Aquaculture compound iodine solution and preparation method thereof

A technology for aquaculture and iodine solution, applied in botany equipment and methods, chemicals for biological control, applications, etc., can solve the problem of low distribution coefficient, achieve simple preparation, suitable for large-scale popularization and application, and process unique effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

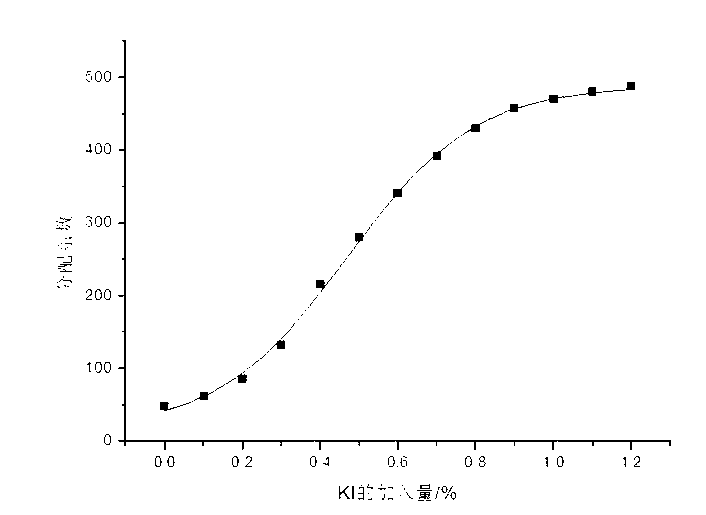

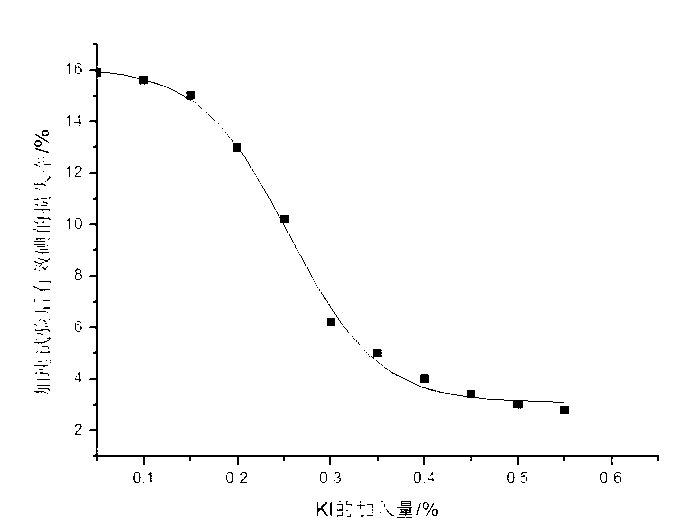

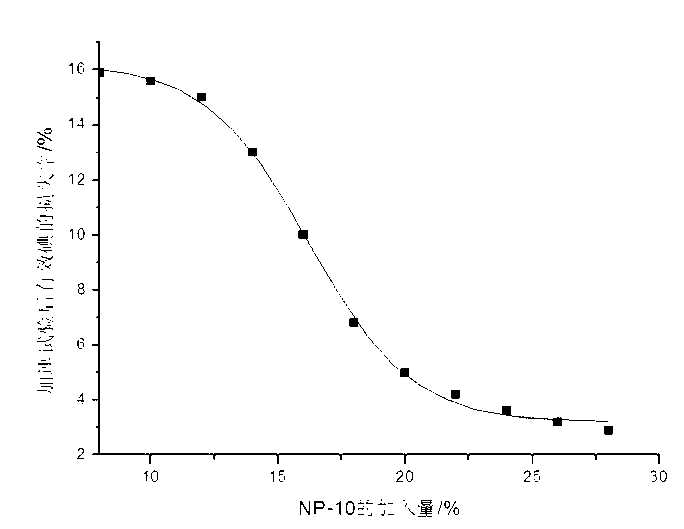

[0027] 1.3 Preparation of compound iodine solution

[0028] Add raw material iodine 1.8%-3%, iodide 0.3%-1%, non-ionic surfactant 15%-30%, then shake well, mix well, let it complex for 30min; then add hydrochloric acid (75%) 3.5 -4.5%, stir evenly; add a part of water, stir evenly, add phosphoric acid (85%) 16%-26%, stir quickly, wait for it to cool, add the rest of water, mix evenly to get the finished product.

[0029] 1.4 Determination of available iodine content

[0030] Accurately weigh about 10g of this product, put it in an iodine measuring bottle, add 50ml of water, and titrate it with sodium thiosulfate titration solution (0.1mol / L) until it becomes colorless. Every 1ml of sodium thiosulfate titration solution (0.1mol / L) is equivalent to 0.1269mg of iodine.

[0031] X ( % ) = c × V st × ...

Embodiment 1

[0073] First, take 2kg of iodine and 0.3kg of potassium iodide, add 15kg of NP-10 (nonylphenol polyoxyethylene ether), and fully stir and dissolve in the stirring tank for 30 minutes. Then add 3.5kg of concentrated hydrochloric acid, stir well until the mixture is uniform, then add 20kg of water, stir until the solution is cooled, then add 26kg of phosphoric acid under the condition of constant stirring, mix thoroughly for 1 hour, then add water to 100kg, after stirring evenly, the product is obtained. After analysis, the distribution coefficient of this solution is 390, and the available iodine content is 1.82%, which meets the requirements of the relevant national standard "Standards for Imported Veterinary Drugs". After the stability accelerated test, the loss rate of available iodine is 2%, and the stability is good.

Embodiment 2

[0077] First, take 2kg of iodine and 0.5kg of potassium iodide, add 20kg of NP-10 (nonylphenol polyoxyethylene ether), and fully stir and dissolve in a stirring tank for 30 minutes. Then add 3.5kg of concentrated hydrochloric acid, stir well until the mixture is uniform, then add 20kg of water, stir until the solution is cooled, then add 26kg of phosphoric acid under the condition of constant stirring, mix thoroughly for 1 hour, then add water to 100kg, after stirring evenly, the product is obtained. After analysis, the distribution coefficient of this solution is 300, and the available iodine content is 1.89%, which meets the requirements of the relevant national standard "Standards for Imported Veterinary Drugs". After the stability accelerated test, the loss rate of available iodine is 3.5%, and the stability is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com