A composite function p-type electrode of vertical structure deep ultraviolet LED and its preparation method

A composite function, vertical structure technology, applied in circuits, electrical components, nanotechnology for materials and surface science, etc. Laser lift-off yield, good adhesion and support, the effect of reducing the threshold energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

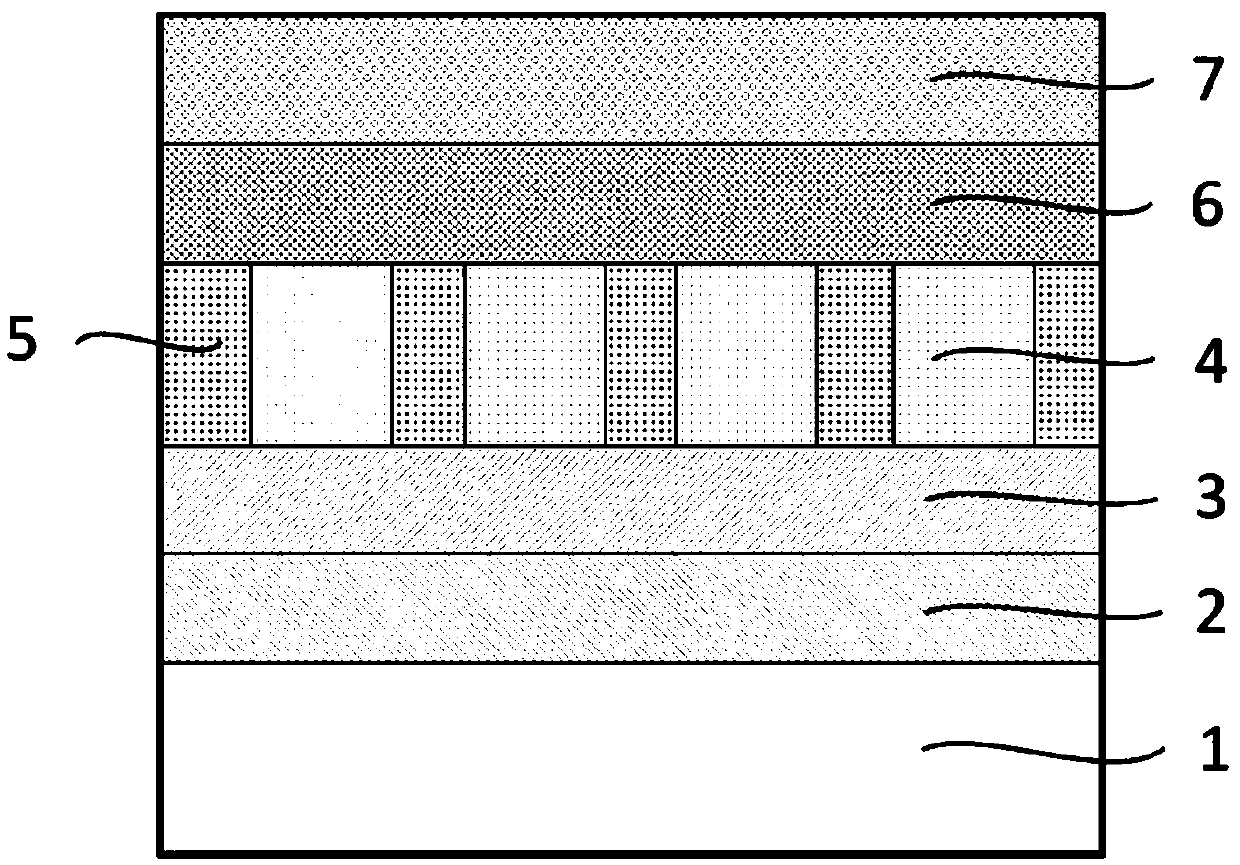

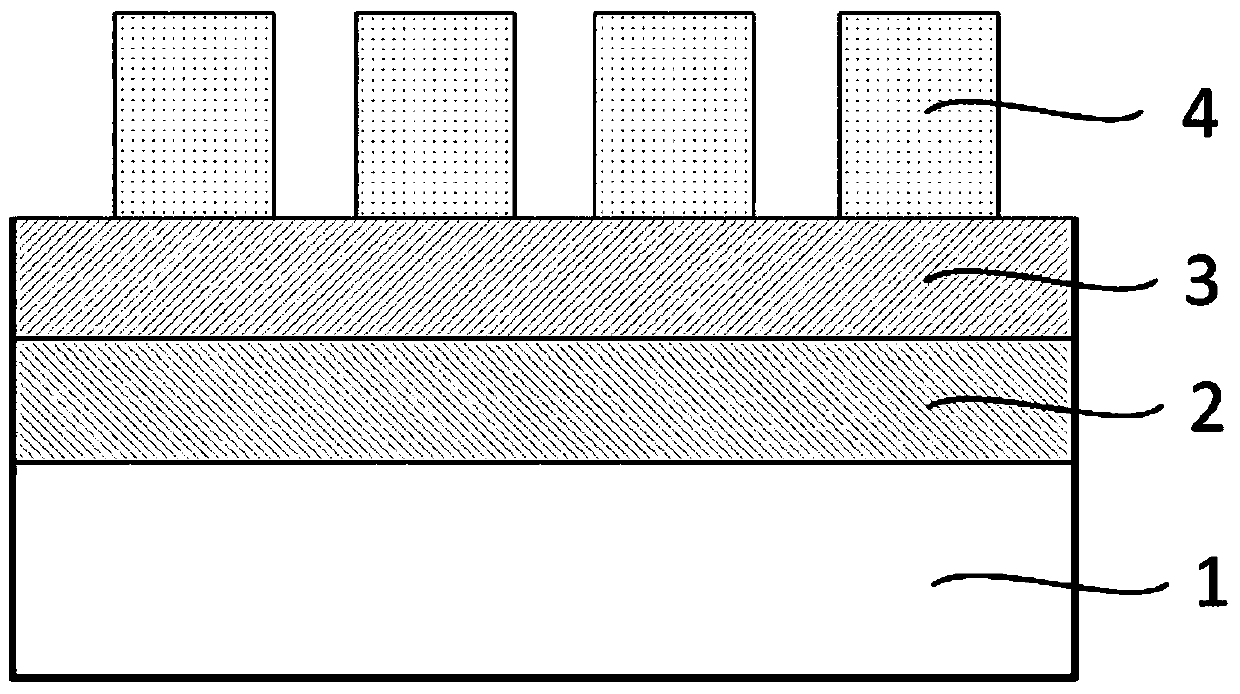

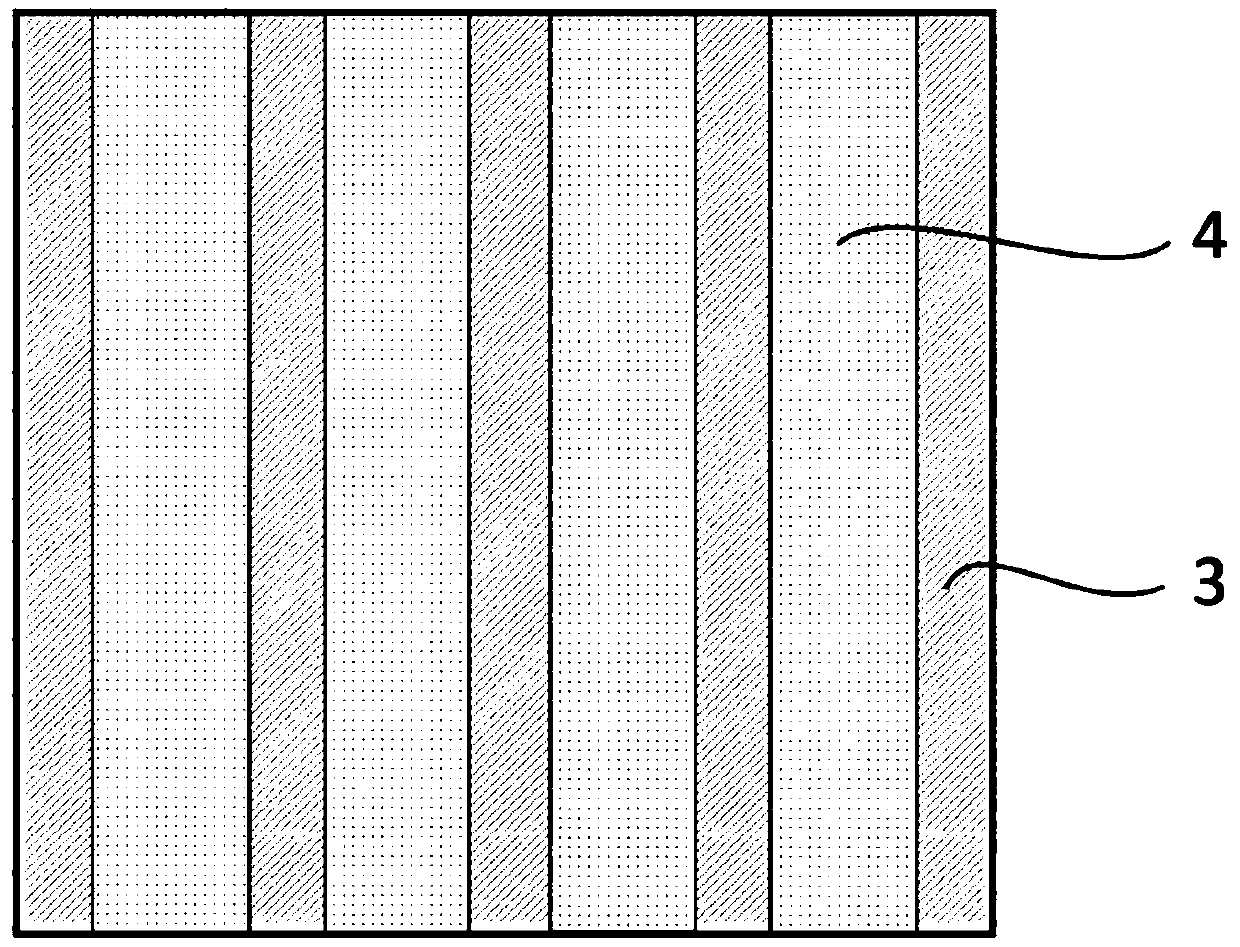

[0039] like figure 1 , Figure 2a , Figure 2b , Figure 3a , Figure 3b , Figure 4a , Figure 4b , Figure 5a , Figure 5b , Figure 6a and Figure 6b As shown, the preparation method of the composite function P-type electrode of a kind of vertical structure deep ultraviolet LED provided by the present invention comprises the following steps:

[0040] The first step is to grow an AlGaN-based deep ultraviolet LED epitaxial structure on a sapphire substrate, and perform in-situ annealing after the growth is completed to realize carrier activation;

[0041] In the second step, the grown AlGaN-based deep ultraviolet LED epitaxial wafer 1 was treated with H 2 SO 4 with H 2 o 2 The mixed solution is heated, then rinsed and dried;

[0042] In the third step, the surface of the P-type layer of the AlGaN-based deep ultraviolet LED epitaxial wafer obtained in the second step after cleaning is prepared through an electron beam evaporation platform or a magnetron sputterin...

Embodiment 1

[0049] Take a piece of AlGaN-based deep ultraviolet LED epitaxial wafer, put it in a concentration of 98% H 2 SO 4 with a mass percent concentration of 30% H 2 o 2 The mixed solution with a volume ratio of 3:1 was heated to 120°C and soaked for 20 minutes, then rinsed with deionized water for 10 minutes, and finally dried with nitrogen to complete the sample cleaning.

[0050] The cleaned epitaxial wafer was placed on the sample holder of the electron beam evaporation table, and a 5nm Ni adhesive layer and a 30nm Al mirror layer were sequentially evaporated.

[0051] The sample was taken out, and a cylindrical pattern mask with a diameter of 1 μm and a duty ratio of 1:1 was prepared by the nanosphere mask method.

[0052] Put the epitaxial wafer with the nanosphere mask into the electron beam evaporation station, and evaporate a 100nm Al three-dimensional composite functional layer.

[0053] Take out the sample, go through conventional processes such as glue removal and cl...

Embodiment 2

[0055] Take a piece of AlGaN-based deep ultraviolet LED epitaxial wafer, put it in a concentration of 98% H 2 SO 4 with a mass percent concentration of 30% H 2 o 2 The mixed solution with a volume ratio of 3:1 was heated to 120°C and soaked for 20 minutes, then rinsed with deionized water for 10 minutes, and finally dried with nitrogen to complete the sample cleaning.

[0056] The cleaned epitaxial wafer was placed on the sample holder of the electron beam evaporation table, and a 20nm Pt adhesive layer and a 10nm Ti mirror layer were evaporated sequentially.

[0057] The sample was taken out, and a quadrangular prism (cuboid) mask with a length of 400 nm, a height of 500 nm, and a duty ratio of 1:0.5 was prepared by nanoimprinting.

[0058] Put the masked sample into the magnetron sputtering station, and sputter a 500nm Al three-dimensional composite functional layer.

[0059] Take out the sample, go through conventional processes such as glue removal and cleaning, and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com