Low-nitrogen burning device applicable to fuel gas with low heat value

A low-nitrogen combustion, low calorific value technology, applied in gas fuel burners, burners, combustion methods, etc., can solve the problems of destroying the stability of gas combustion and fire extinguishing risks, and achieve stable combustion and control the effect of NOx generation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

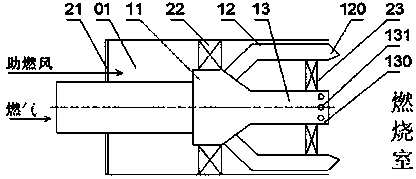

[0013] As shown in the accompanying drawings, a low-nitrogen burner 01 suitable for low calorific value gas is composed of a gas distribution tank 11, 6~12 main combustion spray guns 12, a stable combustion spray gun 13, a combustion air equalizing plate 21, a rotary Flow generator 22, combustion stabilizing plate 23 and main combustion nozzle 120 of main combustion spray gun 12 outlets, combustion stabilization nozzle 130 of combustion stabilization spray gun outlet and several combustion holes 131 distributed thereon.

[0014] When the combustion device is running, the gas first enters the distribution tank 11, and then partially enters the entrance of the combustion-stabilizing spray gun 13 located at the central outlet of the distribution tank, and enters the combustion chamber of the boiler or kiln through several combustion holes 131 on the combustion-stabilizing nozzle 130 , so as to ensure that there is always a certain amount of gas stably burning near the outlet axis ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com