A kind of micro-led chip preparation and substrate peeling method

A chip and substrate technology, applied in the field of Micro-LED chip preparation and substrate stripping, can solve the problems of damage to the LED active layer, failure to effectively melt the GaN buffer layer, and stripping failure, etc., to achieve convenient interconnection and stripping yield High, simple installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

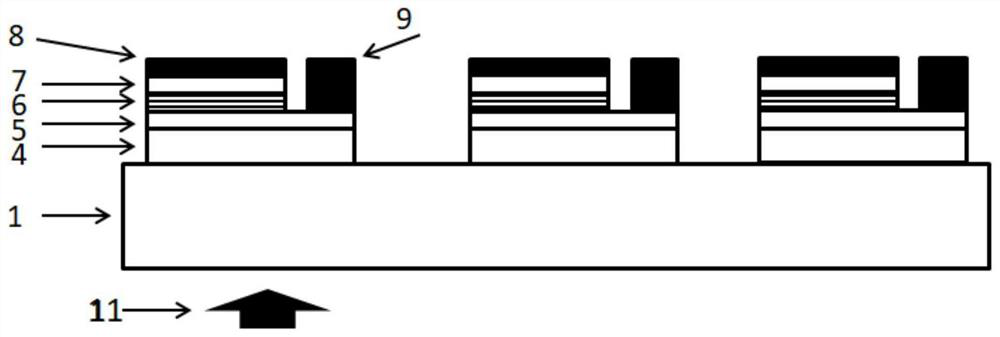

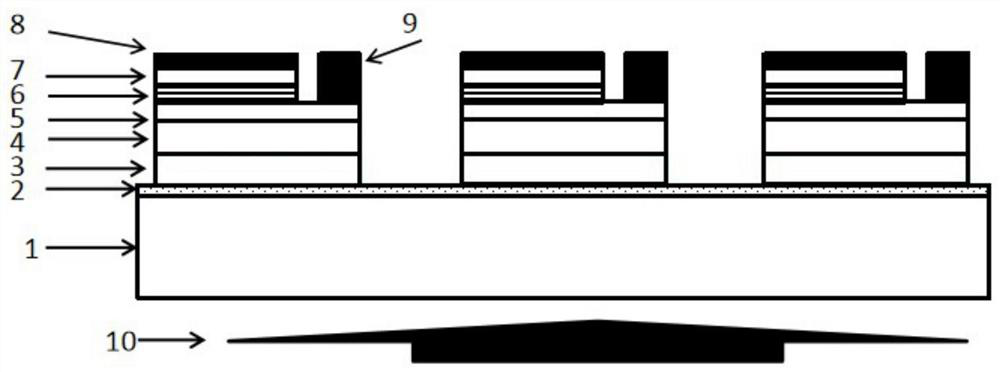

[0027] The present invention will be further clarified below in conjunction with the specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and not to limit the scope of the present invention. The modifications all fall within the scope defined by the appended claims of this application.

[0028] It should be noted that like numerals and letters refer to like items in the following figures, so once an item is defined in one figure, it does not require further definition and explanation in subsequent figures.

[0029] In the description of the present invention, it should be noted that the orientation or positional relationship indicated by the terms "vertical", "peripheral surface", etc. is based on the orientation or positional relationship shown in the accompanying drawings, or is the customary pendulum when the product of the invention is used. The orientation or positional relationship is only for the convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com