Environment-friendly energy-saving pulverized coal and coal gas burner

A burner and energy-saving technology, which is applied in the field of environmental protection and energy-saving pulverized coal gas burners, can solve the problems of difficult combustion control and easy generation of pollutants, achieve fuel saving, significant energy saving effects, and suppress the production of NOx.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

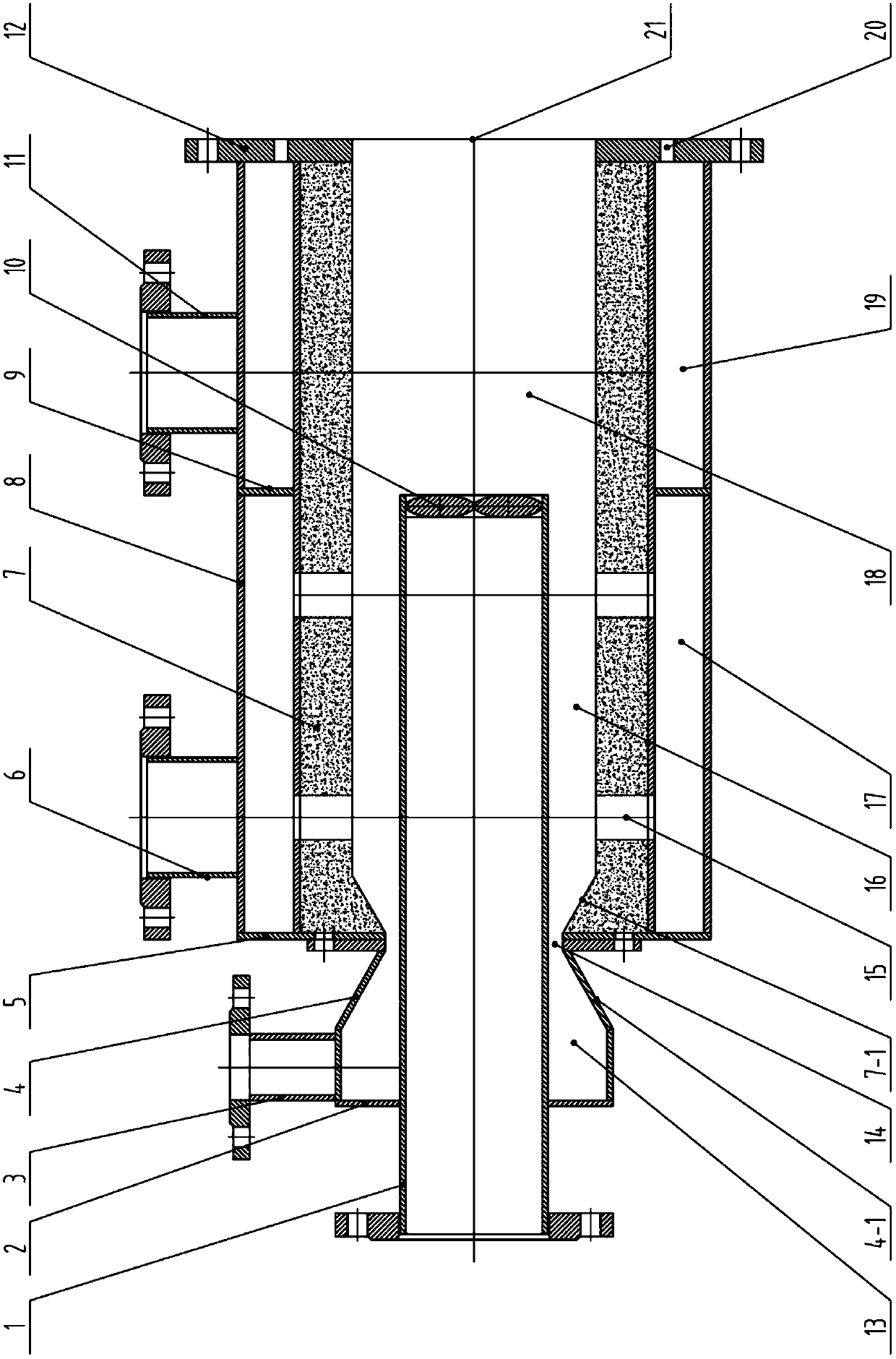

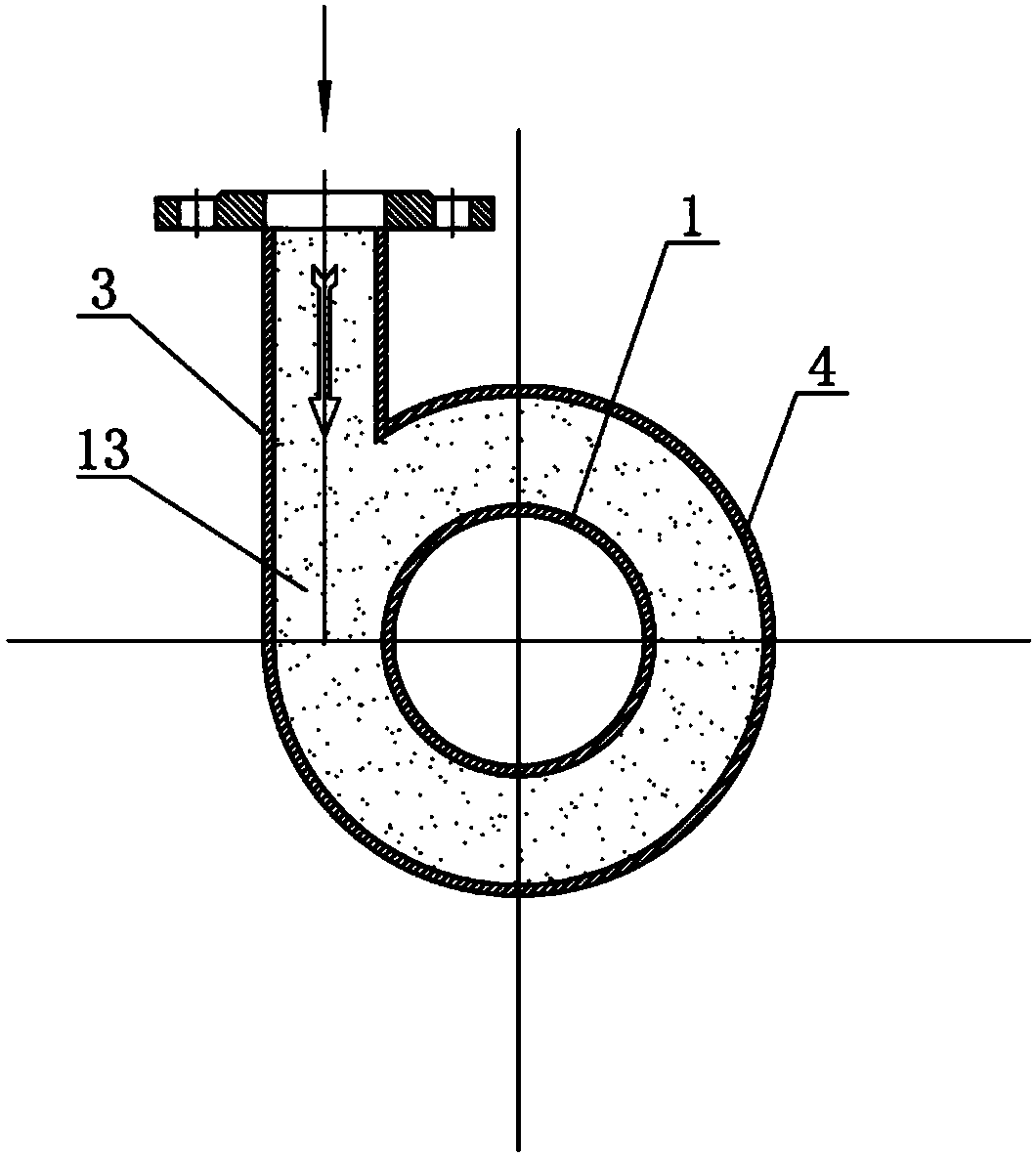

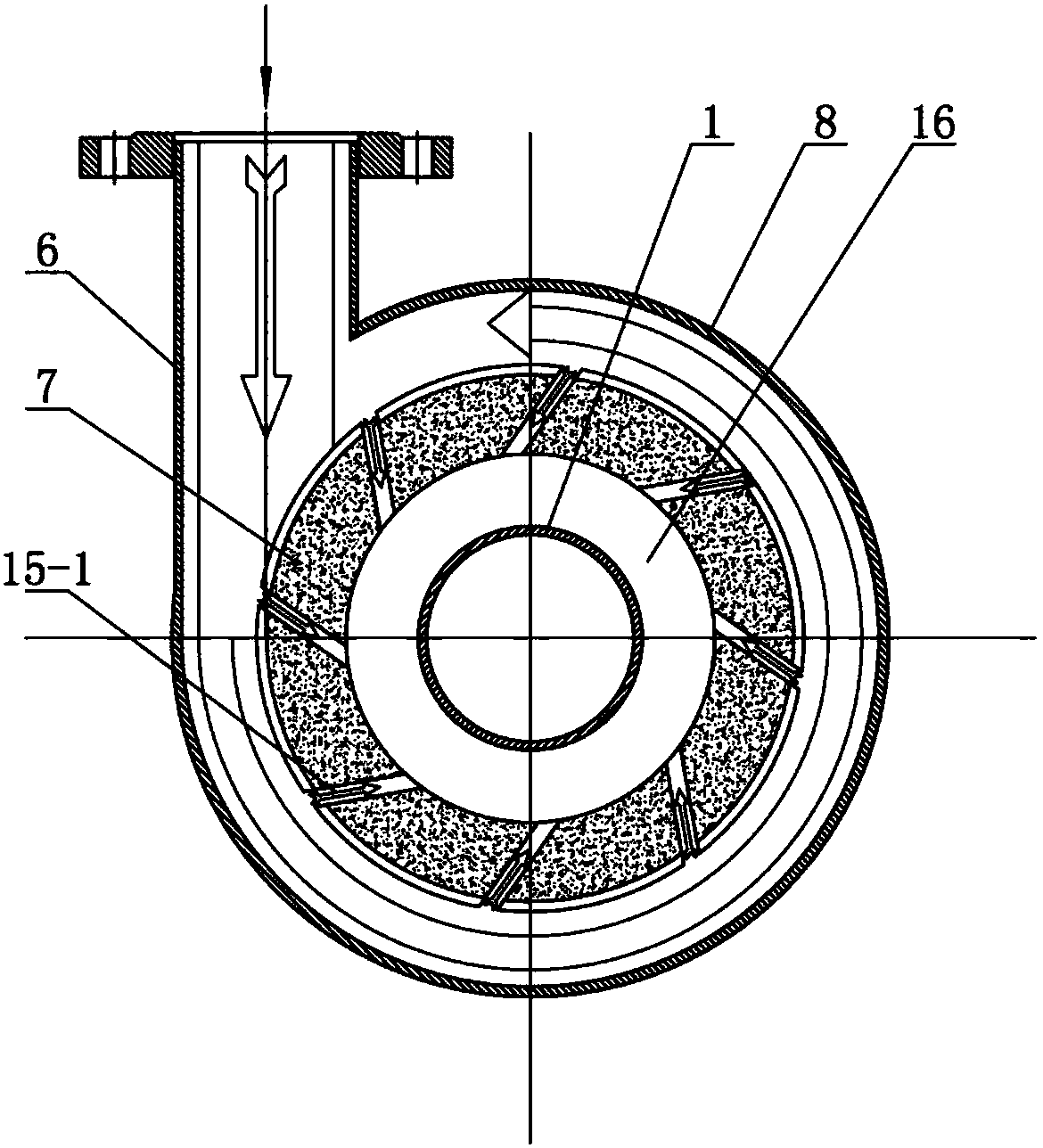

[0026] The present invention will be further explained below in conjunction with the accompanying drawings.

[0027] Such as figure 1 As shown, an environmentally friendly and energy-saving pulverized coal gas burner according to Embodiment 1 of the present invention includes an inner sleeve 7 and a casing 8 that is ringed outside the inner sleeve 7, and one end of the inner sleeve 7 and the outer casing 8 is fixed on the combustion chamber. On the device mounting seat 12, the other end of the inner sleeve 7 and the outer shell 8 is provided with an end face sealing plate a5, a pre-combustion chamber 18 is formed in the inner sleeve, and a middle The partition 9 divides the annular cavity into a secondary air chamber 17 and a tertiary air chamber 19 through the middle partition 9 .

[0028] The center of the burner mounting seat 12 is provided with a burner outlet 21 , the burner outlet 21 matches the inner diameter of the inner sleeve 7 , and the pre-combustion chamber 18 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com