Bonding structure, flexible screen body with bonding structure and manufacturing method thereof

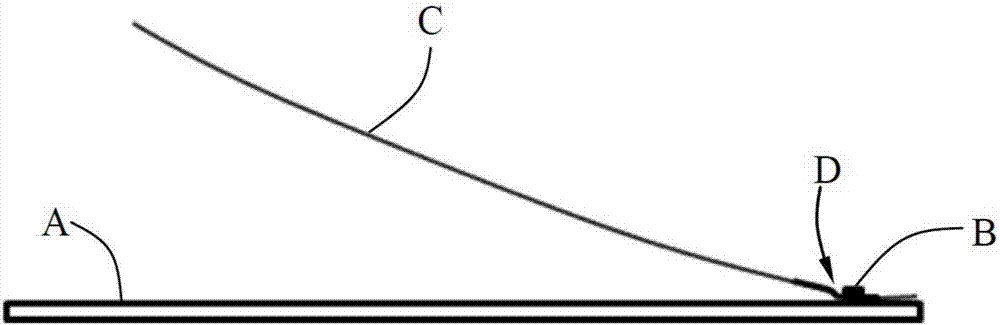

A flexible screen, flexible technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, nonlinear optics, etc., can solve the problems of reducing the yield rate of flexible screens, wire breakage, defective products, etc., to improve the peeling yield, avoid The effect of stress concentration and reducing the risk of the line being pulled off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

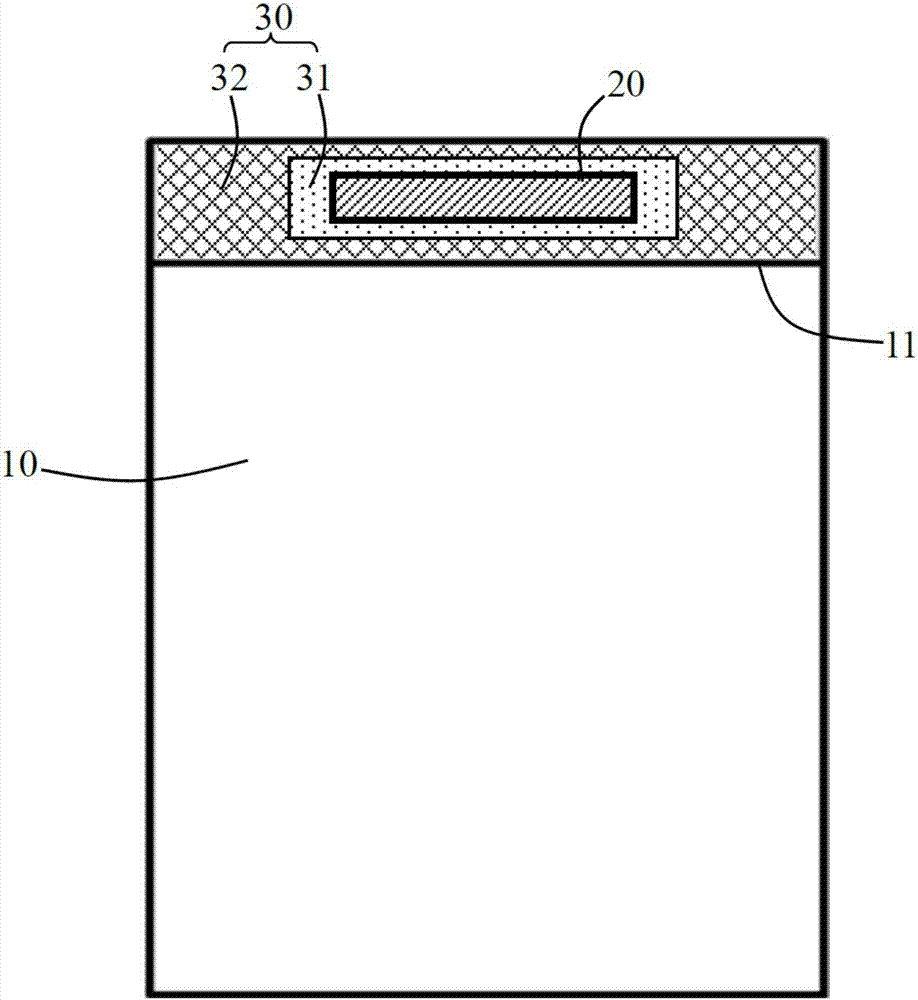

[0029] In order to solve the problem of low peeling yield of the existing flexible screen, the embodiment of the present invention provides a bonding structure for the flexible screen, refer to figure 2 As shown, the flexible screen includes a display area 10 , a bonding area 11 connected to the display area 10 and a chip 20 installed in the bonding area. The bonding area 11 is provided with a flexible protective layer 30 surrounding the chip 20, wherein the flexible protective layer 30 includes a first protective layer 31 arranged around the chip 20, and a first protective layer arranged on the first protective layer The second protective layer 32 on the periphery of 31, the first protective layer 31 and the second protective layer 32 are made of different materials but both are flexible materials, and the thickness of the first protective layer 31 is greater than that of the second protective layer 32 .

[0030] Wherein, the flexible screen is provided with a bonding area 1...

Embodiment 2

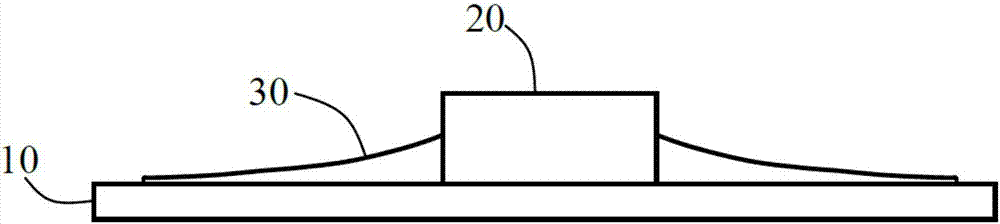

[0033] An embodiment of the present invention provides a flexible screen bonding area structure. An embodiment of the present invention provides a bonding structure for a flexible screen. Refer to figure 2 As shown, the flexible screen includes a display area 10, a bonding area 11 connected to the display area 10, and a chip 20 installed in the bonding area. The bonding area 11 is provided with a flexible protective layer 30 surrounding the chip 20, the flexible protective layer 30 is a single material adhesive layer, which is coated in the bonding area 11 of the flexible screen, and the flexible protective layer The thickness of the layer 30 gradually becomes thicker towards the direction of the chip 20, such as image 3 As shown, that is, the thickness of the flexible protective layer 30 at the edge of the bonding region 11 is smaller than the thickness at the peripheral edge of the chip 20, so that the flexible protective layer 30 with gradually changing thickness can form...

Embodiment 3

[0035] An embodiment of the present invention provides a method for preparing a flexible screen body bonding structure, including the following steps:

[0036] S01: Setting a bonding area on the surface of the flexible screen, and bonding chips in the bonding area; and

[0037] S02: Set up a flexible protective layer around the chip.

[0038] Wherein, in the above S02, "setting a flexible protective layer around the chip" includes: setting a first protective layer around the chip, so that the first protective layer is respectively connected to the surface of the chip and the flexible screen; setting a second protective layer around the first protective layer. layer, and the thickness of the second protective layer is smaller than the thickness of the first protective layer.

[0039] Preferably, the "setting the first protective layer" refers to coating the UV adhesive layer, and irradiating the UV adhesive layer with ultraviolet light to make it cured. The "setting the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com