Working solution for producing hydrogen peroxide by anthraquinone process

A technology of hydrogen peroxide and working fluid, applied in the direction of peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, chemical instruments and methods, etc., can solve the extraction efficiency of hydrogen peroxide extraction tower Low, low yield of hydrogen peroxide, low concentration of hydrogen peroxide, etc., to achieve the effect of reducing equipment investment costs, increasing the solubility of anthraquinone, and reducing the content of hydrogen peroxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

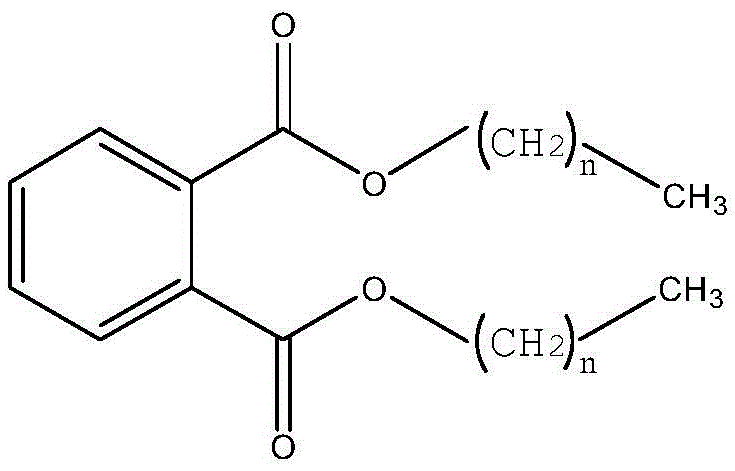

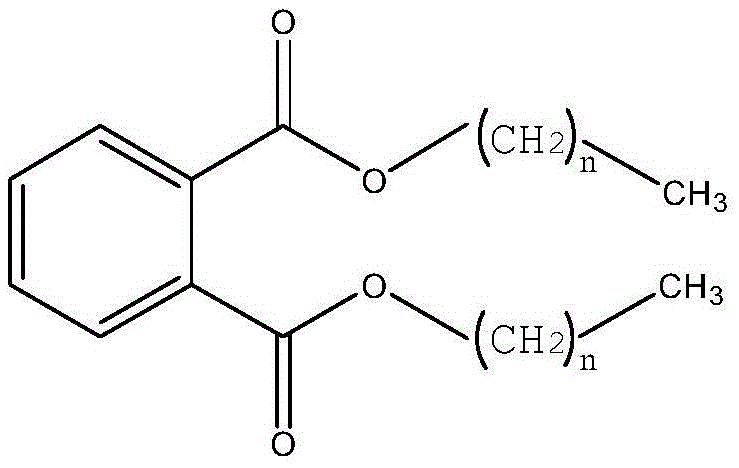

[0023] Working solution preparation method is as follows: mixed solvent: heavy aromatic hydrocarbon 50% (v / v), butyl phthalate 50% (v / v); working carrier: total anthraquinone content 120g / L, wherein 2-ethyl anthracene Quinone 110g / L, 2-ethyltetrahydroanthraquinone 10g / L.

Embodiment 2

[0025] The working solution preparation method is as follows: mixed solvent: heavy aromatic hydrocarbon 60% (v / v), pentyl phthalate 40% (v / v); working carrier: total anthraquinone content 130g / L, wherein 2-ethyl anthracene Quinone 100g / L, 2-ethyltetrahydroanthraquinone 30g / L.

Embodiment 3

[0027] The working solution ratio is as follows: mixed solvent: heavy aromatics 65% (v / v), hexyl phthalate 35% (v / v); working carrier: total anthraquinone content 150g / L, of which 2-ethylanthracene Quinone 90g / L, 2-ethyltetrahydroanthraquinone 60g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com