Biomass polygeneration method and system based on triple medium and low temperature fluidized bed

A biomass and fluidized bed technology, applied in gasification process, manufacture of combustible gas, petroleum industry, etc., can solve the problems of poor stability of internal combustion generator, difficult separation of tar, poor stability, etc., to reduce adverse effects and economic benefits. Optimum, good microporous structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

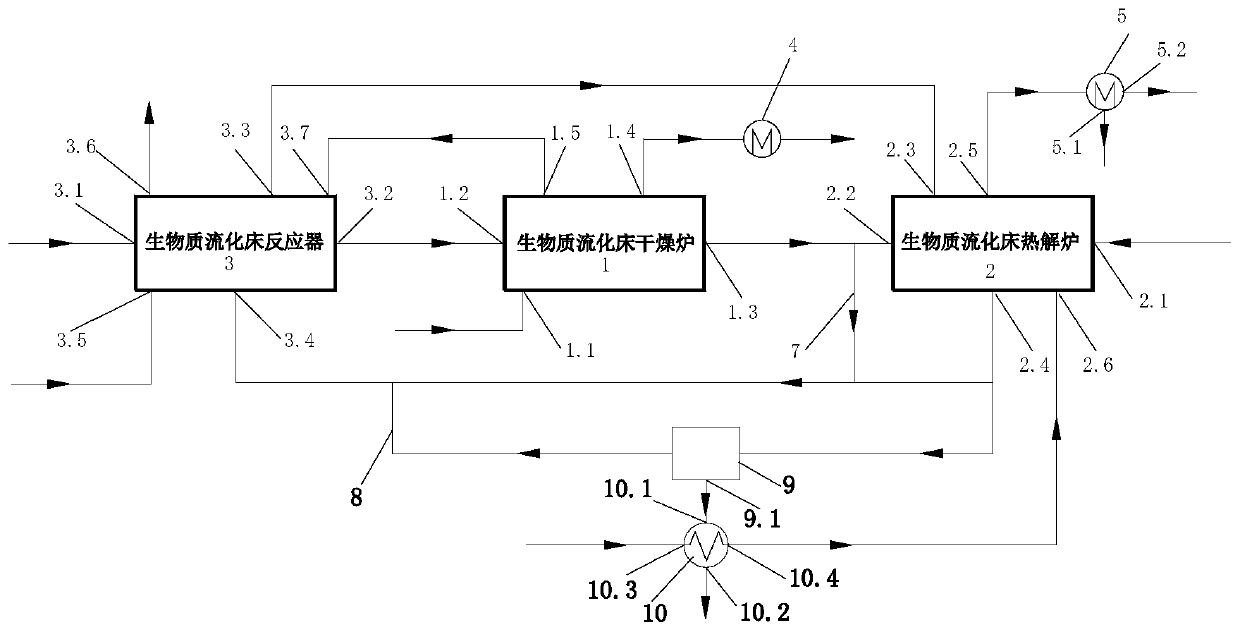

[0045] Such as figure 1 Shown is a biomass polygeneration system based on a triple medium-low temperature fluidized bed according to the first embodiment of the present invention, including a biomass fluidized bed drying furnace 1, a biomass fluidized bed pyrolysis furnace 2, and a biomass flow The fluidized bed reactor 3, wherein the biomass fluidized bed reactor 3 adopts a biomass fluidized bed gasifier, preferably a bubbling bed gasifier, to increase the gasification conversion rate of fixed carbon substances. Biomass fluidized bed pyrolysis furnace 2 can adopt circulating fluidized bed or bubbling bed pyrolysis furnace to meet the needs of pyrolysis products and meet the maximum production of pyrolysis products; biomass fluidized bed drying furnace 1 adopts bubbling bed drying oven.

[0046] The biomass fluidized bed drying furnace 1 is provided with a first biomass inlet 1.1 for entering biomass with high moisture content, and the biomass fluidized bed pyrolysis furnace ...

Embodiment 2

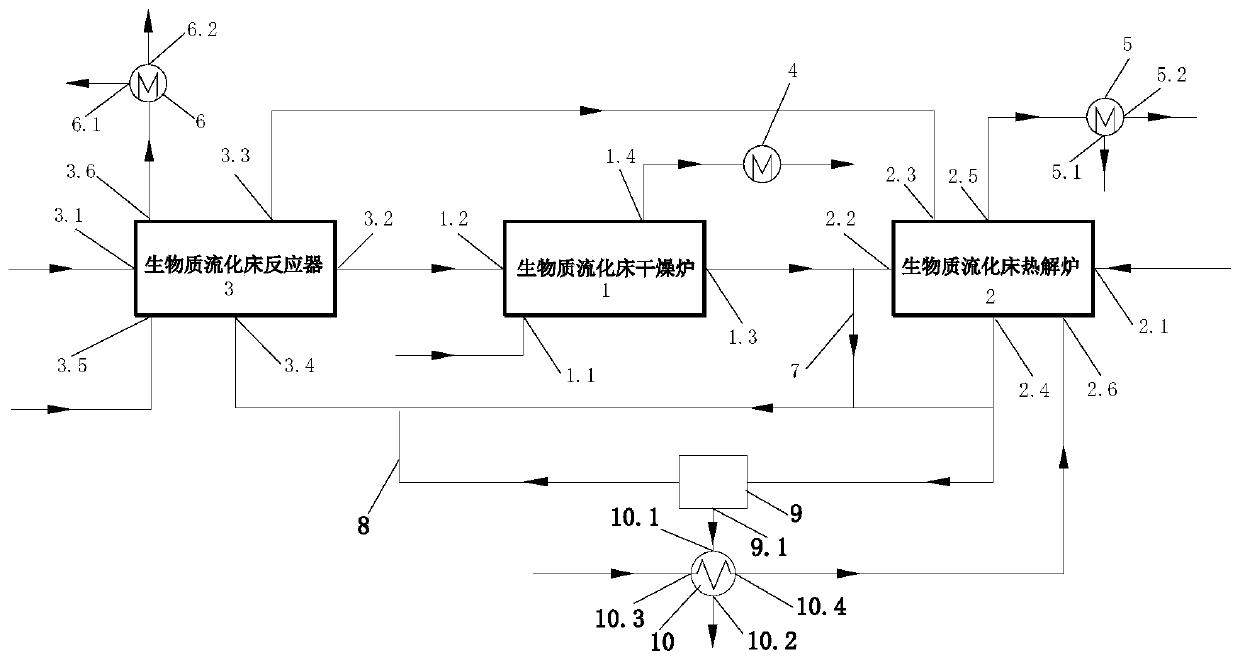

[0059] Such as figure 2 Shown is a biomass polygeneration system based on a triple medium and low temperature fluidized bed according to the second embodiment of the present invention, including a biomass fluidized bed drying furnace 1, a biomass fluidized bed pyrolysis furnace including a biomass fluidized bed Drying furnace 1, biomass fluidized bed pyrolysis furnace 2, and biomass fluidized bed reactor 3, wherein, biomass fluidized bed reactor 3 adopts biomass fluidized bed boiler, preferably a circulating fluidized bed combustion furnace , try to make the fixed carbon substances burn out. The biomass fluidized bed pyrolysis furnace 2 can adopt a circulating fluidized bed or a bubbling bed pyrolysis furnace to meet the needs of pyrolysis products and meet the maximum production of pyrolysis products. The biomass fluidized bed drying furnace 1 adopts a bubbling bed drying furnace.

[0060] The biomass fluidized bed drying furnace 1 is provided with a first biomass inlet 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com