Efficient dephenolizing extractant and extraction and dephenolization method thereof

An extraction agent and extraction technology, applied in chemical instruments and methods, extraction water/sewage treatment, water pollutants, etc., can solve the problems of low extraction rate of refractory phenols, large back extraction loss, high price, etc. Layer time, the effect of reducing extraction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

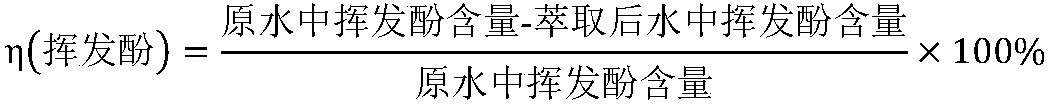

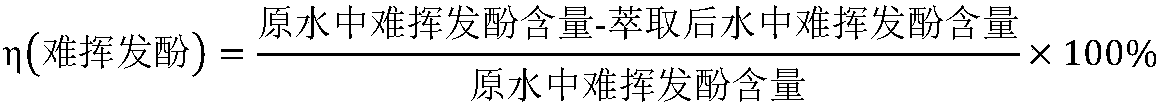

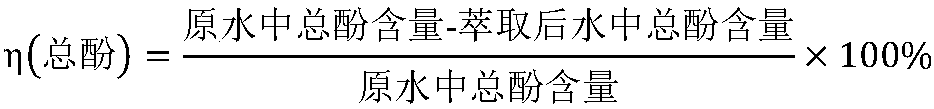

[0045] Embodiment 1: the removal effect investigation of different extractants

[0046] The extraction conditions are as follows: pH value is 6, temperature is 25°C, ratio (that is, the volume ratio of extractant to waste water, the same below) is 1:1, and the extraction time is 15 minutes.

[0047] Extractant 1: tricresyl phosphate;

[0048] Extractant 2: a mixed extractant of tricresyl phosphate + diesel oil (the volume ratio of tricresyl phosphate to diesel is 1:1);

[0049] Extractant 3: a mixed extractant of tricresyl phosphate + kerosene (the volume ratio of tricresyl phosphate to kerosene is 1:1);

[0050] Extractant 4: a mixed extractant of tricresyl phosphate + kerosene + trioctylamine (the volume ratio of tricresyl phosphate, kerosene and trioctylamine is 1:3:0.5);

[0051] Wherein, the preparation method of extractant 4 is to add tricresyl phosphate into kerosene, stir fully, dissolve and mix uniformly, then add trioctylamine, and stir again uniformly, thereby obt...

Embodiment 2

[0056] Embodiment 2: The removal effect investigation of different amine extractants

[0057] The present embodiment was carried out according to the same method as in the above-mentioned embodiment 1, and the only difference is that the "trioctylamine" in the extractant 4 is respectively tripropylamine and tetraethylammonium chloride in equal amounts, that is, the following corresponding relation:

[0058] Extractant 5: tricresyl phosphate + kerosene + tripropylamine

[0059] Extractant 6: tricresyl phosphate + kerosene + tetramethylammonium chloride

[0060] Extractant 7: tricresyl phosphate + kerosene + tetraethylammonium chloride

[0061] The contents of volatile phenols, low-volatile phenols and total phenols in the wastewater after extraction treatment were measured and the corresponding extraction rates were calculated and listed in Table 3.

[0062] Table 3. Various phenol contents and extraction rates after treatment

[0063]

[0064] As can be seen from Table ...

Embodiment 3

[0065] Embodiment 3: the investigation of tricresyl phosphate and kerosene dosage ratio in extractant 3

[0066] Use extraction agent 3, carry out this embodiment according to the same method of above-mentioned embodiment 1, difference is only to change the volume ratio of tricresyl phosphate and kerosene, specific volume ratio and the volatile phenol in the waste water after treatment, difficult volatile phenol And the content of total phenols is measured and the corresponding extraction rate is calculated and listed in Table 4.

[0067] Table 4. Various phenol contents and extraction rates after treatment

[0068]

[0069] It can be seen from Table 4 that when the extractant is a mixture of tricresyl phosphate and kerosene, the volume ratio of the two has a significant impact on the removal effect, and the volume ratio is preferably 1:1-1:3. When exceeding this range When, all will cause extraction rate to have significant reduction, find that the most preferably is 1:3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Extraction efficiency | aaaaa | aaaaa |

| Extraction efficiency | aaaaa | aaaaa |

| Extraction efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com