A kind of laser stripping device and method

A technology of laser stripping and laser beam, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of high process adaptability, non-reusable glass substrate, large volume, etc., and achieve the effect of convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

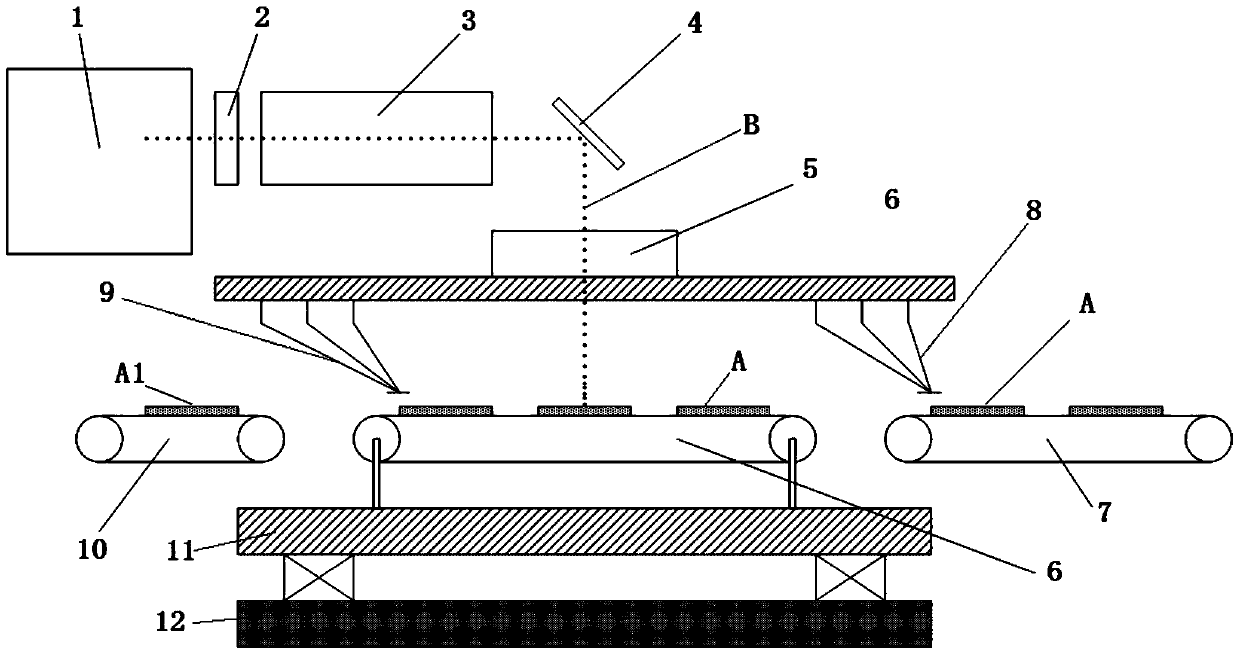

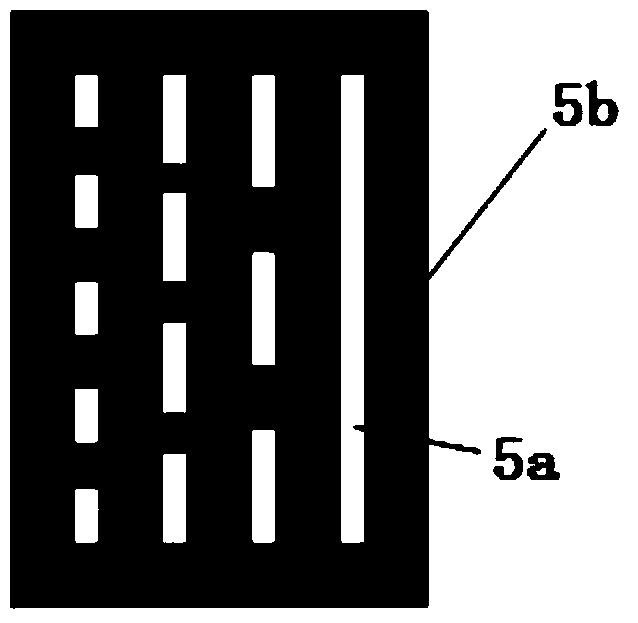

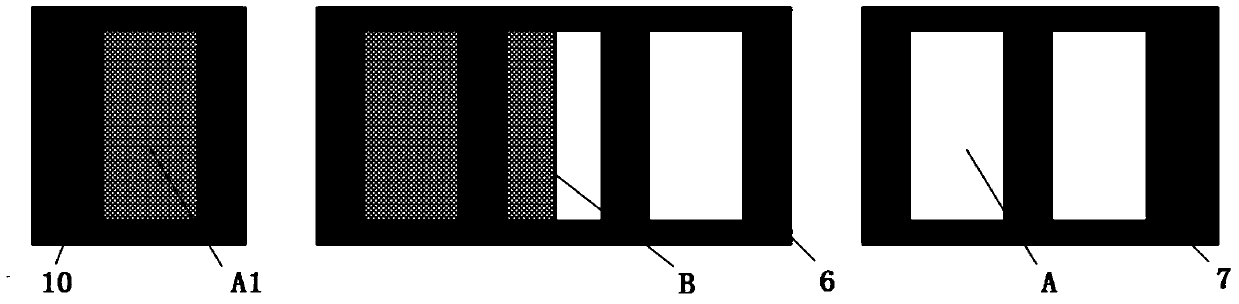

[0049] figure 1A specific embodiment of the laser lift-off device of the present invention is shown, the system includes a laser 1, a shutter 2, a uniform light shaping system 3, a mirror 4, a mask blocking device 5 and a working conveyor belt 6 arranged in sequence along the optical path direction .

[0050] Among them, the laser 1 is used to emit a laser beam B, that is, to provide a light source. The shutter 2 can be opened and closed quickly, and is used to block / release the laser beam emitted by the laser 1 . In practical applications, other forms of light source systems can also be used to replace the laser, and this light source system can have its own shutter, without the need for an additional shutter 2 . When the shutter 2 is in an open state, the laser beam emitted by the laser 1 passes through the shutter and shoots out. When the shutter 2 is in the closed state, the laser beam emitted by the laser 1 is blocked by the shutter and cannot be emitted outward. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com