Preparation method and application of sediment modified material for controlling endogenous phosphorus load in sediments

A technology of load control and modified materials, applied in the fields of sludge treatment by temperature control, chemical instruments and methods, silicon compounds, etc., can solve the problems of high ecological risk and high risk of phosphorus release, and achieve improved adsorption capacity and strong adsorption. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

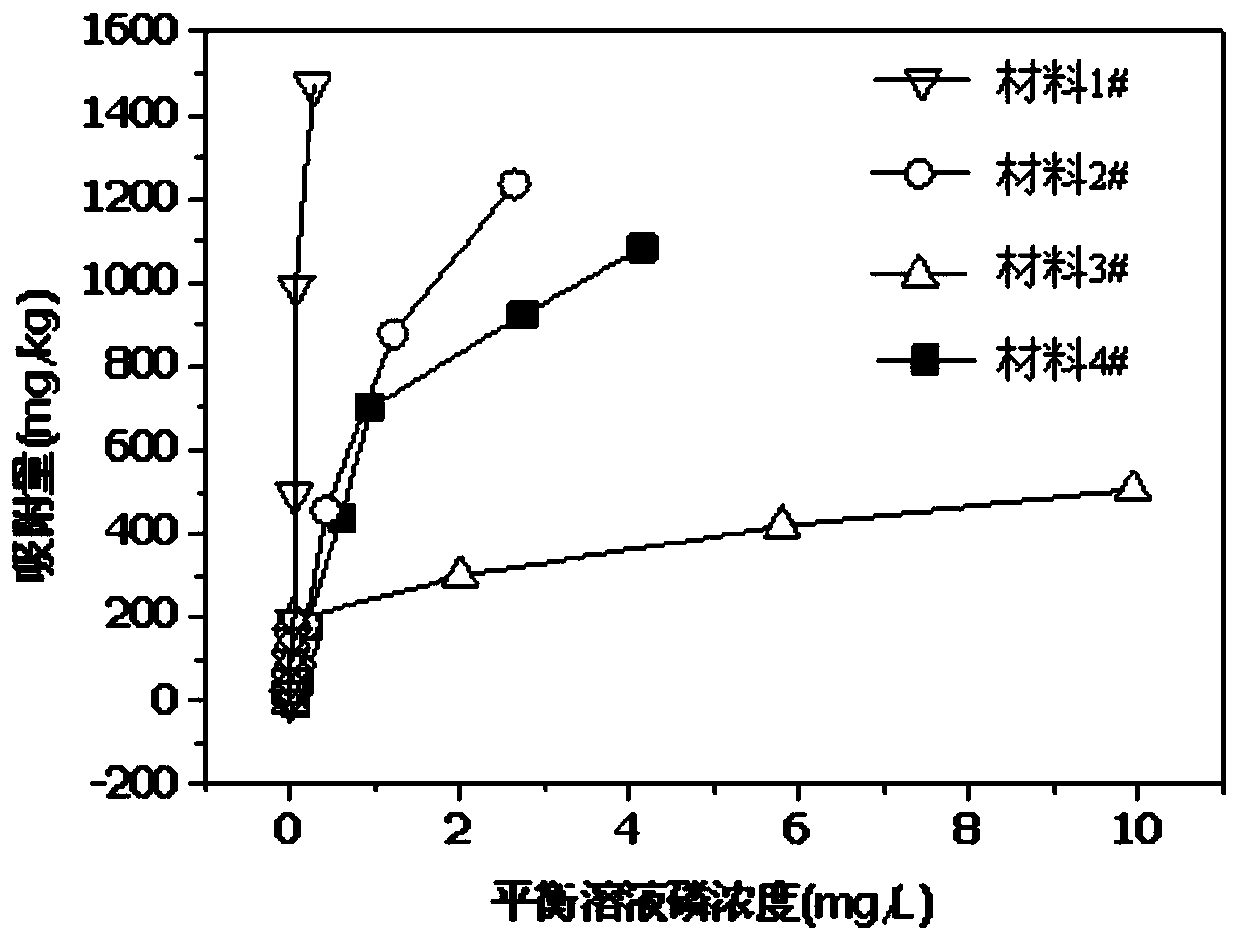

[0041] The endogenous phosphorus load control sediment modification material described in this example is prepared by the following method:

[0042] (1) Collect lake bottom mud as raw material, freeze-dry, grind and sieve to obtain sediment powder with particle size not less than 100 mesh, and set aside;

[0043] (2) Get zeolite, grind and sieve to obtain zeolite powder with particle size not less than 100 mesh, and set aside;

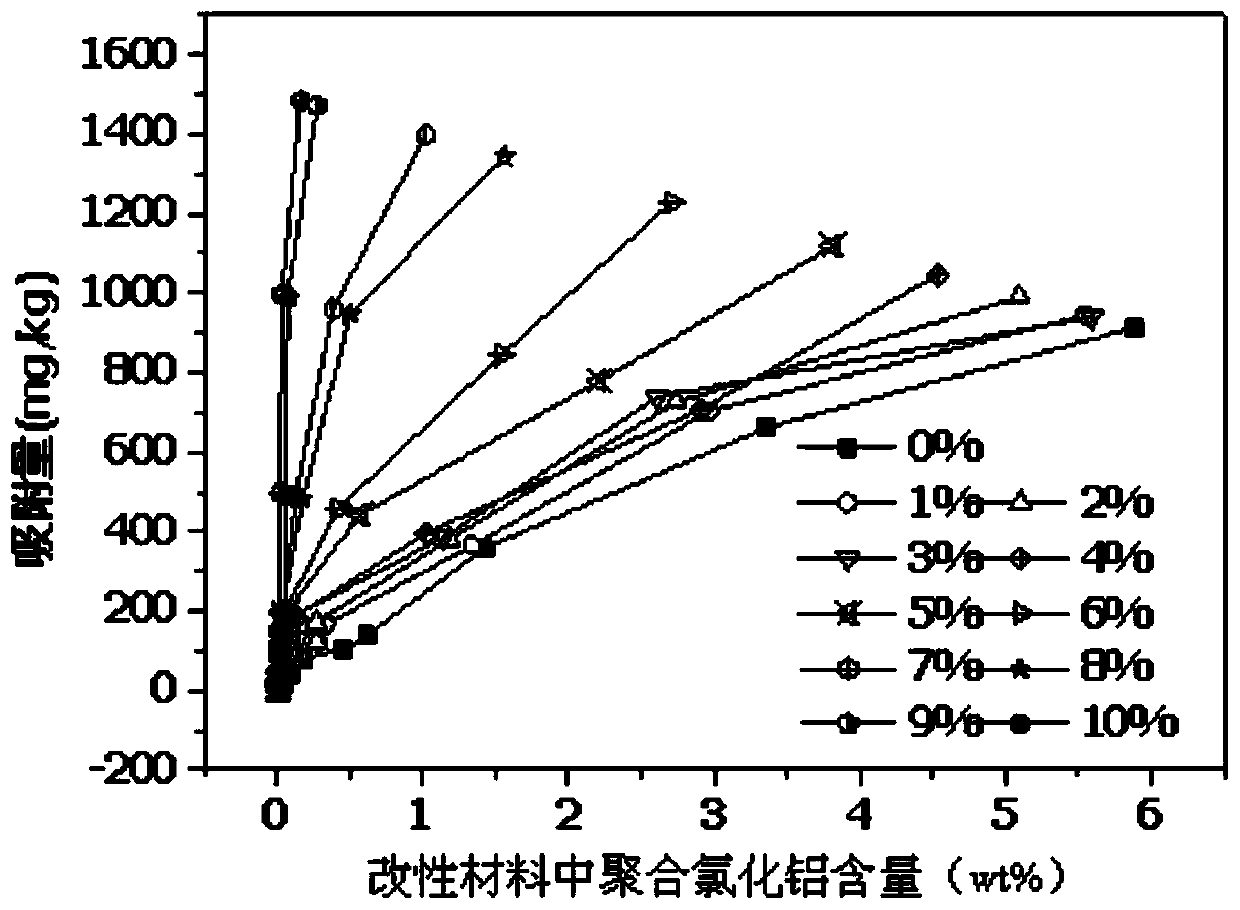

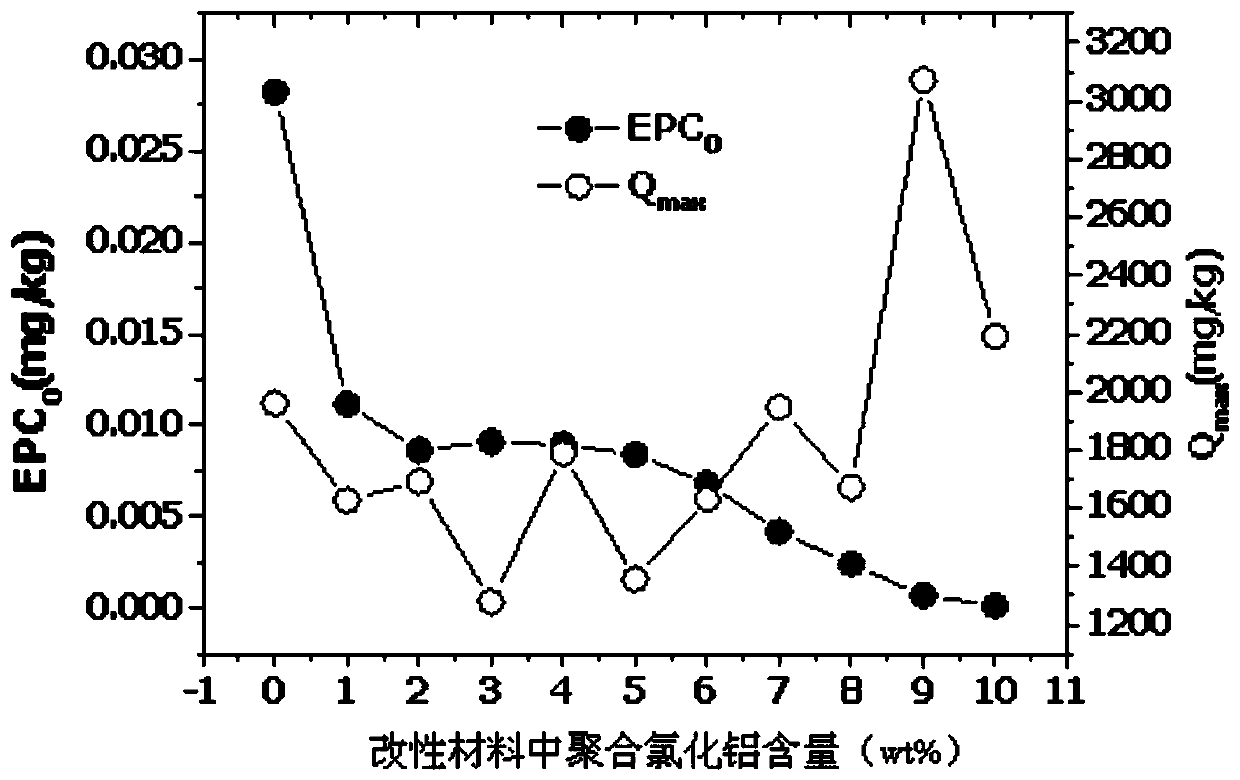

[0044] (3) Mix the sediment powder with the zeolite powder and polyaluminum chloride uniformly to form a mixed powder, the quality of the zeolite powder is 30% of the total mass of the mixed powder, and the polymer The quality of aluminum chloride is 8% of described mixed powder gross mass, standby;

[0045] (4) The mixed powder is soaked with water, the amount of water added accounts for 10wt% of the mixed powder mass, and then extruded into granules, and the molding material is roasted at 400 ° C for 3 hours to obtain a particle size of 3- 5mm of s...

Embodiment 2

[0047] The endogenous phosphorus load control sediment modification material described in this example is prepared by the following method:

[0048] (1) Collect lake bottom mud as raw material, freeze-dry, grind and sieve to obtain sediment powder with a particle size of 100 to 200 mesh, and set aside;

[0049] (2) Get the zeolite, grind and sieve to obtain a zeolite powder with a particle size of 100 to 200 meshes, and set aside;

[0050] (3) Mix the sediment powder with the zeolite powder and polyaluminum chloride uniformly to form a mixed powder, the quality of the zeolite powder is 50% of the total mass of the mixed powder, and the polymer The quality of aluminum chloride is 1% of the total mass of the mixed powder, for subsequent use;

[0051] (4) The mixed powder is soaked with water, the amount of water added accounts for 10wt% of the mixed powder mass, and then extruded into granules, and the molding material is roasted at 700 ° C for 2 hours to obtain a particle size...

Embodiment 3

[0053] The endogenous phosphorus load control sediment modification material described in this example is prepared by the following method:

[0054] (1) Collect lake bottom mud as raw material, freeze-dry, grind and sieve to obtain sediment powder with a particle size of 150-200 mesh, and set aside;

[0055] (2) Get the zeolite, grind and sieve to obtain a zeolite powder with a particle size of 150 to 200 meshes, and set aside;

[0056] (3) Mix the sediment powder with the zeolite powder and polyaluminum chloride uniformly to form a mixed powder, the quality of the zeolite powder is 40% of the total mass of the mixed powder, and the polymer The quality of aluminum chloride is 9% of described mixed powder gross mass, standby;

[0057] (4) The mixed powder is soaked with water, the amount of water added accounts for 10wt% of the mixed powder mass, and then extruded into granules, and the molding material is calcined at 600°C for 2h to obtain a particle size of 4- 5mm sediment ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com