Method of recovery phenol from waste water and system thereof

A technology for recovering phenol and waste water, which is applied in chemical instruments and methods, extraction water/sewage treatment, and preparation of organic compounds. The effect of small solvent loss and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

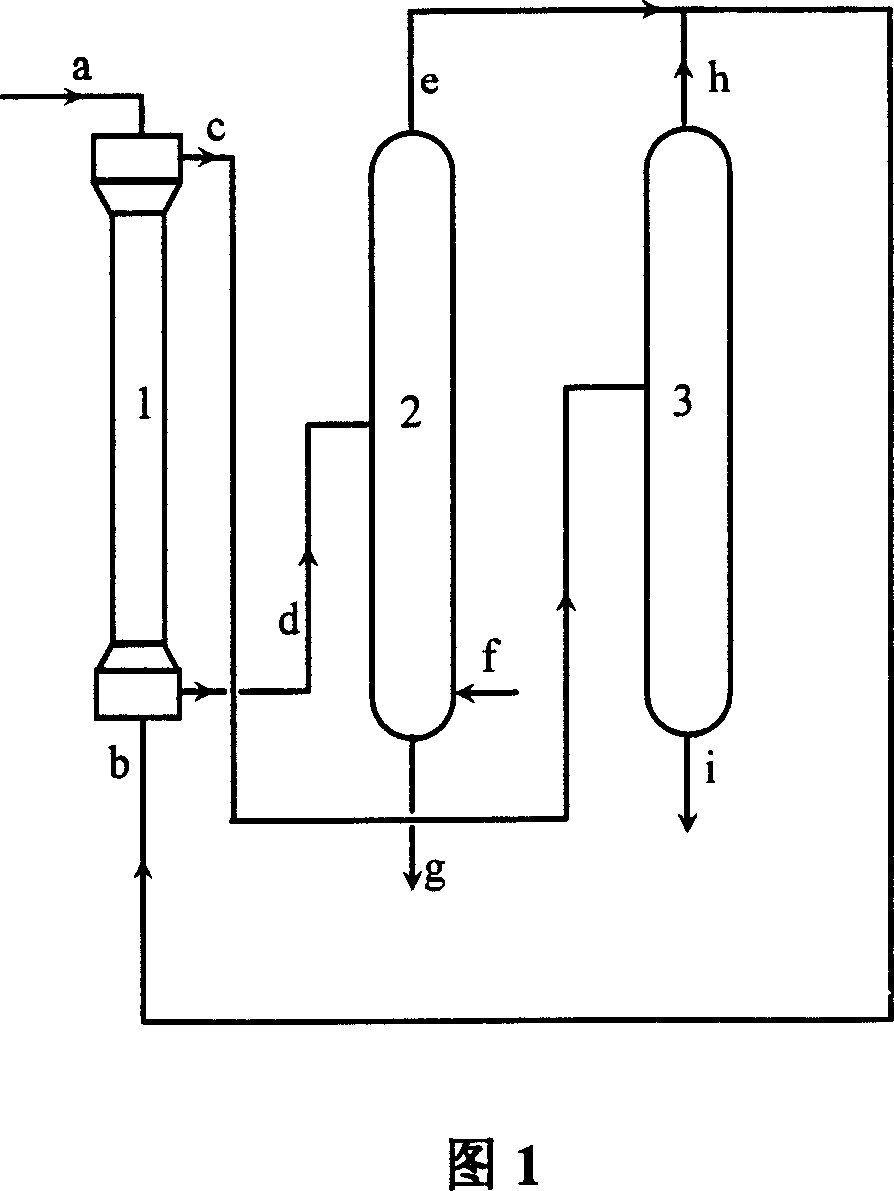

[0031] Flow rate is 15t / hr, and the aqueous solution that content is 40% (mass content) phenol and hydroquinone mixture enters extraction tower 1 through pipeline a, and extraction tower height is 16.0 meters, and tower diameter is 1.0 meters, organic solvent methyl isobutyl The base ketone (MIBK) enters the extraction tower 1 through the pipeline b, and the ratio of the organic solvent phase to the water phase is 1:1. After the two phases are contacted in countercurrent, the content of mixed phenols in the raffinate is 0.03%. The organic solvent loaded with phenol enters the feeding pipe in the middle part of the organic solvent recovery tower 3 through the pipeline c on the top of the extraction tower 1. The organic solvent recovery tower is 18.0 meters high, and the tower diameter is 1.8 meters. °C, the mixed phenols are discharged from the bottom of the tower through pipe i, and MIBK is condensed from the top of the tower and sent to the bottom of extraction tower 1 through...

Embodiment 2

[0033] Flow rate is 50L / hr, and the aqueous solution that content is 7% (mass content) phenol and hydroquinone mixture enters extraction tower 1 through pipeline a, and extraction tower height is 3.0 meters, and tower diameter is 0.05 meters, organic solvent methyl isopropyl The methyl ketone enters the extraction tower 1 through the pipeline b, and the ratio of the organic solvent phase to the water phase is 1:3. After the two phases are countercurrently contacted, the content of mixed phenols in the raffinate is 0.03%. The organic solvent loaded with phenol enters the feed pipe in the middle of the organic solvent recovery tower 3 through the pipeline c on the top of the extraction tower 1. The organic solvent recovery tower is 4.0 meters high, and the tower diameter is 0.1 meters. °C, the mixed phenols are discharged from the tower kettle through pipeline i, and the solvent is condensed from the top of the tower and sent to the bottom of extraction tower 1 through pipeline h...

Embodiment 3

[0035] The flow rate is 2t / hr, and the aqueous solution of unit phenol and polyphenol with a content of 0.5% (mass content) enters the extraction tower 1 through pipeline a. The height of the extraction tower is 10.0 meters, and the tower diameter is 0.3 meters. The organic solvent methyl isobutyl The ketone (MIBK) enters the extraction tower 1 from pipeline b, the ratio of the organic solvent phase to the water phase is 1:6, and after the two phases are contacted in countercurrent, the mixed phenol content in the raffinate is 0.05%. The organic solvent loaded with phenol enters the feeding pipe in the middle part of the organic solvent recovery tower 3 through the pipeline c on the top of the extraction tower 1. The organic solvent recovery tower is 12.0 meters high, and the tower diameter is 0.4 meters. °C, the mixed phenols are discharged from the bottom of the tower through pipe i, and MIBK is condensed from the top of the tower and sent to the bottom of extraction tower 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com