is 30-45 μm, and the oxygen content is lower than 800 ppm, so as to obtain a powder with good fluidity ;

[0036](3) set up a three-dimensional CAD model of parts on a computer, convert the three-dimensional model into STL format and import it into the selective laser melting rapid prototyping equipment;

[0037] (4) Fill the powder prepared by gas atomization into the selective laser melting rapid prototyping equipment, and perfo...

Embodiment 3

[0040] (1) Configure the mixed powder, and then vacuum induction melt the mixed powder to form a mold steel billet, wherein the components contained in the mixed powder and the weight percentages of each component are as follows: 0.5% of C element, 0.70% of Si element, Mn element 0.35%, Cr element 15.6%, V element 0.35%, the balance is Fe element;

[0041] (2) Use argon gas atomization to carry out gas atomization powder production on the above-mentioned smelted alloy, the obtained powder is spherical or quasi-spherical, the particle size distribution is 20-40 μm, and the oxygen content is lower than 800ppm, so as to obtain a powder with good fluidity ;

[0042] (3) set up a three-dimensional CAD model of parts on a computer, convert the three-dimensional model into STL format and import it into the selective laser melting rapid prototyping equipment;

[0043] (4) Fill the powder prepared by gas atomization into the selective laser melting rapid prototyping equipment, and per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com