Preparation method and application of a cationic dye composite adsorption material

A technology of composite adsorption material and cationic dye, applied in the field of preparation of cationic dye composite adsorption material, can solve the problems of limited practical application value, high regeneration cost, high price, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

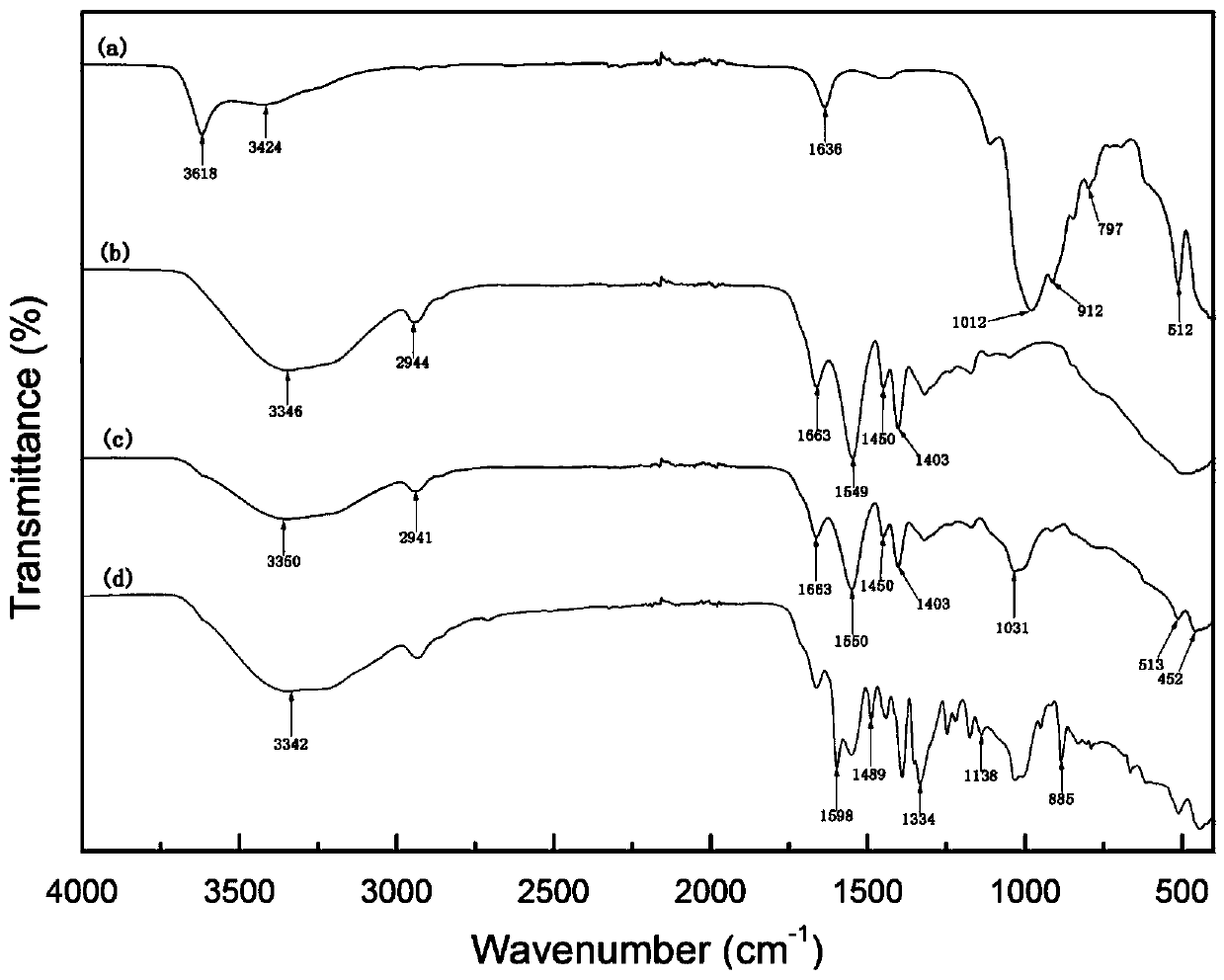

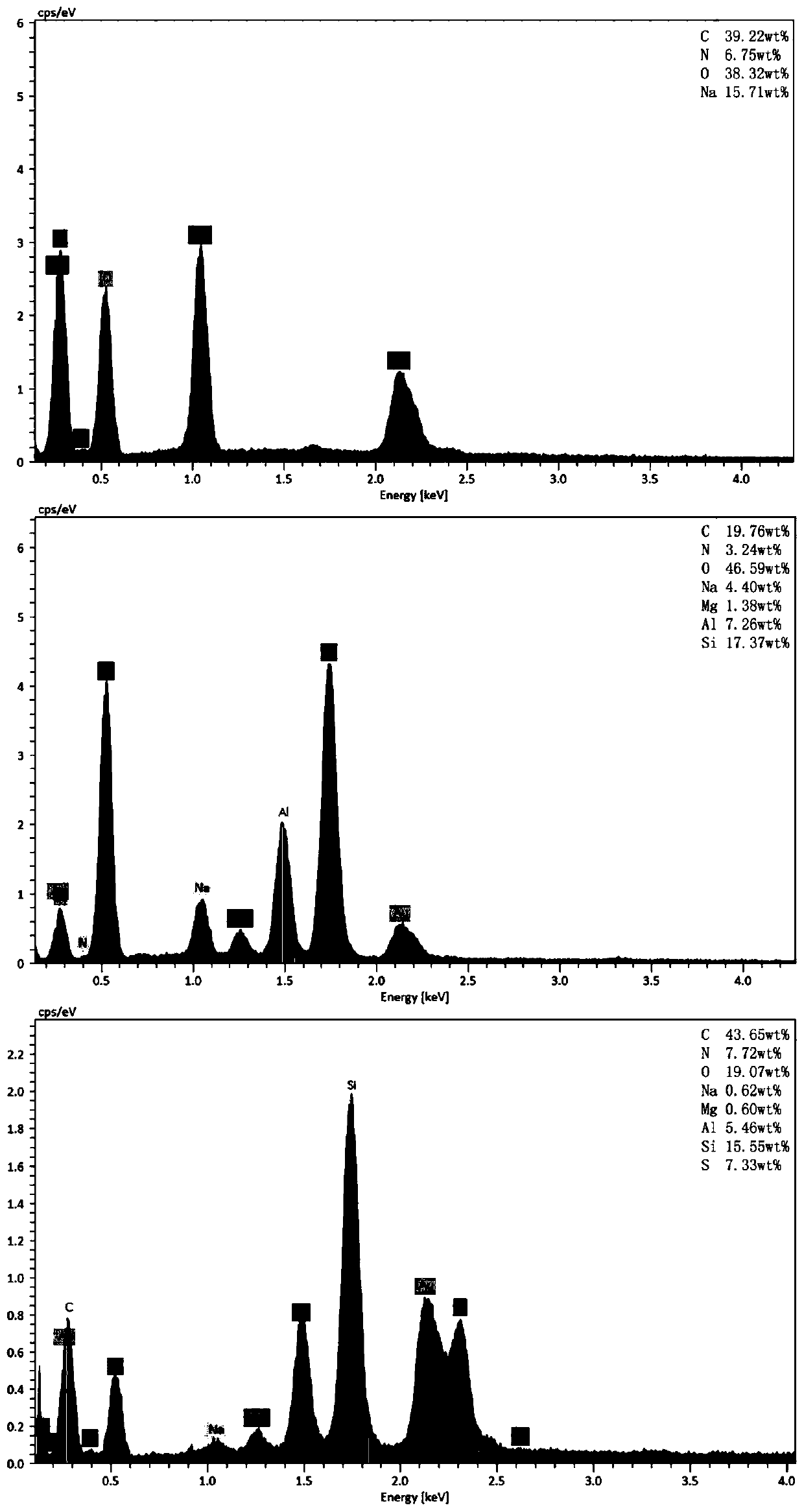

[0022] The invention provides a preparation method of a cationic dye composite adsorption material, which is mainly used for synthesizing poly(acrylic acid-acrylamide) / montmorillonite composite hydrogel, and is applied to remove cationic dyes in sewage. The steps of the preparation method are:

[0023] Use sodium hydroxide solution to partially neutralize acrylic acid, then dissolve N,N'-methylenebisacrylamide in the acrylic acid solution, and then add acrylamide, montmorillonite, ammonium persulfate (APS) and Sodium bisulfite (SHS), diluted with water to obtain a mixture, and then put the mixture in a water bath at 30-70°C for 60-120 minutes to obtain a hydrogel, freeze-dry the hydrogel, and dry to obtain the composite adsorption of the cationic dye Material.

[0024] Among them, the degree of neutralization of the acrylic acid monomer is in the range of 0-100, and the best degree of neutralization is 80%.

[0025] During the preparation process, the degree of polymerizatio...

Embodiment 1

[0028] A kind of preparation method of cationic dye composite adsorption material

[0029] First, 8 g of acrylic acid monomers were partially neutralized to 80% with 10 mol / L sodium hydroxide solution, and then 0.08 g of N,N'-methylenebisacrylamide was dissolved therein. Weigh 2 grams of acrylamide monomer, add an appropriate amount of montmorillonite, add 0.06 grams of APS and 0.06 grams of SHS into the mixture, and finally dilute the solution to 50ml with water, stir the mixture evenly and react it in a water bath at 50°C 2 hours. After the polymerization reaction is completed, the hydrogel is chopped and dried in a freeze dryer for 24 hours, and then stored in an oven at 50°C.

Embodiment 2

[0031] A kind of preparation method of cationic dye composite adsorption material

[0032] First, 8 g of acrylic acid monomer was partially neutralized to 80% with 10 mol / L sodium hydroxide solution, and then 0.06 g of N,N'-methylenebisacrylamide was dissolved therein. Weigh 2g of acrylamide monomer, 0.2g of montmorillonite, 0.06g of APS and 0.06g of SHS into the mixture, and finally dilute the solution to 50ml with water. After stirring evenly, let the mixture react in a water bath at 70°C for 1 hour . After the polymerization reaction is completed, the hydrogel is chopped and dried in a freeze dryer for 24 hours, and then stored in an oven at 50°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com