Reagent for separating amino acid enantiomer

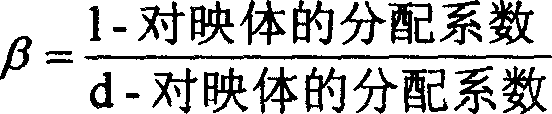

An enantiomer and amino acid technology, applied in the field of mass transfer separation, can solve the problems of limited varieties of chiral catalysts, cumbersome product treatment process, insufficient product optical rotation, etc., and achieves large partition coefficient, high economy, and chiral selectivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The novel reagent used for amino acid enantiomer separation described in the present invention is prepared by the following method: chiral molecule D-dibenzoyl tartaric acid or L-dibenzoyl tartaric acid with a molar concentration ratio of 1:1 to 40 and dibenzoyl tartaric acid (2-Hexylhexyl)phosphoric acid is mixed, diluent n-octanol is added thereto, and after stirring, unreacted chiral molecules containing D-dibenzoyl tartaric acid or L-dibenzoyl tartaric acid, di(2-hexyl tartaric acid, Base hexyl) phosphoric acid, and the mixed solution system that reacts to form a chiral intermediate complex, and the prepared mixed solution system is a new reagent for the separation of amino acid enantiomers.

[0009] The present invention will be described below in conjunction with specific embodiments.

[0010] Reagent 1:

[0011] At normal temperature (25°C) and normal pressure (101.3kPa), accurately weigh 0.358g (0.001mol) D-DBTA or L-DBTA and 0.322g (0.001mol) D2EHPA into a 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com