Tianshan chlorella and Multi-stage cyclic extraction equipment and preparation method of chlorella deep purification factors

A technology for purifying factors and chlorella, applied in chemical instruments and methods, cosmetic preparations, solid solvent extraction, etc., can solve the problems of insufficient contact between materials and extraction liquid, affecting extraction efficiency, and long extraction time, achieving enhanced Skin stratum corneum barrier, improved mixing uniformity, and reduced extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

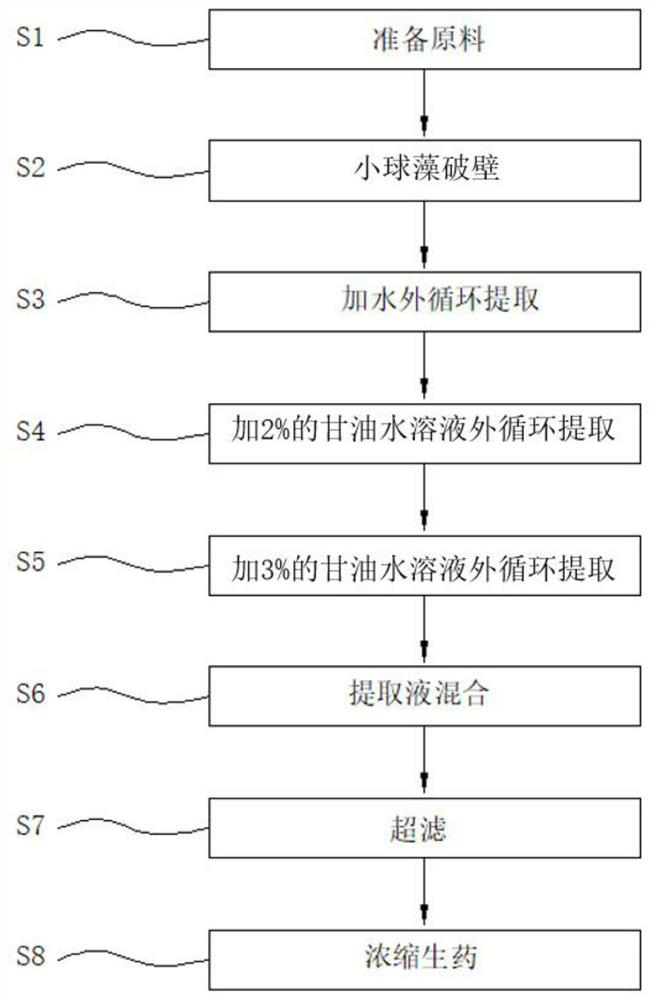

[0047] Such as figure 1 As shown, the above-mentioned chlorella is subjected to wall-breaking treatment to obtain 50%-60% of chlorella wall-breaking algae powder. Specifically, the wall-breaking treatment uses a grinder to break the cells, and adds 6 times of water for external use. Circular extraction, the extraction temperature is 70°C, and the end point is determined according to the monitoring of the online spectrophotometer. The specific range is that the absorbance value at wavelength 240nm is diluted ≥0.9, and the absorbance at 550nm is ≤1.3. Release the extract to obtain A1; The glycerin solution is extracted by external circulation, the extraction temperature is 80°C, the extraction end point is 280nm absorbance value ten times dilution ≥ 1.2, 550nm absorbance ≤ 1.4, release the extract to obtain A2; add 2 times of 5% glycerin solution to algae residue Circular extraction, the extraction temperature is 80°C, the end point of the extraction is 280nm absorbance value 10...

Embodiment 2

[0052] Such as figure 1 As shown, the above-mentioned chlorella is subjected to wall-breaking treatment to obtain 50%-60% of chlorella wall-breaking algae powder. Specifically, a grinder machine is used for cell crushing, and 5 times of water is added for external circulation extraction, and the extraction The temperature is 80°C, and the end point is determined according to the online spectrophotometer monitoring. The specific range is that the absorbance value at 240nm is diluted ≥1.3, and the absorbance at 550nm≤1.6, and the extract is released to obtain A1; External circulation extraction, the extraction temperature is 70°C, the extraction end point is the absorbance value at 280nm, the tenfold dilution is ≥1.2, and the absorbance at 550nm is ≤1.3, and the extract is released to obtain A2; the dregs are added with 2 times of 5% glycerin solution for external circulation extraction. The temperature is 850°C, the end point of extraction is the absorbance value at 280nm, the ...

Embodiment 3

[0057] Such as figure 1 As shown, the above-mentioned chlorella is subjected to wall-breaking treatment to obtain 50%-60% of the chlorella wall-broken algae powder, and the cell is broken by a grinder machine, and 5 times of water is added for external circulation extraction, and the extraction temperature is 90°C , according to the online spectrophotometer monitoring to determine the end point, the specific range is that the absorbance value of wavelength 240nm is diluted by ten times ≥ 1.3, and the absorbance of 550nm is ≤ 1.5, and the extract is released to obtain A1; 4 times of 4% glycerin is added to the algae residue for external circulation extraction, The extraction temperature is 80°C, the end point of the extraction is the absorbance value at 280nm, the ten-fold dilution is ≥1.5, and the absorbance at 550nm is ≤1.4, and the extract is released to obtain A2; the algae residue is added with 3 times of 5% glycerin solution for external circulation extraction, and the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com