Double-tray chemical-looping hydrogen production device and method for treating sludge biomass solid waste

A hydrogen production device and chemical chain technology, applied in chemical instruments and methods, inorganic chemistry, hydrogen, etc., can solve the problems of reducing the use efficiency of oxygen carriers, achieve the effect of reducing formation and emission, and improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

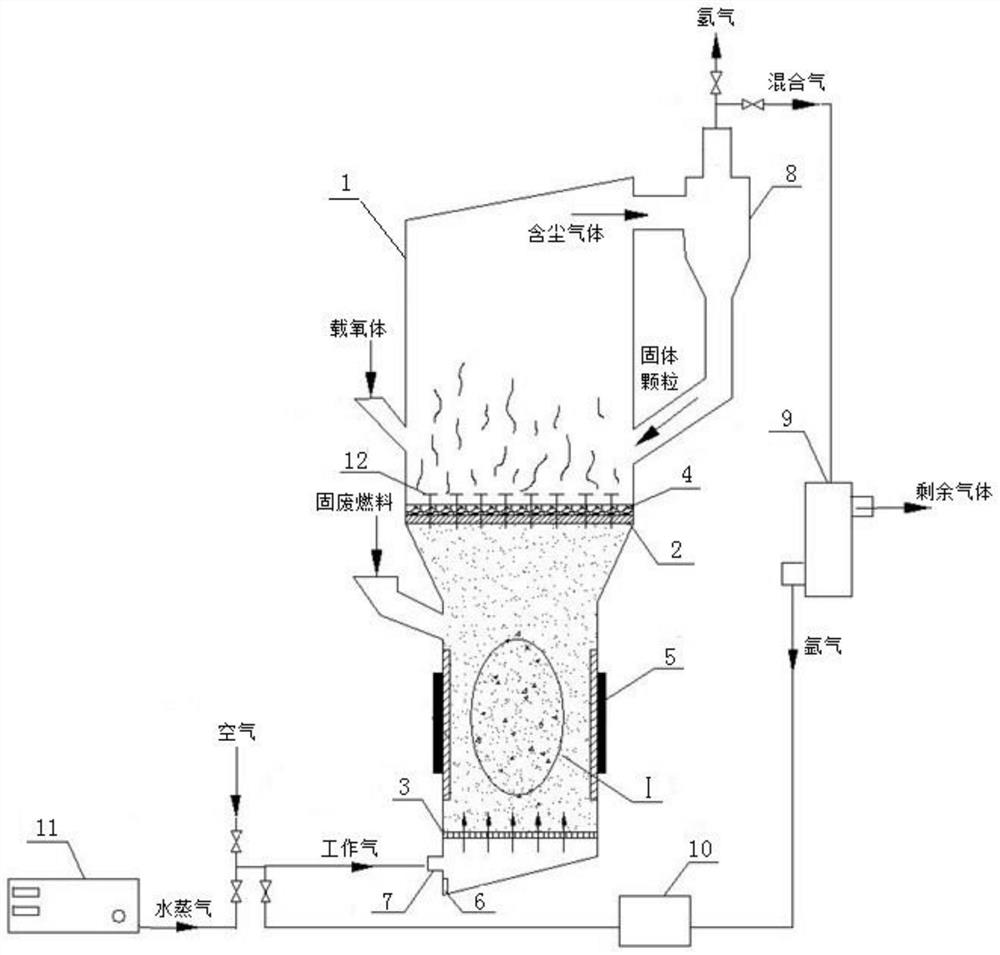

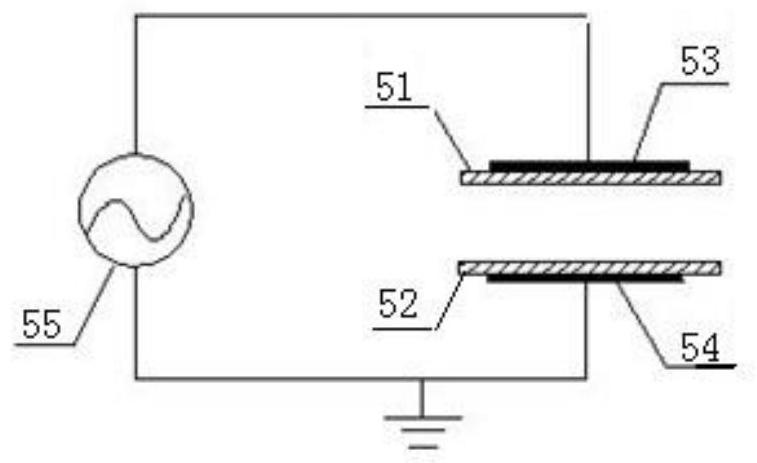

[0027] Such as figure 1 As shown, a double-tray chemical chain hydrogen production device for treating sludge biomass solid waste according to the present invention includes a tower body 1, an upper tray 2, a lower tray 3, a low-temperature plasma generator, and a cyclone separator 8 and a gas separator 9; the middle part of the tower body 1 is provided with an upper tray 2, and the lower part is provided with a lower tray 3; the upper space of the tower body 1 separated by the upper tray 2 is a chemical chain hydrogen production reaction zone, and the lower tray The inner space of the tower body 1 between 3 and the upper tray 2 is a low-temperature plasma reaction zone, and the oxygen carrier 4 is laid flat on the upper tray 2; the upper part of the chemical chain hydrogen production reaction zone is provided with a dusty gas outlet, and the lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com