Complexation extraction dephenolization method of semi coke wastewater containing phenol

A technology for phenol wastewater and extraction, which is applied in chemical instruments and methods, extraction water/sewage treatment, water pollutants, etc. It can solve the problems of high treatment cost, unsatisfactory treatment effect and large loss of chemical precipitation method and advanced oxidation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

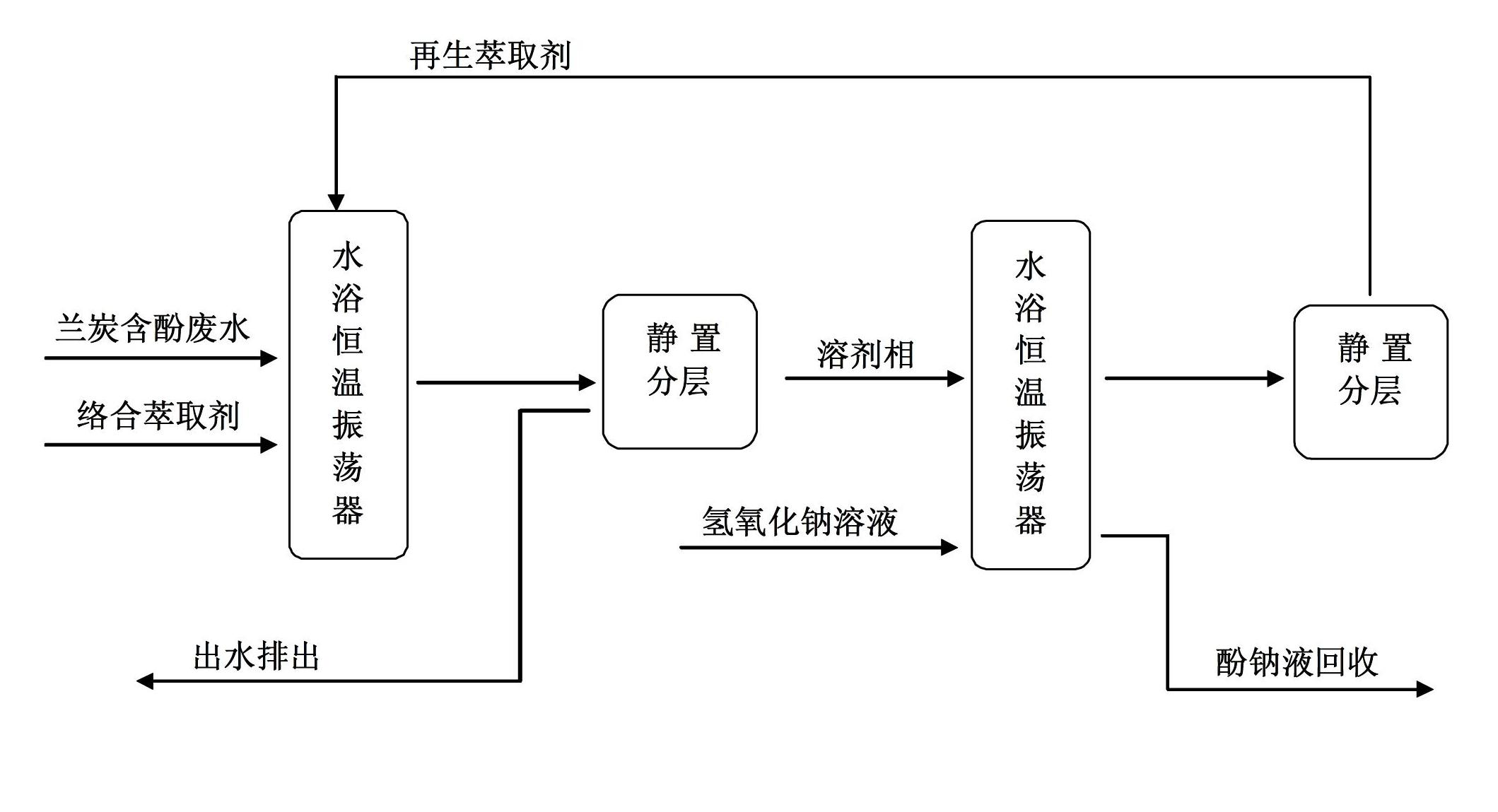

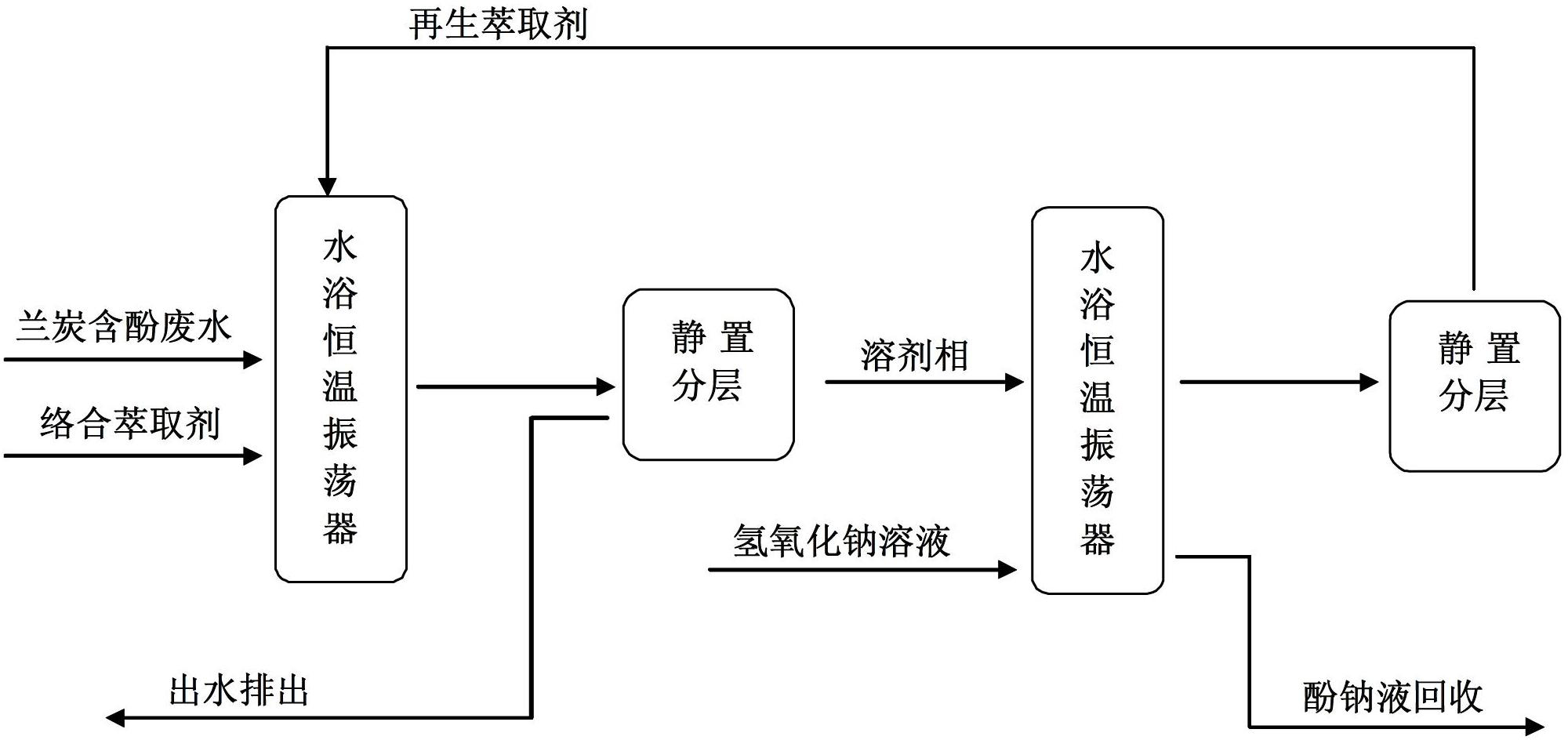

[0014] As shown in the accompanying drawing, a method for complex extraction dephenolization of blue charcoal phenol-containing wastewater, the steps are as follows:

[0015] 1) Prepare the extractant, which is composed of complexing agent + diluent, wherein tributyl phosphate is the complexing agent, toluene is the diluent, and the volume ratio of the extractant is that the complexing agent accounts for 20%, and the rest is the diluent. Mix complexing agent and diluent evenly at room temperature for later use.

[0016] 2) Adjust the pH of the semi-charcoal-containing phenolic wastewater to 8, mix the extractant and semi-charcoal-containing phenolic wastewater in a volume ratio of 1:1, and place it in a constant temperature water bath to shake for 50 minutes at a temperature of 25°C.

[0017] 3) Put the above mixed solution at room temperature for phase separation to obtain a solvent phase and a raffinate aqueous phase.

Embodiment 2

[0022] 1) Prepare the extractant, which is composed of complexing agent + diluent, wherein tributyl phosphate is the complexing agent, toluene is the diluent, and the volume ratio of the extractant is that the complexing agent accounts for 20%, and the rest is the diluent. Mix complexing agent and diluent evenly at room temperature for later use.

[0023] 2) Adjust the pH of the semi-charcoal phenol-containing wastewater to 8, mix the extraction agent and the semi-charcoal-containing phenol-containing wastewater evenly at a volume ratio of 1:10, and place them in a constant temperature water bath and shake for 50 minutes at a temperature of 25°C.

[0024] 3) Put the above mixed solution at room temperature for phase separation to obtain a solvent phase and a raffinate aqueous phase.

[0025] 4) Using 10% sodium hydroxide solution as a stripping agent to strip and regenerate the solvent phase rich in phenols. In the stripping operation, the operating volume ratio range is lye / ...

Embodiment 3

[0029] 1) Prepare the extractant, which is composed of complexing agent + diluent, wherein tributyl phosphate is the complexing agent, toluene is the diluent, and the volume ratio of the extractant is that the complexing agent accounts for 20%, and the rest is the diluent. Mix complexing agent and diluent evenly at room temperature for later use.

[0030] 2) Adjust the pH of the semi-charcoal-containing phenolic wastewater to 8, mix the extractant and semi-charcoal-containing phenolic wastewater at a volume ratio of 1:20, and place it in a constant temperature water bath for 50 minutes at a temperature of 25°C.

[0031] 3) Put the above mixed solution at room temperature for phase separation to obtain a solvent phase and a raffinate aqueous phase.

[0032] 4) Using 10% sodium hydroxide solution as a stripping agent to strip and regenerate the solvent phase rich in phenols. In the stripping operation, the operating volume ratio range is lye / solvent phase of 1:1, and then the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com