Preparing method for phase transited stored energy microcapsule covered with an organic polymer material

An organic polymer and phase change energy storage technology, applied in the field of phase change energy storage microcapsules, can solve the problems of insufficient stability of phase change energy storage material emulsion, poor affinity of organic matrix, wide particle size distribution, etc., to achieve Environmentally friendly affinity, stable physical and chemical properties, uniform distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

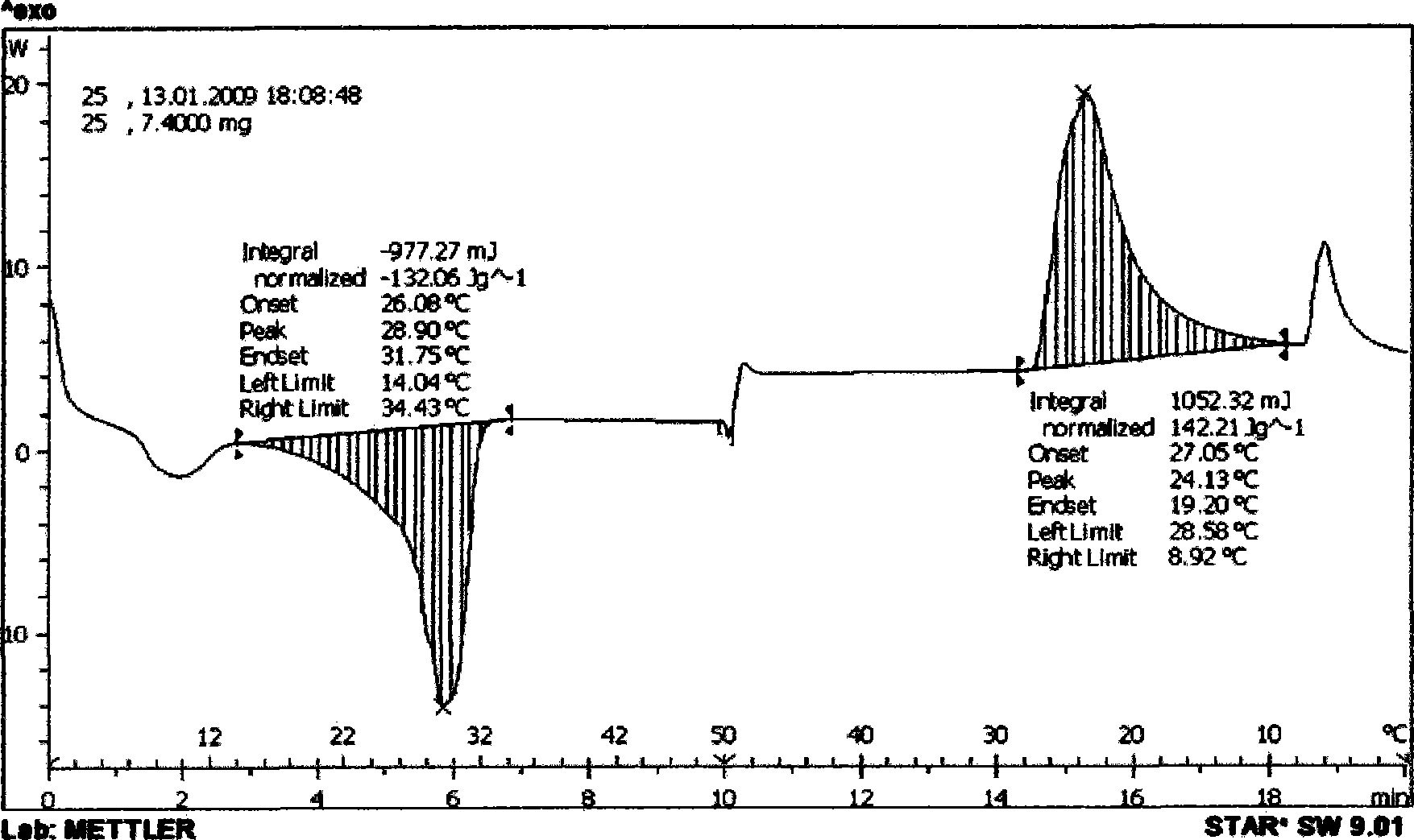

Embodiment 1

[0029] The organic macromolecular monomer A, organic macromolecular monomer B and organic macromolecular monomer C in Example 1 are selected from acrylic acid, acrylamide and epichlorohydrin respectively, and the organic phase change material is 25°C with a phase transition temperature of 30°C. #Phase change paraffin, the preparation process is as follows:

[0030] Take 10g of 25# phase-change paraffin wax with a phase transition temperature of 30°C and 0.5g of epichlorohydrin, add 2g of a mixed emulsifier composed of Span80 and Tween80 at a mass ratio of 0.4:0.6, heat in a water bath at 45°C, and stir at 500r / min Mix evenly to make the oil phase;

[0031] Add 1g of acrylic acid and 1g of acrylamide into 50g or 40g of distilled water at room temperature, stir at 500r / min for 10min and mix evenly to form an aqueous phase.

[0032]Slowly add the above oil phase dropwise to the water phase under stirring under heating in a water bath, heat and emulsify at 35°C for 45 minutes to ...

Embodiment 2

[0037] The organic macromolecular monomer A and the organic macromolecular monomer B in Example 2 are selected from acrylic acid and methyl propyl butyl ester respectively, and the organic phase change material is octadecane whose phase transition temperature is 29° C. The preparation process is as follows:

[0038] Take 10g of octadecane with a phase transition temperature of 29°C, add 0.8g of Span80 and Tween80 as an emulsifier compounded at a mass ratio of 0.5:0.5, heat in a water bath at 45°C and stir at 500r / min and mix evenly to form an oil phase;

[0039] Weigh 1.5 g of acrylic acid and 1 g of methyl propyl butyl ester at room temperature and stir and mix evenly, add 50 g of distilled water, and stir at 500 r / min for 10 min to form an aqueous phase.

[0040] Slowly add the oil phase dropwise to the stirring water phase under heating in a water bath, heat and emulsify at 45°C for 45 minutes to obtain a stable emulsion. Weigh 0.02 g of ammonium persulfate and add 4 g of d...

Embodiment 3

[0042] The organic polymer monomers A, B and C in Example 3 were selected from acrylic acid, methyl methacrylate and styrene respectively, and the organic phase change material was n-butyl stearate with a phase change temperature of 22°C. The preparation process was as follows :

[0043] Take 10g of n-butyl stearate with a phase transition temperature of 22°C and 0.5g of styrene, add 1.5g of a mixed emulsifier composed of Span80 and Tween80 at a mass ratio of 0.4:0.6, heat in a water bath at 35°C, and stir at 600r / min Mix evenly to make the oil phase;

[0044] Weigh 2 g of acrylic acid and 0.5 g of methyl methacrylate at room temperature, stir and mix evenly, add 60 g of distilled water and stir to form an aqueous phase.

[0045] Heat in a water bath at 40°C, slowly add the oil phase dropwise to the water phase under stirring, heat and emulsify at 40°C for 45 minutes to obtain a stable emulsion. Weigh 0.04 g of azobisisobutyronitrile and add 4 g of n-butanone to prepare an i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com