Graphical epitaxial structure laser lift-off device

An epitaxial structure and laser lift-off technology, applied in lasers, laser welding equipment, semiconductor lasers, etc., can solve the problems of high price of homoepitaxial thick film substrates and inability to obtain comprehensive applications, and achieve high lift-off yield and clever design. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

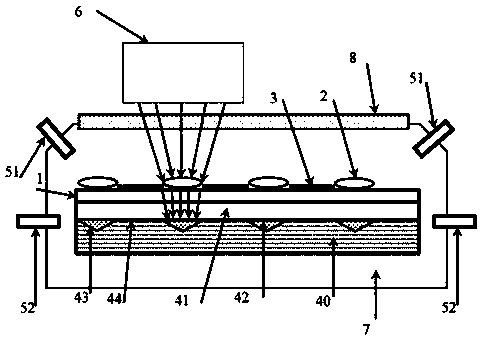

[0021] Embodiment one, the structure diagram of the present invention is as attached figure 1 shown.

[0022] Firstly, adjust the temperature control system in the air intake pipe (51), exhaust pipe (52) and the stripping chamber (7) to achieve suitable conditions for laser stripping.

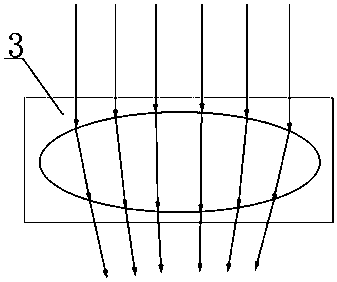

[0023] When the laser light emitted by the ultraviolet light source (6) enters the peeling chamber (7), it is shaped by the shaping structure (2), and there is a local transmittance adjustment film (3) between the shaping structure (2) and the surrounding area (transmittance adjustment structure) A), forming a non-uniform and adjustable light spot from the center to the edge, passing through the substrate (1) (sapphire substrate), reaching the interface between the sapphire substrate (41) and the epitaxial structure (40), the interface Including the oblique interface (43) between the patterned structure (42) and the epitaxial structure (40), the flat interface (44) between the sapphire substra...

Embodiment 2

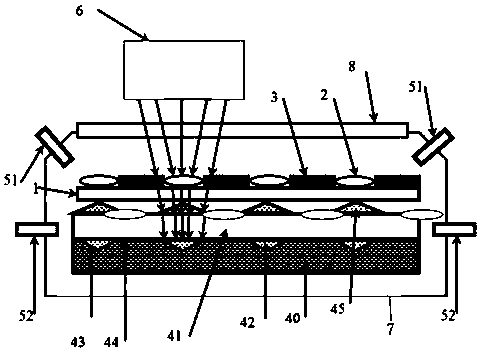

[0025] Embodiment 2, the structure diagram is as follows figure 2 shown. The difference between this embodiment and Embodiment 1 is that after the epitaxial structure (40) is grown on the front side of the sapphire substrate (41), the back side of the sapphire substrate (41) is also polished and processed to form a back patterned structure (45). The shape of the patterned structure (42) can be the same or different, and the size can be the same or different. The function of this structure is to modulate or compensate light. For example, when the light spot passes through the substrate (1) and reaches the upper surface of the sample , if the patterned structure ( 45 ) on the back is a hemispherical lens structure, it can refocus the light, thereby forming a local high energy density. In addition, the adjustment of light has also changed. In addition to the shaping structure (2), the partial transmittance adjustment film (3) adopts a hollow structure, thereby adjusting the tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com