Working solution solvent system used for anthraquinone-process hydrogen peroxide production technology

An anthraquinone hydrogen peroxide, production process technology, applied in the direction of peroxide/peroxyhydrate/peroxyacid/superoxide/ozonide, inorganic chemistry, chemical instruments and methods, etc., can solve the problem of solvent production Difficulties, high market prices of solvents, etc., to achieve the effect of simple and easy-to-obtain raw materials, low market prices, and simple synthesis and preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A working fluid solvent system for anthraquinone hydrogen peroxide production process of the present invention is a five-component mixed solvent, including heavy aromatics (usually C 9 ~C 10 heavy aromatics, the same below), trioctyl phosphate, isooctyl acetate, cyclohexyl acetate and cyclohexyl propionate. The mass fraction of each component in the solvent system is: 20% to 65% of heavy aromatics, 10% to 30% of trioctyl phosphate, 15% to 35% of isooctyl acetate, and 5% to 5% of cyclohexyl acetate. 20%, and cyclohexyl propionate is 2% to 10%. Wherein, the optimized ratio is (mass percentage): heavy aromatic hydrocarbon: trioctyl phosphate: isooctyl acetate: cyclohexyl acetate: cyclohexyl propionate=50%: 18%: 20%: 8%: 4%.

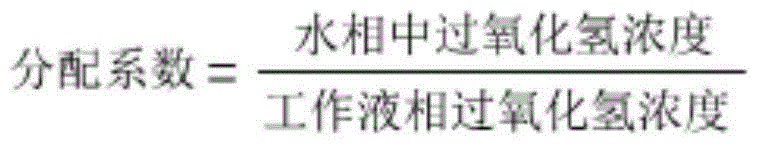

[0026] The above-mentioned solvent system of the present embodiment is used as the hydrogen peroxide working fluid solvent system, and its effect is measured as follows:

[0027] Determination of hydrogenation efficiency:

[0028] (1) Prepare fiv...

Embodiment 2

[0053] A kind of working liquid solvent system for the production process of hydrogen peroxide by anthraquinone method of the present invention is a five-component mixed solvent with a total mass of 890 grams, wherein: 445 grams of heavy aromatics, accounting for 50% of the total mass; 160 grams of octyl esters, the mass fraction is 18%; 178 grams of isooctyl acetate, the mass fraction is 20%; 71 grams of cyclohexyl acetate, the mass fraction is 8%; 36 grams of cyclohexyl propionate, the mass fraction is 4% .

[0054] The solvent system of above-mentioned present embodiment is applied to the anthraquinone method hydrogen peroxide production process, comprises the following steps (here mainly lists the hydrogenation step to check the solvent effect):

[0055] (1) Dissolve 96.8 grams of 2-ethylanthraquinone and 79.2 grams of 2-ethyltetrahydroanthraquinone (the total effective anthraquinone is 176 grams) in the above-mentioned five-component solvent to form a newly prepared hydro...

Embodiment 3

[0062] A working liquid solvent system for the anthraquinone method hydrogen peroxide production process of the present invention is a new three-component mixed solvent, the total mass of the solvent is 890 grams, of which: 560 grams of heavy aromatics, accounting for 63% of the total mass; 205 grams of trioctyl phosphate, the mass fraction is 23%; 125 grams of isooctyl acetate, the mass fraction is 14%.

[0063] When the above-mentioned solvent system of this embodiment is applied to the hydrogen peroxide production process, except changing the five-component working fluid solvent system into a three-component working fluid solvent system, the input amount of the total effective anthraquinone and other various operating steps, All are identical with embodiment 2.

[0064] After testing, 96.8 grams of 2-ethylanthraquinone and 79.2 grams of 2-ethyltetrahydroanthraquinone (the total effective anthraquinone is 176 grams) were dissolved in the three-component solvent system of thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solubility | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com