Method for separating oxygenated chemicals and 1-hexene from Fischer-Tropsch synthesis oil product

A technology of Fischer-Tropsch synthesis and compounds, applied in the purification/separation of oxygenates, preparation of oxygenates, chemical instruments and methods, etc., which can solve the problems of low economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

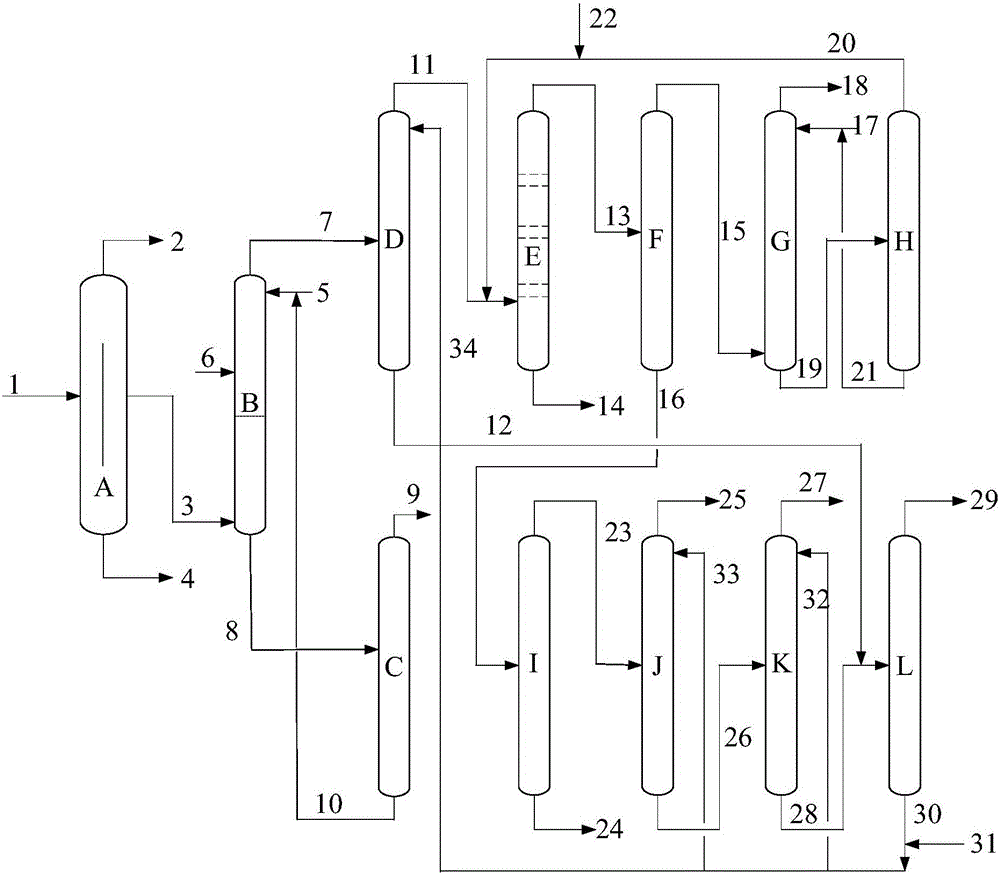

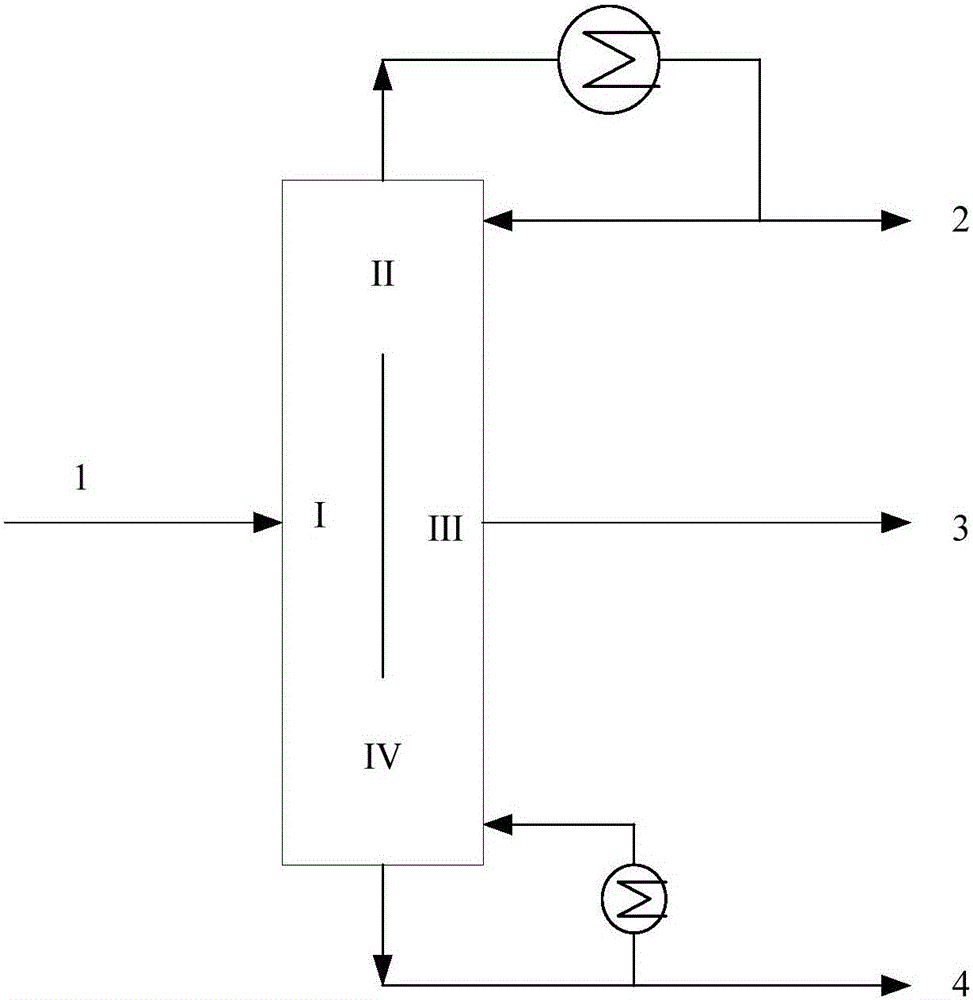

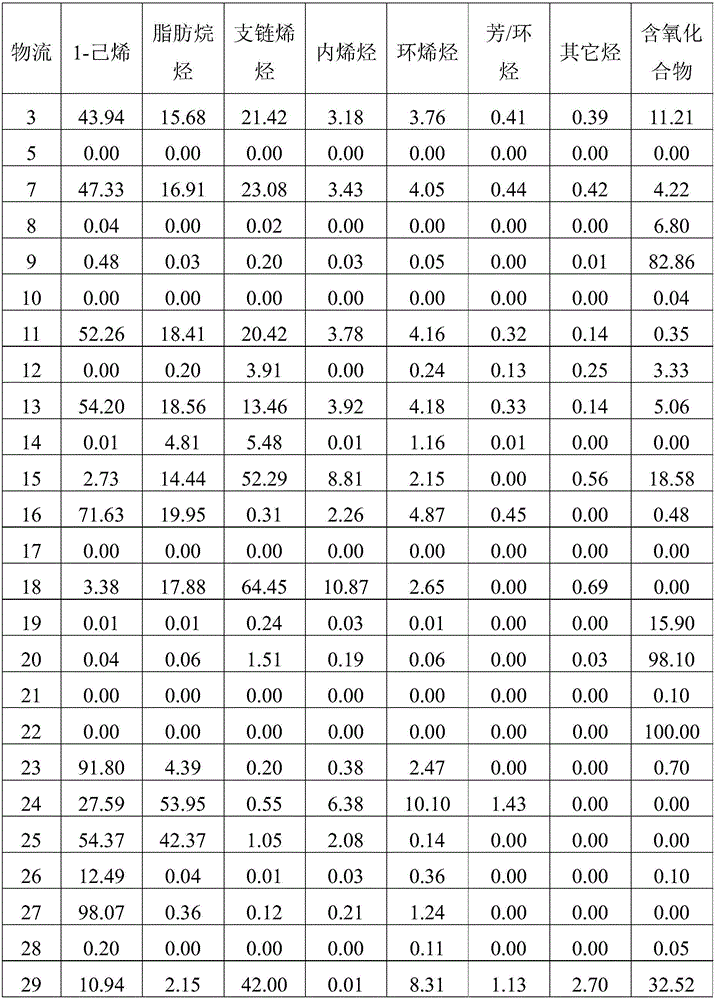

[0081] A method for separating oxygen-containing compounds and 1-hexene from Fischer-Tropsch synthetic oil, the method uses Fischer-Tropsch synthetic oil as raw material, and cuts in a pre-cut tower to obtain C 6 Distillate stream 3, operated with two extractant feeds to obtain oxygenate-enriched stream 9 and crude C after removal of oxygenates in the extraction column 6 Hydrocarbon stream 7; then use the third extractant to further remove crude C 6 Oxygenated compounds in hydrocarbon stream 7, then use methanol to convert tertiary olefins into corresponding ethers under the action of an etherification catalyst and remove them, then further purify by rectification, and then sequentially use the fourth extractant and the fifth extractant Removal of C 6 Isomerization of the paraffin component and cycloolefin component yields 1-hexene product stream 27.

[0082] Its process is as follows figure 1 As shown, the specific operating conditions of each unit in the process flow are:...

Embodiment 2

[0087] A method for separating oxygen-containing compounds and 1-hexene from Fischer-Tropsch synthetic oil, the method uses Fischer-Tropsch synthetic oil as raw material, and cuts in a pre-cut tower to obtain C 6 Distillate stream 3, operated with two extractant feeds to obtain oxygenate-enriched stream 9 and crude C after removal of oxygenates in the extraction column 6 Hydrocarbon stream 7; then use the third extractant to further remove crude C 6 Oxygenated compounds in hydrocarbon stream 7, then use methanol to convert tertiary olefins into corresponding ethers under the action of an etherification catalyst and remove them, then further purify by rectification, and then sequentially use the fourth extractant and the fifth extractant Removal of C 6 Isomerization of the paraffin component and cycloolefin component yields 1-hexene product stream 27.

[0088] Its process is as follows figure 1 As shown, the specific operating conditions of each unit in the process flow are:...

Embodiment 3

[0092] A method for separating oxygen-containing compounds and 1-hexene from Fischer-Tropsch synthetic oil, the method uses Fischer-Tropsch synthetic oil as raw material, and cuts in a pre-cut tower to obtain C 6 Distillate stream 3, operated with two extractant feeds to obtain oxygenate-enriched stream 9 and crude C after removal of oxygenates in the extraction column 6 Hydrocarbon stream 7; then use the third extractant to further remove crude C 6 Oxygenated compounds in hydrocarbon stream 7, then use methanol to convert tertiary olefins into corresponding ethers under the action of an etherification catalyst and remove them, then further purify by rectification, and then sequentially use the fourth extractant and the fifth extractant Removal of C 6 Isomerization of the paraffin component and cycloolefin component yields 1-hexene product stream 27.

[0093] Its process is as follows figure 1 As shown, the specific operating conditions of each unit in the process flow are:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com